Aveo Engineering PosiStrobe CP User manual

Installation

Manual

DOC.NO: AVE-POSW-54G-IM

© 2015 Aveo Engineering Group, s.r.o. All rights reserved. The information contained within this document

must not be disclosed, copied or reproduced in whole or in part without prior written permission from Aveo

Engineering Group, s.r.o. Distribution of this document shall only be as stated in Table 02 unless otherwise

agreed by Aveo Engineering Group, s.r.o.

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 2 of 12

Part 0 Manual Administration

0.1 Table of Contents

PART 0 MANUAL ADMINISTRATION 2

0.1 TABLE OF CONTENTS 2

0.2 DOCUMENT APPROVAL 3

0.3 AMENDMENT RECORD PROCEDURE 3

0.4 EFFECTED PAGES PROCEDURE 4

0.5 DISTRIBUTION LIST 4

1. POSISTROBE CP™ 5

2. OPERATING INSTRUCTIONS 6

3. INSTALLATION SCHEMATIC /WIRING DIAGRAM 6

4. CONTROL &POWER INPUT’S:6

5. TECHNICAL SPECIFICATION 6

6. TECHNICAL DRAWING 8

7. WIRING CHART 8

8. EQUIPMENT LIMITATION 9

9. TESTING OF THE LIGHT BEFORE INSTALLATION 9

10. CARE AND CLEANING OF YOUR AVEO ENGINEERING AVIATION LIGHTS 10

11. NOTES ON INSTALLATION 11

12. CONTINUED AIRWORTHINESS INFORMATION 11

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 3 of 12

0.2 Document approval

This document has been established in accordance with an alternative procedure to DOA approved

under EASA AP429.

This installation manual is according EASA ETSO authorization EASA.21O.10053449 and applicable for

part number AVE-POSW-54G.

Compiled by: 10. – Nov. - 2015

Petr Jaroš

Engineer, Aveo Engineering Group, s.r.o.

Approved by: 10. – Nov. - 2015

Georg Hartl

Head of DO, Aveo Engineering Group, s.r.o.

0.3 Amendment Record procedure

The master copy of this document shall be kept electronically as a read only

document under the control of Aveo Engineering Group,s.r.o. as Master Copy.

ALL amendments to this manual will initiate a raise of Issue

ALL raises of issue will be given a sequential Alphabetic Issue Ident sequentially

from 01 to 99 in Table 01 - Issue No: Column– Initial Issue of Document will

be “01”

ALL Issues of this document will be approved by Head of DO

Issue

No. Details Date

Effected

Pages

01

Initial Issue

29.Jun.2015

ALL

02

Addition of FAA required statements

10.Nov.2015

7, 9

Table 01: Document Amendment Record Table

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 4 of 12

0.4 Effected Pages Procedure

ALL pages affected by ANY raise of issue of this manual will be listed in Table 01 -

Effected Pages Column.

The reason(s) for ALL raise of issue and description of change due to raise of issue will

be provided for ALL raises of issue in Table 01 - Details Column.

Changes from the previous issue are highlighted by YELLOW HIGHLIGHTING over new

content. AND YELLOW HIGHLIGHTING AND CROSSING OUT of deleted content.

Example (CROSSING OUT)

0.5 Distribution List

As stated in 0.3 above; the master copy of this document shall be kept

electronically as a read only document under the control of Aveo Engineering

Group,s.r.o. as Master Copy.

All holders of copies of this Document will be recorded by listing in Table 02 –

Distribution List.

Copy holders listed will be issued a copy of this document with sequential copy

number as shown in Table 02 – Distribution List

Copy No.

Holder

MASTER

Aveo Engineering Group, s.r.o.

