AutomationDirect DURA PULSE GS-2DBU User manual

Dynamic Braking User Manual

GS-DB_UMW

BLANK

PAGE

2nd Ed., Rev.C – 06/14/2019 – DURApulse Drives Dynamic Braking User Manual W–1

~ WARNING ~

Thank you for purchasing automation equipment from Automationdirect.com©, doing business

as AutomationDirect. We want your new automation equipment to operate safely. Anyone who

installs or uses this equipment should read this publication (and any other relevant publications)

before installing or operating the equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national

codes that regulate the installation and operation of your equipment. These codes vary from area

to area and usually change with time. It is your responsibility to determine which codes should be

followed, and to verify that the equipment, installation, and operation is in compliance with the

latest revision of these codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National

Electrical Code, and the codes of the National Electrical Manufacturer’s Association (NEMA). There

may be local regulatory or government offices that can also help determine which codes and

standards are necessary for safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. We do not guarantee the products described in this publication are suitable

for your particular application, nor do we assume any responsibility for your product design,

installation, or operation.

Our products are not fault-tolerant and are not designed, manufactured or intended for use or resale

as on-line control equipment in hazardous environments requiring fail-safe performance, such

as in the operation of nuclear facilities, aircraft navigation or communication systems, air traffic

control, direct life support machines, or weapons systems, in which the failure of the product could

lead directly to death, personal injury, or severe physical or environmental damage (“High Risk

Activities”). AutomationDirect specifically disclaims any expressed or implied warranty of fitness for

High Risk Activities.

For additional warranty and safety information, see the Terms and Conditions section of our catalog.

If you have any questions concerning the installation or operation of this equipment, or if you need

additional information, please call us at 770-844-4200.

This publication is based on information that was available at the time it was printed. At

AutomationDirect we constantly strive to improve our products and services, so we reserve the right

to make changes to the products and/or publications at any time without notice and without any

obligation. This publication may also discuss features that may not be available in certain revisions

of the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies.

The product and company names may be trademarked and are the sole property of their respective

owners. AutomationDirect disclaims any proprietary interest in the marks and names of others.

Copyright 2004, 2009, 2017, 2019 Automationdirect.com© Incorporated

All Rights Reserved

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior,

written consent of Automationdirect.com© Incorporated. AutomationDirect retains the exclusive

rights to all information included in this document.

NOTE: (Table)

W–2 DURApulse Drives Dynamic Braking User Manual – 2nd Ed., Rev.C – 06/14/2019

~ AVERTISSEMENT ~

Nous vous remercions d’avoir acheté l’équipement d’automatisation de Automationdirect.com©,

en faisant des affaires comme AutomationDirect. Nous tenons à ce que votre nouvel équipement

d’automatisation fonctionne en toute sécurité. Toute personne qui installe ou utilise cet équipement

doit lire la présente publication (et toutes les autres publications pertinentes) avant de l’installer ou de

l’utiliser.

Afin de réduire au minimum le risque d’éventuels problèmes de sécurité, vous devez respecter tous

les codes locaux et nationaux applicables régissant l’installation et le fonctionnement de votre

équipement. Ces codes diffèrent d’une région à l’autre et, habituellement, évoluent au fil du temps. Il

vous incombe de déterminer les codes à respecter et de vous assurer que l’équipement, l’installation et

le fonctionnement sont conformes aux exigences de la version la plus récente de ces codes.

Vous devez, à tout le moins, respecter toutes les sections applicables du Code national de prévention

des incendies, du Code national de l’électricité et des codes de la National Electrical Manufacturer’s

Association (NEMA). Des organismes de réglementation ou des services gouvernementaux locaux

peuvent également vous aider à déterminer les codes ainsi que les normes à respecter pour assurer une

installation et un fonctionnement sûrs.

L’omission de respecter la totalité des codes et des normes applicables peut entraîner des dommages

à l’équipement ou causer de graves blessures au personnel. Nous ne garantissons pas que les produits

décrits dans cette publication conviennent à votre application particulière et nous n’assumons aucune

responsabilité à l’égard de la conception, de l’installation ou du fonctionnement de votre produit.

Nos produits ne sont pas insensibles aux défaillances et ne sont ni conçus ni fabriqués pour l’utilisation

ou la revente en tant qu’équipement de commande en ligne dans des environnements dangereux

nécessitant une sécurité absolue, par exemple, l’exploitation d’installations nucléaires, les systèmes

de navigation aérienne ou de communication, le contrôle de la circulation aérienne, les équipements

de survie ou les systèmes d’armes, pour lesquels la défaillance du produit peut provoquer la mort,

des blessures corporelles ou de graves dommages matériels ou environnementaux («activités à risque

élevé»). La société AutomationDirect nie toute garantie expresse ou implicite d’aptitude à l’emploi en

ce qui a trait aux activités à risque élevé.

Pour des renseignements additionnels touchant la garantie et la sécurité, veuillez consulter la section

Modalités et conditions de notre documentation. Si vous avez des questions au sujet de l’installation

ou du fonctionnement de cet équipement, ou encore si vous avez besoin de renseignements

supplémentaires, n’hésitez pas à nous téléphoner au 770-844-4200.

Cette publication s’appuie sur l’information qui était disponible au moment de l’impression. À la

société AutomationDirect, nous nous efforçons constamment d’améliorer nos produits et services.

C’est pourquoi nous nous réservons le droit d’apporter des modifications aux produits ou aux

publications en tout temps, sans préavis ni quelque obligation que ce soit. La présente publication

peut aussi porter sur des caractéristiques susceptibles de ne pas être offertes dans certaines versions

révisées du produit.

Marques de commerce

La présente publication peut contenir des références à des produits fabriqués ou offerts par d’autres

entreprises. Les désignations des produits et des entreprises peuvent être des marques de commerce et

appartiennent exclusivement à leurs propriétaires respectifs. AutomationDirect nie tout intérêt dans les

autres marques et désignations.

Copyright 2004, 2009, 2017, 2019 Automationdirect.com© Incorporated

Tous droits réservés

Nulle partie de ce manuel ne doit être copiée, reproduite ou transmise de quelque façon que ce

soit sans le consentement préalable écrit de la société Automationdirect.com© Incorporated.

AutomationDirect conserve les droits exclusifs à l’égard de tous les renseignements contenus dans le

présent document.

2nd Ed., Rev.C – 06/14/2019 – DURApulse Drives Dynamic Braking User Manual W–3

~ WARNINGS ~

Warning: alWays read this manual thoroughly before using the durapulse dynamic brake

unit With the durapulse ac motor drive.

Warning: ac input poWer must be disconnected before performing any maintenance. do

not connect or disconnect Wires or connectors While poWer is applied to the circuit.

maintenance must only be performed by aqualified technician.

Warning: there are highly sensitive mos components on the printed circuit boards.

these components are especially sensitive to static electricity. toavoid damage to these

components, do not touch these components or the circuit boards With metal objects or

your bare hands.

Warning: a charge may still remain in the ac drive’sdc-link capacitor(s) With hazardous

voltages even if the poWer has been turned off to the ac drive. toavoid personal injury,

do not remove the cover of the durapulse dynamic brake unit or the ac drive until the

poWer has been disconnected from the ac drive and all “discharge” indicators on the

devices are off. please note that there are live components exposed Within the brake unit

and the ac drive. donot touch these live parts.

Warning: ground the durapulse dynamic brake unit using the ground terminal. the

grounding method must comply With the laWs of the country Where the brake unit is to be

installed. refer to the “basic braking Wiring diagram” shoWn in “chapter 3: component

configuration and Wiring.”

Warning: the mounting enclosure of the durapulse dynamic brake unit must comply With

en50178. live parts shall be arranged in enclosures or located behind barriers that meet at

least the requirements of the protective type ip20. the top surface of the enclosures or

barrier that is easily accessible shall meet at least the requirements of the protective type

ip40. users must provide this environment for the brake unit and braking resistor.

W–4 DURApulse Drives Dynamic Braking User Manual – 2nd Ed., Rev.C – 06/14/2019

BLANK

PAG E

DURApUlse Dynamic Braking

User manUal revision History

2nd Ed., Rev.C – 06/14/2019 – DURApulse Drives Dynamic Braking User Manual H–1

Please include the Manual Number and the Manual Issue, both shown below, when communicating

with Technical Support regarding this publication.

