2 Flight Characteristics

Pitch stability - this is immediately noticeable when kiting the wing, if you try to create

"dolphin" movements in the air you will understand exactly what we mean! The Hybrid has

enough air mass and inertia to penetrate through the air rather then being controlled by the

air. Contrary to a Single Skin, you are not tossed around by the currents. the pilot is in control

and will enjoy strong thermal conditions!

Roll stability - especially dominant with a paramotor - this wing is more roll stable than

anything out there. With this wing, there will be NO roll oscillation what so ever!!

When free flying, the pilot will notice that it is "hard" to perform wing-overs.

This is due to the increased roll stability of this wing.

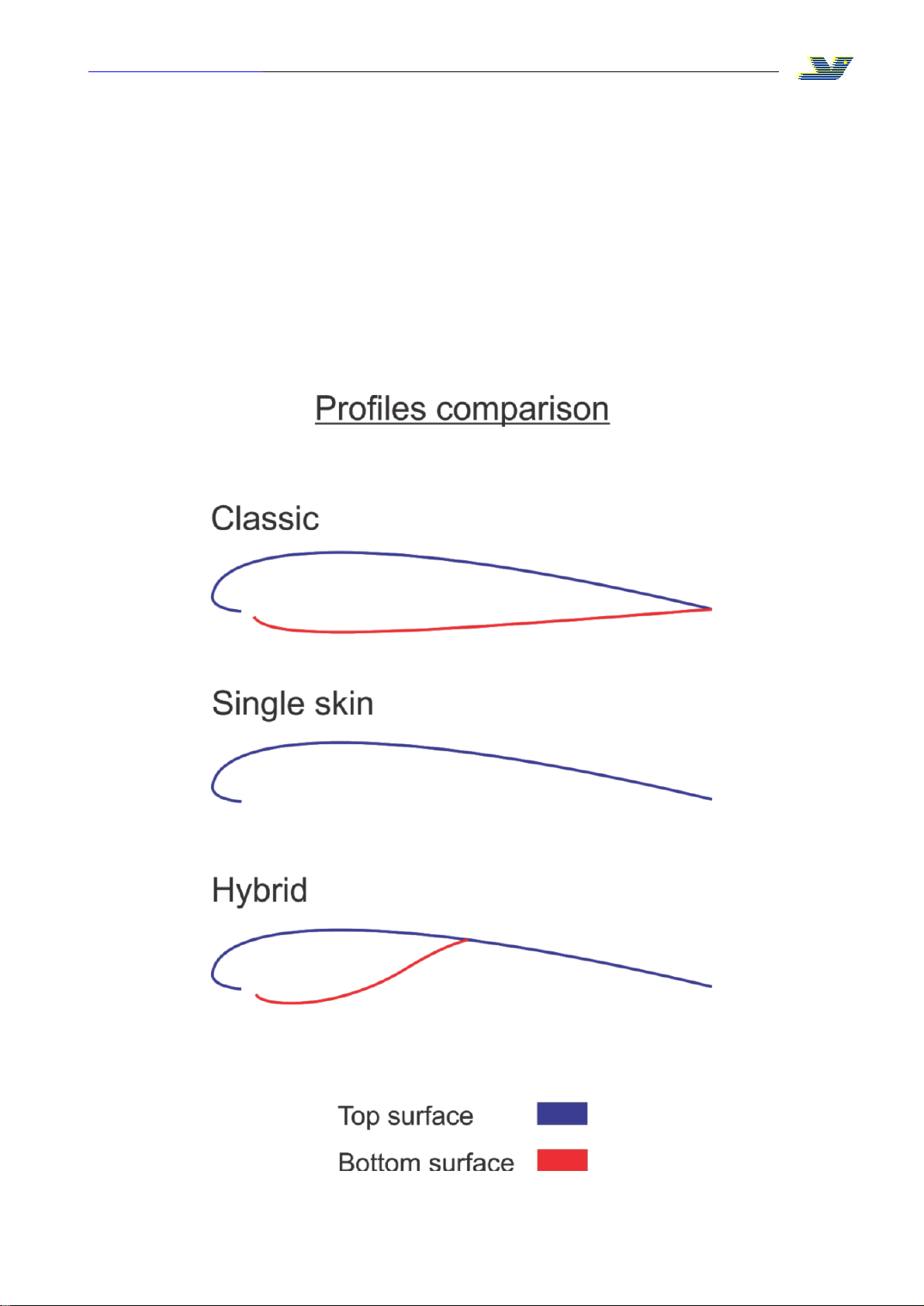

Brake pressure - pleasantly low! On a classic profile, the brakes need to be applied against

the internal pressure of the wing. With the Hybrid, as with single skin designs the brakes

create only drag and therefore are much more efficient. This wing feels accurate and

precise, the brakes are progressive and constantly transmitting the air around you.