Table 02: Distribution List

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 5 of 12

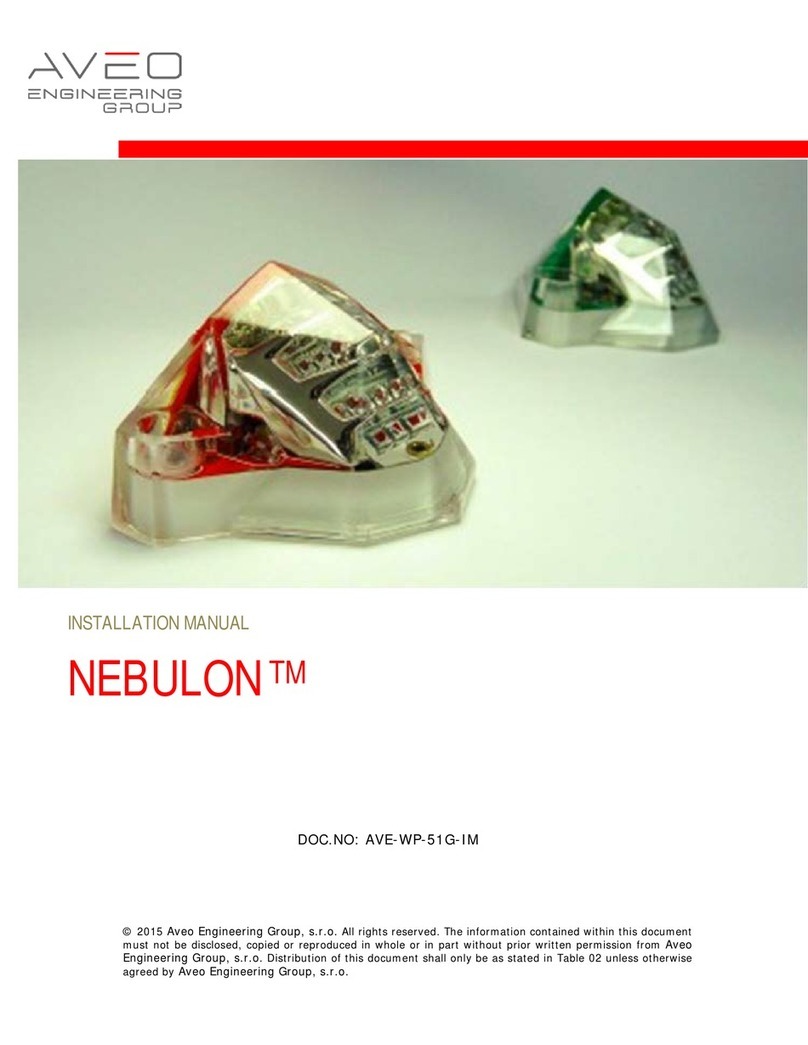

1. PosiStrobe CP™

The PosiStrobe CP is a new generation rudder white position and strobe light.

It fits almost all the standard rudder mounts of aircraft and also features an

optional aluminum adapter mount plate pictured in the installation page. An

extremely lightweight, aerodynamic and low-profile design makes this the light

of choice for any certified aircraft requiring rear coverage light due to wingtip

light coverage zone limits. The PosiStrobe series is the most imitated and

copied light by our competitors, but there is ONLY one PosiStrobe, don't be

fooled by competitive "clones", we were the first and we are the only ones with

our exclusive circuitry, advanced optics and reflectors and candela

performance.

The PosiStrobe CP™ is also encapsulated in the exclusive AveoDiamidium™

formulation, and is virtually unbreakable. With our exclusive aircraft lifetime

warranty there is no risk to the owner that he will ever need to buy another

again. Our policy is simple; IF IT FAILS WE REPLACE IT!

Main Features:

-2-in-1 Position & Strobe light ideal for tail, rudder or rear facing mounts

-Optics designed for FAA/ICAO/EASA requirements

-9-36 volt input range

-No external power supply or strobe unit, an Aveo world first

-Light synchronization feature

-Minimum drag profile

-Unbreakable Diamidium™ encapsulation

-Exclusive Lifetime Warranty

-Unmatched circuit technology

-Advanced computer and goniophotometer engineered optics

List of the major components (by part number) that make up the equipment

complying with the standards prescribed in ETSO.

