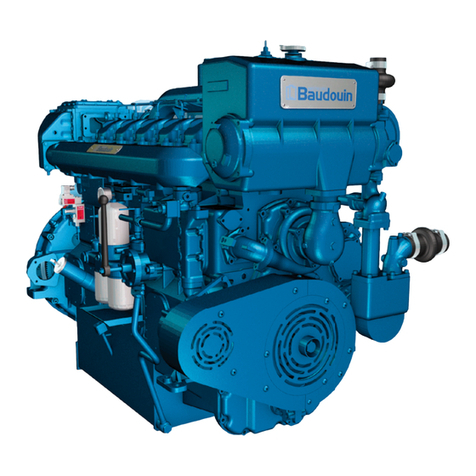

Baudoulin 4M11G User manual

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

MaintenanceManualof4M11SeriesDieselEngineFor

LandPowerGenerators

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

Special Notice

The operator of the diesel engine must carefully read the product service manual of the diesel

engine, strictly abide by the technical operation and maintenance specifications specified in the

product service manual, and notice the warning instructions and signs.

The delivery test was completed for the diesel engine as per the test specification strictly and

the throttle was already limited by lead seal at the time of delivery. It’s prohibited to

disassemble the lead seal to increase the fuel volume.

The turbocharger rotor is a high-speed rotating part. When the machine runs, no moveable

items (like hand, tool, and cotton yarn) are allowed to approach the inlet of turbocharger, so as

to avoid causing damages to personnel or machine; the rotor assembly shall not be

disassembled except for that it is done by professional maintenance personnel or professional

maintenance stations licensed by Weichai;

The strict torque and angle requirements are specified for the main bearing bolts and

connecting rod bolts of the diesel engine. Please do not loosen or disassemble any bolt by self.

The connecting rod bolts are of one-time bolts and can’t be reused.

The oil and fuel added to the diesel engine must be of the designations specified in this service

manual. Dedicated clean filters must be used for the addition. Before addition, the fuel shall

settle for 72 hours. Before driving the vehicle, check that the coolant and oil levels meet the

requirements.

When the user uses a new machine, 50-hour trial running is needed to the machine. After the

run-in period, it is required to replace the engine oil and engine oil filter element.

After the cold start of the diesel engine, slowly increase the engine speed, instead of running at

high speed suddenly or long-term idling (not more than 3min). After the running under heavy

load, run the engine at low speed for 5~10min before stopping the engine, instead of stopping

the engine suddenly (except special cases);

After the engine is stopped, if the temperature of working environment is probably below 0℃

and the coolant without antifreeze additive is used, fully drain the coolant from the water tank

and diesel engine.

It’s prohibited to run the diesel engine without the air filter, in order to prevent the supply of

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

non-filtered air into the cylinders. Under severe working environment, increase the cleaning or

replacement frequency of the air filter element, in order to prevent malfunctions (such as

earlier wear) of diesel engine.

The checking and repair for all parts of the electric system must be fulfilled by the professional

electric technicians.

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

Foreword

This series diesel engine features compact structure, high operation reliability, excellent

power and economy performances, rapid start, simple operations, convenient maintenances,

and advanced emission performance. This service manual is prepared for the extensive users to

rapidly understand and correctly use the 4M11 China-II stationary generator series diesel

engine. The main application scope of this manual includes the engines for stationary

generators, pumps, air compressors, and marine emergency applications.

This manual briefly describes the technical parameters, structural characteristics, operation

and maintenance methods, and service essentials of 4M11 China-II stationary generator series

diesel engine for the user’s reference. Following the continuous development of the product,

the product structure will be subject to improvement and the contents contained in this manual

may become obsolete. For latest product information, the user (or dealer) may access Weichai

website at http://www.weichai.com. Your suggestions and opinions for further improvement of

product are really welcomed.