Manual Number: GS-DB_UMW

Issue: Second Edition, Revision C

Issue Date: 06/14/2019

Publication History

Issue Date Description of Changes

First Edition 11/17/2003 Original

1st Ed. Rev.A 03/2004 Minor changes

1st Ed. Rev.B 07/2009 GS-2050-BR-ENC specifications

Second Edition 09/28/2017

User Manual name change (previous name: GS3-DB-M)

Added GS4 series AC Drives

Added (5) GS-xDB series Dynamic Braking Units; where x = 1,3,5,6,7

Added (19) GS-BR-xxxWxxx series Dynamic Braking Resistors

Added Chapters 2 and 3

Modifications to braking resistor dimension drawings Ch2

2nd Ed. Rev.A 10/26/2017 Bar code

Ch2: Dimensions for resistors GS-20P5-BR & GS-21P0-BR

2nd Ed. Rev.B 05/17/2019 User Manual name change (previous name: GS-DB_UMP)

Ch3: Thermal overload relay recommendation and wiring diagram

2nd Ed. Rev.C 06/14/2019 Ch3: Basic Braking Wiring Diagram

H–2 DURApulse Drives Dynamic Braking User Manual – 2nd Ed., Rev.C – 06/14/2019

User Manual Revision History

BLANK

PAG E

GS DURApUlse AC DriveS

DynAmiC BrAkinG USer mAnUAl

TABle of ConTenTS

TABle

of

ConTenTS

TABle

of

ConTenTS

TABle

of

ConTenTS

2nd Ed., Rev.C – 06/14/2019 – DURApUlse Drives Dynamic Braking User Manual TOC–1

User ManUal Contents

Warnings and tradeMarks � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � W–1

dUrapUlse dynaMiC Braking User ManUal revision History � � � � � � � � � � � � � � � � H–1

CHapter 1: Braking overvieW and CoMponent speCifiCations � � � � � � � � � � � � � � � � 1–1

Manual Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–2

Overview of this Publication � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–2

Who Should Read This Manual � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–2

Supplemental Publications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–2

Technical Support � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–2

Special Symbols � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–3

Introduction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–3

Dynamic Braking � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–3

Dynamic Braking Units � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–3

Braking Duty Cycle � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–4

Overload Relay � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–5

Overload Relay Purpose � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–5

Overload Relay Selection Procedure and Example � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–5

Dynamic Braking Component Selection for DURApulse AC Drives � � � � � � � � � � � � � � � � 1–6

Braking Component Selection for GS3 DURApulse Drives � � � � � � � � � � � � � � � � � � � � � � � �1–6

Braking Component Selection for GS4 DURApulse Drives � � � � � � � � � � � � � � � � � � � � � � � �1–7

Dynamic Braking Unit Specifications� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–8

Lamp/LED Indicators for Dynamic Braking Units � � � � � � � � � � � � � � � � � � � � � � � � � � � � �1–8

Dynamic Braking Resistors Specifications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–9

CHapter 2: Braking CoMponent installation and diMensions � � � � � � � � � � � � � � � � 2–1

Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2–2

General Installation Guidelines � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �2–2

Minimum Clearances and Air Flow � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �2–2

Braking Unit Dimensions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2–4

Braking Resistor Dimensions� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2–5

Table of Contents

TOC–2 DURApUlse Drives Dynamic Braking User Manual – 2nd Ed., Rev.C – 06/14/2019

CHapter 3: Braking CoMponent ConfigUration and Wiring � � � � � � � � � � � � � � � � � 3–1

Operational Electrical Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3–2

Overload Relay � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3–2

Dynamic Braking Unit Setup � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3–3

DBU Jumper and Wiring Terminal Locations � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3–3

DBU Voltage Jumper Settings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3–4

DBU Master/Slave Jumper Settings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3–5

Dynamic Braking Wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3–6

Wiring Warnings and Notes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3–6

Maximum Wiring Distances� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3–7

Dynamic Braking Unit Wiring Terminals� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3–7

Basic Braking Wiring Diagram� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3–9

Specific Braking Wiring Diagrams � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3–10

Braking Overview and

COmpOnent SpeCifiCatiOnS 1

1

1

Chapter

Chapter

Chapter

2nd Ed., Rev.C – 06/14/2019 – DURApUlse Drives Dynamic Braking User Manual 1–1

taBle of Contents

Manual Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–2

Overview of this Publication � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–2

Who Should Read This Manual� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–2

Supplemental Publications� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–2

Technical Support� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–2

Special Symbols� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–3

Introduction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–3

Dynamic Braking � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–3

Dynamic Braking Units � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–3

Braking Duty Cycle � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–4

Overload Relay � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–5

Overload Relay Purpose� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–5

Overload Relay Selection Procedure and Example � � � � � � � � � � � � � � � � � � � � � � � � 1–5

Dynamic Braking Component Selection for DURApulse AC Drives � � � � � � � � � � 1–6

Braking Component Selection for GS3 DURApulse Drives � � � � � � � � � � � � � � � � � � � � 1–6

Braking Component Selection for GS4 DURApulse Drives � � � � � � � � � � � � � � � � � � � � 1–7

Dynamic Braking Unit Specifications� � � � � � � � � � � � � � � � � � � � � � � � � � � � 1–8

Lamp/LED Indicators for Dynamic Braking Units � � � � � � � � � � � � � � � � � � � � � � � � � 1–8

Dynamic Braking Resistors Specifications� � � � � � � � � � � � � � � � � � � � � � � � � 1–9

Chapter 1: Overview and Component Specifications

1–2 DURApUlse Drives Dynamic Braking User Manual – 2nd Ed., Rev.C – 06/14/2019

Manual Overview

The dUrapUlse Dynamic Braking User Manual describes the installation, wiring,

configuration, and operation of the dynamic braking unit and braking resistors as used with

GS3 and GS4 series dUrapUlse AC Drives.

The content of this user manual may be revised without prior notice. Please visit the

Automationdirect.com website to download the most recent version.

(www.automationdirect.com)

This manual contains important information for those who will install, maintain, and/or

operate any dUrapUlse GS3 or GS4 series AC Drive that makes use of the dynamic braking in

their application.

The dUrapUlse AC Drive User Manuals (GS3-M & GS4-M) are available from AutomationDirect

and should be used along with this manual to properly install and operate both the

dUrapUlse AC drive and the dUrapUlse dynamic braking unit.

The National Electrical Manufacturers Association (NEMA) publishes many different

documents that discuss standards for industrial control equipment. Global Engineering

Documents handles the sale of NEMA documents. For more information, you can contact

Global Engineering Documents at:

15 Inverness Way East

Englewood, CO 80112-5776

1-800-854-7179 (within the U.S.)

303-397-7956 (international)

www.global.ihs.com

NEMA documents that might assist with your AC drive systems are:

• Application Guide for AC Adjustable Speed Drive Systems

• Safety Standards for Construction and Guide for Selection, Installation, and Operation of

Adjustable Speed Drive Systems

By Telephone: 770-844-4200 (Mon.-Fri., 9:00 a.m.-6:00 p.m. E.T.)

On the Web: www.automationdirect.com

Our technical support group is glad to work with you in answering your questions. If

you cannot find the solution to your particular application, or, if for any reason you need

additional technical assistance, please call technical support at 770-844-4200. We are

available weekdays from 9:00 a.m. to 6:00 p.m. Eastern Time.

We also encourage you to visit our website where you can find technical and non-technical

information about our products and our company. Visit us at www.automationdirect.com.

Chapter 1: Overview and Component Specifications

2nd Ed., Rev.C – 06/14/2019 – DURApUlse Drives Dynamic Braking User Manual 1–3

When you see the “notepad” icon in the left-hand margin, the paragraph to its

immediate right will be a special note.

When you see the “exclamation mark” icon in the left-hand margin, the paragraph to

its immediate right Will be aWarning. this information could prevent injury, loss of

property, or even death (in extreme cases).

Introduction

All dUrapUlse GS3 and GS4 series AC drives are capable of dynamic braking to enable an AC

motor with a high-inertia load to decelerate more rapidly than could be otherwise achieved,

and to absorb the energy generated when a three-phase induction motor decelerates.

Applications with high-inertia type loads tend to cause the motor to regenerate energy back

into the AC drive. This regeneration causes the AC drive’s internal DC bus voltage to rise,

which can cause an over voltage fault. With dynamic braking, the energy generated by the

overhauling motor is dissipated through dedicated braking resistors as heat.

