Inverter Air Source Heat Pump (AHGR410AW) - Installation and Instruction Manual

06. Troubleshooting

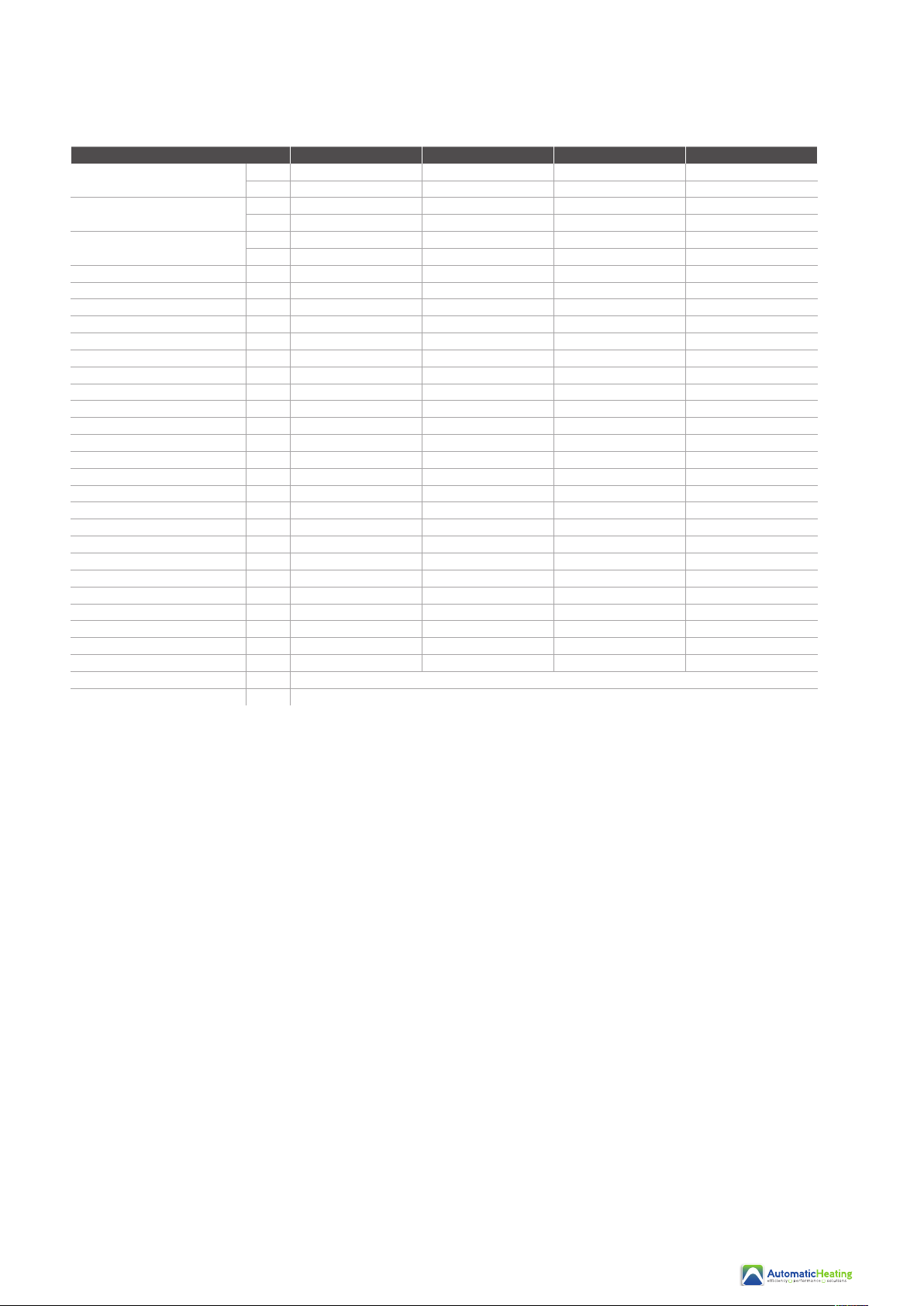

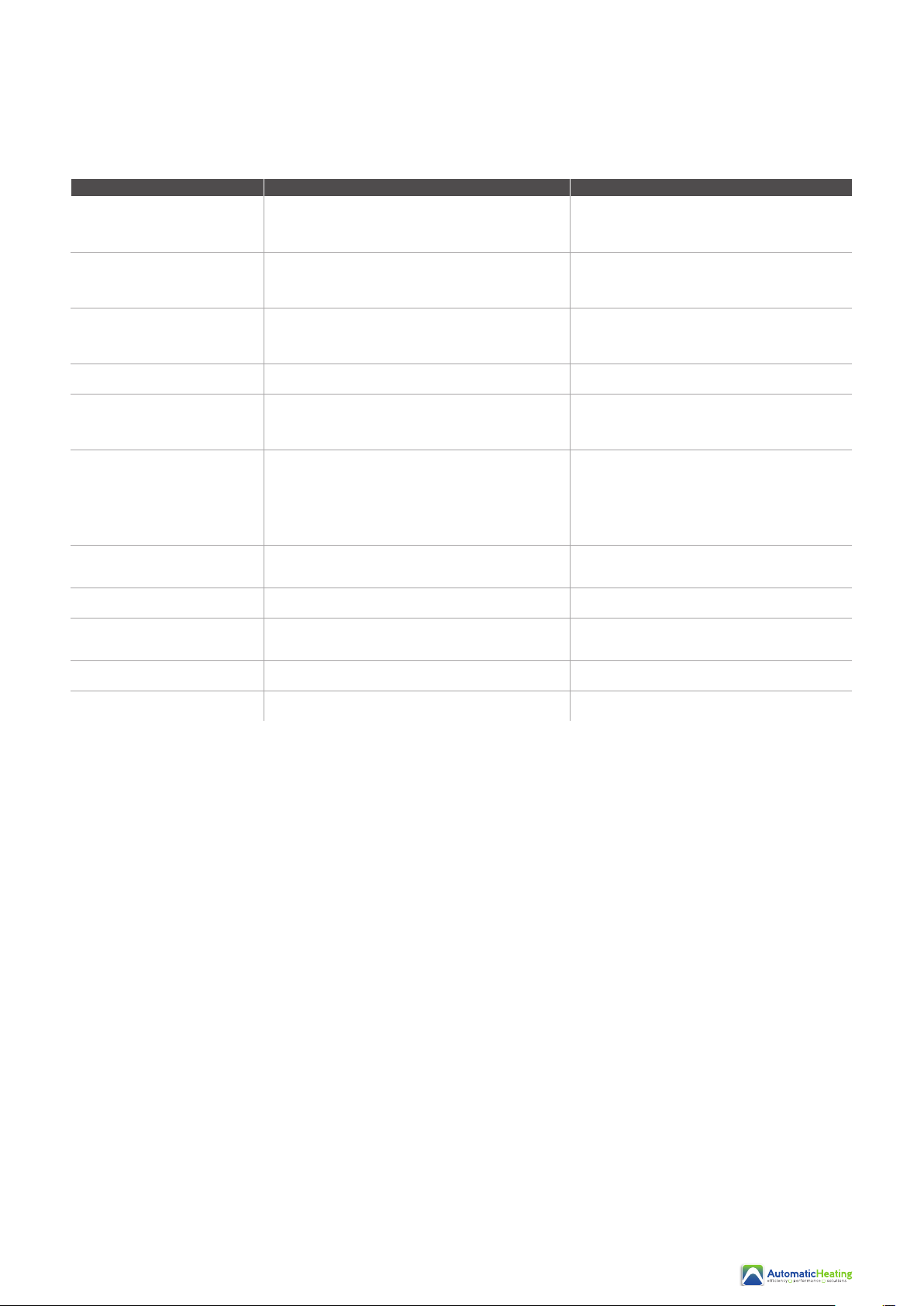

6.4 Equipment Fault Table

Failure Possible causes for the failure Solutions

Heat pump cannot be started • Incompatible power supply

• Power supply cable is loose

• Circuit breaker is open

• Shut o the power and check the power supply.

• Check the power cable and fix the connection.

• Check for the cause and replace the fuse or circuit

breaker.

Water pump is running with

high noise or without water

• Lack of water in the piping

• Too much air in the water loop

• Water valves are closed

• Dirt or blockage on the water filter

• Check the water supply & charge water into the piping.

• Discharge the air from the water loop.

• Open the valves in the water loop.

• Clean the water filter.

Heat pump capacity is low;

compressor does not stop

• Lack in refrigerant

• Bad insulation on water pipe

• Low heat exchange rate on air side exchanger

• Lack of water flow

• Check for gas leakage and recharge the refrigerant.

• Fix the insulation on the water pipe.

• Clean the air side heat exchanger.

• Clean the water filter.

High compressor exhaust • Too much refrigerant

• Low heat exchange rate on air side exchanger

• Discharge the redundant gas.

• Clean the air side heat exchanger.

Low pressure problem of the system • Lack of gas

• Blockage on filter or capillary

• Lack of water flow

• Check for gas leakage and recharge Freon.

• Replace filter or capillary.

