- 15 -

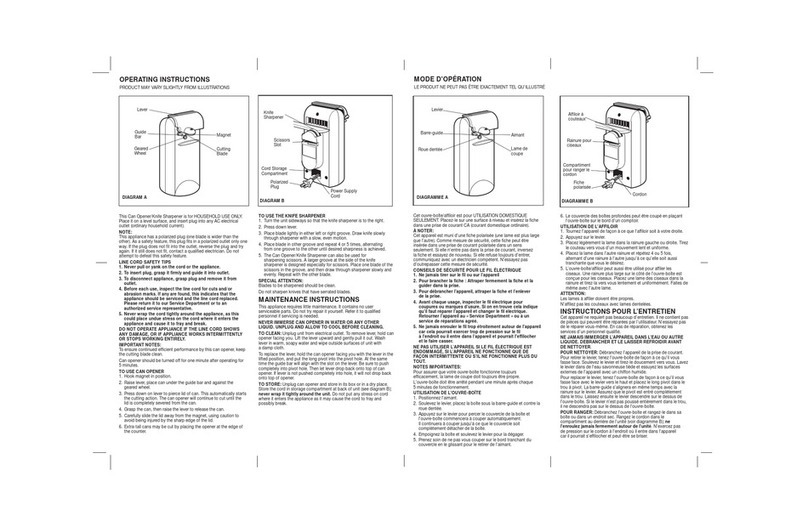

Cleaning

WARNING!

There is a risk of formation of bacteria which may reach the contents of the can

and result in health problems. The can opener must be thoroughly cleaned.

CAUTION!

Do not use any scouring agents that include solvents or corrosive cleaning

agents for cleaning. They may damage the surface.

oRegularly clean the can opener at the end of the working day, or more frequently if

necessary.

oPay particular attention to cleaning of the transport wheel and the stainless steel knife,

because they come into contact with food.

Clean the stainless steel knife and transport wheel with cloth soaked in warm water

with mild cleaning agent. In case of more stubborn dirt, the transport wheel may be

cleaned with a brush for dish washing or a toothbrush. Wipe with a clean cloth to

remove the cleaning agent residues.

oClean other elements of the device with a soft, moist cloth and dry thoroughly or

leave the device to dry in the air.

oIf the device is not used for any lengthy periods, clean it thoroughly as per description

and store (preferably in the original packaging) at the room temperature in dry, clean

place protected against sun and children. Do not place any heavy objects on the

device.

Maintenance

oIn case of intense use of the can opener, the stainless steel knife and transport wheel

may get deformed, therefore they should be regularly checked. If the elements are

worn out, replace them by contacting the service company.

oRegularly inspect the mounting of stainless steel knife, if necessary tighten the

screws.