As shown in the selection tables in this chapter, lower-capacity drives can connect directly

to the optional external braking resistors, but higher-capacity drives also require optional

dynamic braking units installed between the drives and resistors.

dUrapUlse dynamic braking units are used with larger dUrapUlse AC Drives to continuously

monitor the drive’s DC bus voltage. When bus voltage exceeds a predetermined level

(depending on the supply voltage) the dynamic braking unit dissipates the excess energy

into external resistors in the form of heat. dUrapUlse dynamic braking units must be used

along with GS series braking resistors to provide optimum braking performance.

dUrapUlse dynamic braking units are available for both 230V or 460V dUrapUlse AC Drives.

MASTER/SLAVE configurations allow the use of multiple dUrapUlse dynamic braking units in

order to accommodate the power ratings of larger dUrapUlse AC Drives and motors.

dUrapUlse dynamic braking units (GS-1DBU, GS-2DBU, GS-3DBU and GS-4DBU) are approved

by Underwriters Laboratories, Inc. (UL) and Canadian Underwriters Laboratories (cUL).

After receiving the dUrapUlse dynamic braking unit, please check for the following:

• Make sure that the part number indicated on the package corresponds with the part number of

your order.

• Make sure that the package includes the dUrapUlse dynamic braking unit and the dUrapUlse

dynamic braking unit User Manual.

• Inspect the contents to insure they were not damaged during shipment.

Chapter 1: Overview and Component Specifications

1–4 DURApUlse Drives Dynamic Braking User Manual – 2nd Ed., Rev.C – 06/14/2019

Braking Duty Cycle

Application of a dUrapUlse dynamic braking unit should take into account how often the

motor will stop or decelerate during normal operation. The Duty Cycle is the percentage

of time the brake is actually used during deceleration in comparison to the time elapsed

between each start or acceleration of the motor. This Duty Cycle percentage is necessary to

allow the dynamic braking unit and braking resistor(s) sufficient time to dissipate the heat

created during dynamic braking. If the Duty Cycle is exceeded, the braking resistor will not

cool sufficiently, causing resistance to increase as the temperature rises with the loss of

effective braking torque.

Example: If in a given application it is determined that it will take 10 seconds for the motor

to decelerate to a stop using dynamic braking, then the motor can only be cycled on and off

continuously every 1.6 minutes (100 seconds).

• 10 / 100 x 100 = 10% Duty Cycle

Duty Cycle =

T0/T1 x 100(%)

Braking

Time

Cycle Time

100%

T0

T1

The maximum braking On-Time for the maximum 10% Duty Cycle is 10 seconds.

Chapter 1: Overview and Component Specifications

2nd Ed., Rev.C – 06/14/2019 – DURApUlse Drives Dynamic Braking User Manual 1–5

Overload Relay

For safety purposes, install an external overload relay between the dynamic brake unit and

the braking resistor. The thermal overload relay protects the braking resistor from damage

due to frequent braking, or due to the braking unit operating excessively due to unusually

high input voltage.

(For a GS4-4150 drive)

1) Select a thermal overload relay based on its overload capability.

60

40

30

20

10

8

3

2

4

6

1

0.8

0.6

0.4

0.3 0.8 1 1.5 2 3 4 5 6 8 10 157 9

Mu ltiple o f Current Settin g xln (A)

Tripping Time

seconds

2.6

Thermal Overload Response Curve

(for typical hypothetical thermal O/L relay)

Standard braking capacity for

GS3 and GS4 AC drives is 10%

duty cycle (tripping time = 10s).

Determine the 10s Overload

Capacity (Multiple of Current

Setting) for your selected

overload relay.

The intersection of the Trip Time

(10s) and the Multiple of Current

Setting is 2.6 (or 260%) for this

example response curve.

The property of each thermal

relay may vary by

manufacturer, so please read

the specifications carefully.

2) Use the appropriate AC Drive Braking Component Selection table in this chapter to find the

Max Total Brake Current for the motor, drive, and braking components (126A for this example).

GS4AC Drive BrAkinG Component SeleCtion

150 110 4150 1 5DBU 10 1K2W015 74.5 126 6.0 126 95.8 L

3) Divide the Max Total Braking Current by the Overload Capacity (126A / 2.6 = 48.46A), and select

a thermal O/L relay which has the same or higher rated current. In this case, select a 50A

relay.

For wiring information, refer to “Overload Relay” in Chapter 3, page 3–2.

Chapter 1: Overview and Component Specifications

1–6 DURApUlse Drives Dynamic Braking User Manual – 2nd Ed., Rev.C – 06/14/2019

Dynamic Braking Component Selection for AC Drives

The following table provides the selection information for the DURApUlse dynamic braking

units designed for use with GS3 and GS4 series AC drives.

GS3AC Drive BrAkinG Component SeleCtion

#

230V

1 0.7

0n/a

1 0.5 1.9 82 4.6 1.8

A

2 1.5 1 1.0 3.8 82 4.6 1.8

3 2.2 1 1.5 5.4 82 4.6 1.8

5 3.7 1 2.5 9.5 33 11.5 4.4

7.5 5.5 1 3.7 12.7 30 12.7 4.8

10 7.5 1 5.1 19.0 20 19.0 7.2

15 11 1 7.5 27.9 13.6 27.9 10.6

20 15 1 1 10.2 38.0* 10* 38.0* 14.4*

D25 18 1 1 12.2 47.5* 8* 47.5* 18.1*

30 22 1 1 14.9 55.9* 6.8* 55.9* 21.2*

40 30 2 2 20.3 38.0* 10* 38.0* 14.5* F

50 37 2 2 25.1 47.5* 8* 47.5* 18.1*

460V

1 0.7

0n/a

1 0.5 1.0 160 4.8 3.6

A

2 1.5 1 1.0 1.9 160 4.8 3.6

3 2.2 1 1.5 3.0 160 4.8 3.6

5 3.7 1 2.5 5.1 130 5.8 4.4

7.5 5.5 1 3.7 7.6 91 8.4 6.3

10 7.5 1 5.1 10.1 62 12.3 9.3

15 11 1 7.5 15.2 39 19.5 14.8

20 15 1 1 10.2 19.0* 40* 19.0* 14.4*

D

25 18 1 1 12.2 23.8* 32* 23.8* 18.1*

30 22 1 1 14.9 27.9* 27.2* 27.9* 21.2*

40 30 1 1 20.3 38.0* 20* 38.0* 28.9*

50 40 1 1 25.1 47.5* 16* 47.5* 36.1*

60 45 1 1 30.5 55.9* 13.6* 55.9* 42.5*

75 55 2 2 37.2 38.0* 20* 38.0* 28.9* F

100 75 2 2 50.8 55.9* 13.6* 55.9* 42.5*

* These values are per individual DBU, as seen between DBU terminals B1 and B2.