• Clean the water filter and discharge the air from

the water loop.

Compressor does not run • Power supply failure

• Compressor contactor is broken

• Power cable is loose

• Protection on compressor

• Wrong setting on return water temp.

• Lack of water flow

• Check the power supply.

• Replace the compressor contactor.

• Tighten the power cable.

• Check the compressor exhaust temp.

• Reset the return water temp.

• Clean the water filter and discharge the air from

the water loop.

High noise from the compressor • Liquid refrigerant goes into the compressor

• Compressor failure

• Bad evaporation; check the cause for bad evaporation

and get rid of this.

• Change the compressor.

Fan does not run • Failure on fan relay

• Fan motor is broken

• Replace fan relay.

• Replace fan motor.

The compressor runs but heat pump

does not have heating or cooling

capacity

• No gas in the heat pump

• Heat exchanger is broken

• Compressor failure

• Check for system leakage and recharge refrigerant.

• Find out the cause and replace the heat exchanger.

• Replace compressor.

Low outlet water temperature • Low water flow rate

• Low setting on the desired water temp.

• Clean the water filter & discharge air from the water loop.

• Reset the desired water temperature.

Low water flow protection • Lack of water in the system

• Failure on flow switch

• Clean the water filter & discharge air from the water loop.

• Replace the flow switch.

You can refer to the malfunction table below to find out the failure cause & solution

20