Manual 2100-764

Page 6 of 8

“Y1” Potentiometer setting: Not applicable on this

model.

“Y2” Potentiometer setting: Not applicable on this

model.

2-10V Operation

A CO2sensor or other device sending a 2-10V signal

can be used to control the damper motor. Two control

methods are available to control the damper motor:

• Method 1: The control board will accept a

2-10VDC signal with a resistive load greater than

5000 ohms. Bard CO2sensor part #8403-096 can

be used when the 2-10V output is connected to

the "CO2 V IN" tab on the CRV control board. The

pre-purge "PP" and occupied "OCC" potentiometer

settings must be set to the off position and pre-

purge jumper must be set to "0" position for total

modulation. The OCC potentiometer can be used

to maintain a minimum blade position when "3" is

energized.

• Method 2: The damper motor will accept a

2-10VDC signal with a resistive load less than

5000 ohms. This method involves bypassing the

control board and powering the motor directly from

the device providing the 2-10VDC modulating

signal. The 1/4" tab connector of the white wire

coming from the damper motor lead must be

disconnected from the CRV control board wiring.

The 2-10V signal coming from the CO2controller

must be connected to this wire.

During 2-10VDC operation with "3" energized and

pre-purge timed operation active, DC voltage signaling

occupancy from a source such as a CO2sensor will

increase ventilation amounts as needed.

Adding Optional Co2Control Sensor

Adding an optional CO

2

control sensor (Bard Part

#8403-096) to this control will maximize the

capabilities of this vent by only supplying fresh air intake

to maintain CO

2

levels. This has multiple benets.

• Minimizes ventilation load on structure as it only

brings in what is required to maintain CO2levels

thus lowering reconditioning requirements (not

having to heat/cool as much outside air).

• Will self-adjust for various occupancy levels so

that fresh air is not being brought in beyond need.

For example, if a room is designed for a maximum

occupancy of 40 persons (standard ventilation

control would have to be set for that occupancy),

but the room typically only contains 25 persons.

This control will self-adjust the amount of fresh air

intake from 600 to 375 CFM automatically (based

upon 15 CFM per person standard rate to ASHRAE

standards).

Basic Installation

1. Make sure power is turned off to the unit

2. Run four (4) wire thermostat wire from the unit to

the desired CO2sensor location.

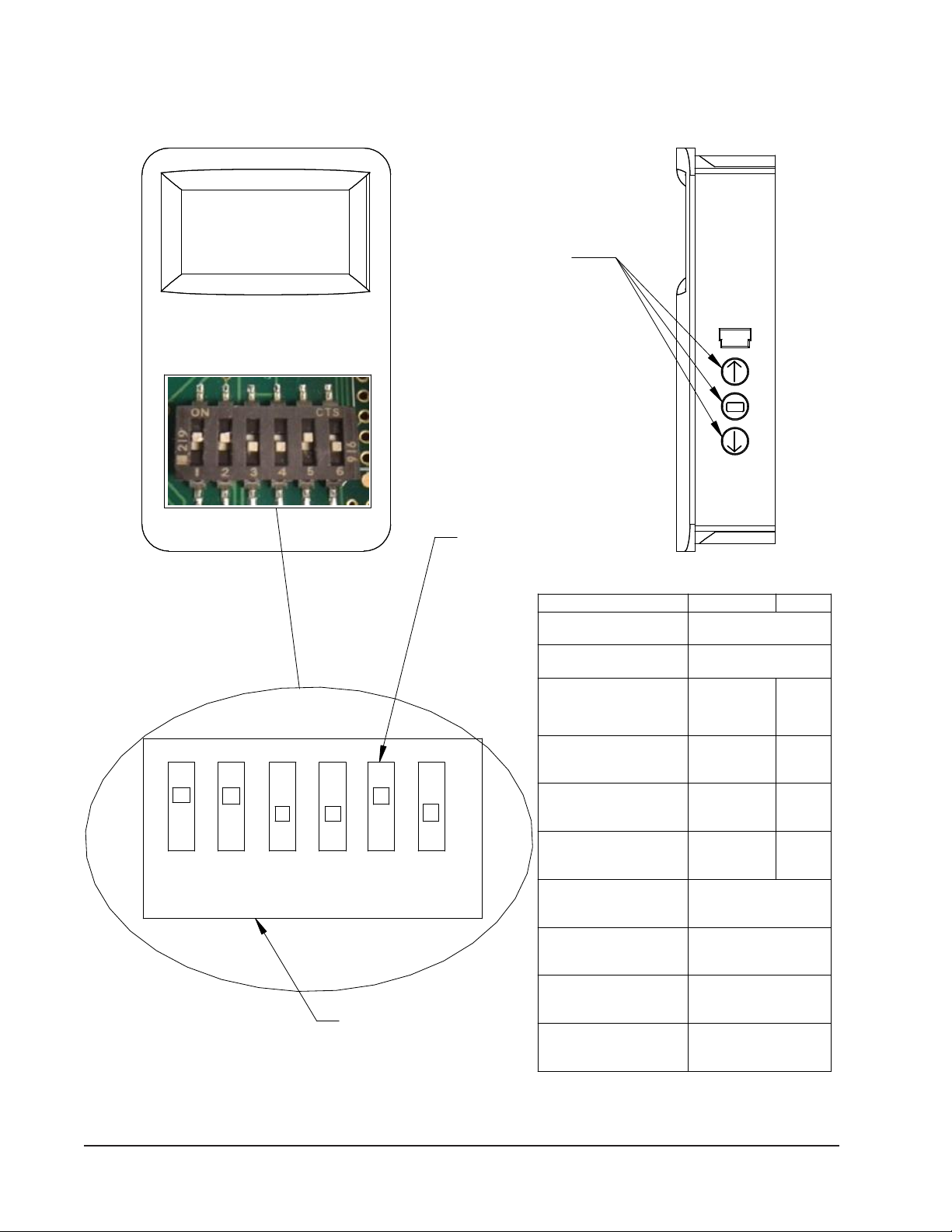

3. Follow Figure 5 on page 8 to congure the CO2

sensor for proper operation.

4.

Connect the thermostat wiring from the CO

2

sensor

to step control assembly following the wiring diagram

in Figure 4 or the one on the ventilator assembly.

5. To check operation, restore power to the unit.

6. Make sure that thermostatic control is in

“occupied” mode of operation calling for

ventilation. Terminal “3” on the low voltage

terminal strip must be energized to open damper.

7. Have someone stand in front of the CO2sensor

and breathe on it. The display should show an

increase in CO2ppm, and the damper blade in the

ventilation package should increase. (It may be

best to have two people to do this—one to breathe

on control and one to observe damper.)