1

TABLE OF CONTENT

INTRODUCTION........................................................................................................................................................2

This manual.........................................................................................................................................................2

The unit................................................................................................................................................................ 2

SAFETY INSTRUCTIONS........................................................................................................................................3

Warning................................................................................................................................................................3

Caution.................................................................................................................................................................5

ITEMS INSIDE PRODUCT BOX............................................................................................................................. 6

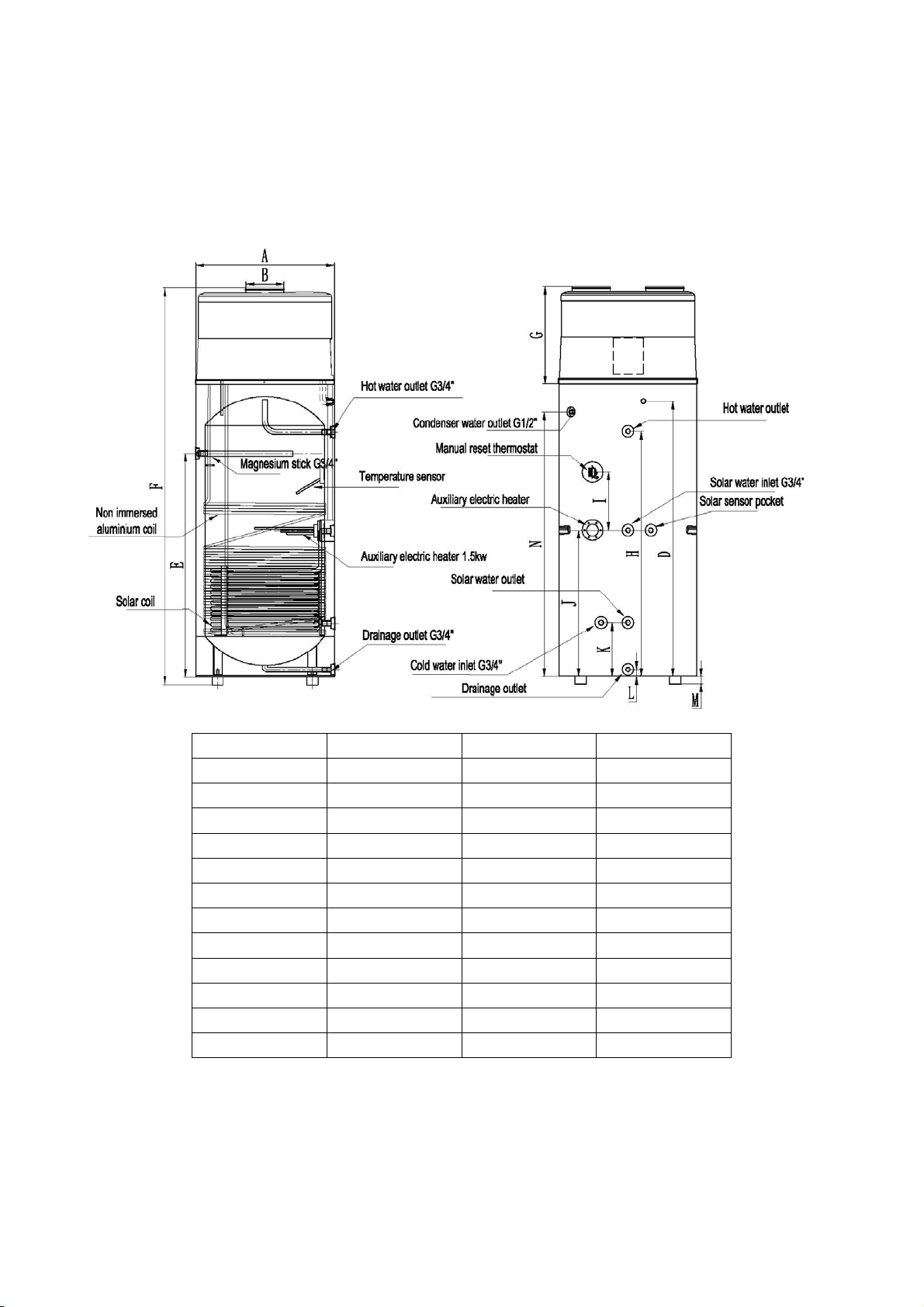

OVERVIEW OF THE UNIT.......................................................................................................................................7

Parts and descriptions.......................................................................................................................................7

Dimensions......................................................................................................................................................... 8

How to replace the magnesium stick..............................................................................................................9

Schematic overview of the water and refrigeration circuit.......................................................................... 9

INSTALLATION.........................................................................................................................................................10

Transportation...................................................................................................................................................10

Required service space...................................................................................................................................11

Installation overview........................................................................................................................................ 12

Installation positions........................................................................................................................................ 14

Water loop connection.....................................................................................................................................15

Water affusion and water emptying.............................................................................................................. 15

Wire connection................................................................................................................................................16

Trial running...................................................................................................................................................... 16

OPERATION THE UNIT......................................................................................................................................... 17

User interface and operation..........................................................................................................................17

LCD icons.......................................................................................................................................................... 20

PARAMETER CHECKING AND ADUSTMENT.................................................................................................. 22

Parameter list....................................................................................................................................................22

Malfunctioning of the unit and error codes.................................................................................................. 23

MAINTENANCE....................................................................................................................................................... 25

TROUBLESHOOTING............................................................................................................................................ 26

ENVIRONMENTAL INFORMATION..................................................................................................................... 26

DISPOSAL REQUIREMENTS............................................................................................................................... 26

WIRING DIAGRAM..................................................................................................................................................27

TECHNICAL SPECIFICATION.............................................................................................................................. 28

AXHW-20a/***...................................................................................................................................................28

TEMPERATURE SENSOR R-T CONVERSION TABLE...................................................................................30

READ THIS MANUAL CAREFULLY BEFORE STARTING UP THE UNIT. DO NOT THROW IT

AWAY.KEEP IT IN YOUR FILES FOR FUTURE REFERENCE.

BEFORE OPERATING THE UNIT, MAKE SURE THE INSTALLATION HAS BEEN CARRIED

OUT CORRECTLY BY A PROFESSIONAL DEALER. IF YOU FEEL UNSURE ABOUT

OPERATION, CONTACT YOUR DEALER FOR ADVICE AND INFORMATION.