Take-off - Take-off speed is surprisingly slower than most EN A wings. This helps

tremendously in "not perfect" take-off conditions. Back-wind of 3-5 [kmh] is not a problem

with the Hybrid (common in Hike & Fly take-off spots). Same goes for front launches with a

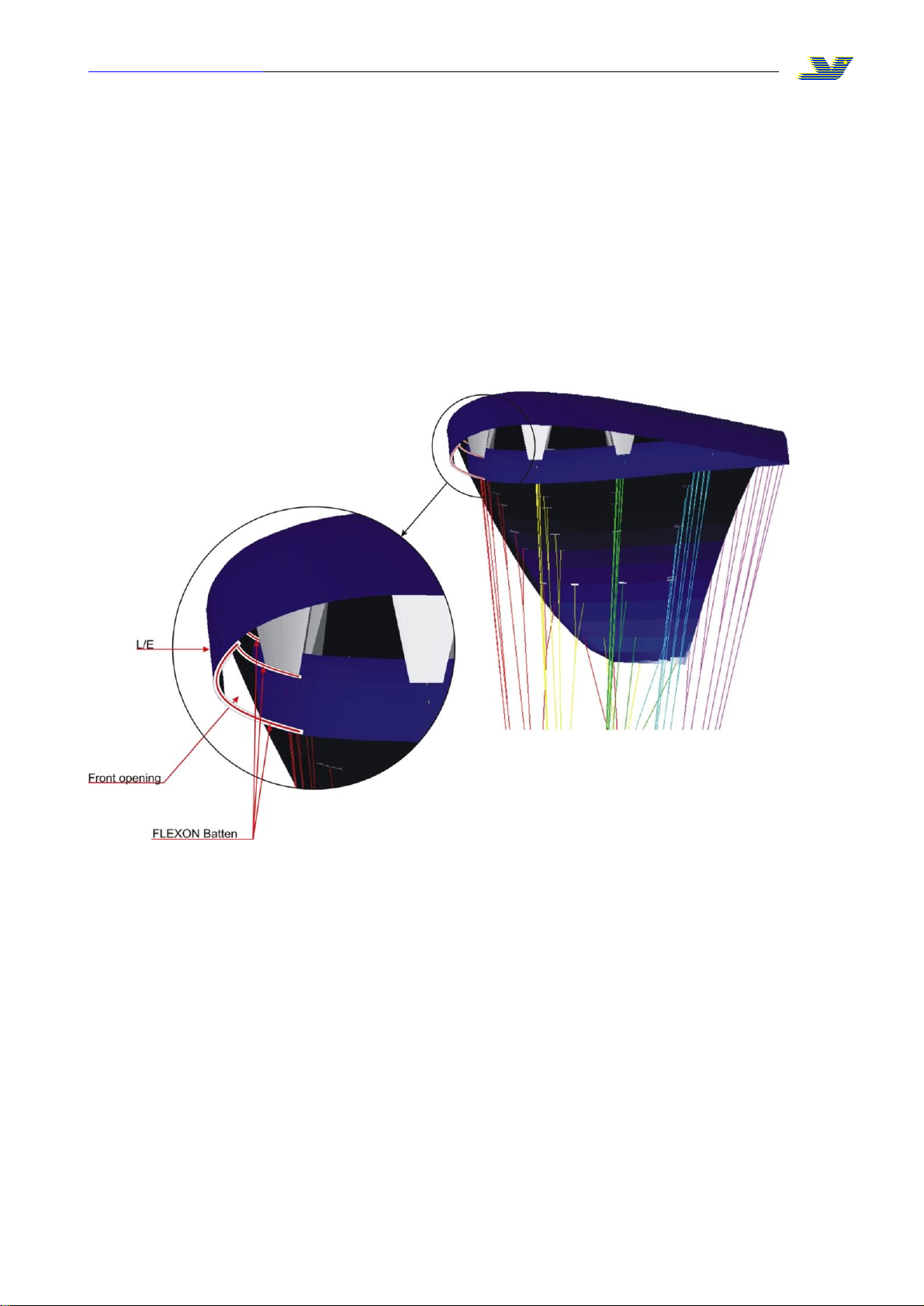

paramotor, few steps and you are airborne. Inflation is as on superlight single-skin wings, it

will come overhead and stay there even in the lightest breeze imaginable!

Flare - Contrary to single skin wings, the Hybrid flare is superb! Due to its high stall

resistance and long brake travel, it flares like an EN-A wing!

Hike and fly - Coming in at only 3 kg including standard webbing risers

(not flimsy rope risers!).

Add to this the ease of take-off at nil wind or even back-wind, and it's perfect for hike and

fly. It has better performance than a single skin with proven Safety - A across the board and

B on only 2 maneuvers. (B rating for only the Front stall and 75% side collapse flying at full

speed bar at maximum weight)

Thermalling - Hybrid thermals like the wing is "stuck" in a banked position turning and

pulling itself into the core.

The wing thermals in such a natural way partially due to the intensely high roll stability.

In general, flying the Hybrid feels like the wing is "taming down" the conditions.

7 [m/s] thermals, will feel like 4 [m/s] with calm and peaceful behaviour.