** Wiring diagrams are shown in Chapter 3: Component Configuration and Wiring.

*** 10% Duty Cycle with maximum ON (braking) time of 10 seconds.

Chapter 1: Overview and Component Specifications

2nd Ed., Rev.C – 06/14/2019 – DURApUlse Drives Dynamic Braking User Manual 1–7

GS4AC Drive BrAkinG Component SeleCtion

#

1 0.7

0n/a

1 0.5 1.9 63.3 6 2.3

A

2 1.5 1 1.0 4.2 47.5 8 3.0

3 2.2 1 1.5 5.4 38.0 10 3.8

5 3.7 1 2.5 9.5 19.0 20 7.6

7.5 5.5 1 3.7 19 14.6 26 9.9

10 7.5 1 5.1 19 14.6 26 9.9

15 11 1 7.5 29 12.6 28 10.6

20 15 2 10.2 44 8.3 46 17.5

B25 18 2 12.2 44 8.3 46 17.5

30 22 2 14.9 58 5.8 66 25.1

40 30 2 4 20.3 75* 4.8* 80* 30.4*

G50 37 2 4 25.1 97* 3.2* 120* 45.6*

60 45 2 4 30.5 118* 3.2* 120* 45.6*

75 55 3 6 37.2 145* 2.1* 180* 68.4* J

100 75 4 8 50.8 190* 1.6* 240* 91.2* K

1 0.7

0n/a

1 0.5 1 190 4 3.0

A

2 1.5 1 1 2.1 126.7 6 4.6

3 2.2 1 1.5 3 108.6 7 5.3

5 3.7 1 2.5 5.1 84.4 9 6.8

7.5 5.5 1 3.7 10.2 54.3 14 10.6

10 7.5 1 5.1 10.2 47.5 16 12.2

15 11 1 7.5 17.6 42.2 18 13.7

20 15 2 10.2 24 26.2 29 22.0

B25 18 2 12.2 24 23.0 33 25.1

30 22 2 14.9 29 23.0 33 25.1

40 30 4 20.3 47.5 14.1 54 41.0 C

50 40 1 4 25.1 50* 12.7* 60* 45.6* E

60 45 1 4 30.5 59* 12.7* 60* 45.6*

75 55 2 8 37.2 76* 9.5* 80* 60.8* H

100 75 2 8 50.8 100* 6.3* 120* 91.2* I

125 90 2 8 60.9 117* 6.3* 120* 91.2*

150 110 1 10 74.5 126* 6.0* 126* 95.8* L

175 132 1 12 89.4 190* 4.0* 190* 144.4* M

200 160 1 12 108.3 190* 4.0* 190* 144.4*

250 185 1 14 125.3 225* 3.4* 225* 172.1* N

300 220 2 20 148.9 252* 3.0* 252* 190.5* O

* These values are per individual DBU, as seen between DBU terminals B1 and B2.

** Wiring diagrams are shown in Chapter 3: Component Configuration and Wiring.

*** 10% Duty Cycle with maximum ON (braking) time of 10 seconds.

Chapter 1: Overview and Component Specifications

1–8 DURApUlse Drives Dynamic Braking User Manual – 2nd Ed., Rev.C – 06/14/2019

Dynamic Braking Unit Specifications

The following table provides the specifications and applications for the dUrapUlse dynamic

braking units designed for use with GS3 and GS4 series AC drives.

DynAmiC BrAkinG Unit SpeCifiCAtionS

230 460

20

[15]

30

[22]

40

[30]

60

[45]

150

[110]

200

[160]

250

[185]

40 60 40 60 126 190 225

15 20 15 18 45 50 100

330/345/360/

380/400/415 ±3V

660/690/720/

760/800/830 ±6V

618/642/667/690/

725/750 ±6V

10

200–415 400–830 400–750

10 6.8 20 13.6 6 4 3.4

Comes ON until DC bus voltage

(+P – -N) drops below 50VDC

Comes ON when DC bus

voltage (DC+ – DC-) rises

above 300VDC.

Goes OFF when DC bus

voltage (DC+ – DC-) drops

below 100VDC.

ON during braking

ON if an over-temperature fault has

occurred n/a

n/a 190 290 340

n/a Comes ON > 176°F [80°C];

Goes OFF < 149°F [65°C]

203°F [95°C] n/a

5A @ 120VAC/28VDC (RA,RB,RC) 3A @ 250VAC/28VDC

(RA,RC)

indoor (no corrosive gases; no metallic dust)

14°F to 122 °F [-10 to +50 °C]

-4 to +140 °F [-20 to +60 °C]

less than 90% RH, non-condensing

9.8 m/s2[1G] under 20Hz ; 2m/s2[0.2G] at 20–50 Hz

IP50 wall-mount enclosed IP10 wall-mount enclosed

* 10% Duty Cycle with maximum ON (braking) time of 10 seconds

CHARGE ACT OC OH

GS-5DBU, GS-6DBU, GS-7DBU

CHARGE

(GREEN) ACT

(YELLOW)

ERR

(RED)

GS-1DBU, GS-2DBU, GS-3DBU, GS-4DBU

See “DBU Jumper and Wiring Terminal Locations” in Chapter 3 for locations of indicators.