October, 2015

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

Table of Contents

Chapter I General Information ···································································································1

1.1 Exterior View of Diesel Engine ······················································································1

1.2 Model Meaning of Diesel Engine····················································································3

1.3 Main Specification of Diesel Engine ················································································3

1.4 Unsealing of Diesel Engine ···························································································4

1.5 Hoisting of Diesel Engine·····························································································4

1.6 Assembly of Diesel Engine ···························································································5

1.7 Pre-start Preparations of Diesel Engine ·············································································5

1.8 Start of Diesel Engine ·································································································6

1.9 Running of Diesel Engine·····························································································6

1.10 Stop of Diesel Engine··································································································8

Chapter II Maintenance Guide ···································································································9

2.1 Fuel Oil, Lubricating Oil, Coolant, and Auxiliary Materials for Diesel Engine·······························9

2.1.1 Fuel Oil ······································································································9

2.1.2 Lubricating Oil ·····························································································9

2.1.3 Coolant····································································································· 10

2.1.4 Auxiliary Materials ······················································································ 11

2.2 Routine Maintenance ································································································ 12

2.3 Contents of Maintenance at Each Level ·········································································· 15

2.4 Maintenance for Long-term Storage··············································································· 20

2.4.1 Clean ······································································································· 20

2.4.2 Protection·································································································· 20

Chapter III Typical Faults and Solutions······················································································ 22

3.1 Diagnostic Method ··································································································· 22

3.2 Diesel Engine General Fault and Troubleshooting ······························································ 23

3.2.1 Start Failure or Difficult Start of Diesel Engine ····················································· 23

3.2.2 Unstable Running of Diesel Engine ··································································· 24

3.2.3 Low Power of Diesel Engine ··········································································· 24

3.2.4 Abnormal Oil Pressure of Diesel Engine ····························································· 25

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

3.2.5 Diesel Engine Overheating ············································································· 25

3.2.6 Abnormal Exhaust Gas Color of Diesel Engine ····················································· 26

3.2.7 Diesel Automatic Parking ··············································································· 27

3.2.8 Abnormal Sound during Running of Diesel Engine················································· 27

Chapter IV Disassembly and Assembly of Engine ·········································································· 29

4.1 Overview ·············································································································· 29

4.1.1 Danger Sign ······························································································· 29

4.1.2 Safety Sign ································································································ 30

4.1.3 Used Tools································································································· 31

4.1.4 Precautions for Health Protection······································································ 31

4.1.5 Environmental Protection Measures··································································· 32

4.1.6 Precautions on Disassembly and Assembly of Engine·············································· 32

4.2 Cylinder Head Group ································································································ 34

4.2.1 Disassembly and Assembly of Cylinder Head ······················································· 34

4.2.2 Disassembly, Inspection, Repair, and Assembly of Cylinder Head Group······················· 36

4.2.3 Disassembly, Inspection, Repair, and Assembly of Cylinder Head ······························· 37

4.2.4 Disassembly, Inspection, Repair, and Assembly of Oil-gas Separator···························· 41

4.2.5 Disassembly, Inspection, Repair, and Assembly of Lifting Ring·································· 42

4.3 Engine Block Group ································································································· 43

