Ava-Toast 184BT18A User manual

Adjustable Speed Vercal Conveyor Bun Toasters

184BT18A - 120V 1600W

184BT18AXL - 120V 1600W - includes XL feed tray

184BT18H - 208/240V 2400/3200W

184BT18HXL - 208/240V 2400/3200W- includes XL feed tray

Troubleshooting

Operation ...............................

Part diagrams ......................... 9

8

........

.........................

....................

.......................

.......................

.......................

............

13

12

........

When using electrical appliances, basic safety precauons should always be followed,

including the following:

1. Read all instrucons carefully and completely.

2. For commercial use only.

3. DO NOT touch hot surfaces.

4. Protect against electrical shock by keeping all cords, plugs, and other electrical

components away from water or other liquids.

5. Unplug this unit when not in use and before cleaning.

6. Allow the unit to cool before pung on or taking off parts.

7. DO NOT operate this or any appliance with a damaged electrical cord or plug.

8. DO NOT operate this or any appliance aer it has malfunconed or has been

damaged in any way.

9. DO NOT use outdoors.

10. DO NOT place on or near a hot gas or electric burner.

11. Aach plug to appliance first, then plug electrical cord into the wall outlet.

12. Disconnect the unit by removing the electrical plug from the wall outlet.

13. DO NOT use appliance for any applicaon other than intended use.

14. DO NOT insert metal utensils or oversized foods into this unit, as they may cause

a fire and heighten the risk of electrical shock.

15. DO NOT store any item on top of this unit when in operaon.

16. DO NOT allow this oven to touch or to be covered by flammable material,

such as curtains, draperies, walls, etc., when in operaon.

17. DO NOT clean with metal scouring pads, as pieces can break off and touch electrical

components, heightening the risk of electrical shock.

18. Never place materials such as paper, cardboard, plasc, etc. in this oven.

19. DO NOT cover interior of this unit with metal foil, as it may cause the oven to overheat.

20. Avoid scratching the surface or nicking the edges of this unit. If the oven is damaged

or broken, contact customer service before use.

21. Turn off the appliance by removing the plug from the wall outlet.

22. Note that the use of accessories not recommended by the manufacturer

may result in injury.

23. Children should be supervised to ensure that they DO NOT play with the oven.

24. This appliance is not intended for use by persons (including children) with reduced

physical sensory or mental capabilies, or lack of experience and knowledge,

unless a person responsible for their safety has given them supervision or instrucon

concerning use of the appliance.

25. When using the appliance in shops, snack bars, hotels etc., check the voltage and

outlet to make sure the appliance is correctly connected with power.

26. Place unit on a flat surface that is well venlated. The appliance must be supervised

during operaon. DO NOT leave appliance without powering off.

NOTE: Save these instrucons for future reference.

SAFETY

CIRCUIT DIAGRAM

CONVEYOR MOTOR - 120V

M1

BUTTER ROLLER SWITCH

MAIN SWITCH

PILOT LIGHT FOR THERMOSTAT

HEATING ELEMENT

- 1600W

CONTROL THERMOSTAT

S2

S1

H1

E1

B1

DESCRIPTION

LEGEND

MODEL: VERTICAL BUN TOASTER - 120V

MODEL CODE: 184BT18A

WIRING DIAGRAM

BUTTER ROLLER MOTOR - 120V

CONVEYOR SPEED CONTROL - 120V

M2

SC

E1

H1

S1

M1

120V 60Hz

L2

L1

E

B1

SC

S1

S2

S2

M2

BUTTER ROLLER

MOTOR

BUTTER ROLLER

MOTOR

SWITCH

THERMOSTAT

CONVEYOR

MOTOR

MAIN SWITCH

635

LN

CIRCUIT DIAGRAM

4.

E1

H1

S1

M1

208/240V 60Hz

L2

L1

E

B1

SC

S1

S2

S2

M2

BUTTER ROLLER

MOTOR

BUTTER ROLLER

MOTOR

SWITCH

THERMOSTAT

CONVEYOR

MOTOR

MAIN SWITCH

CONVEYOR MOTOR - 208V/240V

M1

BUTTER ROLLER SWITCH

MAIN SWITCH

PILOT LIGHT FOR THERMOSTAT

HEATING ELEMENT

- 2400W / 3200W

CONTROL THERMOSTAT

S2

S1

H1

E1

B1

DESCRIPTION

LEGEND

MODEL: VERTICAL BUN TOASTER - 208/240V

MODEL CODE: 184BT18H

WIRING DIAGRAM

BUTTER ROLLER MOTOR - 208V/240V

CONVEYOR SPEED CONTROL - 208V/240V

M2

SC

INSTALLATION

5.

