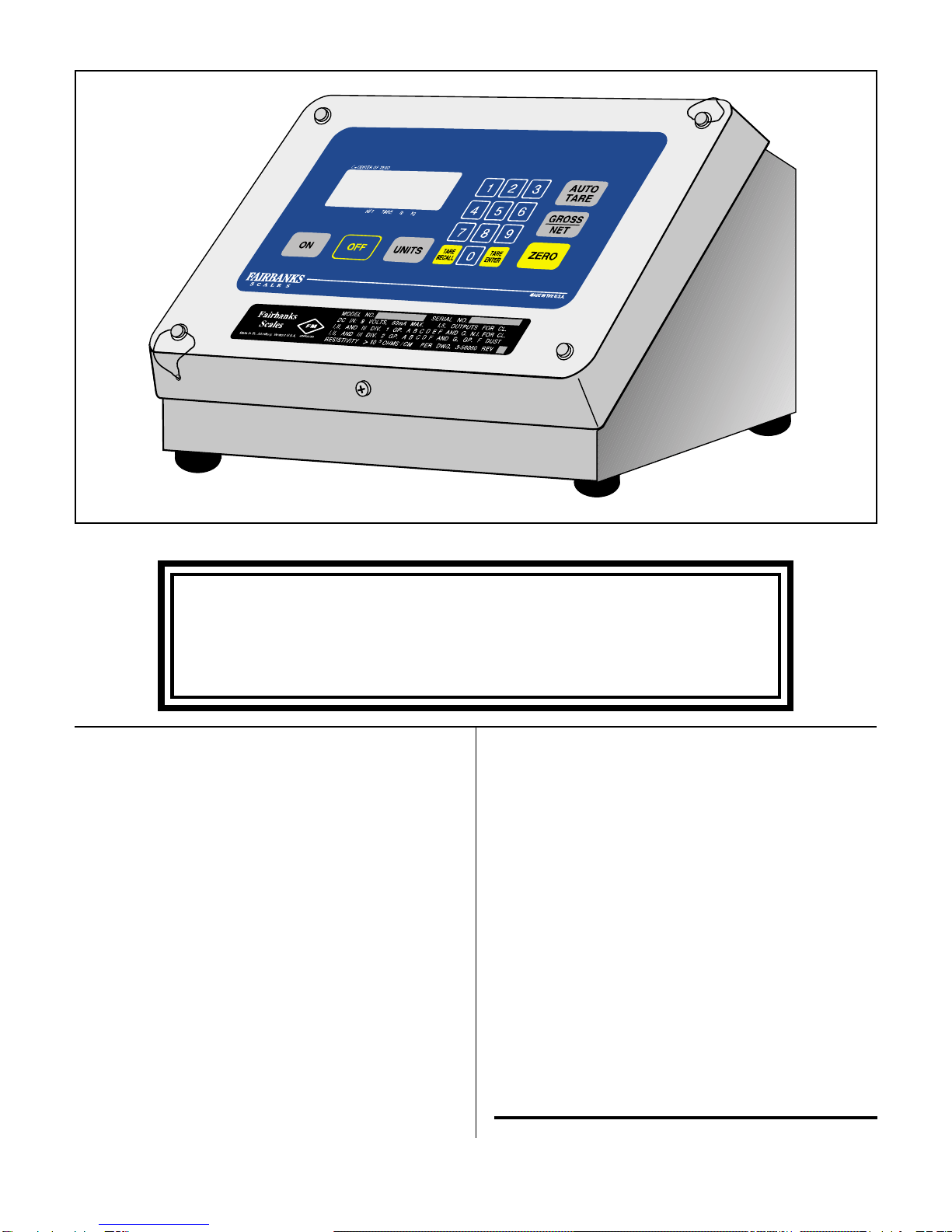

SECTION 4:

