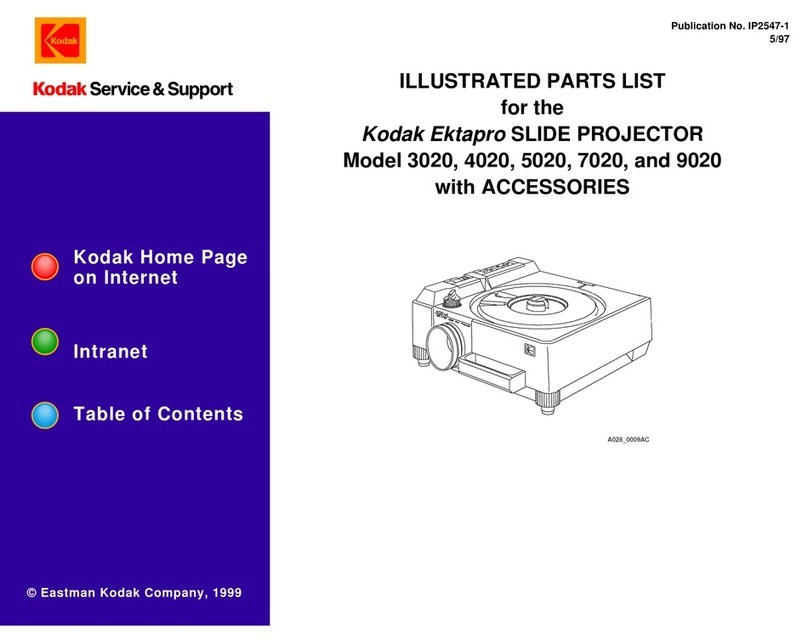

Table of contents

12. UV filter............................................................................................................ 117

12.1 UV filter replacement...............................................................................................................118

13. Cold mirror assembly........................................................................................... 119

13.1 Diagnostic. . .........................................................................................................................120

13.2 Removal of the cold mirror assembly..............................................................................................121

13.3 Mounting the new cold mirror + fan assembly.....................................................................................124

13.4 Adjusting the cold mirror ...........................................................................................................127

14. Lens holder....................................................................................................... 129

14.1 Removing the lens holder ..........................................................................................................130

14.2 Installing the lens holder ...........................................................................................................132

14.3 Adjusting the lens holder...........................................................................................................135

15. Vertical and Horizontal shift motors ......................................................................... 139

15.1 Removing the vertical shift motor..................................................................................................140

15.2 Mounting a new vertical shift motor................................................................................................143

15.3 Removal of the horizontal lens motor..............................................................................................146

15.4 Mounting the new horizontal lens motor...........................................................................................149

16. FLM liquid cooling circuit...................................................................................... 153

16.1 Safety ...............................................................................................................................155

16.2 Introduction .........................................................................................................................156

16.3 Diagnostics .........................................................................................................................157

16.4 Pressure verification of the liquid cooling circuit...................................................................................159

16.5 Draining the liquid cooling circuit...................................................................................................160

16.6 Filling the liquid cooling circuit .....................................................................................................163

16.7 Refreshing the liquid cooling circuit................................................................................................167

16.8 Expelling air from the liquid cooling circuit.........................................................................................170

16.9 Pressurizing the liquid cooling circuit ..............................................................................................172

16.10 Calibrating the liquid cooling circuit................................................................................................175

17. Heat exchanger.................................................................................................. 179

17.1 Removing the defective heat exchanger . . . . . . ....................................................................................180

17.2 Disassembling the heat exchanger assembly . ....................................................................................182

17.3 Assembling the new heat exchanger ..............................................................................................184

17.4 Mounting the heat exchanger assembly into the projector . . . .....................................................................186

18. Cooling pump.................................................................................................... 189

18.1 Maintaining the cooling pump......................................................................................................190

18.1.1 Opening the cooling pump and rotor movement............................................................................191

18.1.2 Cleaning pump ...............................................................................................................192

18.1.3 Closing the pump ............................................................................................................193

18.2 Cooling pump body replacement...................................................................................................194

18.2.1 Removing the pump body ...................................................................................................195

18.2.2 Mounting the new pump body ...............................................................................................196

18.3 Cooling pump replacement.........................................................................................................197

18.3.1 Removing the pump .........................................................................................................198

