Page 5

Operation and Maintenance Instructions

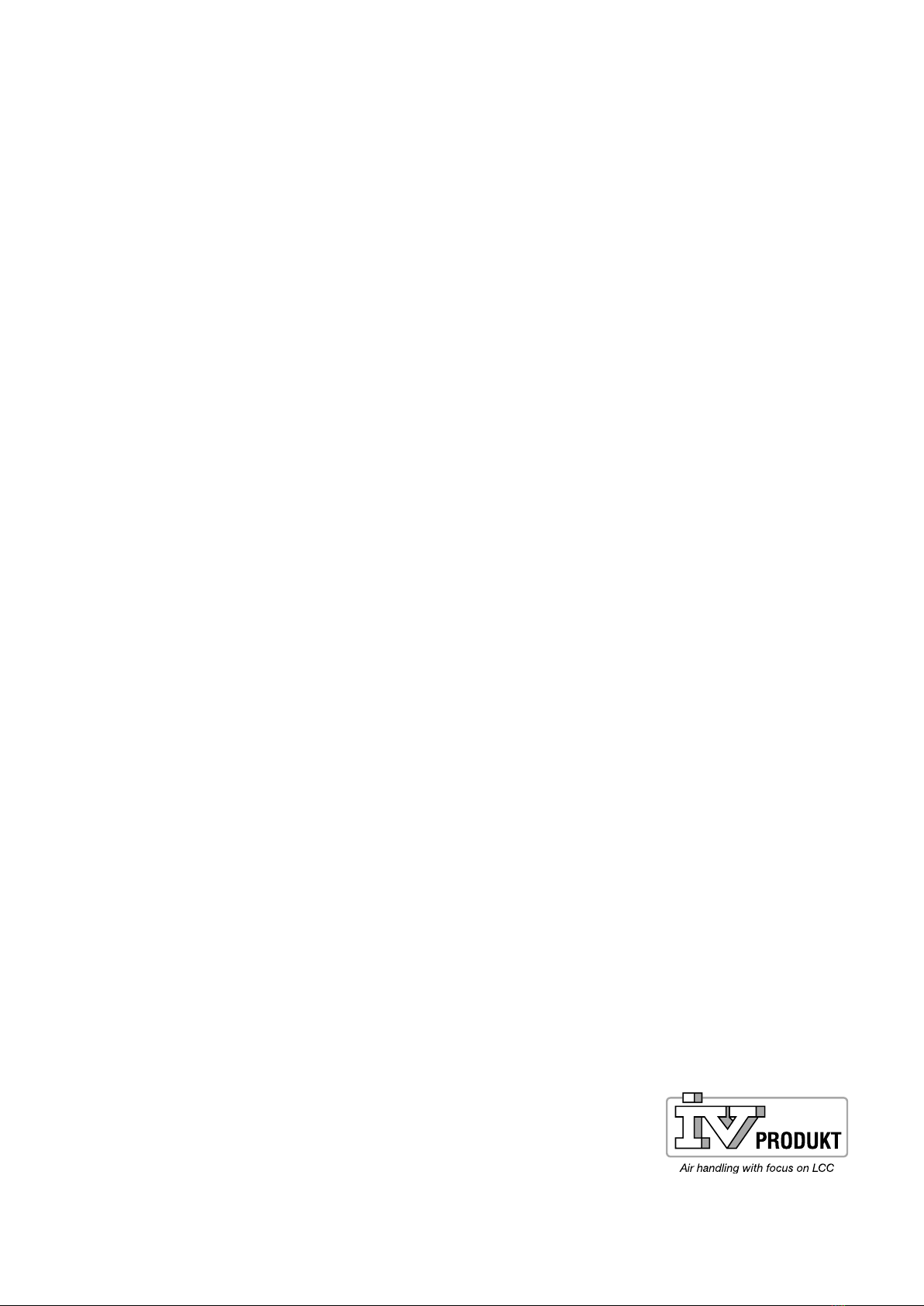

THE NEW EcoHeater

DSEH180401.00.EN

Continuous product development may give rise to specification changes without notice.

Leakage inspection and registration

The following applies to one-piece units with 5 CO2e(ton) refrigerant content or

more per circuit (EcoHeater sizes 150 – 300):

• Leakage inspection must be carried out by a certified refrigeration techni-

cian:

– When installing/commissioning the unit

– Periodically at least once per 12 months,

i.e. no more than 12 months between inspections

– within one month of any work being performed (e.g. sealing a leak, replac-

ing a

component).

• The operator must record events, such as the volume and type of refrigerant

topped up, refrigerant taken into possession, results of inspections and work

done, person and company who carried out service and maintenance.

If the total refrigerant content is below 5 CO2e (ton)

(EcoHeater sizes 060 – 100)

no periodic leak detection is needed, although an initial leak inspection should

be performed in conjunction with installation.

If the total refrigerant content of the ventilation system exceeds 14 CO2e(ton),

the result of the inspections (inspection report) must be sent to the regulatory

authorities and be in their possession no later than 31 March of the following

year. For a unit that will contain 14 CO2e(ton) or more, the intended operator

must inform the supervisory authority of the installation well in advance.

1.8 Extended warranty

In cases in which the equipment delivered falls under a 5-year warranty, in ac-

cordance with ABM 07 with supplement ABM-V 07 or in accordance with NL 09

with supplement VU13, the IV Produkt Service and Warranty Manual is supplied

with the product.

In order to lay claim to an extended warranty, a complete, documented and

signed IV Produkt Service and Warranty Manual must be presented.

1.9 Spare parts

Spare parts and accessories for this unit are ordered from your nearest IV

Produkt sales representative. When ordering, state the order number and desig-

nation.

These are stated on a data label, affixed to each component.

A separate spare parts list is supplied with the unit.

1.10 Dismantling and decommissioning

When an air handling unit is to be dismantled, separate instructions must be

followed, refer to Dismantling and decommissioning the AHU under Documenta-

tion at docs.ivprodukt.com.