autogaz AC STAG-50 Assembly instructions

Page 1 of 17

STAG-50, STAG-100, STAG-150

LAMBDA SENSOR CONTROLLER

INSTALLATION & PROGRAMMING MANUAL

version : V1.77 -V1.79

Manufacturer:

AC Spółka Akcyjna.

15-181 Białystok, ul. 42 Pułku Piechoty 50, Poland

tel. +48 85 7438148, fax +48 85 653 8649

Page 2 of 17

SET COMPONENTS

1. STAG-50 or STAG-100 or STAG-150 - lambda sensor controller

2. Actuator (stepping motor) & base plate

3. A group of wires

4. Installation set:

- control panel

- fastening screws

- temperature sensor

- connectors, screws

5. Programming & operation manual

APPLICATION OF THE CONTROLLER

The STAG-50/100/150 lambda sensor controller has been designed for controlling of

operation of engines adapted for LPG and fitted with a lambda sensor. The control

panel enables manual, automated or emergency switching over working mode

(gasoline / LPG) as well as visual monitoring of LPG quantity.

INJECTOR EMULATOR LPG LEVEL INDICATION

STAG-50 - only LPG reserve indication (1 LED)

STAG-100 single-point emulator full indication (5 x LEDs)

STAG-150 four-point emulator LPG reserve or full indication

CONTROLLER OPERATION

After starting of the engine and reaching of required rpm (in the automatic mode green LED blinks) LPG

supply is switched on (green LED shines constantly). The LPG output is controlled with a actuator and

depends on lambda sensor indications. All STAG-50/100/150 parameters are set with an external tester

or a PC (AcLpgWin software).

CONTROL PANEL FUNCTIONS

The control panel contains:

working mode switch (gasoline / LPG) - B/G key

working mode indicator - green LED

LPG quantity indicator: five LEDs

After switching on the ignition switch (without starting the engine) LPG supply may be switched on in

the normal (automatic) mode or emergency mode (starting up of the engine with LPG). Next functions

are switched on by pressing the working mode selector.

green LED does not shine - running with gasoline

green LED blinks - automatic mode (LPG supply begins after starting the engine, reaching

required rpm and, alternatively, reaching the temperature set at the pressure regulator).

green LED shines constantly - emergency mode (starting up the engine with LPG). The function is

available only with switched ignition switch but without starting up the engine.

The last working mode is stored and recalled automatically during next engine start-up.

Page 3 of 17

WIRING DIAGRAM AND INSTALLATION MANUAL

The STAG-50/100/150 controller should be mounted within the engine room in the place, which is not

exposed to high temperature, water and fuel.

CAUTION!

It is recommended to install the controller vertically using its mounting eye and a screw, placing

sockets downward to avoid water penetration. Install bundle protecting rubbers carefully to seal the

entire housing.

Electrical connections should be soldered, carefully insulated and protected from humidity to avoid

shorting.

CONTROL PANEL FIXING & INSTALLATION

The control panel should be mounted within the driver's cab in the range of driver's sight.

First check fitting of the lower panel part, then drill two openings Ø 1,8 mm for fastening the panel and

one Ø 5 mm for the bundle. Fix the lower part of the panel (together with a plate) with screws

(installation set) in the chosen place and cover it with panel's upper part. Check the working mode

switch function.

50 100

150

CABLE COLOUR DESCRIPTION

11 15 11 BLACK GND

1 2 1 BLACK-RED +12 V BATTERY

15 13 15 RED +12 V IGNITION SWITCH

19 14 19 BROWN RPM - 5/12 V PULSES

14 1 14 BLUE LPG SWITCH ON

12 8 12 YELLOW-GREEN TPS

18 10 18 WHITE LPG LEVEL SEN SOR

20 9 20 ORANGE TEMPERATURE SENSOR

- 16 - YELLOW EMULATOR RELAY ( SWITCHING OVER )

- 17 - WHITE-GREEN EMULATOR RELAY ( CLOSED )

- 18 - GREEN EMULATOR RELAY ( OPEN )

10 15 10 BLACK SWITCHBOARD LED-100 or LED-50 ( new ) * (GND)