INSTALLATION

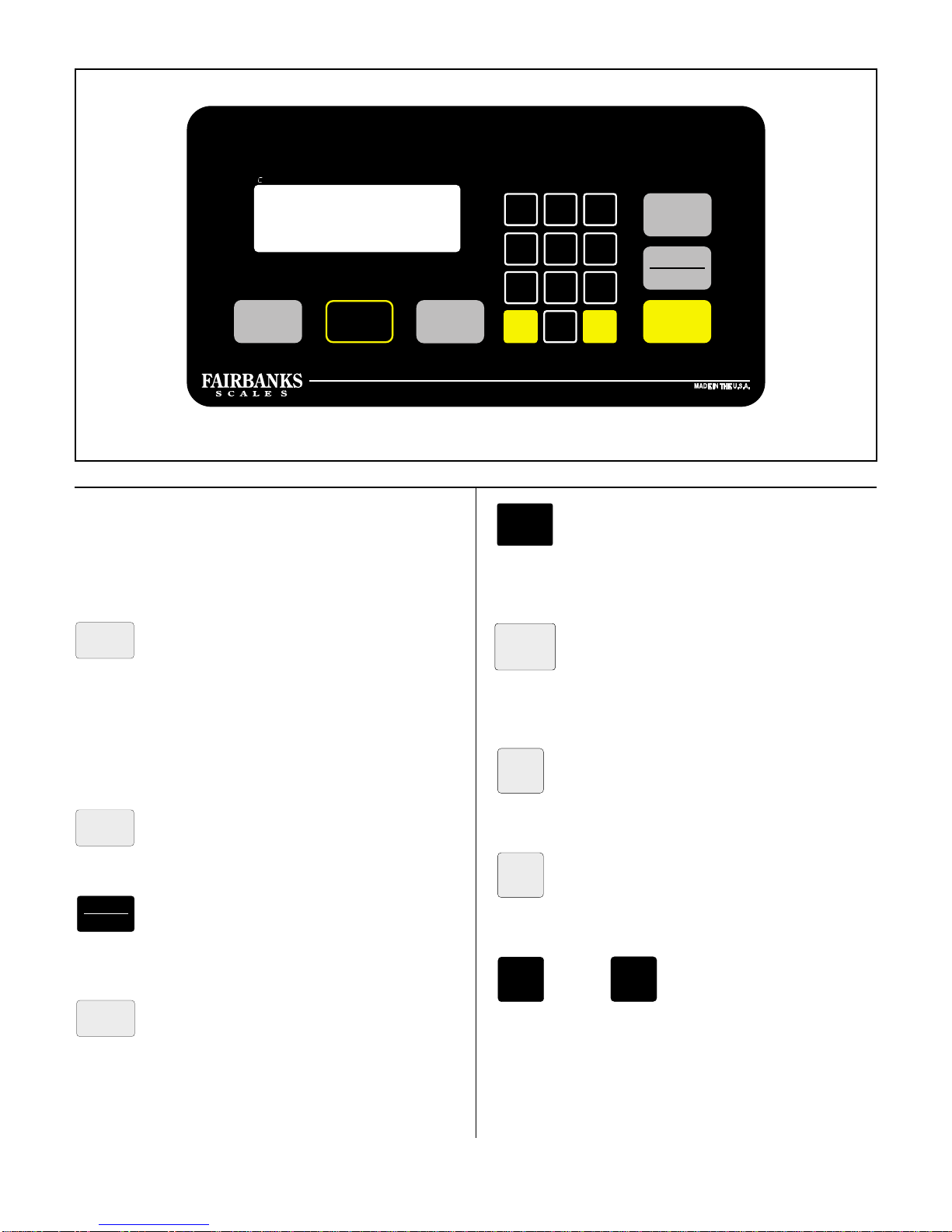

4.1 H90-3051 Front Panel Printer

Programming, Channel A

A. Channel A, Printers

1. Data available to be printed:

Gross weight

Tare weight

Net weight

Time

Date

ID

Ticket Number

The above data items can be enabled or disabled for

printing. See Function Key Programming, Channel A.

2. The data will be transmitted over Channel A each time

the key is pressed if there is no motion on the

platform and a valid weight is displayed, ie. not out of

weighing range or in a non-weighing mode. “ACK”

legend will appear momentarily.

3. If the key is pressed during an inhibit condi-

tion, printing will not occur once the inhibiting condition

ends. The key will have to be pressed again.

