Manual 2100-420H

Page 2 of 34

CONTENTS

Getting Other Information and Publications

For more information, contact these publishers: .......... 3

QTEC General Information

QTEC Model Nomenclature .......................................... 4

Shipping Damage ......................................................... 8

Unit Removal From Skid .............................................. 8

Handling Unit After Removal From Skid ....................... 9

General ......................................................................... 9

Minimum Installation Height ......................................... 9

Duct Work .................................................................. 11

Filters .......................................................................... 11

Fresh Air Intake .......................................................... 12

Condensate Drain ...................................................... 12

Service Light ............................................................... 13

Installation Instructions

Mounting the Unit ....................................................... 14

Wiring — Main Power ................................................. 15

Wiring — Low Voltage Wiring ..................................... 15

Low Voltage Connections ........................................... 16

Start Up

Description of Standard Equipment ............................... 21

Optional CFM (QH362, QH422, QH482 & QH602 Only) ..... 21

Important Installer Note .................................................. 21

Phase Monitor ................................................................ 21

Three Phase Scroll Compressor Start Up

Information ................................................................ 21

Service Hints .................................................................. 22

Mist Eliminator Service .................................................. 22

Vent Options .................................................................. 23

Sequence of Operation .................................................. 26

Optional Climate Controls Sequence

of Operation .............................................................. 26

Pressure Service Ports .................................................. 26

Defrost Cycle ................................................................. 27

Troubleshooting

Solid State Heat Pump Control Troubleshooting

Procedure ...................................................................... 29

