Table of contents

0 - 1

1 Safety 1-1

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Potential instances of misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Other risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.6 Machine labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.6.1 USA identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.7 Responsibilities of the employer . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.8 Supplementary and operational equipment . . . . . . . . . . . . . . . . . 1-14

1.8.1 SENNEBOGEN CONTROL System (SENCON) . . . . . . . 1-14

1.8.2 Oils and lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.8.3 Diesel fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.8.4 Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.8.5 coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.8.6 Fuel (not for equipment with electric motors) . . . . . . . . . . 1-20

1.9 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

1.9.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

1.9.2 Cleaning work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

1.9.3 Safe entry and exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

1.9.4 Emergency exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

1.9.5 Emergency exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

1.9.6 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

1.9.7 Operation/driving operation . . . . . . . . . . . . . . . . . . . . . . . 1-34

1.9.8 Particle filter regeneration (level 4i) . . . . . . . . . . . . . . . . . 1-35

1.9.9 Setup work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

1.9.10 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

1.9.11 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

1.9.12 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

1.10 Protective features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-42

1.11 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-43

1.12 Hand signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

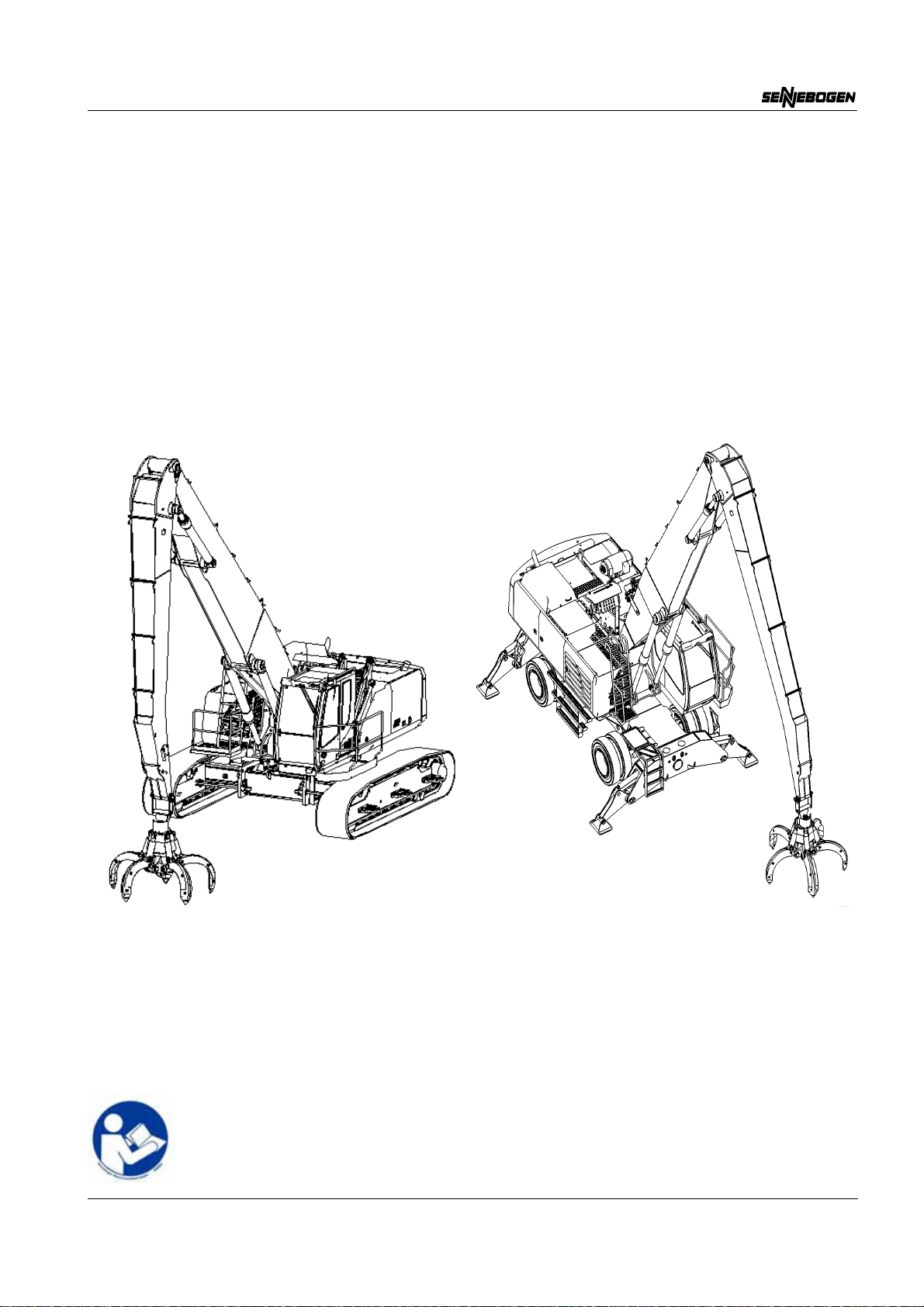

2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Overall machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Overall machine – crawler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Undercarriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.1 4-point outrigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3