Autojack IG2200i Installation manual

IG2200i

2000W Inverter Generator

IG2200i

ORIGINAL INSTRUCTIONS

SAFETY AND OPERATING MANUAL

IG2200i

TABLE OF CONTENTS

Welcome to Autojack!

Dear Customer, Congratulations on your purchase. Before using the

product for the first time please be sure to read these instructions for use.

They provide you with allinformation necessary for using the product safely and to

ensure its long service life.

Closely observe allsafety information in these instructions!

General Power Tool Safety Warnings………………………………….…......01

Symbols & Cable Rating Chart ……….…………………………………….………04

Machine Details and Product features……….…………………………….….05

Assembly.................………………………………………………………………....07

Operation…………………………………………………………………………………….11

Maintenance and Service…………………………………….……………………..14

Troubleshooting……………………………………………………..………………..17

Autojack Guarantee…………………………………………………………………….18

Declaration of conformity……………………………………………………………20

Parts list/Parts Diagram……………………….……………………………………...21

IG2200i 01

WARNING Read all safety warnings and

all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for

future reference. The term "power tool" in

the warnings refers to your electric (corded)

power tool or battery-operated (cordless) power

tool.

1. Work area safety

a)Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with grounded power tools.

Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with grounded surfaces,

such as pipes, radiators, ranges and

refrigerators.There is an increased risk of electric

shock if your body is grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk

of electric shock.

3. Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off position before connecting to

power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

finger on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

GENERAL POWER TOOL SAFETY WARNINGS

IG2200i 02

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes,

jewellery or long hair can be caught in moving

parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused

by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking

into account the working conditions and the work

to be performed. Use of the power tool for

operations different from those intended could

result in a hazardous situation.

GENERAL POWER TOOL SAFETY WARNINGS

IG2200i 03

6. Additional Safety Instructions for

Generators

a).Keep the generator at least 1 m (3 ft.) from

buildings orother equipment, ortheengine may

overheat.

b).Place the generator ona solid, flat surface.

c).Make sure the surrounding area is free from

any material that could burn or be damaged by

heat.

d).Never move or tilt the generator whilst itis

switched on.

e).Alwaysswitch the engine OFF when refuelling.

f).Always refuel in a well-ventilated area.

g).Never overfill the tank, fill to the level

specified.

h).Never smoke whilst refuelling and avoid

smoking or usinga naked flame near the

generator.

i).Never start the engine if there isspilled fuel.

Any spillage must be wiped clean and the

generator allowed drying before attempting to

start theengine.

j).Never usethe generator inwet conditions

unless itis well protected/covered. Under these

conditions, adequate ventilation MUST be

provided.

k).Never operate the generator with wet hands

l).Never usewater orany other liquids toclean

the generator.

m).Make sure you ground (earth) the generator.

n).Always makesure the applied load does not

exceed the generator rating. Overloading the

generator isdangerous and could cause serious

damage.

o).Always disconnect the generator when carrying

out any maintenance.

p).Always allowthe generator toreach operating

speed before connecting a load.

q).Never allow thegenerator to run out offuel

when a load isconnected.

r).Never transport the generator with fuel inthe

tank.

s).Never connect the generator toa commercial or

residential power supply; e.g. ringmain.

t).Never allow the generator air vents to become

blocked.

GENERAL POWER TOOL SAFETY WARNINGS

IG2200i 04

SYMBOLS AND POWER RATING CHART

Danger! – Read the operating

instructions to reduce the risk of

injury.

Caution! Wear safety goggles.

Caution! Wear ear defenders. The

impact of noise can cause damage

to hearing.

IG2200i 05

MACHINE DETAILS AND PRODUCT FEATURES

Machine Details

Specifications:

Engine

Engine model – XY156F

Type – petrol

Displacement – 60m3

Ignition type – C.D.I

Fuel tank capacity – 4.1L

Maximum run time at 3/4 load– 3.5h

Engine oil capacity – 0.52L

Guaranteed sound power – 58dB

(Taken at 7m)

Generator

Rated Frequency – 50Hz

Rated AC voltage – 230V

Max output power – 2200W

Continuous output power – 2000W

Output type – modified sine wave

Rated DC voltage – 12V

Rated DC current – 4A

Rated output current – 4.354A

Rated power factor – 1

Performance Class – G1

Quality Class – A

IP Rating – IP23M

Package Contents:

InverterGenerator

12Volt Connecting Lead Assembly

Spark Plug Box Spanner

Cross-Head Screwdriver

Intended Use

Designed to generate electric energy

Using equipment in ways other than its

intended use the user and not the

manufacture will be liable for any damage or

injuries caused.

