XLR-6, XLR-8 and XLR-12 Installation Instructions 3

Table of Contents

Chapter 1 General Information and Warnings ........................................................................................5

About this Manual ..............................................................................................................5

Text Conventions ........................................................................................................5

Special Messages .......................................................................................................5

Installation ..........................................................................................................................6

Routine Maintenance .........................................................................................................6

Cleaning the Machine ........................................................................................................6

Training ..............................................................................................................................6

Sharp Objects ....................................................................................................................6

Declaration of Conformity (CE approval) ...........................................................................7

FCC and EMC Declarations of Compliance .......................................................................8

Technical Support ..............................................................................................................8

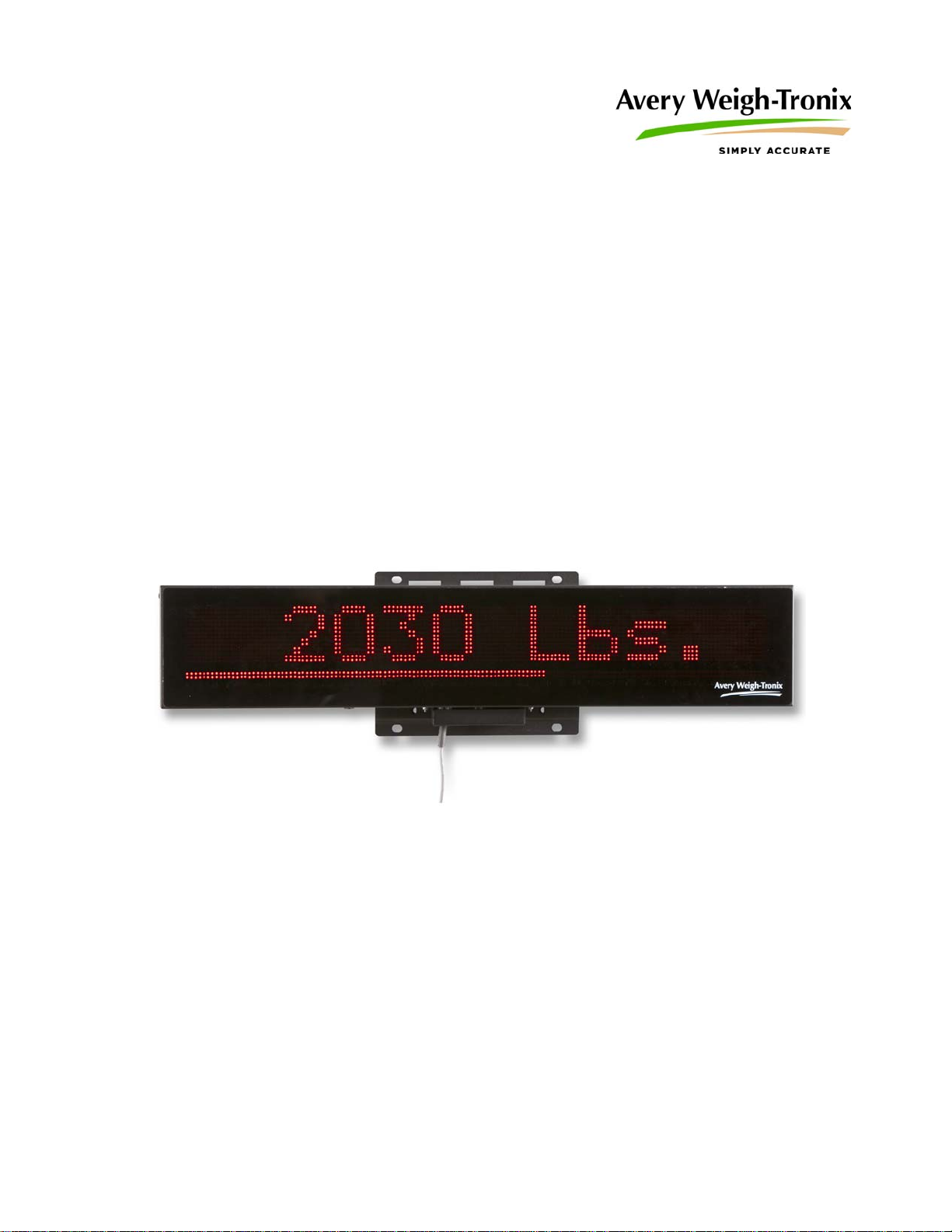

Chapter 2 Introduction ..............................................................................................................................9

Chapter 3 Installation ..............................................................................................................................10