8 6 8 WHITE-RED SWITCHBOARD LED-100 or LED-50 ( new ) *

4 5 4 WHITE-GREEN SWITCHBOARD LED-100 or LED-50 ( new ) *

9 4 9 GREY-BLACK SWITCHBOARD LED-100 or LED-50 ( new ) *

- 3 14*

GREEN-RED SWITCHBOARD LED-100 (+12V)

10 - - BLACK SWITCHBOARD LED-50 ( old ) (GND)

8 - - GREEN-RED SWITCHBOARD LED-50 ( old )

4 - - YELLOW SWITCHBOARD LED-50 ( old )

9 - - BROWN SWITCHBOARD LED-50 ( old )

5 12 5 PURPLE LAMBDA SENSOR

13 11 13 GREY CAR COMPUTER ( SIMULATION )

- 7 - option – WHITE-BLACK RESERVED CONNECTION

- 23 option – BLUE-BLACK RESERVED CONNECTION

-

6 19 6 BLUE-BLACK ACTUATOR

7 20 7 WHITE-BLACK ACTUATOR

17 21 17 ORANGE-BLACK ACTUATOR

16 22 16 VIOLET-BLACK ACTUATOR

* STAG-50 only LED-50 , STAG-100 only LED-100 , STAG-150 - LED-50 or LED-100

Page 4 of 17

STAG-50 installation diagram

Page 5 of 17

STAG-100 installation diagram

RELAY FUNCTIONS IN STAG-100

Connect wires Cut/Connect Connect

resistor ”Relay” parameter

Emulation of single-

point injector

yellow

white-green

Injector power supply

point ~20Ω Emulation of injections

Emulation of multi-

point injector

yellow

white-green

+12 power supply of

all injectors ~100Ω Emulation of injections

Fuel pump cutoff yellow

white-green

Pump power supply

circuit Emulation of injections

External emulator

controlling

yellow

green

+12V

Emulator

Emulation of injections

Error erasure yellow

green

+12V

Computer Memory erasure

Page 6 of 17

STAG-150 Installation diagram.

OUTLETS OF STAG 150 EMULATOR WIRE SET

No.

WIRE COLOUR DESCRIPTION

1 (option) BLACK FRAME POWER SUPPLY OF EXTERNAL EMULATOR

8 (option) BLUE + 12V POWER SUPPLY OF EXTERNAL EMULATOR

2 YELLOW INJECTOR 1 - POWER SUPPLY

9 YELLOW-BLACK INJECTOR 1 - COMPUTER

3 GREEN INJECTOR 2 - POWER SUPPLY

10 GREEN-BLACK INJECTOR 2 - COMPUTER

4 RED INJECTOR 3 - POWER SUPPLY

11 RED-BLACK INJECTOR 3 - COMPUTER

5 BLUE INJECTOR 4 - POWER SUPPLY

12 BLUE-BLACK INJECTOR 4 - COMPUTER

14 (option) RESERVED CONNECTION

Near the STAG 150 emulator socket, there is an emulator resistance switch. When the switch is not

pressed, the resistance is 100Ω, and when it is pressed the resistance is 50Ω.

Page 7 of 17

STAG-50/100/150 - PROGRAMMING WITH A PC AND AcLpgWin SOFTWARE

To set STAG-50/100/150 parameters using a PC it is indispensable to connect the PC through a RS socket

and a RS-232 interface to the STAG-50/100/150 programming socket and start the AcLpgWin.exe

software.

During communication appears the screen PARAMETERS and transmission percentage indicator .

If after a few trials the software cannot establish communication with the controller then instead of the

transmission percentage indicator appears the window CONNECT, which should be activated to renew

communication. If there is no communication check RS-232 connection, change the serial port number

or activate auto-search (V1.76 only).

If the communication is established appears the window PARAMETERS, oscilloscope function is on.