ASSEMBLY AND CONVEYOR INSTALLATION

holes provided. The unit can then be levelled using the adjustable part of the leg.

NOTE :

THE UNIT MUST NOT BE USED WITHOUT THE FEET BEING IN POSITION.

socket.

back wards. See diagram A.

gently to engage the drive gear. See diagram B.

NOTE:

CARE MUST BE TAKEN IN FITTING THE CONVEYOR CASSETTE. THE CASSETTE IS

HEAVY AND IT IS IMPORTANT THAT IT IS NOT DROPPED INTO PLACE TO AVOID

POTENTIAL DAMAGE TO THE DRIVE GEARS.

that order.

1

2

1

3

4

5

6

7

8

8

A. B.

drive gear

cassette gear

The cassee assembly height bolt is preset

from the factory. If the cassee gear does not make adequate contact, or is binding with the

drive gear, ghten or loosen the height bolt to ensure proper contact.

OPERATING INSTRUCTIONS.

6.

NOTE

THE TEFLON SHEET SHOULD BE INSTALLED PRIOR TO FITTING THE CONVEYOR CASSETTE AS

DESCRIBED ABOVE. IT IS RECOMMENDED THAT A LIGHT COATING OF EDIBLE OIL IS APPLIED TO THE

GRILL PLATE PRIOR TO FITTING THE TEFLON SHEET

NOTE:

THE TOASTED COLOUR OF THE BUN CAN BE ADJUSTED LIGHTER OR DARKER BY USING THE

TEMPERATURE CONTROL OR THE SPEED CONTROL OR A COMBINATION OF BOTH. WHEN

OPTIMUM BUN COLOUR AND SPEED HAVE BEEN ACHIEVED IT IS RECOMMENDED A NOTE IS TAKEN

OF THE SETTINGS FOR FUTURE REFERENCE.

INSTALLATION OF OPTIONAL TEFLON SHEET .

1. Lay the Teflon sheet on a flat surface and measure approximately 2’’ from the end of the

sheet. Notch the corners at 45 degrees as needed and fold a flap 2’’ long.

Carefully crease the flap at the 2’’ fold.

2. Remove the bun feeder chute (7). From the rear of the Teflon sheet retainer bracket slip

the 2’’ fold under the bracket. Bring the balance of the sheet forwards and smooth the

sheet down against the grill plate.

3. Reinstall the feeder chute.

C.

1. Thoroughly clean the unit as described in the cleaning secon of this manual on page 7.

2. Turn on the main switch the conveyor will now run.

3. Set the temperature to approx. 400F which equates to 5.7 on the scale. If using the oponal

Teflon sheet it is advisable to increase the temperature seng to approx. 450F which

equates to 6.5 on the scale (1-85F, 2-140F, 3-200F, 4-285F, 5-350, 6-410F, 7-480F).

4. Any high-quality edible oil can be used with this bun toaster. It is preferable to use oil

specifically suited for use in toasters.

5. The pilot cycle cycles with the heang element and indicates when the heater is on. It is

preferable to wait unl the unit has reached operang temperature and the light has cycled

on and off twice.

6. Heat the toaster oil to melng point and carefully fill the buer tray 2/3 full. Turn on the

buer roller using the switch provided.

7. Hold the bun half in the palm of the hand and in one moon slide the sliced side of the bun

onto the buer roller. Drop the bun with the sliced surface towards the grill plate using the

feeder chute provided. See diagram C.

8. The toasted bun will drop out into the receiving tray at the boom of the unit.

CONVEYOR ADJUSTMENT.

CLEANING & MAINTENANCE

7.

NOTE:

THE UNIT MUST BE DISCONNECTED FROM THE POWER SOURCE AND ALLOWED TO COOL DOWN

BEFORE CLEANING TAKES PLACE.

1. All of the removable panels can be cleaned either in a sink with hot water and detergent or

placed in a dishwasher.

2. It is recommended the conveyor cassee is only cleaned in a sink with regular detergent.

Make sure the chains are lubricated aer cleaning with a suitable toaster oil.

3. The grill plate can be cleaned can be cleaned with a suitable grill plate scourer. Aer drying a

light film of toaster oil should be applied.

If opmum bun grilling is not achieved using the speed and temperature sengs it is possible to

adjust the posion of the conveyor system relave to the grill plate. Moving the conveyor closer to

the grill plate will apply more pressure to the bun and result in more effecve toasng.