Chapter 1: Overview and Component Specifications

2nd Ed., Rev.C – 06/14/2019 – DURApUlse Drives Dynamic Braking User Manual 1–9

Dynamic Braking Resistors Specifications

BrAkinG reSiStor SpeCifiCAtionS

80 200

open

1

80 200 1

300 100 1

300 70 1

400 40 1

500 30 2

1000 20

enclosed

4

2400 13.6 5

3000 10 5

4800 8 6

4800 6.8 6

3000 10 5

4800 8 6

80 750

open

1

300 400 1

300 250 1

400 150 1

500 100 2

1000 75 3

1000 50

enclosed

4

1500 40 7

4800 32 8

4800 27.2 8

6000 20 8

9600 16 9

9600 13.6 9

6000 20 8

9600 13.6 9

80 200

open

10

80 750 10

200 91 10

200 360 10

300 70 10

300 250 10

400 40 10

400 150 10

1000 4.3 11

1000 5.1 11

1000 16 11

1000 20 11

1000 75 11

1200 3.9 11

1200 15 11

1500 3.3 11

1500 12 11

1500 13 11

1500 43 11

Chapter 1: Overview and Component Specifications

1–10 DURApUlse Drives Dynamic Braking User Manual – 2nd Ed., Rev.C – 06/14/2019

BLANK

PAG E

This manual suits for next models

1

Table of contents

Other AutomationDirect Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

Murata

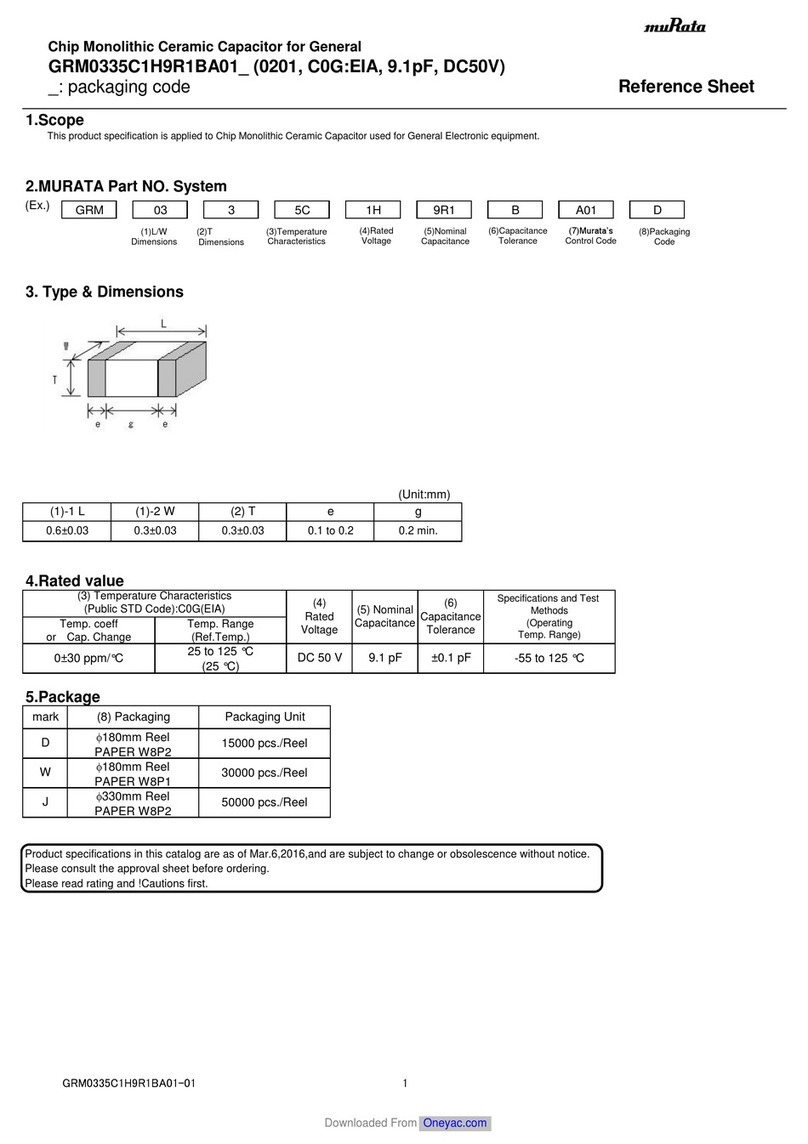

