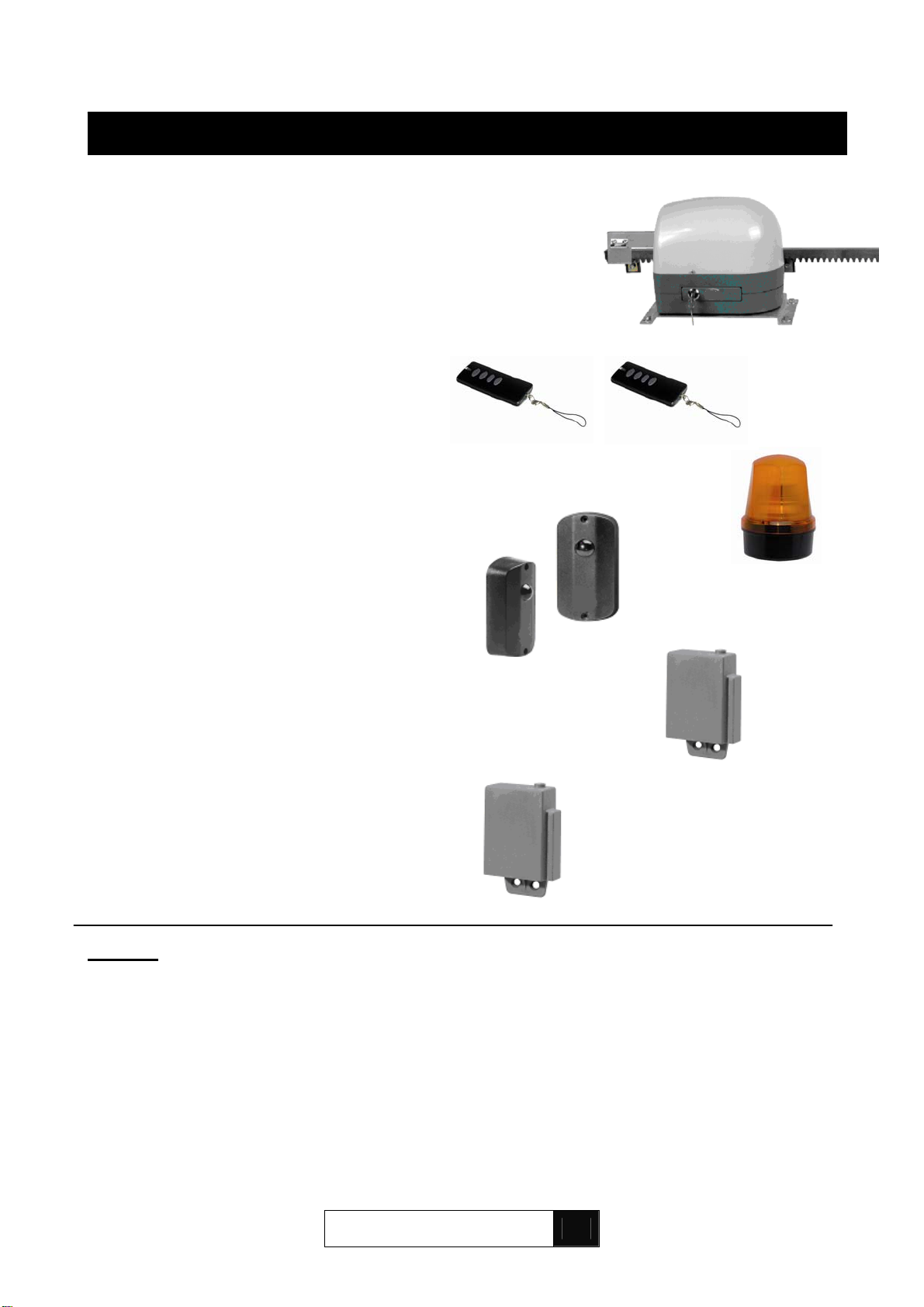

WEAT C2 N - V1

f – PROTECT THE ENVIRONMENT

- Packaging materials (cardboard, plastic, polystyrene, etc) must not be dumped and must not be left within

children’s reach, because they are a potential source of danger.

g – USERS GUIDE

Do not touch the parts of the automated system and the gate itself when it is moving

(The gate must installed at a distance from children’s play areas).

Remote controls, keyboards or auxiliary controls must only be accessible to authorised individuals.

Warning to users (Must be read prior to first use).

- Keep remote controls away from children (they are not toys)

- Keep children away from moveable parts

- The product must be used for the purpose for which it was designed and must be installed professionally

especially for assembly fittings and bases. Any other use must be considered improper and therefore dangerous.

Also, the information in this document could be changed without notification. It is provided for information. CFI

declines all responsibility.

- Keep products, devices, documentation and all other parts in a safe place.

- Changing the parameters must be done by a qualified and specialised individual.

- Should there be a problem, however minor, cut the electrical supply (disconnect the optional battery), disengage

the motor(s) and call a qualified and specialised individual.

- Regularly checking the condition and proper functioning of photo-electric cells is one of the important points

for the safety of individuals and property.

- You are responsible for maintaining your automated system.

- Connect the electrical supply; after installation you must completely check the safety elements (flashing light,

photo-electric cell, etc.).

Flashing light: Check that it is working properly and can be seen from the road and close to the gate or door.

Photo-electric cells: Check that it is working properly with the closing movement.

Optional sensor bar: Check that it is working properly, use a piece of wood to check it.

Optional emergency button: Check that it is working properly.

Important:

The fitter at the end of the installation must check that the motor conforms to paragraph 5.1.1.5 of the EN

12453 standard (limitation of forces article 5.2.1 of the EN 12453 standard).

Starting of the leaves: The force must be sufficient and not excessive to open and stop the gate, without re-

bound and without distortion, you should, if necessary, adjust the setting VR1 – (FOR), this setting controls the

speed of the leaves, and must be adapted to the type of the gate used (heavy, light, full or open-work….).

Stop on obstacle: To avoid any risk of injury, the force at the end of the leaf shall not exceed 15 kg of driving

force whatever the conditions of use. If necessary, consult a qualified fitter.

If necessary, you have to adjust the setting VR5 (OVL) according to the type of gate used (For safety reasons,

you must be able to stop the course of the gate by hand).

Lighting system of the clearance area around the gate: Check that it is working properly (the lighting duration

is temporised).

Reminder: The person who installed the automated system is responsible for the installation.

h - MAINTENANCE

- Keep the installation in good working, electrical, mechanical condition and regularly check the condition and

proper functioning of the various parts.

We recommend you check your automated system and the safety elements every 6 months at the most or after