Also note that this equipment is not designed

for commercial or industrial use. Warranty will

be voided if used for these purposes.

1. Fuel tank

2. Spark plug

3. Muffler

4. Carrying handle

5. Choke lever

6. Air filter

7. Fuel pump

8. Fuel cock

9. Recoil starter

10.Oil filler cap

11.Fuel tank cap

12.Fuel filter

13.AC pilot light

14.Overload indicator light

15.Oil warning light

16.Economy control switch

17.DC 12V output

18.USB output

19.Parallel outlets

20.Ground (earth) terminal

21.AC receptacle

22.DC protector

23.Output reset

IG2200i 06

MACHINE DETAILS AND PRODUCT FEATURES

IG2200i 07

Assembly

Before using the generator

IMPORTANT: Generators should ALWAYS be

earthed. Make sure you earth the generator.

Before using your generator check that:

-The generator is in good condition and free

from any damage.

-The generator is clean and free from fuel or oil

spillage.

-The generator is correctly located for use

-There is no leakage.

Note: To avoid accidental spillage offuel, always

use a funnel to fill the fuel tank. If fuel is spilt it

must be removed from the unit before

attempting to start the engine.

Earthing

WARNING:It isadvisable to properly earth your

generatorbefore starting using a wire and a

small metal earth spike. The wire and earth are

not supplied with the unit.

An earth spike and cable can be purchased at

your localcamping supplier, oralternatively an

earth spike can be made, and itissuggested you

get advice from a qualified electrician.

Tomake a spike use a copper tube orcopper rod

12mm diameter, a minimum length of 200mm

and with an M6 machine screw one end.

The cableused should bea maximum length of 1

metre anda minimum of 1.0mm2to carry a 10

amp load.

Attach the cable to the generator at the earth

point screw on the generator.

When pushing the spike into the ground the

generator must not be running and it is suggested

that the spike is pushed into the ground by at least

100mm.

Earth of generators is covered in BS7430:2011, If

you have any doubts about this subject consult a

qualified electrician.

Oil warning system

When the oil level falls below the lower level, the

engine stops automatically. Unless you refill with

oil, the engine will not start again.

IG2200i 08

PRE-OPERATION CHECK

ECONOMYCONTROL SWITCH

When the economy control switch is turned

ON, the economy control unit controlsthe

engine speed according to the connected

load. The results are better fuel connection

and less noise.

DC CIRCUIT PROTECTOR

The DC circuit protector turns off automatically

when the load exceeds the generator rated

out?

CAUTION:Reduce the load to within

specified generator rated output if the

DC circuit protector turn off.

FUEL TANK CAP AIR VENTKNOB

The fuel tank cap is provided with an air vent knob

to stop fuel flow. The air vent knob must be turned

once clockwise from the closed position. This will

allow fuel to flow to the carburetor and the engine

to run.

When the engine is not in use, tighten the air vent

knob counter clockwise until it is finger-tight to

stop fuel flow.

OUTPUT RESET

Push the reset button for continuous 2seconds,

thegenerator will recover the ACoutput when

the generator stopsACoutput under overload

protect. NOTE: Please reduce theload of the

generator toensure that the total load is within

the rated power.

IG2200i 09

PRE-OPERATION CHECK

PRE-OPERATION CHECK

NOTE:Pre-

operation checks should be made

each time the generator is used.

CHECK ENGINE FUEL

-Make sure there issufficient fuel inthe tank.

-If fuel islow, refill with unleaded automotive

fuel.

-Be sure to use the fuel filter screen on the fuel

filter neck.

-Recommended fuel: Unleaded fuel

-Fuel tankcapacity:

WARNING:

-Do not refill tank while engine isrunning or

hot.

-Close fuel cock before refueling with fuel.

-Be careful not to let dust, dirt, water or other

foreign objects into the fuel.