4.3.1 Disassembly, Inspection, Repair, and Assembly of Engine Body Combination Group ········ 43

4.3.2 Disassembly, Inspection, Repair, and Assembly of Body Components ·························· 46

4.3.3 Disassembly, Inspection, Repair, and Assembly of Front Wall Cover···························· 48

4.3.4 Disassembly, Inspection, Repair, and Assembly of Flywheel Cover ····························· 50

4.3.5 Disassembly, Inspection, Repair, and Assembly of Oil Pan········································ 52

4.3.6 Disassembly, Inspection, Repair, and Assembly of Piston Nozzle ································ 53

4.3.7 Disassembly, Inspection, Repair, and Assembly of Thrust Halfring ······························ 54

4.3.8 Disassembly, Inspection, Repair, and Assembly of Front and Rear Oil Seal ···················· 55

4.4 Crank Connecting Rod Mechanism················································································ 57

4.4.1 Disassembly and Assembly of Crank Connecting Rod Mechanism ······························ 57

4.4.2 Disassembly, Inspection, Repair, and Assembly of Piston Connecting Rod Group ············ 58

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

4.4.3 Disassembly, Inspection, Repair, and Assembly of Crankshaft···································· 61

4.4.4 Disassembly, Inspection, Repair, and Assembly of Flywheel and Ring Gear ··················· 63

4.4.5 Disassembly, Inspection, Repair, and Assembly of Torsional Damper, Belt Pulley and Hub · 64

4.4.6 Disassembly, Inspection, Repair, and Assembly of Crankshaft Bearing Shell ·················· 65

4.4.7 Disassembly, Inspection, Repair, and Assembly of Secondary Balance Mechanism··········· 66

4.5 Valve Mechanism ···································································································· 68

4.5.1 Disassembly and Assembly of Valve Mechanism ··················································· 69

4.5.2 Disassembly, Inspection, Repair, and Assembly of Camshaft and Timing Gear ················ 70

4.5.3 Disassembly, Inspection, Repair, and Assembly of Rocker Arm and Rocker Arm Shaft ······ 73

4.5.4 Disassembly, Inspection, Repair, and Assembly of Tappet and Push Rod ······················· 75

4.5.5 Disassembly, Inspection, Repair, and Assembly of Valve ·········································· 76

4.5.6 Disassembly, Inspection, Repair, and Assembly of Intermediate Gear ··························· 77

4.6 Intake and Exhaust System ························································································· 78

4.6.1 Disassembly and Assembly of Intake and Exhaust System ········································ 79

4.6.2 Disassembly, Inspection, Repair, and Assembly of Intake Pipe ··································· 80

4.6.3 Disassembly, Inspection, Repair, and Assembly of Exhaust Pipe ································· 81

4.6.4 Disassembly, Inspection, Repair, and Assembly of Turbocharger System ······················· 82

4.7 Fuel System ··········································································································· 86

4.7.1 Disassembly and Assembly of Fuel System ·························································· 86

4.7.2 Disassembly, Inspection, Repair, and Assembly of Injection Pump ······························ 87

4.7.3 Disassembly, Inspection, Repair, and Assembly of High-pressure Oil Pipe ····················· 89

4.7.4 Disassembly, Inspection, Repair, and Assembly of Fuel Injector ································· 90

4.7.5 Disassembly, Inspection, Repair, and Assembly of Engine Oil Filter ···························· 91

4.7.6 Disassembly, Inspection, Repair, and Assembly of Low-pressure Oil Pipe ····················· 92

4.8 Cooling System······································································································· 92

4.8.1 Disassembly and Assembly of Cooling System ····················································· 92

4.8.2 Disassembly, Inspection, Repair, and Assembly of Water Pump ·································· 94

4.8.3 Disassembly, Inspection, Repair, and Assembly of Thermostat ··································· 95

4.8.4 Disassembly, Inspection, Repair, and Assembly of Fan ············································ 96

4.9 Lubrication System ·································································································· 97

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

4.9.1 Disassembly and Assembly of Lubrication System ················································· 97

4.9.2 Disassembly, Inspection, Repair, and Assembly of Oil Pump ····································· 98

4.9.3 Disassembly, Inspection, Repair, and Assembly of Engine Oil Filter ···························· 99

4.9.4 Disassembly, Inspection, Repair, and Assembly of Oil Cooler ···································100

4.9.5 Disassembly, Inspection, Repair, and Assembly of Main Oil-way Pressure Control Valve ··101

4.9.6 Disassembly, Inspection, Repair, and Assembly of Oil Suction Filter···························102

4.10 Starting System ······································································································103