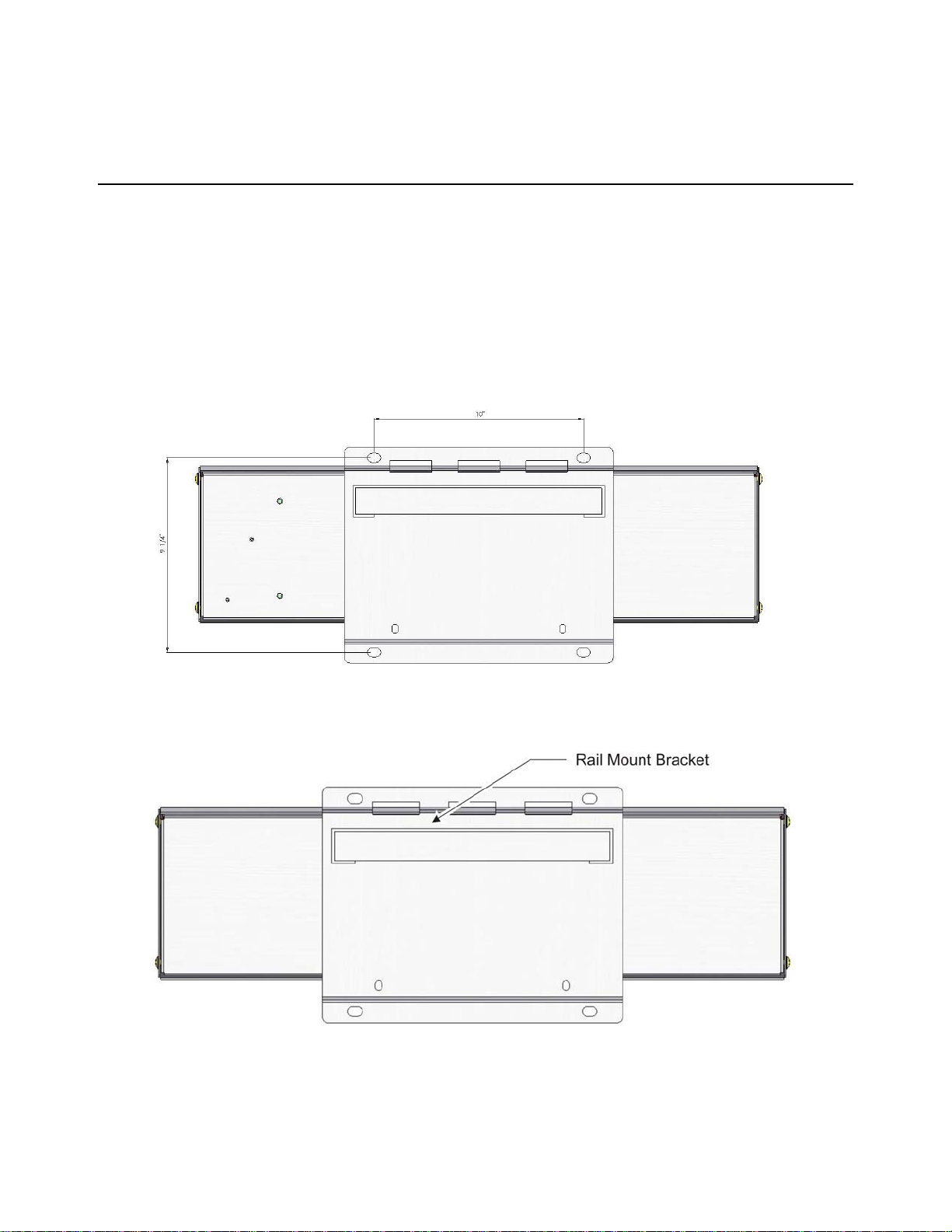

Mounting Brackets ...........................................................................................................10

Adapter Mounting Plate ...................................................................................................11

Stainless Steel Shield ......................................................................................................11

Connecting the Display to Your Equipment .....................................................................12

XLR-8 / XLR-12 Connections ....................................................................................12

XLR-6 Connections ...................................................................................................13

Cables .......................................................................................................................14

Stainless Steel Shield Installation ....................................................................................15

Setup of AWT Ag Indicators for Use With XLR Displays .................................................16

Setup for 640 Series Indicators .................................................................................16

Setup for 1040 and 2040 Series Indicators ...............................................................17

Setup for 2060 Indicators ..........................................................................................17

Setup for 3060 Touch Screen Indicators ...................................................................18

Using two XLR's with 2060 or 3060 Indicators ..........................................................18

Setup for Digi-Star Indicators ....................................................................................19

Chapter 4 Communicating With the Remote Display ...........................................................................20

Computer Control Protocol ..............................................................................................20

Transmit a Weight String ...........................................................................................21

Transmit Status Characters .......................................................................................21

Transmit an Alphanumeric Message / Data String ....................................................21

Control Commands ...................................................................................................22

Sample Data Strings Sent to the Display ..................................................................22

Connector Pin outs ..........................................................................................................23

Chapter 5 Learn a New Transmitter Code (channel 1) .........................................................................24

Chapter 6 Specifications and Parts Lists ..............................................................................................25

Specifications ...................................................................................................................25

Service Parts List .............................................................................................................26

Accessory Parts List ........................................................................................................27