Manual 2100-533A

Page 7 of 12

CLEANABILITY AND PERFORMANCE

In order to maintain energy recovery ventilation

systems, energy transfer surfaces must be accessible for

washing to remove oils, grease, tars and dirt that can

impede performance or generate odors. Washing of the

desiccant surfaces is required to remove contaminate

buildups that can reduce adsorption of water molecules.

The continued ability of an enthalpy wheel to transfer

latent energy depends upon the permanence of the bond

between the desiccant and the energy transfer surfaces.

Bard wheels feature silica gel desiccant permanently

bonded to the heat exchange surface without adhesives;

the desiccant will not be lost in the washing process.

Proper cleaning of the Bard energy recovery wheel will

restore latent effectiveness to near original performance.

MAINTENANCE PROCEDURES

NOTE: Local conditions can vary and affect the

required time between routine maintenance

procedures, therefore all sites (or specific units

at a site) may not have the same schedule to

maintain acceptable performance. The

following timetables are recommended and can

be altered based on local experience.

QUARTERLY MAINTENANCE

1. Inspect mist eliminator/prefilter and clean if

necessary. This filter is located in the wall sleeve

and can be accessed by either removing the exterior

louver grille, the vent package from inside the unit,

or by disconnecting the unit from the wall brackets,

and rolling the unit away from the sleeve on its

integral wheel system. The filter is an aluminum

mesh filter and can be cleaned with water and any

detergent not harmful to aluminum.

2. Inspect the comfort air filter and clean or replace as

necessary. This filter is located behind the front-

hinged service door.

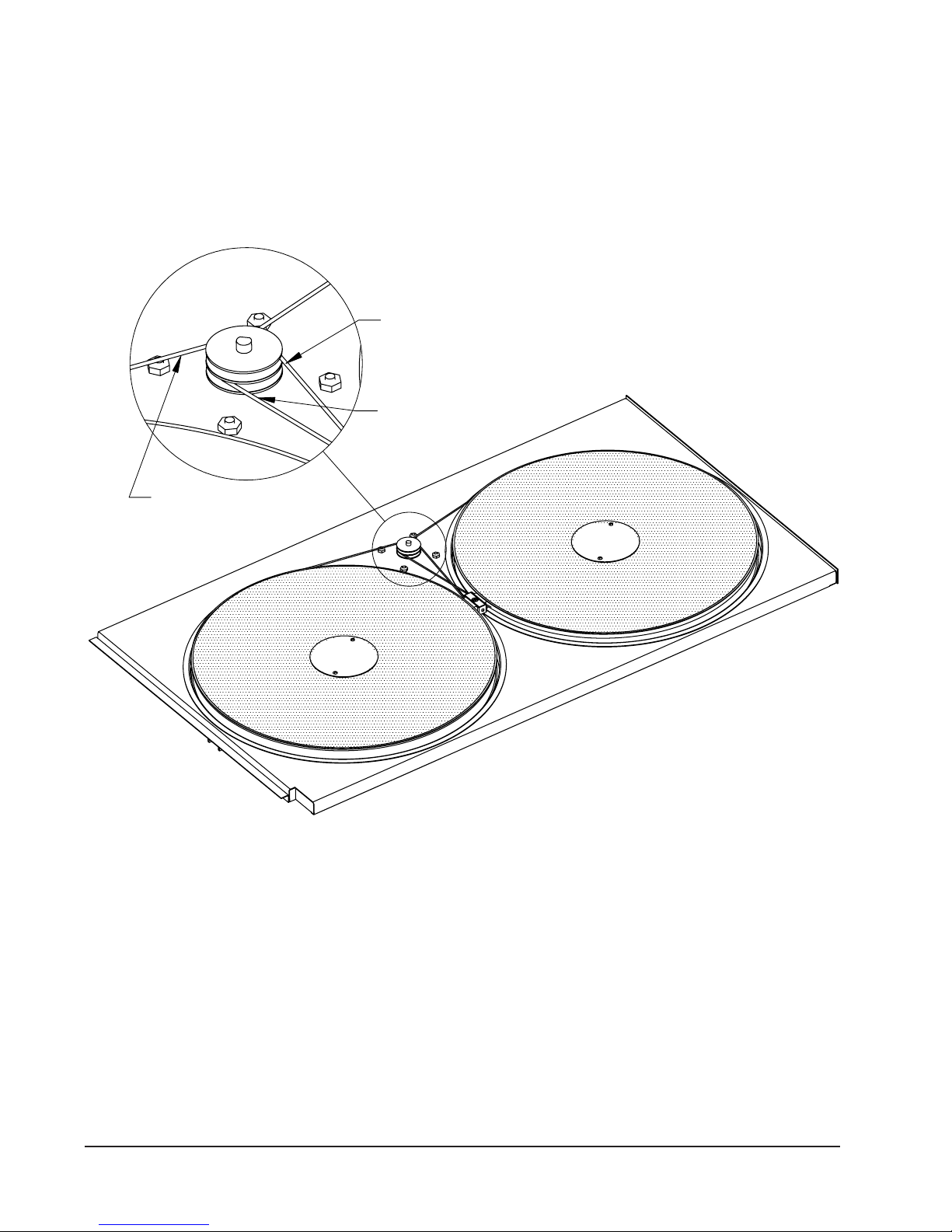

3. Inspect energy recovery ventilator for proper wheel

rotation and dirt buildup. This can be done in

conjunction with Item 2 above. Energize the energy

recovery ventilator after inspecting the filter and

observe for proper rotation and/or dirt buildup.

4. Recommended energy recovery wheel cleaning

procedures follow: Disconnect all power to the unit.

Open the front-hinged service door to the unit.

5. Remove the front cassette retaining panel from the

front of the ERV. Unplug the amp connectors to the

cassette drive motor. Slide energy recovery cassette

out of the ventilator.

6. Use a shop vacuum with brush attachment to clean

both sides of the energy recovery wheels.

7. Reverse shop vacuum to use as a blower and blow

out any residual dry debris from the wheel.

NOTE: Discoloration and staining of the wheel

does not affect its performance. Only

excessive buildup of foreign material needs

to be removed.

8. If any belt chirping or squealing noise is present,

apply a small amount of LPS-1 or equivalent dry

film lubricant to the belt.

ANNUAL MAINTENANCE

1. Inspect and conduct the same procedures as outlined

under Quarterly Maintenance.

2. To maintain peak latent (moisture) removal

capacity, it is recommended that the energy

recovery wheels be sprayed with a diluted nonacid

based evaporator coil cleaner or alkaline detergent

solution such as 409.

NOTE: Do not use acid based cleaners, aromatic

solvents, temperatures in excess of 170°F or

steam. Damage to the wheel may result.

Do not disassemble and immerse the entire heat

wheel in a soaking solution, as bearing and

other damage may result.

3. Rinse wheel thoroughly after application of the

cleaning solution, and allow to drain before

reinstalling.

4. No re-lubrication is required to heat wheel bearings

of the drive motor, or to the intake and exhaust

blower motors.

5. If any belt chirping or squealing noise is present,

apply a small amount of LPS-1 or equivalent dry

film lubricant to the belt.