4.10.1 Disassembly, Inspection, Repair, and Assembly of Starter········································103

4.11 Vehicles Accessories System ······················································································104

4.11.1 Disassembly, Inspection, Repair, and Assembly of Alternator····································104

Appendix A Fit Clearances for Main Parts of Diesel Engine ·····························································111

Appendix B Wear Evaluation References for Main Friction Pairs in Diesel Engine ··································112

Appendix C Tightening Torques for Main Bolts············································································114

Appendix D Recommended Torques for Other Standard Bolts···························································115

Appendix E Assembling Torques for Hollow Bolts ················································· 错误!未定义书签。

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

1

Chapter I General Information

1.1 Exterior View of Diesel Engine

Figure 1-1 Exterior View of 4M11 Diesel Engine

Figure 1-2 Intake and Exhaust Side of 4M11 Diesel Engine

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

2

Figure 1-3 Flywheel End of 4M11Diesel Engine

Figure 1-4 Fan End of 4M11Diesel Engine

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

3

1.2 Model Meaning of Diesel Engine

1.3 Main Specification of Diesel Engine

Table 1-1 Main Specification of 4M11 Diesel Engine

Item Unit Model

Engine type 4M11G

Engine type —

Four-stroke, water-cooling, in-line, direct-injection, wet-type

sleeve, high-speed diesel engine

Intake type — Turbochargerd Turbochargerd and inner-cooling

Displacement L 4.5

Bore × Stroke mm×mm 105×130

Number of cylinders — 4

Valve number of per cylinder — 2

Compression ratio — 18:1

Ignition Sequence — 1-3-4-2

Fuel injector — Mechanical pump

Emission level — Non-road stage II

Fuel consumption at rated power g/(kW·h) ≤250

Minimum fuel consumption under

full-load condition

g/(kW·h) ≤215

Cold starting-without auxiliary ℃-10

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

4

starter

Cold starting-with auxiliary starter ℃-30

Noise at 1m reach dB(A) ≤115

B10Lifetime km 500,000

1.4 Unsealing of Diesel Engine

After the diesel engine is unpacked, the user shall firstly count the diesel engine and its

accessories as per the delivery packing list, check the exterior of diesel engine for presence of

damage and the connectors for presence of looseness, and then fulfill the following works:

(1) Wipe the anti-rusting layer and anticorrosive agent on the exposed parts.

(2) Drain the sealing oil from the inside of fuel filter and the parts of fuel system (It’s

allowed to start the engine without draining the sealing oil from the fuel system. However, it’s

permitted to run the engine under loaded condition only when the sealing oil in the fuel system is

used up and the diesel is supplied to the engine). But the user should pay attention that the oil

sealing period for diesel engine is one year. At the expiration of one year, conduct checking and

take necessary supplemental measures.

(3) Check the water plug and oil plug for presence of blockage, check for completeness of

water temperature and oil temperature sensors, and ensure that all parts to be self-provided are

completely fitted.

Notice: Do not start the diesel engine before it’s correctly assembled and connected to the

final position. When the diesel engine is running in an enclosed environment, keep well ventilated

to ensure that the exhaust gas is drained to the open air.

1.5 Hoisting of Diesel Engine

During the hoisting, maintain level the centerline of engine crankshaft. It’s prohibited to

hoist in tilted or unidirectional manner. Hoist up and down slowly. The incorrect hoisting will

damage the diesel engine during hoisting.

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

5

a) b)

Figure 1- 1Hoisting Diagram of Diesel Engine

Every diesel engine is fitted with two special cylinder head bolts for hoisting of diesel

engine. The end face of the hexagon head of these bolts has a M14 screw and a lifting eye is

assembled on this screw. During the hoisting, it’s recommended to use the slings shown in

figure a) of Figure 1-4. Keep the crankshaft of diesel engine level during the hoisting. If the

slings are not on one same line with the cylinder head bolts or lifting eyes, the cylinder head

bolts will be damaged or even broken during hoisting to damage the diesel engine. Therefore,

it must be especially cautioned by the user.