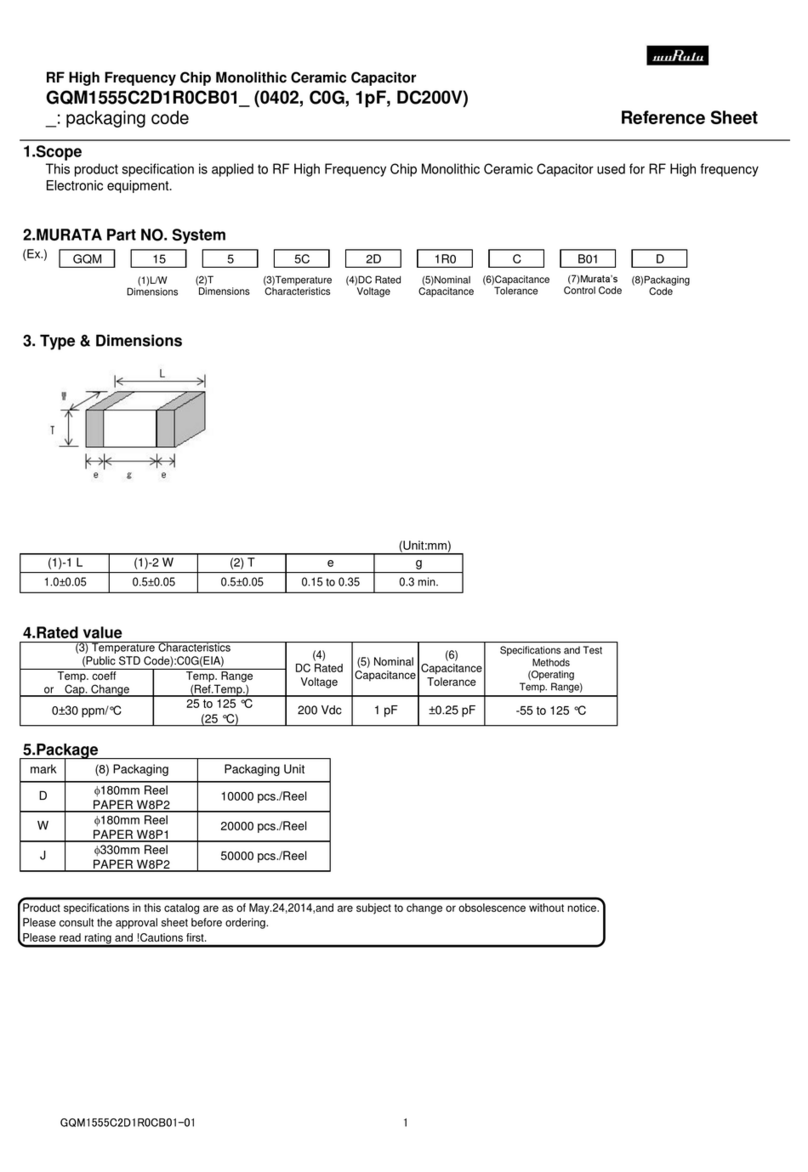

Murata GQM1555C2D1R0CB01 Series Reference sheet

Murata

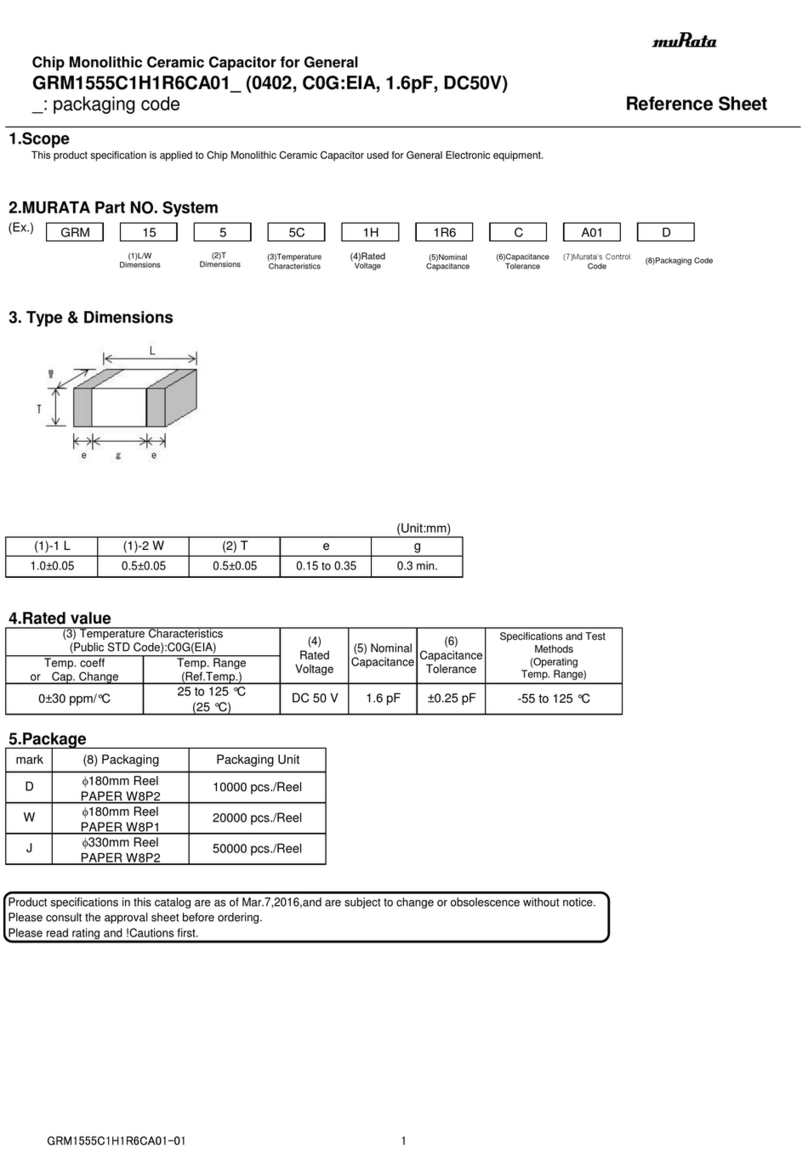

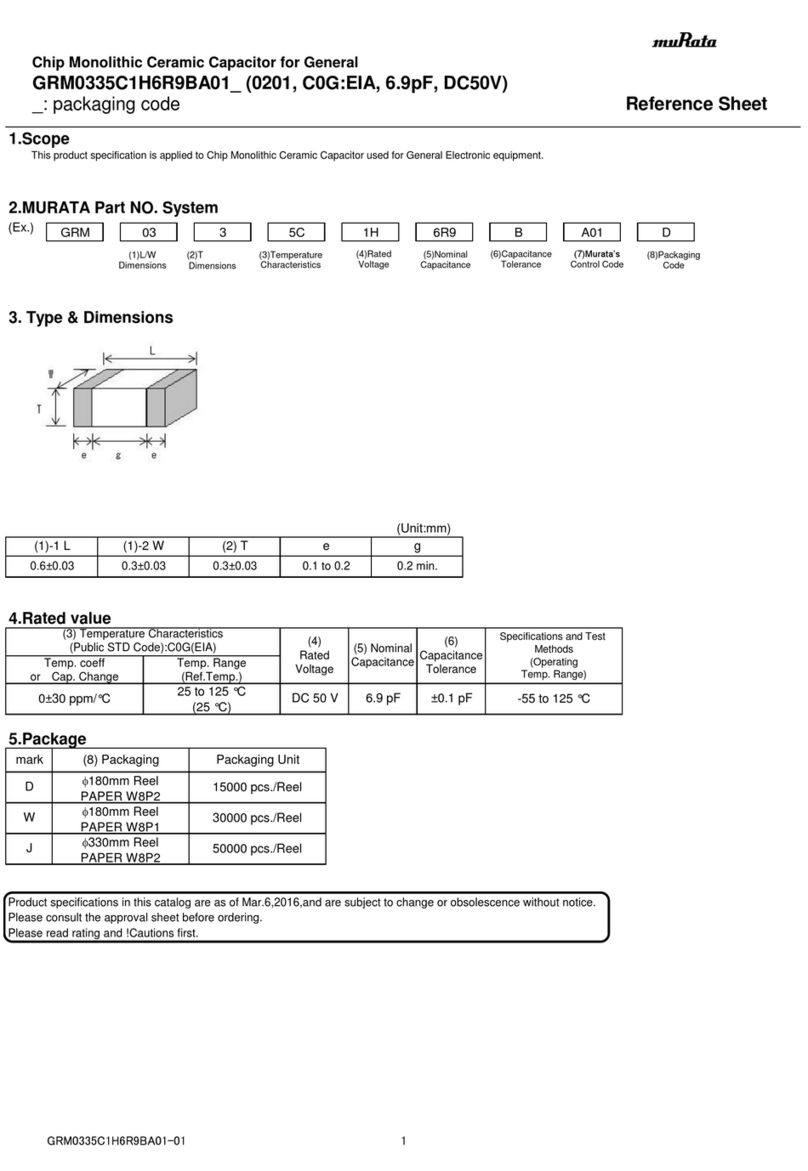

Murata GRM0335C1H6R9BA01 Series Reference sheet

Murata

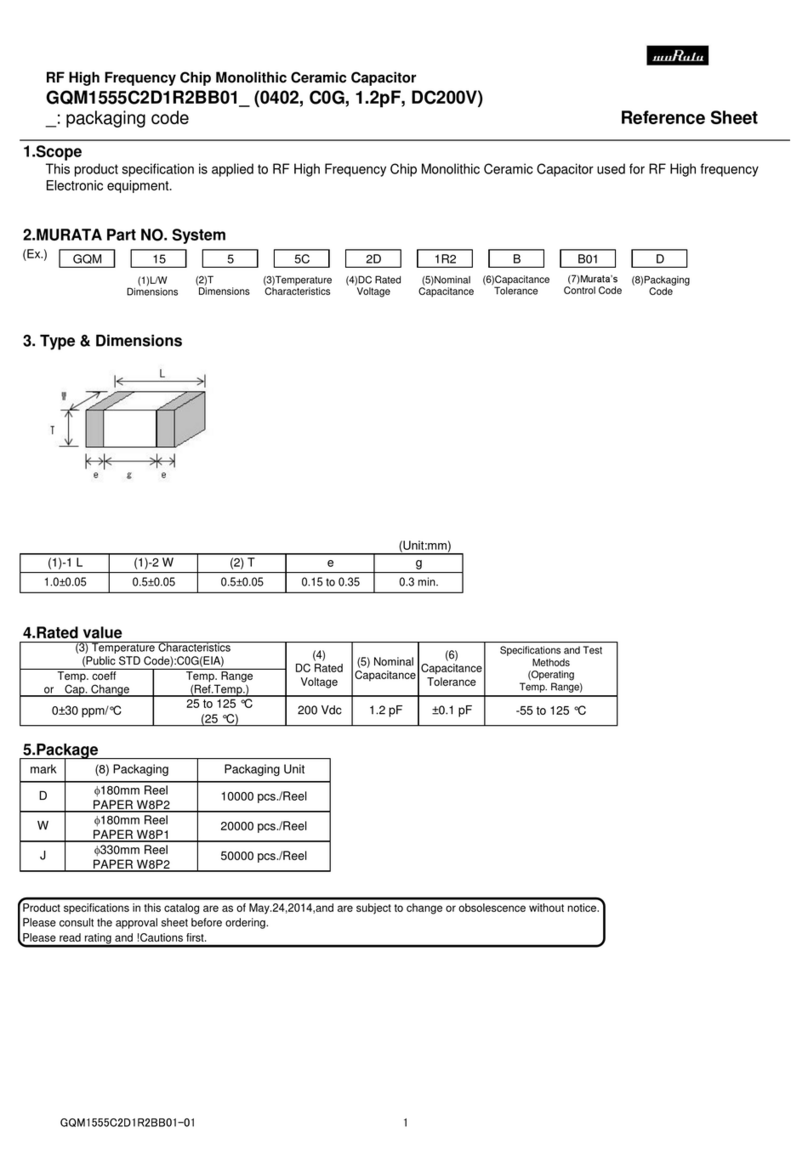

Murata GQM1555C2D1R2BB01 Series Reference sheet

Allen-Bradley

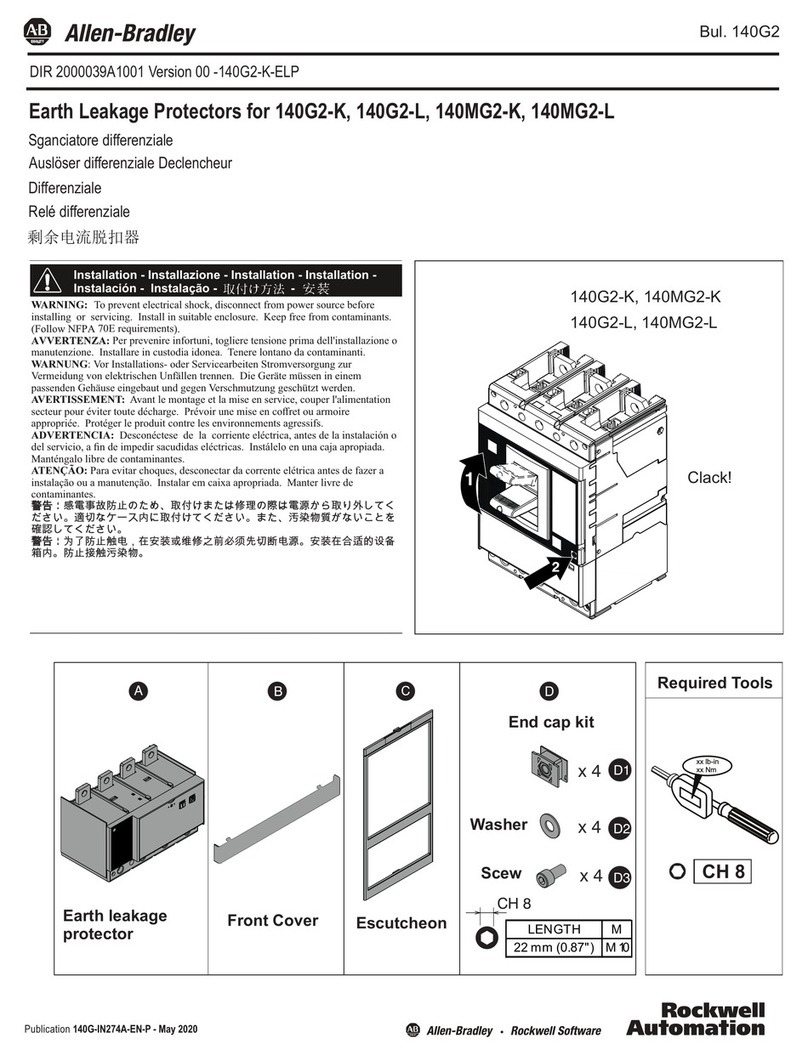

Allen-Bradley 140G2-K quick start guide

Murata

Murata GRM31CR60J476ME19 Series Reference sheet

Leviton

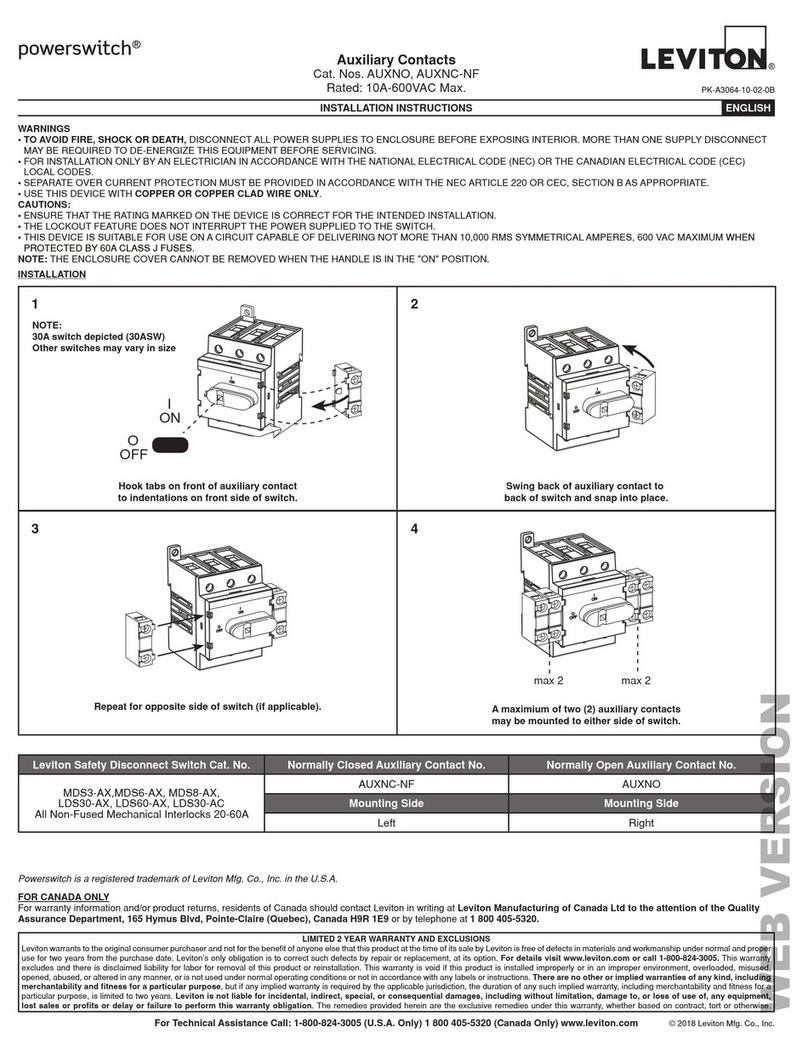

Leviton powerswitch AUXNO installation instructions