Page 8 of 17

or -control panel - working mode change (mouse click )

- open help file

- window layout

- open gauges window

- controller parameters readout

- grid on

- start / stop oscilloscope

- oscilloscope time base change

- save visualisation file

- open visualisation file

- oscilloscope on / off; graph colour change

- save controller configuration file

- open controller configuration file

- restore manufacturer’s parameters

Page 9 of 17

On the oscilloscope you can see basic STAG controller signals:

lambda sensor, lambda simulation, TPS and actuator positions .

Below the graph, there is a signal table.

You can enable each graph and select its colour in the “Graph” column.

Apart from the oscilloscope, signal values are displayed in the “Values” column and visualised as line

graphs.

Gauge windows – display signals, it is possible to change

their position, size and shape ([-][+][O] buttons)

Additionally, in V1.77 version the windows of additional gauges are also accessible. They are displayed

by clicking a list below the “Gauges” button or by double-clicking relevant line in the signal table. It is

possible, separately for each such window, to change its position (using left mouse button), size ([-] [+]

buttons), shape ([O] button) and close ([X] button).

KEYBOARD SHORTCUTS

F1 - full function switch names / abbreviations

F2 - screen SETTINGS

F3 - screen PARAMETERS

F4 - screen CONFIGURATION

F6 - screen VERSION

F7 - parameter table activation for the screen PARAMETERS

F8 - working mode change GASOLINE / AUTO / LPG

NOTE: working mode change is possible also with mouse

F9 - font change

F10 - start of communication with the controller

QUICK CHANGE OF PARAMETERS

To change parameters and their values it is possible to use mouse buttons through

clicking on selected parameter as well as keyboard keys:

UP / DOWN - parameter change

RIGHT / LEFT - parameter value change

Page 10 of 17

STAG-50/100/150 ADJUSTMENT PARAMETERS

IGNITION COIL - according to the connection of rpm pulse and ignition type it is indispensable to

choose such type of coil to obtain the same rpm indication at the tachometer and

software window. In certain vehicles it is indispensable to use an ignition pulse adder.

COIL SIGNAL – change of the rpm detection voltage threshold. Set suitable detection level

depending on rpm pulses voltage value.

TPS - after connection of a throttle opening sensor choose its type and voltage range.

TPS THRESHOLD – voltage level, which causes switching over from idle operation to operation

with load

ADJUSTMENT FROM TPS - adjustment from TPS on / off

TPS HISTERESIS - removal of voltage noise from the TPS sensor

ENRICHMENT - number of actuator steps proportional to accelerator's pressing

WEAKENING - number of actuator steps proportional to accelerator's loosing

ACTUATOR SPEED - actuator speed during enrichment / weakening

OPEN - additional opening of actuator after reaching of TPS level

TPS LEVEL - TPS voltage level causing mixture enrichment – additional opening of the actuator

ACTUATOR AT THE POSITION - number of actuator steps during additional opening

ACTUATOR SPEED - actuator speed during opening

CUT OFF - additional closing of actuator during accelerator's loosing and reaching TPS level

downward. This function works if rpm falls to the set level.

RPM LEVEL - rpm level activating CUT OFF function

ACTUATOR AT THE POSITION - number of actuator's steps during CUT OFF execution

ACTUATOR SPEED - actuator speed during CUT OFF

LAMBDA SENSOR TYPE - lambda sensor operation range

LAMBDA SENSOR - lambda sensor type:

STANDARD – zirconium

RESISTIVE (-) – load from the frame

RESISTIVE (+) – load from the positive pole (+)

Page 11 of 17

ADJUSTMENT FROM LAMDBA SENSOR - adjustment from sensor on / off

LAMDBA SENSOR THRESHOLD - a voltage causing mixture weakening

ACTUATOR SPEED ABOVE TPS THRESHOLD- actuator speed during LPG – air mixture

adjustment set by the sensor during idle operation

ACTUATOR SPEED BELOW TPS THRESHOLD- actuator speed during LPG – air mixture

adjustment set by the sensor during idle operation

LAMDBA SENSOR COLD - theoretical time of sensor heating. At each switching of LPG supply the

controller ignores sensor indications maximally for the set time period

and awaits sensor's proper operation. Until the parameters become

stable, the controller uses internal map.