1.6 Assembly of Diesel Engine

Adopt the flexible connections and ensure that the crankshaft centerline of the diesel

engine is coaxial with the axis of input shaft of drive unit (gearbox, transmission, or

alternator) and ensure that the crankshaft is free of additional axial force due to assembly.

1.7 Pre-start Preparations of Diesel Engine

(1) Check the coolant level

If the engine is already assembled on a machine, observe the coolant level. If the coolant

is insufficient, add coolant through the filler port cap. The filler cap is equipped with a

pressure relief valve and a bleeding button. Before opening the filler cap, press the bleeding

button to open the cap in the case of a hot engine. If the diesel engine remains hot, do not add

a great deal of coolant. Dramatic temperature change could cause damage to the parts. Start

the engine. While the engine is running (1,000 r/min), continue to add the coolant to specified

location, till the coolant level is stable, and finally assemble the filler port cap.

(2) Check the fuel level

With the engine assembly on the complete machine, turn on the power supply switch,

True False

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

6

and check fuel level from the fuel gauge or check the fuel tank.

(3) Check the engine oil level

The engine oil level shall be between upper and lower markings of the oil dipstick. If

necessary, add engine oil through the engine oil filler port.

(4) Check all accessories of diesel engine for reliable connections and solve any

abnormal phenomenon. Check the starter system for normal wiring and check and

ensure that the battery is sufficiently charged. Open the valve fuel tank. Loosen the

bleeding screw of the fuel coarse filter. By operating the manual pump, bleed air

from the fuel coarse filter.

1.8 Start of Diesel Engine

Adjust the throttle of the diesel engine to an appropriate position. If the environmental temperature is

≤5ºC, the opening extent of the throttle can be increased appropriately. Press the starter button to start the

engine. To prevent the damage of starter motor, do not run the starter motor continuously

for >15s. If the diesel engine fails to start in 15s, wait for 2min before retry. If the engine

can’t be started by three consecutive attempts, stop the attempt and find out and solve the

malfunction before retry.

After the start of diesel engine, observe the readings of the instruments and keep the

engine idling. In such case, the engine oil pressure shall be no less than 120kPa. Do not idle

the engine for a long time.

The auxiliary starter shall be used to start the diesel engine under cold temperature. By

running the electric heating device via intake, the engine can start successfully under -30ºC

environment.

1.9 Running of Diesel Engine

After the start of diesel engine, idle the engine for (2~3) min. The engine oil pressure

shall be higher than 120kPa. When the coolant temperature is less than 60ºC, do not run the

engine immediately at high speed under heavy-load, otherwise the wear resistance and

reliability of the engine will be impaired. Apply load and increase the speed gradually. Avoid

the sudden loading and unloading whenever possible.

In the run-in period (3000km), the diesel engine is better to run under a moderate load.

Normally the diesel engine can continuously run with rated output and rated speed. The

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

7

diesel engine may not run for more than 20 minutes at the speed 105% the rated speed or the

output 110% the rated output. After the unloading, idle the diesel engine for (1~2) min before

stop.

Parameters and checking locations to be observed at all times during operations are as

below:

(1) Engine oil pressure (300~600) KPa (Idle speeds ≥120kPa);

(2) Engine oil temperature (85~105)℃;

(3) Outlet temperature of coolant (80~90)℃;

(4) Exhaust temperature after turbine ≤550℃

(5) Diesel inlet temperature : 35~41 ℃

(6) Check the exhaust fume color, to estimate the performances of the injectors and the

load of the engine. If the color of exhaust gas is black, stop and check the engine.

Note: During the diesel engine operation, check the engine for presence of water, air, and

fuel leakages. If any, stop the engine for troubleshooting.

The operator shall understand the following characteristics of diesel engine:

The power output of the engine increases along with the increasing of the speed and reaches

rated value at the rated speed.