1. Switch off the unit and allow to cool down.

2. Remove the buer roller and tray and feed chute.

3. Remove the top panel and the boom panel.

4. Remove the conveyor cassee carefully by liing up and pulling towards the front

NOTE:

THE CONVEYOR IS HEAVY AND MUST BE HANDLED CAREFULLY.

5. The hanger adjustment brackets will now be exposed. Loosen the brackets and move

them EQUALLY towards the grill plate in increments of 1/8”. See diagram D.

6. Reghten the bracket screws.

7. Adjust the drive gear engagement as needed with the bolts at the boom of the hanger

plate.

Ensure that the lock nuts are reghtened.

1

2

1

3

4

5

6

7

8

8

screws

D.

adjustment bracket

DIMENSIONS

8.

MODEL:

184BT18A - 120V 1600W

184BT18H - 208/240V 2400/3200W

528

635

(635)

(528)

635

(492)

MODEL:

184BT18AXL - 120V 1600W

184BT18HXL - 208/240V 2400/3200W

703

(703)

635

(635)

635

(573)

20.7”

19.3”

25”

25”

27.6”

22.5”

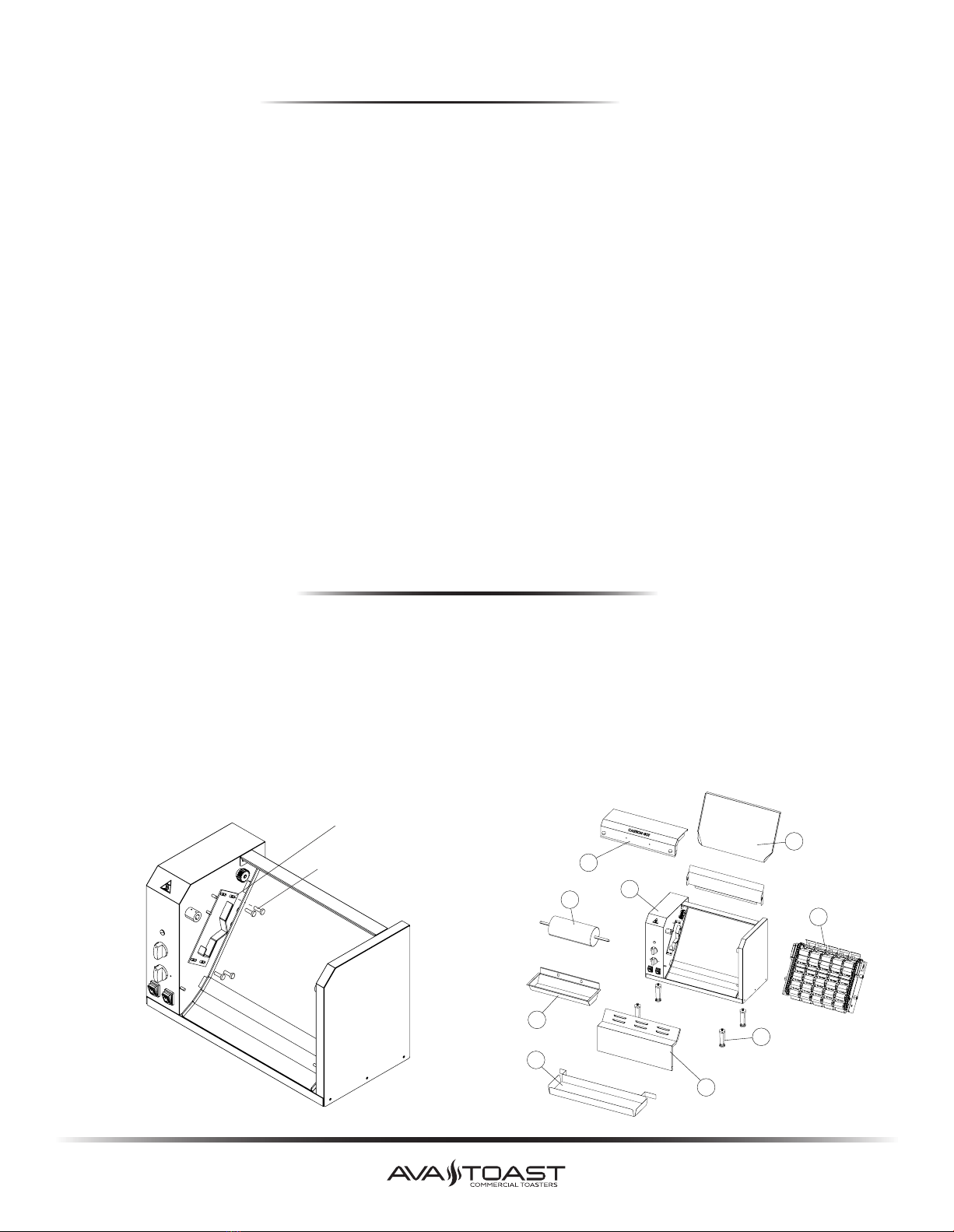

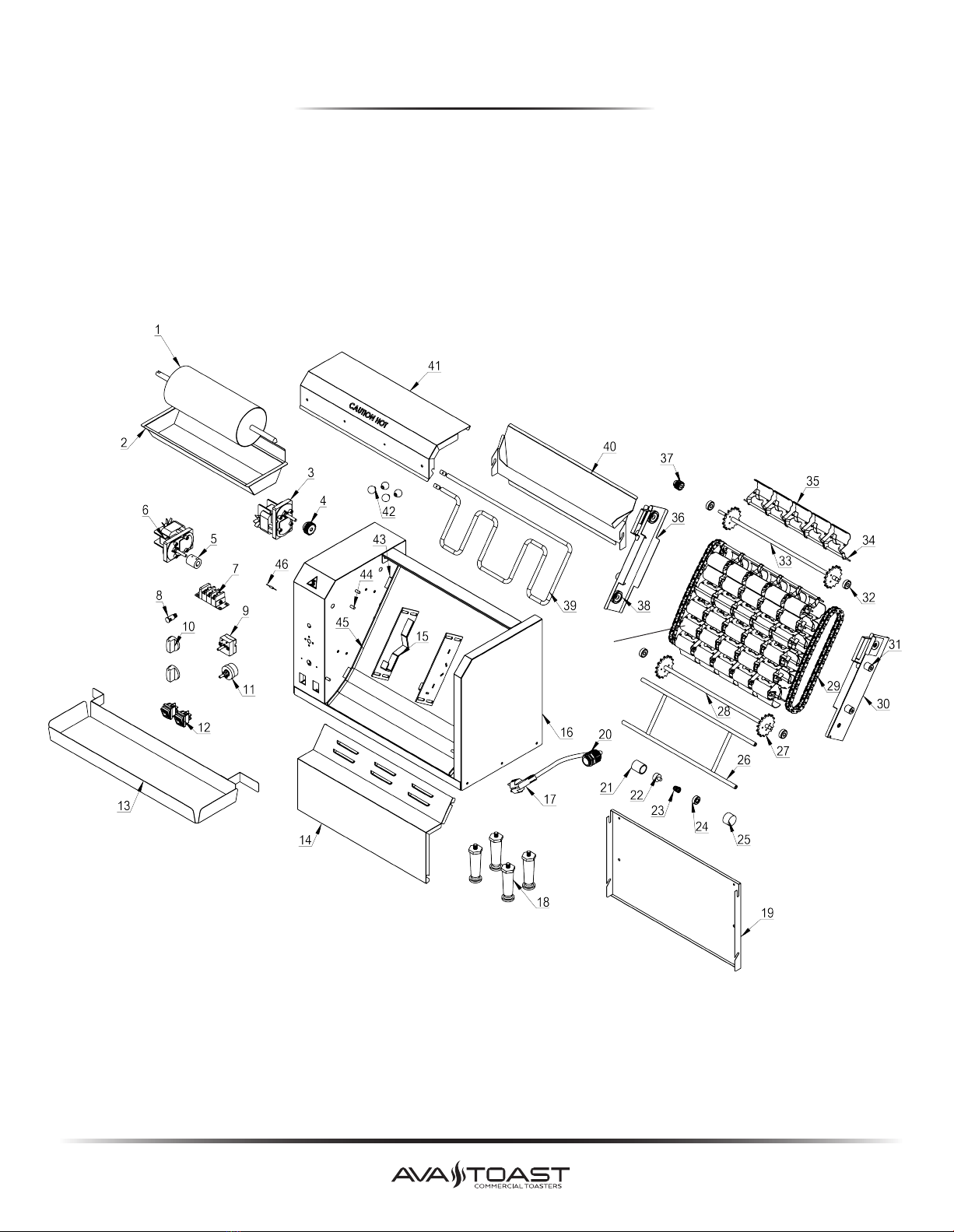

PARTS DIAGRAM

9.

