Section 3 Rear wheel/Rear brake/Rear wheel axle................................................................ 81

(I) Removal steps....................................................................................................... 83

(II) Inspection stepes.................................................................................................. 85

(III) Installation steps................................................................................................. 88

Section 4 Steering operation system...................................................................................... 92

(I) Removal steps of steering bar................................................................................ 93

(II) Removal steps of steering vertical column welding............................................ 94

(III) Inspection content............................................................................................... 95

(IV) Installation steps................................................................................................. 96

(V) Installation steps of steering bar.......................................................................... 99

Section 5 Front shock absorber and front wheel fork............................................................ 100

(I) Disassembly........................................................................................................... 101

(II) Inspection steps.................................................................................................... 103

(III) Installment steps................................................................................................. 104

Section 6 Rear shock absorber and rear wheel fork............................................................... 107

(I) Disassembling steps.............................................................................................. 108

(II) Checking steps..................................................................................................... 110

(III) Mounting steps................................................................................................... 112

Chapter IV Electric appliance................................................................................................ 115

Section 1 Electric assembly.................................................................................................... 115

Section 2 Inspect switch......................................................................................................... 116

(I) Inspect switch........................................................................................................ 116

(II) Inspect the switch circuit..................................................................................... 117

Section 3 Check headlight lamp............................................................................................. 118

Wire diagram.............................................................................................................. 119

Section 4 Troubleshooting the ignition system failure........................................................... 120

Section 5 Running starting circuit.......................................................................................... 124

Section 6 Troubleshooting electric starting system................................................................ 125

Section 7 Starting motor......................................................................................................... 128

Section 8 Check starting motor............................................................................................... 129

Section 9 Battery will not hold charge.................................................................................... 131

Section 10 Troubleshooting.................................................................................................... 133

Section 11 Inspection of lighting system................................................................................ 135

(I) Headlight not working........................................................................................... 135

(II) Taillight not working............................................................................................ 136

Section 12 Troubleshooting.................................................................................................... 137

(I) If indicated lamp is out of work............................................................................. 137

Section 13 Inspection of signal system.................................................................................. 139

(I) If the neutral indicated lamp is out work............................................................... 139

(II) If the reverse indicated lamp is out work............................................................. 140

(III) If the HB indicated lamp is out work.................................................................. 141

Chapter V Engine................................................................................................................... 142

Section 1 Disassembly of Engine........................................................................................... 142

(I) Remove the engine from nished ATV.................................................................. 142

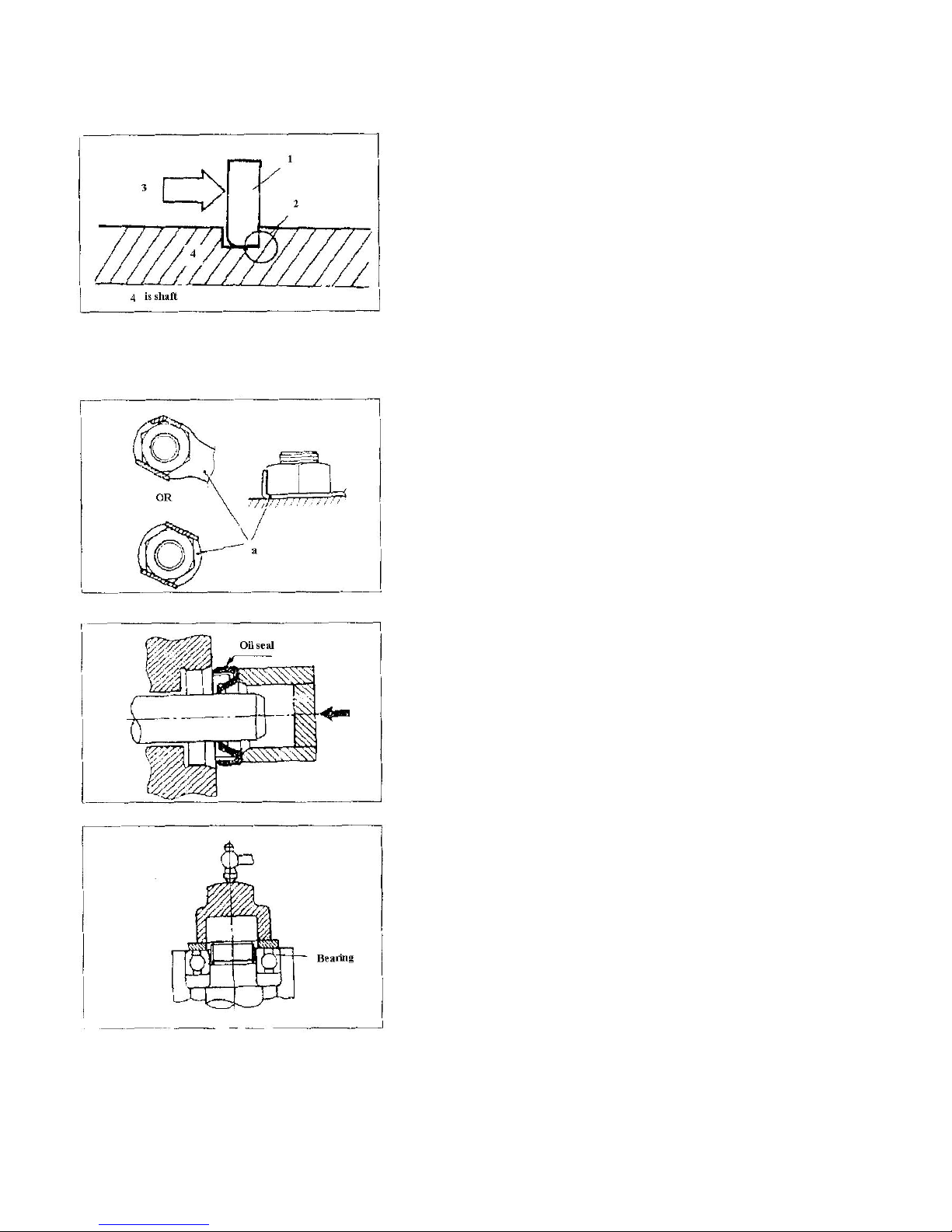

(II) Disassembly of engine......................................................................................... 145

4