SIMULATION - during running with LPG vehicle's computer receives simulated signal with adjustable

parameters instead of lambda sensor signal

TYPICAL - square wave 08 / 08 s.

AUTO - simulation of the sensor regarding petrol engine characteristics

FRAME - vehicle's computer input connected to the frame

USER - square wave adjusted freely

TIME HI - duration of simulation pulse upper course

TIME LO - duration of simulation pulse lower course

TIME OFF - total time of pauses between pulses' groups, 0 = no pause

PULSE NUMBER - number of pulses within a group, 0 = no groups

DISCONNECTED - vehicle's computer input disconnected from the sensor

RELAY – switchover of additional relay function, which can operate as a injection emulator or switch

off of car computer (erase car computer errors)

CAUTION! Function available only for STAG – 100

SWITCH-OVER TIME – time of fuel “overlapping” during switching on the LPG (function RELAY –

emulator)

SWITCH OFF TIME – time of relay switch off after the ignition switch is off (function RELAY –

memory erase)

SWITCH-OVER TYPE - LPG supply switch on according to rpm

RPM UP - LPG supply on during rpm increase

RPM DOWN - LPG supply on during rpm decrease

RPM + TPS - additional TPS voltage check at rpm (driver opens / closes throttle)

SWITCH OVER RPM - rpm causing LPG supply on

SWITCH OVER POSITION – position of controller actuator during switching on the LPG

SWITCH OVER TEMPERATURE - temperature causing LPG supply on if the pressure regulator

temperature sensor is connected

MAX rpm for LPG - rpm level causing switchover to gasoline. Rpm decrease causes switchover to LPG.

Page 12 of 17

ACTUATOR MAX LEVEL - number of steps for max. actuator opening.

3000 RPM LEVEL - number of steps of actuator at 3000 rpm (sensor cold or off).

900 RPM LEVEL - number of steps of actuator at 900 rpm (sensor cold, off or damaged).

ACTUATOR MIN LEVEL - number of steps for min. actuator opening.

LEAKAGE – actuator opening just after switching on the ignition switch (while working with gasoline)

LPG LEVEL SENSOR – depending on LPG level sensor, voltage thresholds for activation of relevant LEDs

indicating LPG level

FAULTS DETECTED BY THE STAG-50/100/150 CONTROLLER

VOLTAGE SUPPLY FAULT - to big voltage drop or disconnection of battery, which causes controller's

reset

DATA FAULT - faults within controller's memory (damage or improper assembly)

LAMBDA SENSOR FAULT - long-lasting lack of voltage from the sensor

TPS FAULT - long-lasting lack of TPS voltage change

Page 13 of 17

CONFIGURATION

To match controller parameters to the individual vehicle type choose CONFIGURATION menu; software

detects petrol engine parameters and automatically adjusts LPG mode parameters.

CONFIGURATION is activated with the key GASOLINE.

Dialog windows shows commands to execute to configure the controller for a LPGpowered vehicle.

During check of gasoline mode parameters individual parameters will be displayed within a table; during

LPG mode configuration revolutions of actuator will be added for individual rpms.

CONFIGURATION – GASOLINE

Start controller configuration for gasoline with the key GASOLINE.

According to dialog window commands proceed as follows:

start the engine

set working mode GASOLINE (control panel key or mouse)

keep idle rpm - gasoline mode parameters will be checked

increase rpm to 3000 - gasoline mode parameters will be checked once again

At this moment all parameters indispensable for LPG controller operation will be stored to the

parameter table - match them to the engine type.

NOTE: sensor type (standard / resistive +, -) is not recognised automatically. Insert sensor parameters

manually to the window PARAMETERS after CONFIGURATION (e.g. OPEL OMEGA, lambda sensor

5 V, resistive +).

Page 14 of 17

Finish the gasoline configuration pressing one of following keys:

NEXT - LPG mode configuration

OK - save gasoline mode settings

SKIP - skip settings

CONFIGURATION – LPG

NOTE: LPG MODE CONFIGURATION SHOULD BE MADE AFTER PRELIMINARY PRESSURE REGULATOR

ADJUSTMENT! (SEE QUICK START P. 12)

LPG mode configuration may be activated with LPG or NEXT - if gasoline configuration has been

performed previously.