47

MODEL: Adjustable Speed Vertical Conveyor Bun Toasters

184BT18A - 120V 1600W

184BT18H - 208/240V 2400/3200W

10.

PARTS DIAGRAM

MODEL: Adjustable Speed Vertical Conveyor Bun Toasters

184BT18AXL - 120V 1600W

184BT18HXL - 208/240V 2400/3200W

47

11.

ITEM PART NO. DESCRIPTION

1184PBT1 BUTTER ROLLER WHEEL FOR 184BT18 UNITS

2184PBT2 BUTTER ROLLER PAN FOR 184BT18 UNITS

3A 184PBT3A MAIN DRIVE MOTOR, 120V 60HZ FOR 184BT18A UNITS

3H 184PBT3H MAIN DRIVER MOTOR, 208-240V, 60HZ FOR 184BT18H UNITS

4184PBT4 BUTTER ROLLER DRIVING GEAR FOR 184BT18 UNITS

5184PBT5 BUTTER ROLLER SHAFT BUSHING FOR 184BT18 UNITS

6A 184PBT6A BUTTER ROLLER DRIVING MOTOR, 120V 60HZ FOR 184BT18A UNITS

6H 184PBT6H BUTTER ROLLER DRIVING MOTOR, 208-240V 60HZ FOR 184BT18H UNITS

7184PBT7 TERMINAL BLOCK FOR 184BT18 UNITS

9184PBT9 THERMOSTAT FOR 184BT18 UNITS

10 184PBT10 CONTROL KNOB FOR 184BT18 UNITS

11A 184PBT11A SPEED CONTROL 400 OHMS 120V FOR 184BT18A UNITS

11H 184PBT11H SPEED CONTROL 400 OHMS 208-240V FOR 184BT18H UNITS

12 184PBT12 SWITCH FOR 184BT18 UNITS

13 184PBT13 CRUMB TRAY FOR 184BT18 UNITS

17A 184PBT17A POWER CORD, 120V NEMA 5-15P FOR 184BT18A UNITS

17H 184PBT17H POWER CORD, 208-240V NEMA 6-20P FOR 184BT18H UNITS

18 184PBT18 ADJUSTABLE FOOT 4" SS FOR 184BT18 UNITS

21 184PBT21 BUTTER ROLLER DRIVING AXLE BUSHING FOR 184BT18 UNITS

22 184PBT22 BUTTER ROLLE RSHAFT POSITIONING PIN FOR 184BT18 UNITS

23 184PBT23 BUTTER ROLLER SHAFT SPRING FOR 184BT18 UNITS

24 184PBT24 BUTTER ROLLER BEARING FOR 184BT18 UNITS

25 184PBT25 BUTTER ROLLER BEARING BUSHING FOR 184BT18 UNITS

28 184PBT28 CONVEYOR CHAIN DRIVE AXLE FOR 184BT18 UNITS

29 184PBT29 CONVEYOR CHAIN FOR 184BT18 UNITS

39A 184PBT39A ELEMENT, 1600W 120V FOR 184BT18A UNITS

39H 184PBT39H ELEMENT, 208-240V, 2600-3200W FOR 184BT18H UNITS

40 184PBT40 BUN LOADING TRAY STANDARD FOR 184BT18 UNITS

40A 184BTXLFT BUN LOADING TRAY XL FOR 184BT18 UNITS

42 184PBT42 TOP PANEL REPLACEMENT HANDLE FOR 184BT18 UNITS

44 184PBT44 CASSETTE POSITIONING PIN FOR 184BT18 UNITS

47 184PBT47 CONVEYOR CASSETTE ASSEMBLY FOR 184BT18 UNITS

PART LEGEND

PART LEGEND

12.

PROBLEM POSSIBLE CAUSE POTENTIAL SOLUTION.

UNIT DEAD NO POWER. 1. NO POWER AT WALL RECEPTACLE. 1. CHECK SUPPLY CIRCUIT BREAKER.

2. PLUG DISCONNECTED. 2. CHECK PLUG.

3. MAIN SWITCH. 3. CHECK SWITCH IS ON

4. SUPPLY CIRCUIT BREAKER. 4. CHECK AND RESET.

NO HEAT. 1. FAULTY THERMOSTAT. 1. REPLACE THERMOSTAT.

