1324D-1624D Owner’s Manual 8/29/18 Page 6 of 19

MAINTENANCE PREPARATION

Only trained & qualified personnel should perform maintenance or repairs of the trencher. Before

performing any service, maintenance, adjustments, repairs, or off-season long-term storage, follow the

SHUT DOWN PROCEDURE in the OPERATOR’S MANUAL.

Do not touch the engine, muffler, or any of the hydraulic components until cool.

WARNING: Muffler and engine get hot enough to cause serious burns. For the

safety of yourself and others, allow enough time for the engine, muffler, and the

hydraulic fluid to cool completely before performing any cleaning or maintenance.

Avoid contact with hydraulic fluid.

WARNING: When machine is operating, hydraulic fluid is under extreme pressure and can get

under skin and burn or poison.

If you need to lower the dig chain boom without power, do the following:

1. Position a pan under the trencher to catch hydraulic fluid.

2. Support the boom front end with a hoist or forklift.

WARNING: The boom with dig chain is heavy. Manpower alone is not recommended, but if

necessary, use a team of two strong workers to support the boom, and a third worker to loosen the

hose.

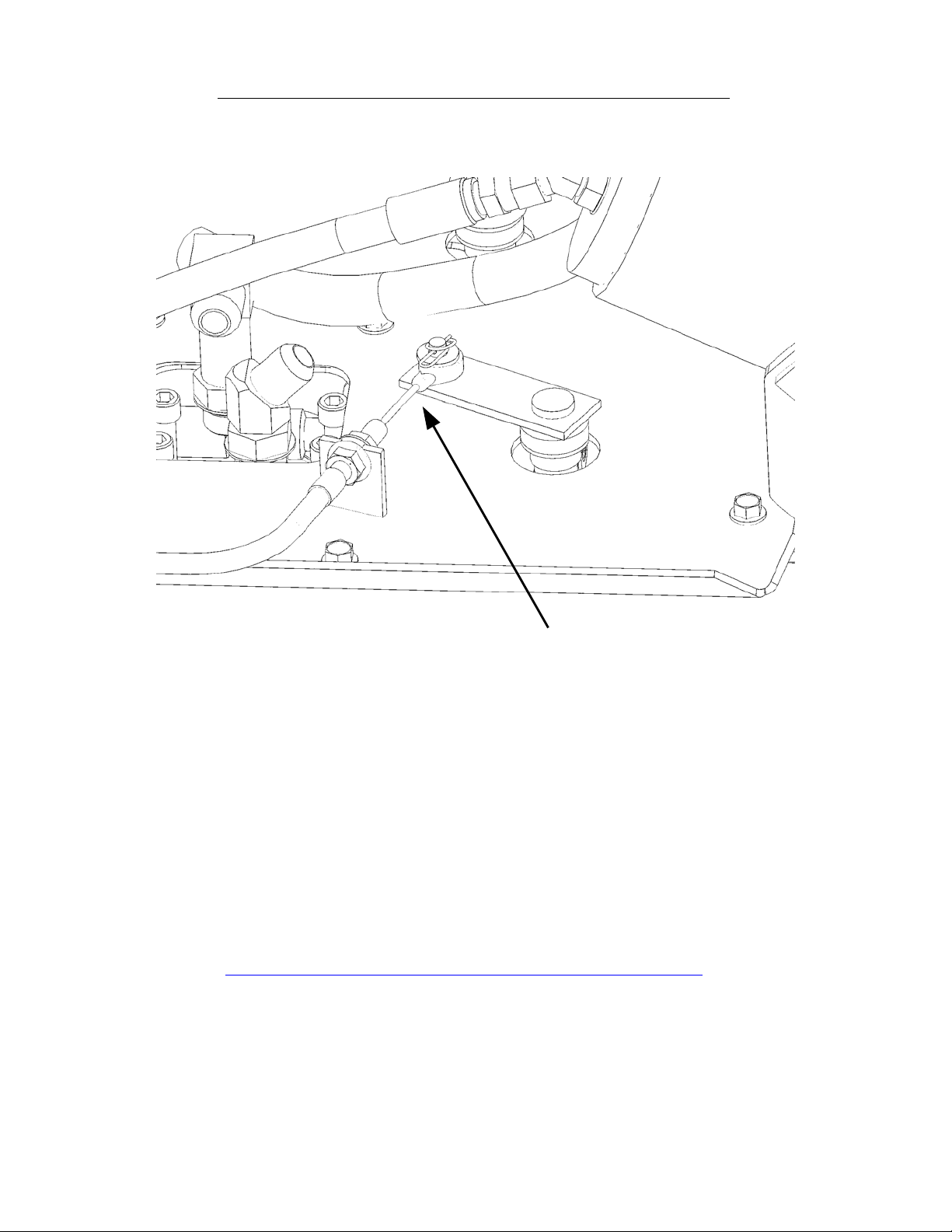

3. Loosen the hose at the rod end (front) port of the boom cylinder and lower the boom.

4. If it still will not lower, then loosen the hose at the back end port of the boom cylinder.

BARRETO

MANUFACTURING, INC.

EQUIPMENT

WARRANTY

Barreto Manufacturing, Inc. warrants all BARRETO equipment to be free of defects in material and

workmanship for a period of one (1) year. All BARRETO fuel components, fuel tank, cap, lines &

fittings are warranted for two (2) years. Warranty period begins on date of delivery to the original

user.

This warranty is in lieu of all other warranties, whether written or implied, and is limited to:

1. Replacement of parts returned to the dealer and/or factory and determined defective upon

inspection. (Replacement for parts to dealers shall be at dealer cost plus shipping charges.)

2. Time for pick-up and/or delivery, transportation of service calls by dealers is

excluded. Manufacturer reserves the right to determine reasonable time required for

repair.

Warranty does not apply to damage caused by abuse or neglect. Time and materials required for

normal maintenance and service are also excluded from warranty coverage.

Engines, engine attached fuel tanks, engine accessories, batteries and tires are warranted by the

original manufacturer and are not covered by the Barreto Equipment Warranty.

Wear parts such as dig chains, dig teeth, sprockets, chain rollers, bearings, bushings etc. are

excluded unless it can be determined that a defect has contributed to premature wear.