According to dialog window commands proceed as follows:

set AUTO working mode (control panel key or mouse)

increase rpm to ca. 2000 to switch over to LPG

leave idle rpm - actuator position will be adjusted

increase to 3000 rpm - actuator position will be adjusted

Finish the configuration with:

OK - save LPG mode settings

SKIP - skip settings

Other controller settings as e.g. sensor simulation, LPG mode on level etc. may be adjusted with menu

PARAMETERS.

QUICK START, FIRST PRESSURE REGULATOR ADJUSTMENT

First pressure regulator adjustment must be done before use of CONFIGURATION -LPG function.

Adjustment should be done using menu PARAMETERS.

start the engine in gasoline mode and wait for proper lambda sensor operation

set the controller for GASOLINE mode.

Check lambda sensor operation for idle and 3000 rpm (sensor indications should be between

upper and lower voltage value).

Set the controller for AUTO

Increase rpm to ca. 2000 to switch over to LPG

Watching lambda sensor graph at the oscilloscope adjust LPG output (with an adjustment screw

located on the pressure regulator) so that the actuator works in the range 50 - 100 steps (idle

engine rpm)

Check sensor balancing at 3000 rpm

If the sensor shows long return time to balancing during rpm change check pressure regulator

membrane tension and adjust it with a screw, if necessary.

NOTE: if during pressure regulator adjustment it is impossible to obtain sensor

balance at high rpm and the mixture is weak, it means that the system pressure

regulator - mixer does not work properly, thus before adjustment of electronics some

mechanical components must be adjusted. If the pressure regulator has been

adjusted and works properly, proceed with LPG CONFIGURATION.

Page 15 of 17

CALIBRATION OF LPG LEVEL INDICATOR

LPG level indicator calibration should be performed with ignition switch on without starting the engine.

Displayed voltage will be quickly responding to changes in float position.

VERSION

The STAG-50/100/150 controller from the version 1.60 on is provided with the option of user-made

software modification.

After connecting the controller to a PC the new window VERSION appears.

If the folder containing the program AcLpgWin.exe includes also a batch program of the STAG

50/100/150 controller marked with the wildcard .img, the batch program will be also displayed after

activation of the VERSION window; this enables controllers software exchange.

Click with the mouse on the program, which should be copied into the controller software

Click the button Write

When the question “Start software installation?” appears, press OK.

Page 16 of 17

wait until the installation progress bar reaches 100%

when the message “Programming finished successfully” appears, press OK.

The controller performs restart and begins to work with the new version of the

software.

If the programming process is interrupted or there are some errors, diagnostic software will display the

“Software error ...” message. Press OK and repeat the controller programming procedure.

Page 17 of 17

TECHNICAL DATA

Operation voltage 12V ( +30% - 25% )

Max current consumption 0,3 A

Max current supplied to LPG control system 6,5 A

Max injection emulator current 5 A

Ignition pulse input voltage 3 – 12 V

PROGRAMMABLE FUNCTIONS

Number of cylinders and ignition type…………………3, 4, 5,6, 8 cylinders, single or double coil

Type of throttle position sensor………………………………..0-5 V, 5-0V linear, switch 0-12/12-0 V

Lambda sensor type…………………………………..0-1V, 0-5V, 5-0V, 0.8-1.6V, standard or resistive