-Do not fill above the top of the fuel filter orit

may overflow when the fuel heats up later and

expands.

-Wipe off spilt fuel thoroughly before starting

engine.

CHECK ENGINE OIL

-Remove oil filler cap and check the engine oil

level.

-If oil level is below the lower level line, refill with

suitable oil toupper level line. Do not screw in

the oil filler cap when checking oil level.

-Change oil if contaminated.

-Oil capacity: (see page 20-21)

-Recommended engine oil:

API Service “SJ”

IG2200i 10

PRE-OPERATION CHECK

GROUND (Earth)

WARNING:It is advisable to properly earth your

generator before starting using a wire and a

small metal earth spike. The wire and earth spike

are not supplied with the unit.

Parallel

Parallel running of two generators through

the using parallel terminal operation the

special terminal. The parallel operation needs

two generators with parallel function and a

special cable.

(a)Connect the special cable

(b)Start two generators separately

(c)The two generators running well, and green

light is on, the parallel is ok. Then you can

connect the device.

NOTE:

-Turn theeconomic switches oftwogenerators

on or off at the same time.

-The twogenerator’s parallel rated output is

90% of the total oftwogenerator’s rated

output.

-To shut down. Disconnect the electric device

firstly, and stop the two generators, disconnect

ct the special cable at the end.

-Don’t coconnect ordisconnect the special

cable when the generators are running.

The parallel running is only applicable tothe

same model.

E

IG2200i 11

OPERATION

NOTE: The generator has been shipped without

engine oil. Fill with oil or it will not start.

Do not tilt the generator when adding engine oil.

This could result in overfilling and damage to the

engine.

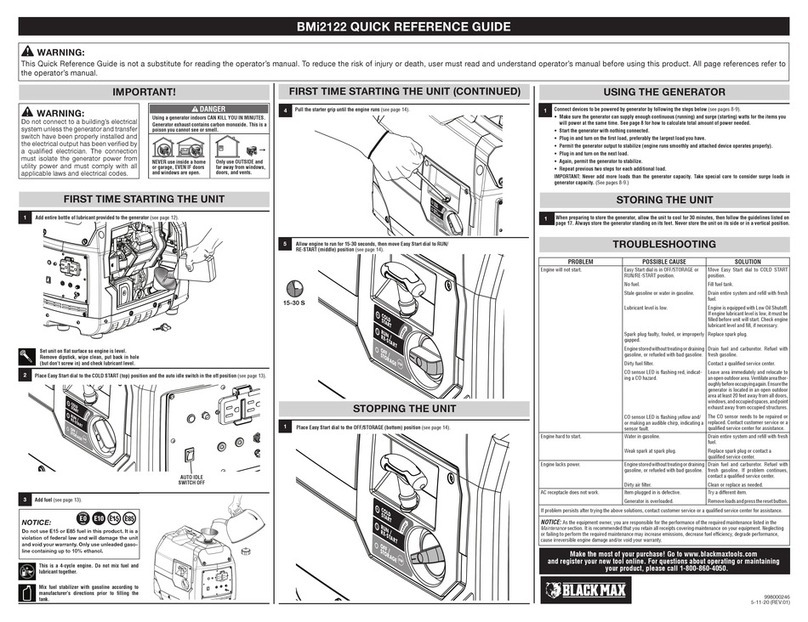

STARTING THE ENGINE

NOTE: Before starting the engine, do not

connect the electric apparatus.

Recoil start

1. Open the fuel tank air vent to the OPEN

position.

2. Turn the fuel cock lever to the ON position.

3. When running for the first time use the

generator sets, pressing the primer bulb 6 times

after refueling.

4.Turn the choke lever to the CHOKE

position.

5.Pull the starter handle slowly until resistance is

felt. This is the “Compression” point. Return the

handle to its original position and pull swiftly. Do

not fully pull out the rope. After starting, allow the

starter handle to return to its original position

while still holding the handle. Grasp the carrying

handle firmly to prevent the generator from falling

over when pulling the recoil starter.

IG2200i 12

OPERATION

6.Warm up the engine.

7.Turn the choke lever back to the │ │RUN

position.

8.Warm up the engine without a load for a few

minutes.