Checking Temperature Sensor ...................................... 29

Troubleshooting GE ECM™ Blower Motors ............. 30-31

Fan Blade Setting Dimensions ...................................... 32

Refrigerant Charge ........................................................ 32

Pressure Charts ...................................................... 33 - 34

Figures

Figure 1 Unit Dimensions .......................................... 7

Figure 2 Air Seal on Bottom of Unit ........................... 8

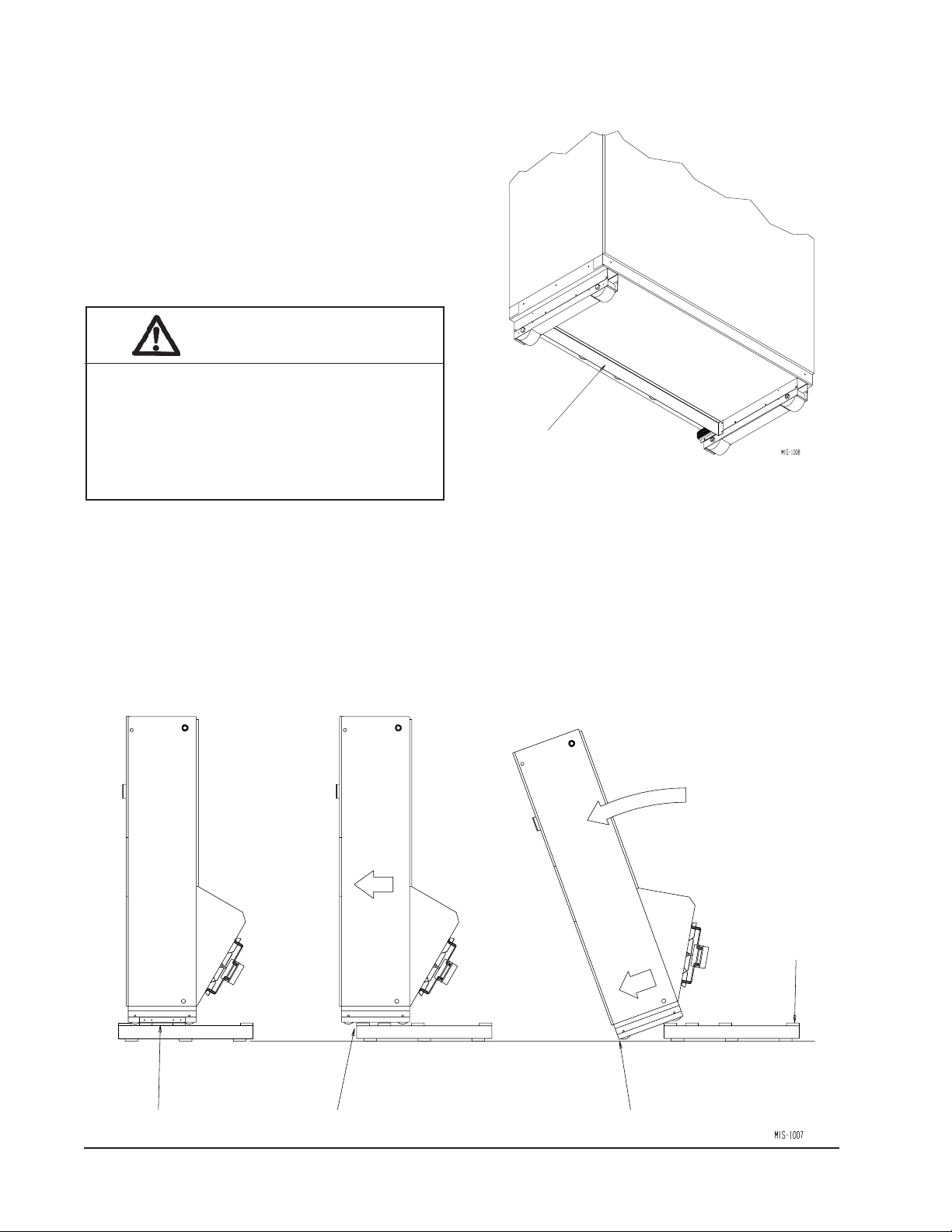

Figure 3 Removal of Unit From Skid ......................... 8

Figure 4 Unit on Appliance Cart for Moving ............... 9

Figure 5 Installation With Free Blow Plenum .......... 10

Figure 6 Ducted Application ..................................... 10

Figure 7 Supply Duct Connections .......................... 11

Figure 8 Filter Location ............................................ 11

Figure 9 Optional Side Drain ................................... 12

Figure 10 Standard Rear Drain .................................. 12

Figure 11 Rear Drain (Top View) ............................... 13

Figure 12 Unit Mounting ............................................ 13

Figure 13 Removing Locking Screws from Wheels... 14

Figure 14 Component Location ................................. 15

Figure 15 Thermostat Plug Terminals ........................ 17

Figure 16 Thermostat Wiring Diagram "X" Option .... 18

Figure 17 Thermostat Wiring Diagram "A" Option .... 19

Figure 18 Thermostat Wiring Diagram "D" Option ... 20

Figure 19 Fresh Air Damper Removal ....................... 24

Figure 20 QERV Removal ......................................... 25

Figure 21 Heat Pump Control Board ......................... 26

Figure 22 Low Pressure Control Bypass Timer ......... 27

Figure 23 Control Disassembly ................................. 31

Figure 24 Winding Test .............................................. 31

Figure 25 Drip Loop ................................................... 31

Figure 26 Fan Blade Setting ...................................... 32

Tables

T

able 1 Factory Built-In Electric Heat Table .............. 4

Table 2 Electrical Specifications ................................ 5

Table 2A Electrical Specifications ................................ 6

Table 3 Operating Voltage Range ........................... 15

Table 4 Wall Thermostats ........................................ 17

Table 5 Troubleshooting .......................................... 28

Table 6 Temperature vs Resistance of

Temperature Sensor ................................... 29

Table 7 Fan Blade Dimensions ............................... 32

Table 8 Super Heat at Compressor ......................... 32

Table 9 Indoor Blower Performance ........................ 32

Table 10 Cooling Pressure ........................................ 33

Table 11 Heating Pressure ........................................ 34