4

Main characteristics

Efficient and economical

The unit's Coefficient of Performance (cop) ≥4.0. In comparison, an electric boiler (cop) ≤0.95, a gas

or oil boiler (cop) is about 0.5--0.8, a coal-boiler (cop) is only about 0.3--0.7.

Safety ensured

When the unit is working, all electrophorus parts are absolutely isolated from circulating water, thus

avoiding some possible dangers such as explosion, dry heating, gas poisoning, which may happen

with a common water heater.

Environmentally friendly

The applied refrigerant is not Freon, and when the unit is working, no waste water, no waste residue,

no waste heat and no waste gas will pollute the circumstance.

Installation convenient

It can be installed at outdoor area, balcony, flat roof, carbon, equipment floor, and does not need

special room only for it.

Modularized control function

You can combine several units to make one heat water supply system controlled by modularization.

The system can adjust the running time and order automatically, by which the whole system can run

efficiently, and every unit's total running time can be unified.

Operation convenient

The unit is controlled by microcomputer. According to the condition of water temperature and circular

water volume, the unit will adjust itself. There is no need for anybody to keep on watching it.

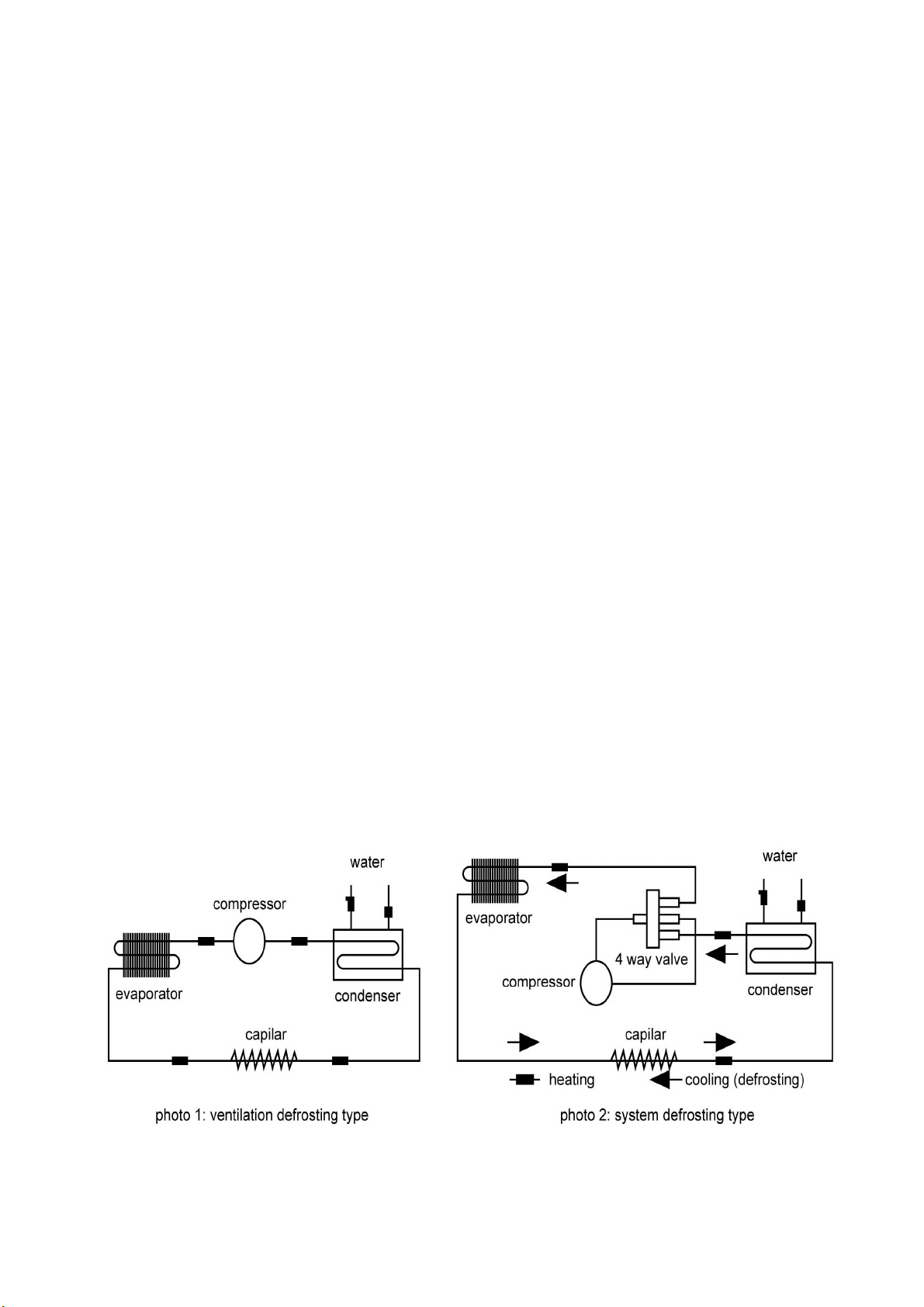

Automatic defrost function

With intelligent zed defrost function, you can set defrost condition according to different climates to

make the unit defrost in a flexible way.

Far-ranging applicability

Can be used in hotel, bathe centre, school, factory, indoor natatorium and so on.