USING ELECTRIC POWER

1. AC APPLICATION

(a) Check the AC pilot lamp for proper voltage.

(b) Turn off the switch (es) of the electrical

appliance(s) before connecting to the generator.

(c) Insert the plug(s) of the electrical appliance(s)

into the receptacle.

CAUTION: Be sure the electric apparatus is

turned off before plugging in.

Be sure the total load is within generator rated

output.

Be sure the socket load current is within socket

rated current.

The economy control switch must be turned to

OFF when using electric devices that require a

large starting current, such as a compressor or

asubmersible pump.

2.OVERLOAD INDICATOR LIGHT

The overload indicator light comes on when an

overload ofa connected electrical device is

detected, the inverter unit overheats, orthe AC

output voltage rises. The electronic breaker will

then activate, stopping power to the generator in

order to protect the generator and any connected

electric devices. The output pilot light (green) will

flicker and the overload indicator light (red) will

turn on, then the engine will stop running. If so

please follow the following steps:

(a)Turn off any connected electric devices and stop

the engine.

(b)Reduce the total wattage of connected electric

devices within the application range.

(c)Check for blockages in the cooling air inlet and

around the control unit. If any blockages are

found, remove.

(d)After checking, restart the engine.

IG2200i 13

OPERATION

CAUTION:

The generator AC output automatically resets

when theengine isstopped and then restarted.

The overload indicator light may come on for a

few seconds at first when using electric

devices that requirere a large starting current,

such asa compressor or a submersible pump.

However, this isnot a malfunction.

3. DC APPLICATION (option)

This usageis applicable to 12V battery charging

only.

(a) Charging instruction for battery.

(b) Disconnect the leads for the battery.

(c) Loosen the filler cap.

(d) Fill distilled water tothe upper limit, ifthe

battery fluid is low level.

Measure the specific gravity forthe battery fluid

by using the hydrometer, and calculate the

charging time in according with the table shown

on right side.

The specific gravity for the fully charged battery

shall be within 1.26 to1.28. Itis recommended

toconfirm every hour.

(b)Connect between theDC output socket and the

battery terminals using the charging leads. The

leads should be connected making sure ofthe (+)

and (-) polarity.

(c)The DC circuit protector isto be set to ONafter

confirming the connection, ifthe protector isin

OFF position.

CAUTION:

Be sure the economy control switch is turned OFF

while charging the battery.

IG2200i 14

OPERATION AND MAINTENANCE AND SERVICE

STOPPING THE ENGINE

1. Turn off the power switch of the electric

apparatus or disconnect any electric devices.

2. Turn the fuel cock lever to OFF.

3. Turn the fuel tank cap air vent knob counter

clockwise to the CLOSED position.

ENGINE OIL REPLACEMENT

1.Place the machine on a level surface and warm

up the engine for several minutes. Then stop the

engine and turn the fuel cock knob to OFF. Turn

the fuel tank cap air vent knob counter clockwise

to the CLOSED position.

2. Loosen the screw and remove the cover.

3. Remove the oil filler cap.

4. Place an oil pan under the engine. Tilt the

generator to drain the oil completely.

5. Replace the generator on a level surface.

6. Add engine oil to the upper level.

7.Install the oil filler cap.

8.Install the cover and tighten the screw

Recommended engine oil: (SAE 10W30)

API Service “ SJ”

CAUTION:

Be sure no foreign material enters the crankcase.

Do not tilt the generator when adding engine oil.

This could result in overfilling and damage to the

engine

IG2200i 15

MAINTENANCE AND SERVICE

AIR FILTER

Maintaining anair filter is very important. Dirt

induced through improperly installed,

improperly serviced, orinadequate elements

damages and wears out engines. Keep the

element always clean.

1. Remove the cover.

2. Remove the air filter cover and element.

3. Wash the element in solvent and dry.

4. Oil the element and squeeze out excess oil.

The element should be wet but not dripping.

5. Insert the element into the air filter.

6. Install the cover.

CAUTION:

The engine should never run without the

element; excessive piston and/or cylinder wear

may result.

CLEANING AND ADJUSTING SPARK PLUG

1. Remove the cover.

2. Check for discoloration and remove the carbon.

3. Check the spark plug type and gap.

4. Install the spark plug.

5. Install the cover.

CAUTION:

Standard electrode colour: Tan Colour.