• PosiStrobe CP™ PN : AVE-POSW-54G

Figure 1: Features of PosiStrobe CP

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 6 of 12

2. OPERATING INSTRUCTIONS

When installed on the aircraft, using the aircraft’s power (14 or 28 volts), the

light will be at its maximum intensity. (Meet the requirement of ETSO-C30C,

Aircraft Position Light and ETSO- C96A, Anticollision Light Systems)

3. INSTALLATION SCHEMATIC / WIRING DIAGRAM

4. CONTROL & POWER INPUT’s:

+VCCP positive position/nav power supply line

+VCCS positive strobe power supply line

GND negative common power supply line (ground)

SYNC strobe synchronization line

(Mutually interconnect on all installed AveoFlash lights)

5. TECHNICAL SPECIFICATION

Dimensions (mm): 56 x 44.9 x 26

Dimensions (inches): 2.19” x 1.76” x 1.02”

Weight (g): 50g

Weight: (oz): 1.76

Nominal Operating Voltage (Vdc): 9 – 36 Vdc

Power – position (peak Watts): 4.2W

Power – strobe (peak Watts): 6.5W (32.5W peak)

Current – position (@12V): 0.35A

Current – strobe (@12V): 0.54A (2.7A peak)

Repetition Rate of Strobe: 50 cycles per minute

Exceed requirements of: - TSO C30c C96a

- SAE AS 8037 and AS8017a

- DO-160F

Recommended size of mounting screw: M3

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 7 of 12

Summary of Environmental Tests

Test title

Specification

Section

Category

Temperature / Altitude

DO-160F

4

F2

Temperature Variation

DO-160F

5

A

Humidity

DO-160F

6

C

Operational Shock

DO-160F

7

B

Vibration

DO-160F

8

S

Explosive Atmosphere

DO-160F

9

H

Waterproofness

DO-160F

10

T

Fluid Susceptibility

DO-160F

11

F

Sand and dust

DO-160F

12

S

Fungus

DO-160F

13

F

Salt Spray

DO-160F

14

T

Magnetic Effects

DO-160F

15

Z

Power Input

DO-160F

16

B

Voltage Spike

DO-160F

17

B

Audio Freq. Conducted Susceptibility

DO-160F

18

B

Induced Signal Susceptibility

DO-160F

19

AC

Radiated and conducted Susceptibility

DO-160F

20

T

Radiated and conducted Emissions

DO-160F

21

H

Lightening Induced Transient Susceptibility

DO-160F

22

A3J3X

Icing

DO-160F

24

A

Electrostatic Discharge

DO-160F

25

A

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 8 of 12

6. TECHNICAL DRAWING

Figure 2: Dimensions are in millimeters / inches

7. WIRING CHART

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 9 of 12

8. EQUIPMENT LIMITATION

™ should only be powered by 9-36 Vdc, typically a 12 or 24 voltPosiStrobe CP

aircraft battery.

This article meets the minimum performance and quality control standards required

by the technical standard order ETSO C30c and ETSO C96a. Installation of this

article requires separate approval.

Deviations

This article deviates from the ETSO C30c and ETSO C96a by the usage of newer

revisions of the following standards:

•SAE AS 8017 rev. B used instead SAE AS 8017 rev. A

•SAE AS 8037 rev. A used instead SAE AS 8037 initial release

9. TESTING OF THE LIGHT BEFORE INSTALLATION

All Aveo Aviation lights undergo rigorous testing prior to being released from our

engineering manufacturing department. This testing involves a burn-in time as

well as other function testing. No light is released for sale without undergoing this

extensive operational testing.

When you receive the light, and wish to test the function of the lightUltra Galactica

prior to installation on your aircraft, please note the following:

Please review the written information that is enclosed in the packaging. Warranty

information as well as a cautionary note about power supply removal is enclosed

with each package.

1. Remove the lights from the package. Note that there are four (4) wires

coming from each light. These wires are:

a. Black wire Ground wire (negative lead)

b. Red wire Position/Navigation light function wire (positive lead)

c. Yellow wire Strobe light function wire (positive lead)

d. Blue wire used if the synchronization of the Aveo lights is

selected

2. Testing of the function of each light can be done with a regular 12V/5A dc

power supply (not a battery charger). Connect the black wire to the

ground (negative) leads of a power supply, then connect the red wire to

the positive (+) leads on the power supply. The position light should light

up. While the red wire is still in contact with the positive side of the power

supply, connect the yellow wire to the positive lead. Both the position and

the strobe function should work. For the Galactica Series of lights, the

strobe function is separate from the nav function and can be tested

separately. To test the strobe function separately, just connect the yellow

wire only to the positive terminal of the power supply while the black wire is

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 10 of 12

connected the ground side of the power supply. Connecting the blue wires

from each light together (and not to the ground or positive terminals on the

battery) should show that the lights are flashing together and indicates the

synchronization feature is working properly. When installed on the aircraft,

using the aircraft’s power (14 or 28 volts), the lights will be at their

maximum intensity.