Avtech

Avtech RMA-CL1-SEN Package Contents

Murata

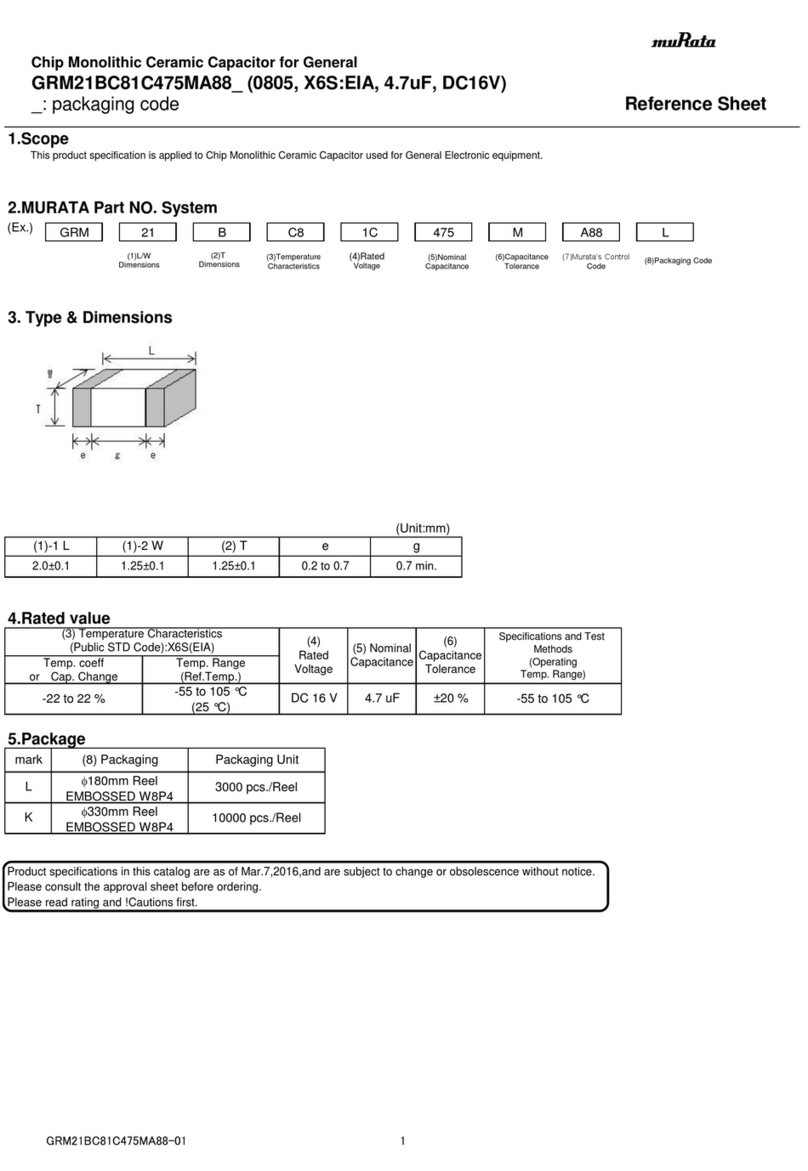

Murata GRM21BC81C475MA88 Series Reference sheet

Murata

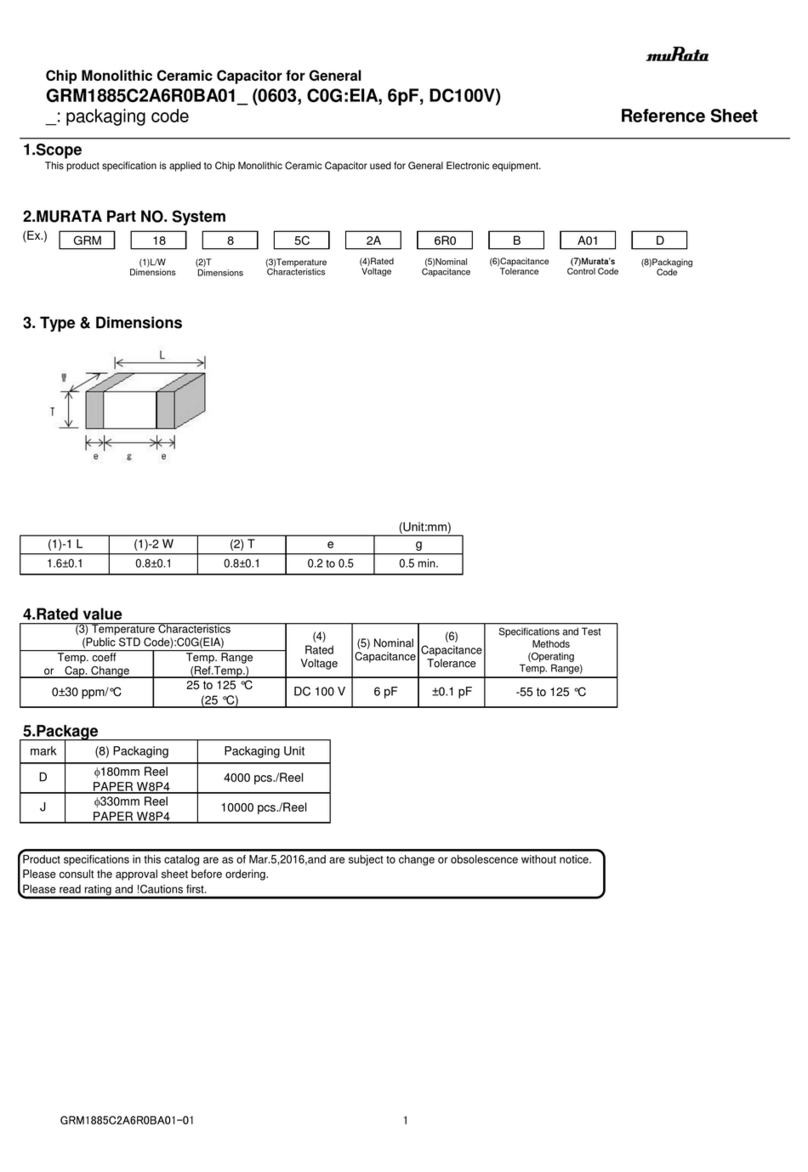

Murata GRM1885C2A6R0BA01 Series Reference sheet

Murata

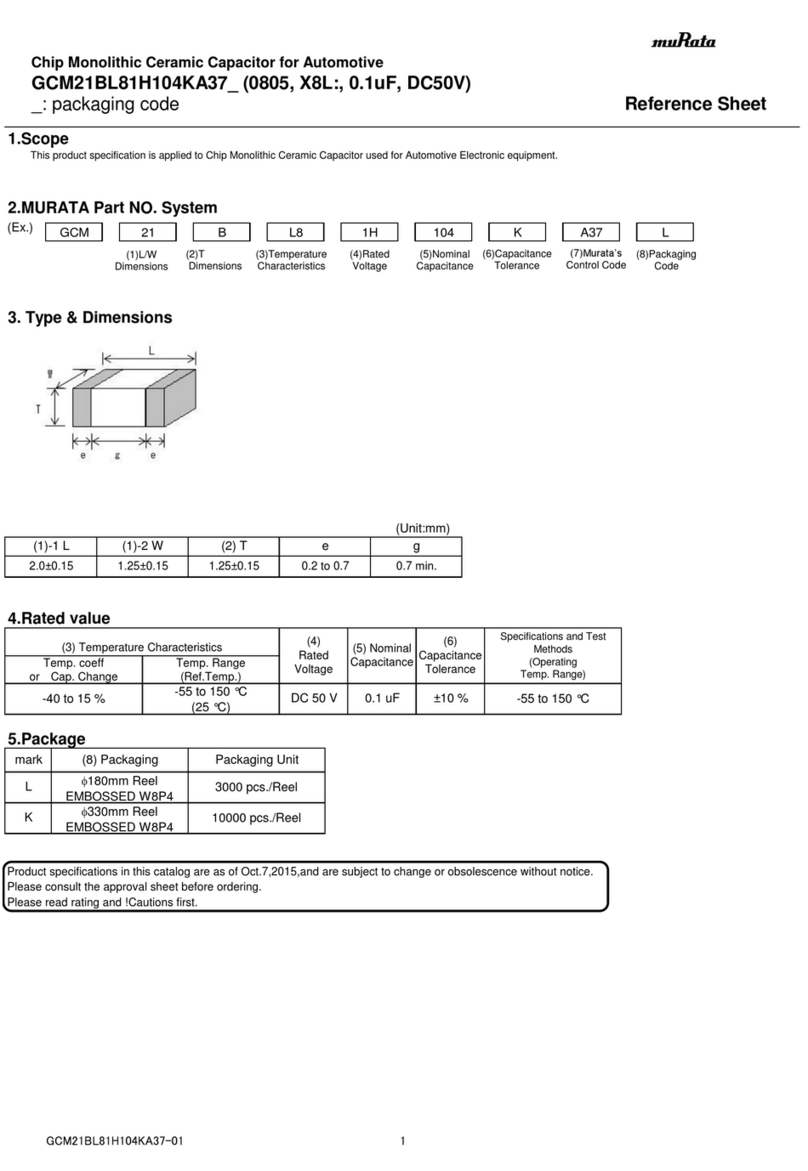

Murata GCM21BL81H104KA37 Series Reference sheet

Murata

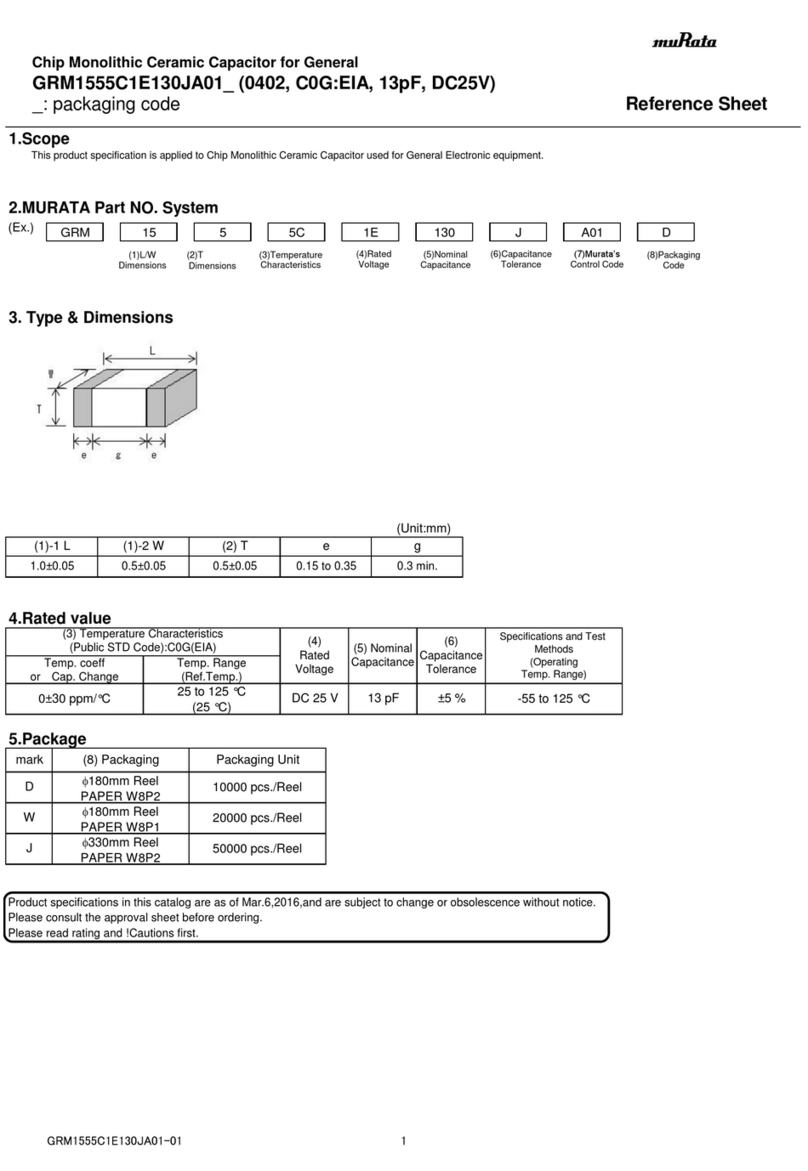

Murata GRM1555C1E130JA01 Series Reference sheet

Murata

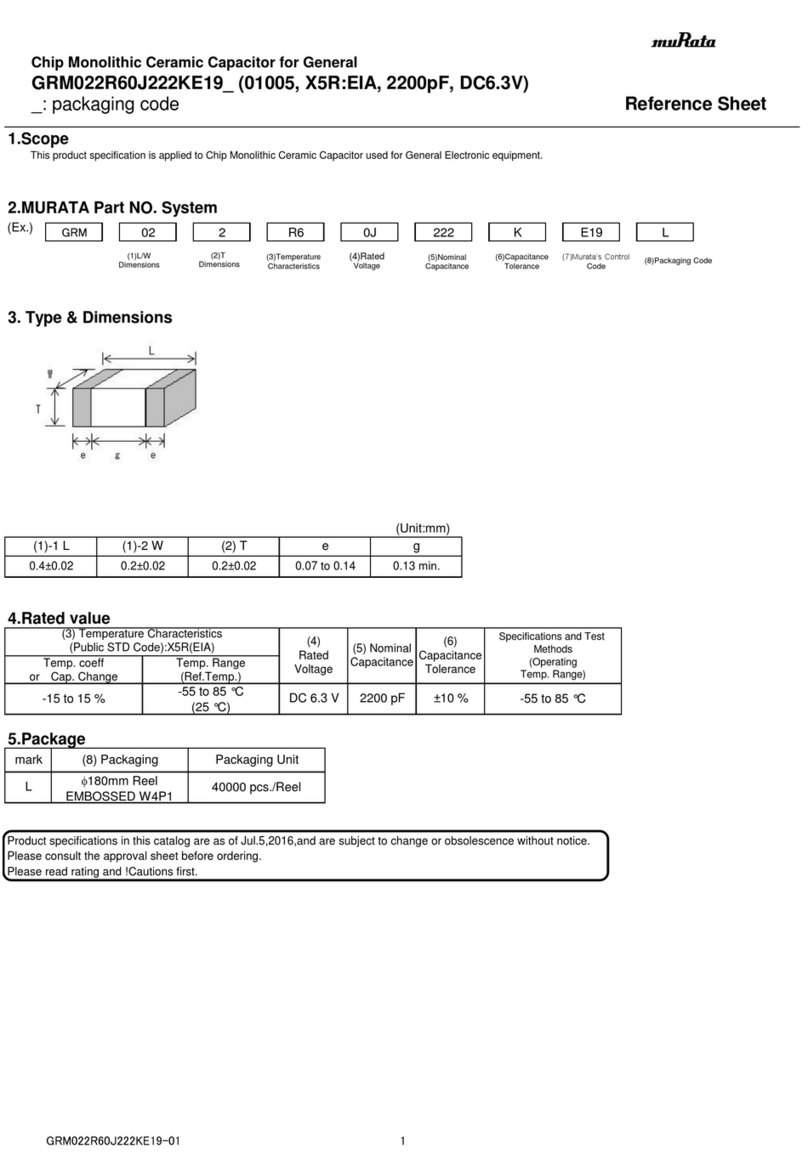

Murata GRM022R60J222KE19 Series Reference sheet