Barnstead Thermolyne Corporation Nuova II User manual

1

LT756X1 • 9/11/97

Type HP18300

Nuova II Hot Plates

OPERATION MANUAL

AND PARTS LIST

SERIES 756

Model # Top Plate Size (cm) Voltage

HP18320

HP18320-26

HP18324

HP18325

7" x 7" (18 x 18)

7" x 7" (18 x 18)

7" x 7" (18 x 18)

7" x 7"

(

18 x 18

)

220-240

220-240

100

120

BARNSTEAD|THERMOLYNE

2

Table of Contents

Safety Information .............................................................................................................................................. 3

Alert Signals.................................................................................................................................................... 3

Safety Information........................................................................................................................................... 3

Warnings......................................................................................................................................................... 3

Introduction ........................................................................................................................................................ 6

Principles of operation .................................................................................................................................... 6

Specifications ..................................................................................................................................................... 7

Electrical Specifications .................................................................................................................................. 7

General Specifications.................................................................................................................................... 7

Installation .......................................................................................................................................................... 8

Operation ........................................................................................................................................................... 9

Maintenance and Servicing.............................................................................................................................. 10

Troubleshooting Guide ................................................................................................................................. 10

Preventive Maintenance ............................................................................................................................... 10

Exploded View ................................................................................................................................................. 16

Replacement Parts Listing ............................................................................................................................... 17

Ordering Procedures .................................................................................................................................... 17

Material Safety Data Sheet .............................................................................................................................. 18

One Year Limited Warranty.............................................................................................................................. 20

3

Safety Information

This manual contains important operating and

safety information. You should carefully

read and understand the contents of this manual

prior to the use of this equipment.

Safety Information

Your Thermolyne Nuova II Hot Plate has been

designed with function, reliability, and safety in

mind. It is your responsibility to install it in

conformance with local electrical codes. For safe

operation, please pay attention to the alert signals

throughout the manual.

Warnings

1. Do not immerse unit for cleaning.

2. As with all laboratory equipment,

appropriate safety clothing, glasses,

gloves and coats should be worn when

operating hot plates. Always use

appropriate hand and eye protection when

handling hazardous chemicals.

3. DO NOT remove or modify grounded

power plug. Use only properly grounded

outlets to avoid shock hazard. Not rated

for use in hazardous atmospheres.

4. Do not use in the presence of flammable

or combustible chemicals; top surface and

element can reach the “Flash Point

Temperature” of many chemicals. THESE

HOT PLATES ARE NOT EXPLOSION

Warning

Warnings alert you to a possi-

bility of personal injury.

Caution

Cautions alert you to a possi-

bility of damage to the equip-

ment.

Note

Notes alert you to pertinent

facts and conditions.

Alert Signals

4

PROOF. Fire or explosion may result.

Unit contains components which may

ignite such materials.

5. “Caution: Hot Surface. Avoid Contact.”

The top plate will remain hot without visual

indication for some time after the unit has

been turned off.

To avoid electrical shock:

1. Always use a properly grounded electrical

outlet with correct voltage and current

handling capacity.

2. Disconnect from power supply before

servicing.

3. Refer servicing to qualified personnel.

SAFETY INFORMATION

5

Please note the following WARNINGS:

Warning

This warning is presented for compliance with California Proposition 65 and other regulatory

agencies and only applies to the insulation in this product. This product contains refractory

ceramic, refractory ceramic fiber or fiberglass insulation, which can produce respirable dust

or fibers during disassembly. Dust or fibers can cause irritation and can aggravate

preexisting respiratory diseases. Refractory ceramic and refractory ceramic fibers (after

reaching 1000°C) contain crystalline silica, which can cause lung damage (silicosis). The

International Agency for Research on Cancer (IARC) has classified refractory ceramic fiber

and fiberglass as possibly carcinogenic (Group 2B), and crystalline silica as carcinogenic to

humans (Group 1).

The insulating materials can be located in the door, the hearth collar, in the chamber of the

product or under the hot plate top. Tests performed by the manufacturer indicate that there

is no risk of exposure to dust or respirable fibers resulting from operation of this product

under normal conditions. However, there may be a risk of exposure to respirable dust or

fibers when repairing or maintaining the insulating materials, or when otherwise disturbing

them in a manner which causes release of dust or fibers. By using proper handling

procedures and protective equipment you can work safely with these insulating materials

and minimize any exposure. Refer to the appropriate Material Safety Data Sheets (MSDS)

for information regarding proper handling and recommended protective equipment. For

additional MSDS copies, or additional information concerning the handling of

refractory ceramic products, please contact the Customer Service Department at

Barnstead|Thermolyne Corporation at 1-800-553-0039.