After testing, the light can be installed on the aircraft.

IMPORTANT

NOTES:

1. Under no circumstances should any power supply other than a 9-32V dc, or a

12/24 volt battery be used to test the lights. Do not use: Battery chargers,

battery back-up power devices, or other bench avionics testing methods to

test the aviation lights. The lights are functional between 9 and 32 volts. Use

of a battery charger or other power unit to test the lights will void the warranty

and may damage the lights.

2. All power supplies for existing strobe lights, flasher beacons, etc. are required

to be removed from the aircraft prior to the installation of the Aveo light.

If you have any questions about the installation of the lights, please refer to our

web site: www.aveoengineering.com, and check FAQ and other links on our aviation

lights web page.

10. CARE AND CLEANING OF YOUR AVEO ENGINEERING

AVIATION LIGHTS

When you receive your Aveo Engineering Aviation Lights, they will have

been factory polished and ready to install on the aircraft. Upon installation, just

give the lights a good coat or two of a quality automotive polish. This should

protect the lights from dirt and other environmental factors. Once or twice a

month, just refresh the polish and hand buff to bring back the lights to factory like

new condition.

If the lights need a deeper cleaning, they can be polished with a good

automotive cleaner wax and/or a liquid polishing compound. The liquid

polishing compounds can normally be found at automotive parts stores or an

automotive paint store. After using a polishing compound, just give the

lights another coat of an automotive polish and you will again protect the

lights against dirt, etc. An electric buffing machine, with a lamb’s wool cover,

can also be used for deeper cleaning and polishing. Under no circumstances

should any petroleum based product be used to clean the lights.

For continued UV protection Aveo Engineering offers NonocloakTM UV Protectant

Spray and Cleaner, available at any Aveo Engineering Authorized installation

Center.

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 11 of 12

11. NOTES ON INSTALLATION

Please use tapered headed screws for installation. Spread the tightening forces evenly

around the mounting hole. Screw size is a M3, stainless steel recommended. Length depends

upon placement location on aircraft tail/rudder.

12. CONTINUED AIRWORTHINESS INFORMATION

This product is delivered with EASA Form1 which is for the operator to report any

occurrences to Aveo Engineering as the ETSO holder. The form contains the Aveo

Engineering telephone number and the occurrence e-mail address

(occurrence@aveoengineering.com). The operator must report immediately as

the ETSO holder must report occurrences having a potential for an unsafe condition

within 72 hours.

a. Circuit/Wiring

Protection

Each Galactica series light features a Negative Temperature Coefficient

(NTC) circuit that limits internal temperatures by attenuating operating

current (with a corresponding reduction of brightness) when internal

temperatures reach a certain threshold. This proprietary circuitry serves to

protect the light itself, and associated aircraft wiring, against a thermal

runaway condition. It's recommended that the operation of strobes without

airflow be limited to avoid heat buildup and this NTC circuitry feature is

designed to more than triple the life of the LEDs and electronic components

thereby providing an even great margin of safety for continued

airworthiness due to the dramatic enhancement of electronics reliability.

b. Periodic Inspection Procedure for Galactica

Series

The PosiStrobe CP™ light should always be checked for proper operation

during preflight. This procedural information is already provided in all

general aviation aircraft flight manuals.

The lights should be visually inspected for general condition, proper

operation, and correct installation at each annual and/or 100 hour

inspection. Any debris or atmospheric deposits accumulated on the surface

of the lights should be removed using a UV Wax such as Farecia Profile

UV Wax to ensure ongoing optical clarity. In addition refer to section 10 of

installation manual for detailed cleaning instructions.

Turn the lights on and do the following:

1. Put on polarized sunglasses or welder goggles to prevent eye damage

when looking into the lights.

2. Examine the individual LEDs as per the diagram below. If any of the

conditions as indicated on the diagram are exceeded, the light shall be

Installation Manual

PosiStrobe CP

_______________________________________________________________________________________________________________________

Page 12 of 12

removed and sent to Aveo Engineering for replacement under the Aveo

Lifetime Warranty Program.

Figure 3: Strobe LEDs

Figure 4: Position Light LEDs

This manual suits for next models

1

Table of contents

Other Aveo Engineering Flashlight manuals