Air Conditioner Service Manual

9

indoor fan motor is running at setting speed (the speed is same as that of heating).

2) Vane motor control: running according to the setting.

3) The outdoor unit is not working under fan mode.

6. Sleeping mode

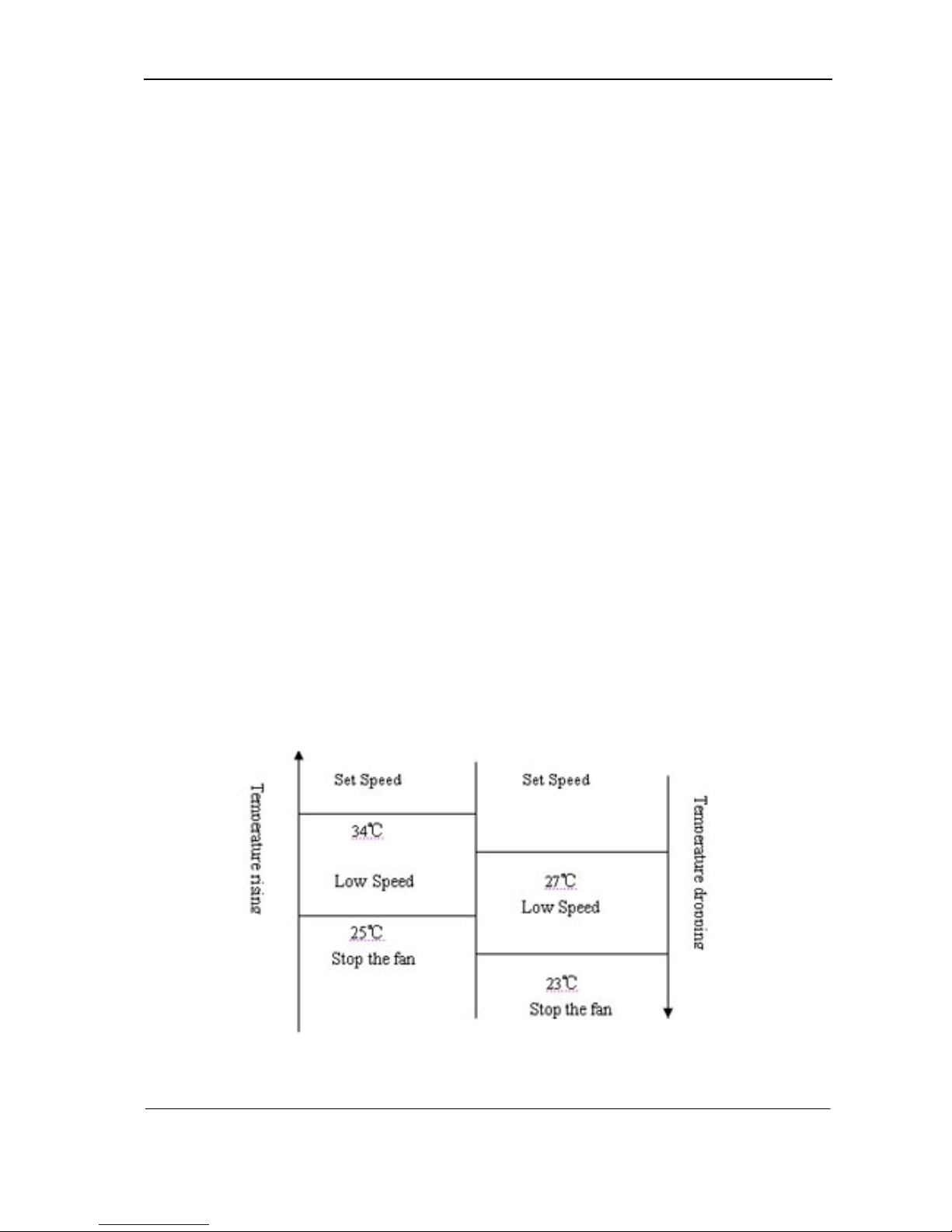

1) Under sleep mode, the indoor fan motor is running at a low-airflow speed,except that the power

light and sleep light are on, timer light is on/off according to the setting state, running light is off. LED

is off after displaying 5min.

2) Temperature control:

(1) From cool mode to sleep mode, one hour later, the operates Temp.=ST+1,another one hour

later, the operates Temp.=ST+2,after then unchanged.

(2) From heating mode to sleep mode, one hour later, the operates Temp.= ST-1,another one hour

later, the operates Temp.=ST-2,after then unchanged.

3) the machine will automatically shut up after running 8 hours under sleep mode.

Timer on start-up and sleep mode are implemented at the same time, and the sleep mode can not be

functioned.

7. Timing fuction

The timing scale is between 10min to 24h, when the time fixed is less than “10” hours, the displayed

time is shown by 0.5 hour as the unit, when the time fixed is more than or equal to “10” hours, the

displayed time is shown by 1 hour as the unit.

8. Emergency switch(ON/OFF)

1) When stand-by, to operate by pressing the emergency switch as follows:

To Press the emergency switch in three seconds, the buzzer rings once, and to release, the machine

runs into cooling mode; if to holding on, the buzzer rings twince, then the machine runs into heating

mode, while when the machine is on, to press the emergency Switch, the buzzer rings once and then

the machine shut down.

2) The machine is running mandatorily as the selected mode within 30min after emergency operation,

indoor fan motor is running in high-speed, and vane board is swinging. The machine runs into

automatic mode 30min later, the selected mode unchanged, the set temperature is 23° C ,the rotate

speed of indoor fan motor is automatic, and vane board is swinging too.

3) To press the emergency button when the machine operating, then the machine runs into stand-by

state.

4) Under emergency operation,the Compressor’s time-lapse protection, anti-frosting protection in

cooling, Overheating protection in heating and sensor fault protection and defrost operate are

effective.

5) Under emergency operation, once effective signal from remote controller is received, then the

machine exits form the emergency mode, and operate according to the setting from remote controller.

9. Auto-restart function

1) The PCB retains the setting parameters in case of power off. When the power supply is resumed,

the machine, which has been started up the power-off memory function, is able to restore into the

original running state automatically.

2) To press the emergency button and power on, and hold on 10 seconds, exit from the power-off

memory function, buzzer rings four tomes.(default: no this function)

10. Protection/ Troubleshooting functions