FXV3/CXVT Rigging & Assembly Instructions –Table of Contents Page | 3

FXV3 - CLOSED CIRCUIT COOLING TOWER

CXVT - EVAPORATIVE CONDENSER

RIGGING & ASSEMBLY INSTRUCTIONS

Contents

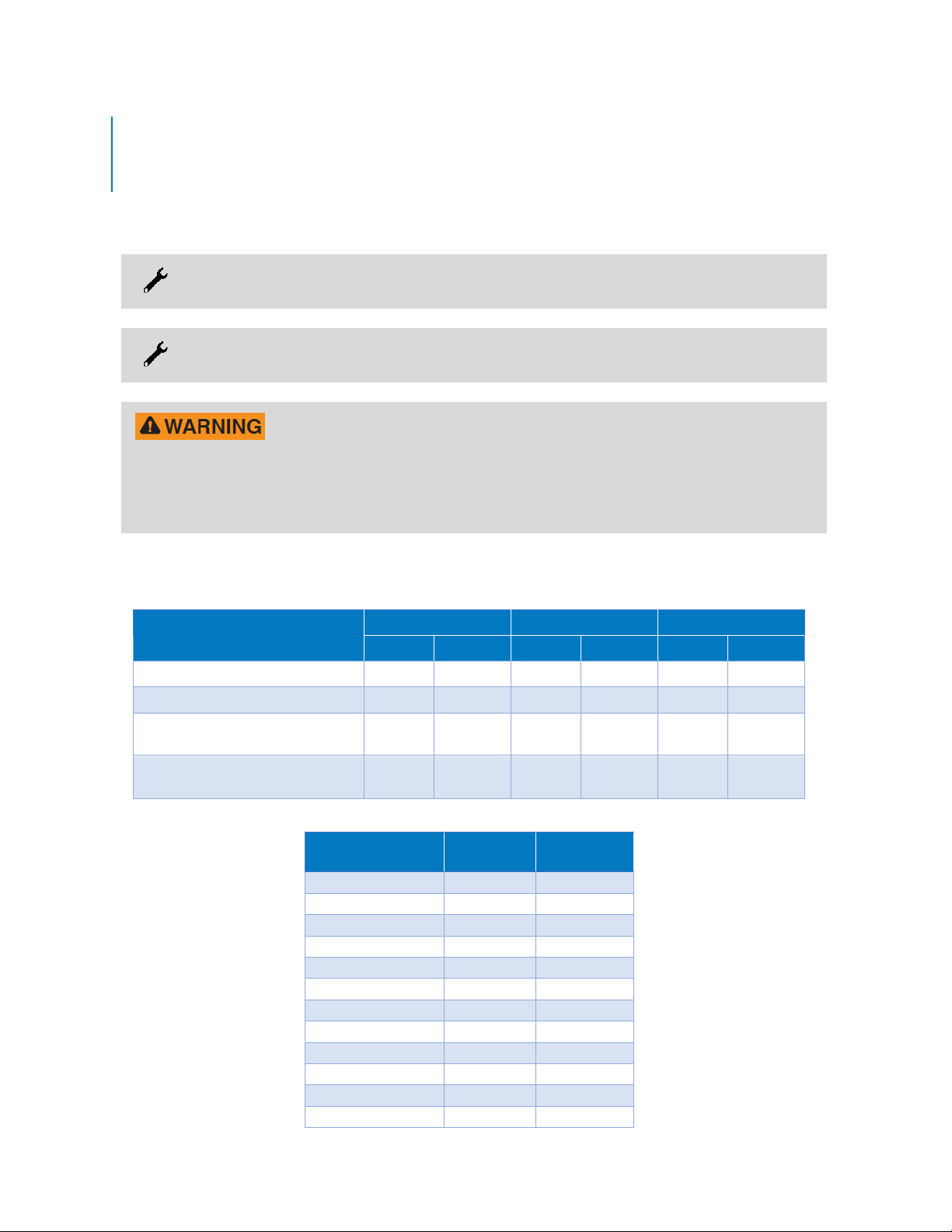

1. Warnings and Cautions................................................................................................................................................................................. 5

Safety Precautions ..................................................................................................................................................................................... 5

Equipment Precautions.............................................................................................................................................................................. 6

2. Introduction ................................................................................................................................................................................................... 7

Safety........................................................................................................................................................................................................... 7

Shipping ...................................................................................................................................................................................................... 7

Pre-Rigging Checks.................................................................................................................................................................................... 8

Unit Weights ........................................................................................................................................................................................... 8

Anchoring ............................................................................................................................................................................................... 8

Cold Weather Operation............................................................................................................................................................................. 9

Placement.................................................................................................................................................................................................... 9

Warranties ................................................................................................................................................................................................... 9

Unit Operation............................................................................................................................................................................................. 9

3. Unit Rigging & Assembly............................................................................................................................................................................. 10

Rigging ...................................................................................................................................................................................................... 10

Section Assembly..................................................................................................................................................................................... 13

Mechanical Section’s Shipping Braces Removal on (Optional) Gear and Belt Drive Units (Optional) ............................................. 21

Plain Pipe Stub Coil Connections Nitrogen Charge Removal .............................................................................................................. 22

3. Accessory Installation ................................................................................................................................................................................. 23

General Packing & Labeling Information................................................................................................................................................ 23

ENDURADRIVE®Fan System Installation............................................................................................................................................... 24

Warnings for the ENDURADRIVE®Fan System................................................................................................................................. 24

Important Notes for the ENDURADRIVE®Fan System...................................................................................................................... 24

Access Door Platform & Ladder Installation.......................................................................................................................................... 25

Fan Deck Extension Installation.............................................................................................................................................................. 28

External Motor Gear Drive Motor Base, Platform & Ladder Installation .............................................................................................. 31

Positive Closure Damper (PCD) Hood Platform & Ladder Installation ................................................................................................ 36