SAFETY INFORMATION

Warning

Refer servicing to qualified personnel.

This manual suits for next models

4

Table of contents

Other Barnstead Thermolyne Corporation Cooktop manuals

Popular Cooktop manuals by other brands

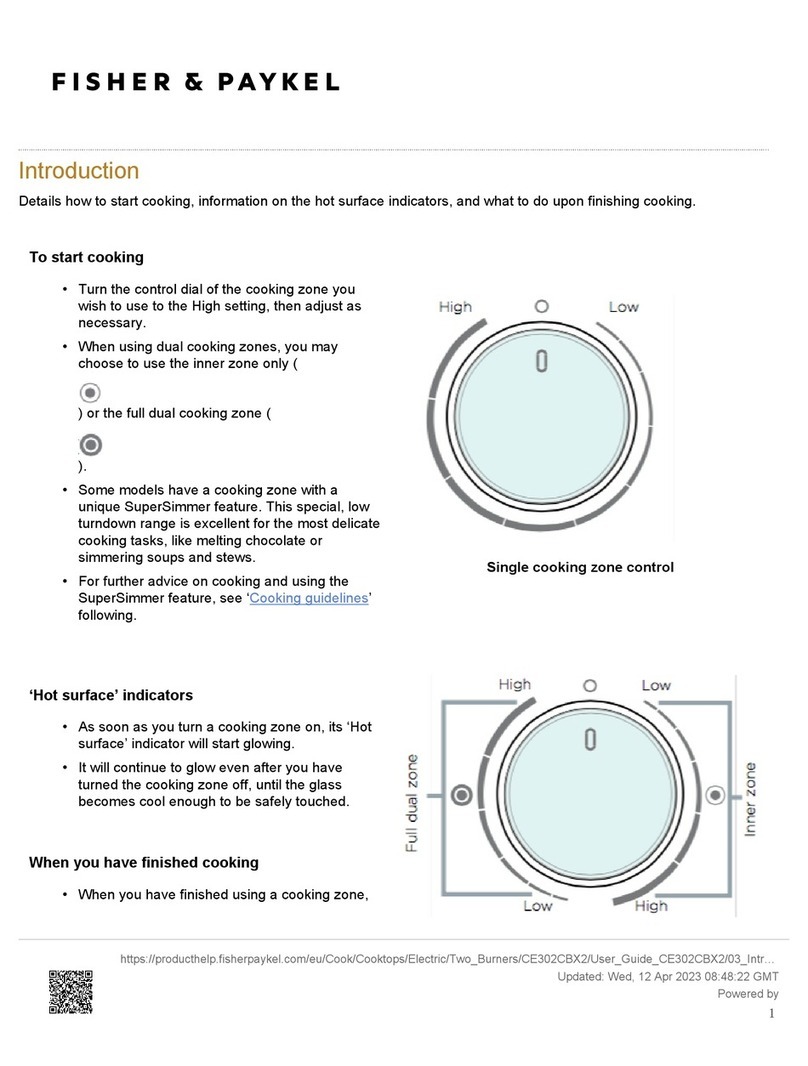

Fisher & Paykel

Fisher & Paykel CE302CBX2 manual

Whirlpool

Whirlpool GJC3634RB00 parts list

Whirlpool

Whirlpool ACH7324/BLV Use, care and installation guide

Frigidaire

Frigidaire Professional FPDF4085KF Important safety instructions

Bonnet

Bonnet OPTIMUM 700 Technical instructions

Jenn-Air

Jenn-Air JGCP430 installation instructions

Bompani

Bompani BO374AA/E User instructions

Kleenmaid

Kleenmaid cooking GCTK9011 Instructions for use and warranty details

Waldorf

Waldorf RN8603E-B Technical data sheet

Whirlpool

Whirlpool SMP658CNEIXL quick guide

Electrolux

Electrolux E36IC80ISS - 36" Induction Cooktop Wiring diagram

Wolf

Wolf CI243C/B Use and care guide