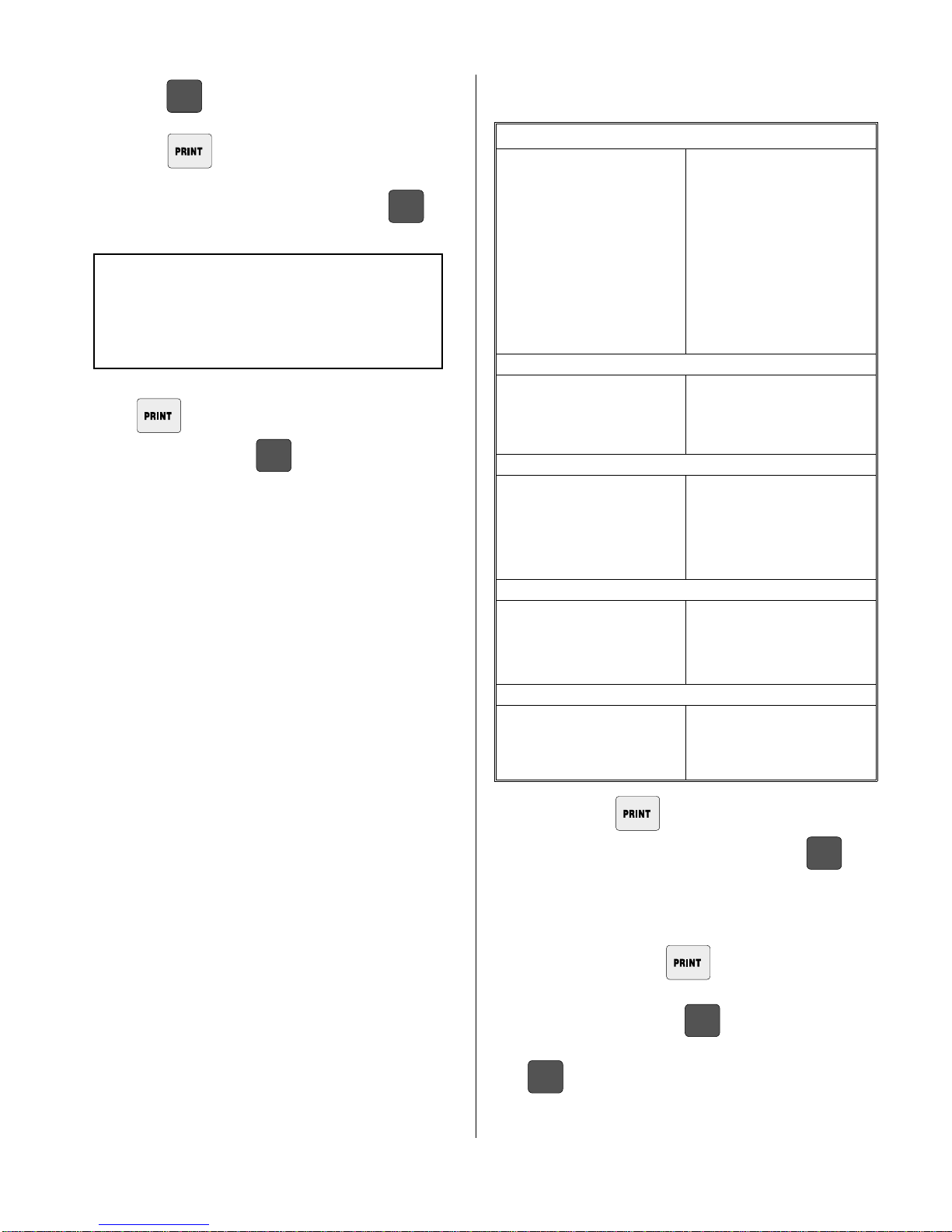

B. Formatting Print Locations For Data

Strings To Be Printed

The locations are set by entering a line number and a

column number for the data item. A line number of 0 will

inhibit the printing of an item. Three types of printers are

provided for: a ticket printer, a form printer and a tape

printer.

A weight string consists of 6 or 7 weight characters, six

units characters and three legend characters as shown

below:

“39050 tonne GR”or “390.02 ton TA”or “1234.56 gal NT”

Each character within the quotation marks (spaces in-

cluded) will be printed. The six units characters and/or

the three legend characters may be suppressed.

For the remaining strings, typical outputs are given below:

“ 3:38 PM” or “17:56” time

“11–13–90” or “4– 4–91” date

“ 123” or “123456” or “ 0” identifier

“# ...123” or “# . ....7” ticket number

Tare and net weights may be printed only when the

instrument is in the NET weighing mode (net weight

displayed).

For all three printers, all characters in the weight strings

only may be printed with enlarged character sizes

(spaces included). Large characters are two columns

wide.

Ticket printer line spacing is set by the printer switches at

5, 6, 7 or 8 lines per inch. The form printer and the tape

printer have a fixed line spacing.

Both the ticket and tape printers have a 40 character width

with normal size characters. For large characters, the

width changes to 20 and 24 characters respectively.

Inverted printing is possible with the ticket printer - the

printer switch (inverted print switch - 7) must be set to the

closed position at all times.

Interface characteristics such as baud rate, number of

bits/char etc. are programmed as follows. At the comple-

tion of that sequence, the prompt “PtAL 0”is given.

Pushing the key will exit the program mode

whereas pushing the key will change the prompt

to “PtAL 1”. Pushing the key will now get the

operator into the formatting program (pushing the

key will change the prompt back to “PtAL 0”).

In addition to I/O Output Accessory A5805 being installed

in the instrument, Accessories 4901656, 5807, and 5808

must be installed and Channel A must be enabled at

Service Program Step 15.

1. Place the instrument into the weighing mode.

2. Press . “FunC”will be displayed.

3. Press and the display will show “CuSt”.

4. Press key and the display will show “Chan”.

ENTER

ENTER

7

PROG

8SJ4511