Standard Spark Plug: CM6RA (TORCH)

Spark Plug Gap: 0.6-0.7 mm (0.024-0.028 in)

FUEL TANK FILTER

1. Remove the fuel tank cap and filter.

2. Clean the filter with solvent. If damaged,

replace.

3. Wipe the filter and insert it.

! WARNING

Be sure the tank cap is tightened securely.

IG2200i 16

MAINTENANCE AND SERVICE

MUFFLER SCREEN

WARNING

The engine and muffler will be very hot after the

engine has been run.

Avoid touching the engine and muffler while

they are still hot with any part of your body or

clothing during inspection or repair.

1.Remove the cover.

2.Remove the muffler screen.

3.Use the flathead screw driver to pry the spark

arrester out from the muffler.

4.Remove the carbon deposits on the muffler

screen and spark arrester using a wire brush.

5.Install the muffler screen.

6.Install the cover.

IG2200i 17

Troubleshooting

Problem

Cause

Solution

The generator

fails to start

Fuel in tank

Fuel tank cap air vent

knob to OPEN, fuel cock

knob to ON.

Not enough oil in the

generator

Add more oil

No fuel

Add more fuel

Spark plug not working

correctly

Change the spark plug

The generator

fails to generate

electricity

The device you are trying

to power is faulty

Make sure the device

you want to power is

working properly

The overload indicator is

on

Remove the appliance

immediately, do not

connect any appliance

that requires more than

power

(DC supply only) The DC

overload protector has

activated

Press the reset button

The generator is

difficult to start

The air filter is dirty Clean the air filter

If this does not solve your problem, please contact the AUTOJACK service

department.

IG2200i 18

AUTOJACK GUARANTEE

1.Guarantee

1.1 Autojack guarantees that for a period of 12

months from the date of purchase the

components of qualifying products (see clauses

1.2.1 to 1.2.8) will be free from defects caused

by faulty construction or manufacture

1.2 During this period, Autojack, will repair or

replace free of charge any parts which are

proved to be faulty in accordance with

paragraph 1.1 providing that:

1.2.1 You follow the claims procedure set out in

clause 2.

1.2.2 Autojack and its Authorised Dealers are

given reasonable opportunity after receiving

notice of the claim to examine the product.

1.2.3 If asked to do so by Autojack or its

Authorised Dealer, you return the product at

your own cost to Autojack’s or the supplying

Authorised Dealer’s Premises, For the

examination to take place clearly stating the

Returns Material Authorisation Number given by

Autojack or an Authorised Dealer.

1.2.4 The fault in question is not caused by

industrial use, accidental damage, fair wear and

tear, wilful damage,neglect, incorrect electrical

connection, misuse, alteration or repair of the

product without approval.

1.2.5 The product has been used in a domestic

environment only.

1.2.6 The fault does not relate to consumable

items such as blades, bearings, drive belts or other

wearing parts which can reasonably be expected

to wear at different rates depending on usage.

1.2.7 The product has not been used for hire

purposes.

1.2.8 The product has been purchased by you, as

the guarantee is not transferable from a private

sale.

2. Claims Procedure

2.1 In the first instance please contact the

Authorised Dealer who supplied the product to

you. In our experience many initial problems with

machines that are thought to be fault due to faulty

parts are actually solved by correct setting up or

adjustment of the machine. A good Authorised

Dealer should be able to resolve the majority of

these issues much more quickly than processing a

claim under the guarantee. If a return is requested

by the Authorised Dealer or Autojack, you will be

provided with a Returns Material Authorisation

Number which must be clearly stated on the

returned package, and any accompanying

correspondence. Failure to provide a Returns

Material Authorisation Number may result in item

being refused delivery.

Table of contents

Other Autojack Portable Generator manuals

Popular Portable Generator manuals by other brands

RIDGID

RIDGID RD907500P Operator's manual

Rentquip

Rentquip Patron GI-3000 Operation manual

iPower

iPower SUA15000EC owner's manual

Power Tech Generators

Power Tech Generators PTI-15SS-T4F Operator's manual

Westerbeke

Westerbeke 10TWO Operator's manual

Mase Generators

Mase Generators IS 10 T Use and maintenance manual