18.3.2 Mounting the new pump . . ...................................................................................................200

19. Shutter replacement ............................................................................................ 203

19.1 Shutter replacement................................................................................................................204

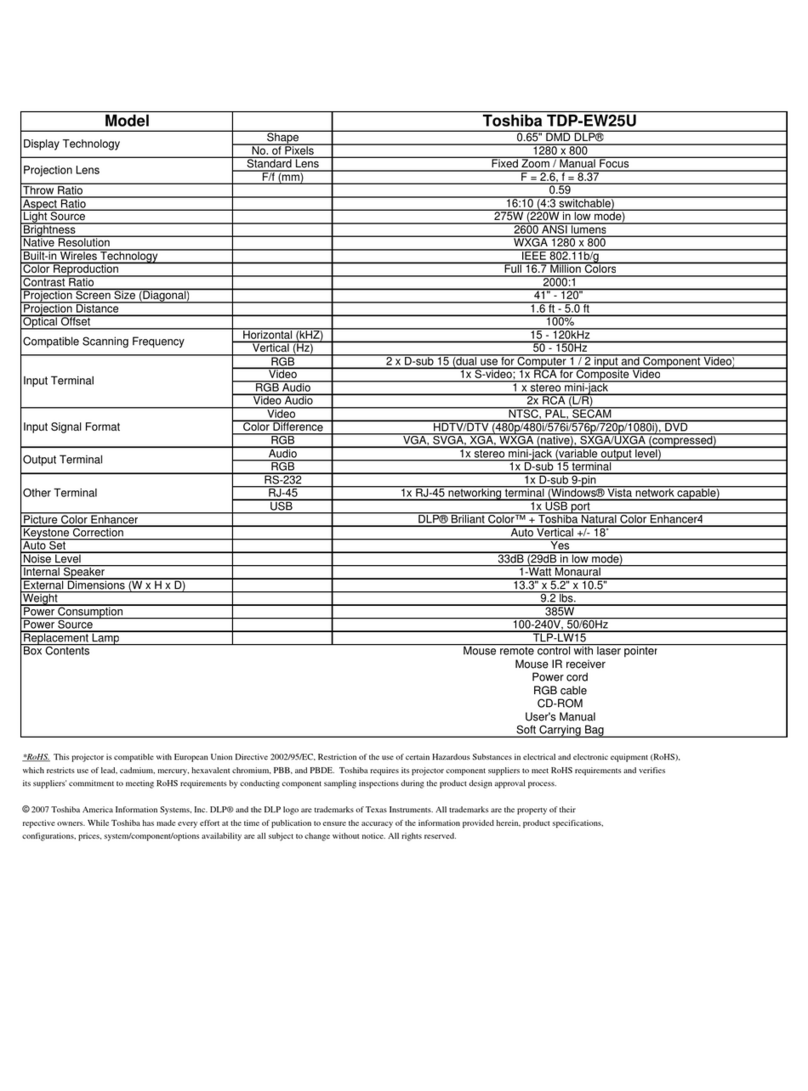

20. Formatter Interface Board ..................................................................................... 207

20.1 Removing the FIB ..................................................................................................................208

20.2 Mounting a new FIB ................................................................................................................209

21. Pixel map processor board.................................................................................... 211

21.1 Diagnostics .........................................................................................................................212

21.2 Building out the PMP ...............................................................................................................213

21.3 Mounting a new PMP board........................................................................................................216

22. LCD panel replacement ........................................................................................ 219

22.1 Removing the LCD panel. ..........................................................................................................220

22.2 Mounting a new LCD panel . . . . . ...................................................................................................223

23. Keypad board replacement.................................................................................... 227

23.1 Removing the keypad unit..........................................................................................................228

23.2 Mounting the new keypad unit .....................................................................................................230

24. Fan replacements ............................................................................................... 233

24.1 Heat exchanger fan.................................................................................................................234

24.1.1 Building out the heat exchanger assembly. .................................................................................235

24.1.2 Replacing the old fan with a new fan........................................................................................237

24.1.3 Mounting the heat exchange assembly into the projector . .................................................................238

24.2 Cold mirror fan......................................................................................................................239

24.2.1 Removal of the cold mirror fan ..............................................................................................240

24.2.2 Mounting a new cold mirror fan. . . ...........................................................................................242

2R59770072 FLM SERIES 19/03/2007