Lambda sensor emulation………………………………………………square wave, disconnected, frame

Type of changeover gasoline / LPG……………………………………….rpm up, rpm down, rpm + TPS

Time of simultaneous operation gasoline + LPG…………………………………………………..0 - 1,020 s

Temperature of switchover gasoline / LPG…………………………………………………………..60 - 185°C

Switchover rpm………………………………………………………………………………………..1000 - 10000 rpm

Max rpm for LPG mode…………………………………………………………………………….5000 - 10000 rpm

Fuel level sensor STAG-100/150………………………………………..0-90 Ω, 90-0 Ω, 0-50 kΩ, 50-0 kΩ

Actuator operation range…………………………………………………………………………………0 - 255 steps

Actuator speed………………………………………………………………………………………………………….0 - 255

Option of automated actuator opening during acceleration…………………………………….on / off

Option of additional actuator opening during acceleration………………………………………on / off

Option CUT OFF………………………………………………………………………………………………………..on / off

Emulator relay operation mode STAG-100…………………………1 point emulator / erase vehicle

computer memory

Default parameters option …………………………………………………………………………………………….yes

Fault recognition…………………………………………………power supply (reset), TPS, lambda sensor

This manual suits for next models

2

Table of contents

Popular Controllers manuals by other brands

Arco Computer Products

Arco Computer Products MicroRaid Disk Drive user manual

Deep Sea Electronics Plc

Deep Sea Electronics Plc DSE7310 MKII Installation instructions and operators manual

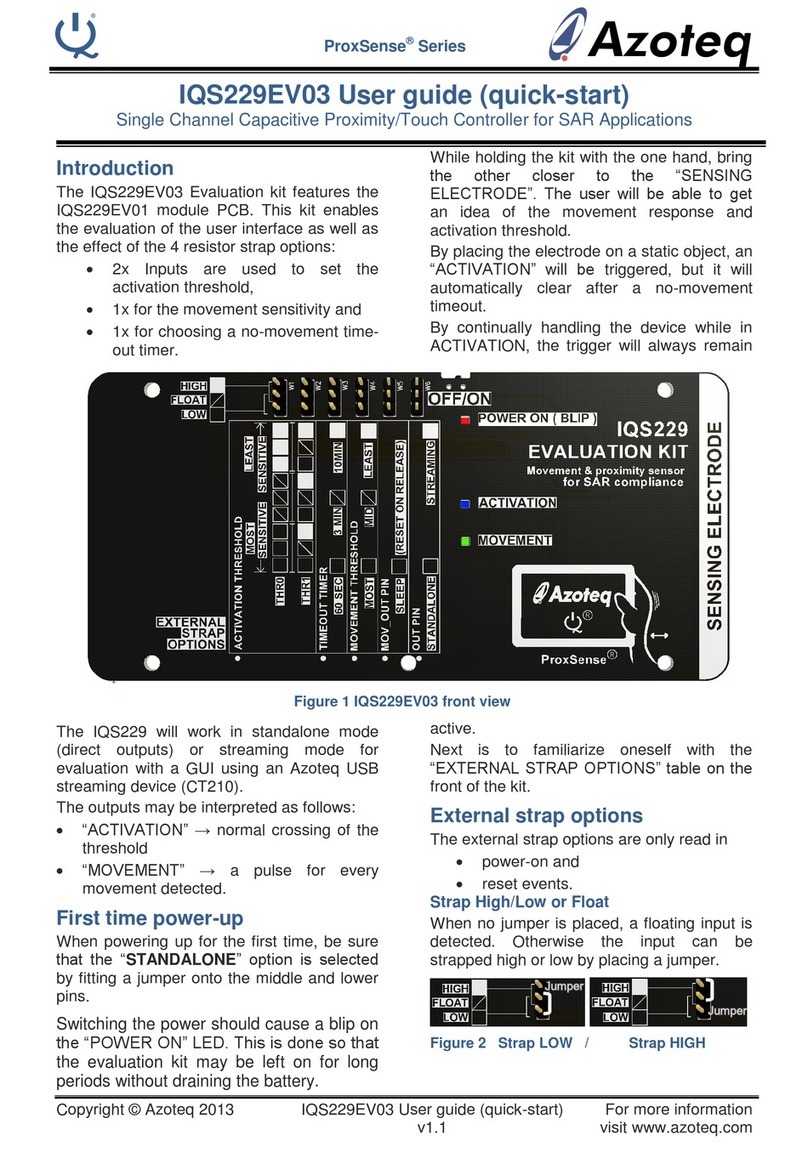

Azoteq

Azoteq ProxSense Series user guide

OXO

OXO TM4BOX instruction manual

Sparkel

Sparkel Smart-MPPT Series manual

IAI

IAI SS-S instruction manual