2. FAULTY ELEMENT. 2. REPLACE ELEMENT

3. LOOSE CONNECTIONS. 3. CHECK WIRING CONNECTIONS

4. MAIN SWITCH OFF. 4. CHECK SWITCH IS ON

CONVEYOR AND BUTTER 1. LOOSE CONNECTIONS. 1. CHECK WIRING CONNECTIONS

ROLLER NOT WORKING. 2. FAULTY MAIN SWITCH. 2. REPLACE MAIN SWITCH

3. FAULTY BUTTER ROLLER SWITCH. 3. REPLACE BUTTER ROLLER SWITCH

4. MOTORS DEFECTIVE. 4. CHECK AND REPLACE FAULTY MOTORS.

BUTTER ROLLER NOT 1. AS POINTS IN SECTION 3 ABOVE. 1. SEE SECTION 3.

TURNING. 2. ROLLER SHAFT INCORRECTLY 2. CHECK ROLLER IS PROPERLY ENGAGED

INSERTED INTO DRIVE SOCKET. INTO DRIVE SOCKET.

3. MOTOR FAULTY 3. CHECK AND REPLACE MOTOR.

MAIN CONVEYOR 1. AS POINTS IN SECTION 3 ABOVE. 1. SEE SECTION 3.

STATIONARY 2. DRIVE GEARS NOT ENGAGING 2. REINSTALL CONVEYOR AS PER INSTRUCTIONS

3. CONVEYOR LINKAGE BINDING. 3. CHECK CONVEYOR FOR BENT OR FAULTY LINKS

4. SPEED CONTROL FAULTY. 4. REPLACE SPEED CONTROL

5. MOTOR FAULTY 5. REPLACE MOTOR.

BUNS DO NOT TOAST 1. INCORRECT TEMPERATURE 1. ENSURE THERMOSTAT SET AT AROUND

PROPERLY SETTING SETTING 5/6

2. CONVEYOR SPEED TOO FAST 2. REDUCE SPEED UNTIL TOASTING CORRECT.

3. WRONG OIL USED. 3. IDEALLY USE TOASTER OIL OR COCONUT OIL.

4. POORLY SLICED BUNS. 4. ENSURE BREAD IS CUT CORRECTLY.

BUNS TOAST UNEVENLY. 1. INSUFFICIENT CONVEYOR PRESSURE 1. ADJUST CONVEYOR AS IN INSTRUCTIONS

2. POOR APPLICATION OF OIL OR BUTTER 2. ENSURE EVEN COATING WHEN USING THE

3. POORLY SLICED BUNS. BUTTER ROLLER

3. ENSURE BREAD IS CUT CORRECTLY.

BUNS TEND TO STICK TO 1. WRONG OIL USED. 1. IDEALLY USE TOASTER OIL OR COCONUT OIL.

GRILL PLATE 2. GRILL PLATE HAS BAKED ON OIL 2. CLEAN GRILL SURFACE AS INSTRUCTED.

RESIDUE

3. DOUGHY BUNS OR EXCESS SUGAR 3. CONSIDER USING DAY OLD BUNS OR

CAN CAUSE STICKING. INCREASING THE GRILL TEMPERATURE.

4. BUNS NOT PROPERLY DEFROSTED. 4. DEFROST BUNS CORRECTLY.

TROUBLESHOOTING

13.

To Make a Warranty Claim:

This warranty is only valid on equipment purchased from an authorized dealer. To makea claim, please contact Ready Kitchen

Warranty.

• Phone: 717-381-4844

calling.

• Email: Help@ReadyKitchenWarranty.com

your email. Including clear pictures of the issue will help expedite the process. Failure to

This Limited Warranty does not cover:

•

•

• Equipment not purchased directly from an authorized dealer.

•

•

• Equipment where the serial number plate has been removed or altered.

•

• Defects and damage due to improper maintenance, wear and tear, misuse, abuse, vandalism, or Act of God.

thedate ofdelivery. Contact your authorized place of purchase for assistance.

Covered Models:

This warranty covers these Avatoast models only:

• 184BT18A, 184BT18AXL, 184BT18H, 184BT18HXL

Avatoast warrants its equipment tobefree from defects in material and workmanshipfor a period of 1 yearwhen

purchased from an authorized dealer. This is the sole and exclusive warranty made by Avatoast covering your Avatoast

brand equipment. A claimunder this warranty must be made within 1 year from the date ofdelivery of the equipment. Only

the equipment’s original purchaser may make a claimunder this warranty. Avatoast reserves the right to approve ordeny

the repair or replacement of any part or repair request. The warranty is not transferable.

EQUIPMENT LIMITED WARRANTY

This manual suits for next models

3

Table of contents

Other Ava-Toast Toaster manuals