Notice: To prevent damaging the diesel engine, it’s prohibited to disconnect the cable to

the diesel engine voltage regulator or to the positive terminal of battery while the engine is

running. Differing from DC generator, it’s prohibited to temporarily ground an alternator for

voltage checking.

Notice the following items while the diesel engine is running in cold regions:

(1) Fuel: Choose diesel of different trademarks depending on the environmental temperature

in winter.

(2) Lubricating oil: Choose lubricating oil of different viscosities depending on the seasons.

(3) Coolant: Add antifreeze additive into the cooling system and choose the coolant of

different trademarks and quantities depending on the ambient temperature.

(4) Start: The auxiliary starter can be adopted if necessary in winter. After the start of the

diesel engine, wait for the oil pressure and water temperature to turn normal before

running at high speed under loaded condition.

(5) Before the approach of the cold season, make sure to check the level and viscosity of

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

8

electrolyte and unit voltage of the battery. If the diesel engine is not to be used for a

long time and is under extremely low temperature, disassemble the battery and store in

a warm indoor place.

(6) Stop: To stop the engine under cold weathers, unload the engine, idle the engine for

(1~2) min, and wait for all the temperature to cool down before stop. Please be noted

that it’s disallowed to drain the coolant containing antifreeze additive after the stop of

the engine. If the coolant contains no antifreeze additive, make sure to open the water

drainage valves or water plugs on the engine block, oil cooler cover, radiator, and

water inlet pipe to fully drain the coolant, in order to prevent the frozen cracking of the

engine.

1.10 Stop of Diesel Engine

Avoid the stop of engine under full load. Before stopping the engine, reduce the load and

speed and run the engine under idling or low-load condition for 3~5min. This is intended to

cool down the piston, cylinder sleeves, bushings, shaft sleeve, and turbocharger for a

sufficient time, in order to prevent the cylinder scuffing and bushing scratch. This is

especially important for a turbocharged diesel engine. The bearings and oil seals in the

turbocharger are subject to the influence of the high temperature exhaust gas. This heat is

carried away by the circulating engine oil during the running of the diesel engine. If the diesel

engine is stopped suddenly, the turbocharger temperature will increase remarkably to cause

overheating, which will lead to seizure of bearings or failure of oil seals.

Rotate the key switch to position “OFF” or press the stop button to stop the engine, till

the flywheel stops rotation or the speed indication on the instrument panel is zero.

If the diesel engine circulating coolant is not added with antifreeze, ensure to drain the

coolant after stop in cold days, in order to prevent the frozen damage of diesel engine. The

water drainage valve is located beneath the engine oil cooler. Rotate the water drainage valve

switch to drain the water from diesel engine. In addition, disassemble the water drainage plug

from the radiator to drain the coolant from the radiator.

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

9

Chapter II Maintenance Guide

2.1 Fuel Oil, Lubricating Oil, Coolant, and Auxiliary Materials for Diesel Engine

2.1.1 Fuel Oil

Summer: 0# diesel (GB 252)

Winter: generally -10# diesel fuel shall be used; however, -20# diesel fuel shall be used

if ambient temperature is lower than -15ºC.

-35# diesel fuel shall be used if ambient temperature is lower than -30ºC.

The fuel used must conform to the requirements in section D.1 of Appendix D to

national standard GB20891-2007.

2.1.2 Lubricating Oil

The capacity of diesel engine lubricating is 9.8L, depending on the marking of the oil

dipstick (The oil capacities vary depending on different models).

For Weichai Power non-road phase-II series diesel engines, CF-4 grade engine oil shall be used.

For details, refer to Table 2-1.

Table 2-1 Selection Specification of Weichai Special Engine Oil

Variety Product category

Packing

specification

Applicable model

Diesel

engine oil

CF-4

10W/30

15W-40

20W-50

4L, 18L,

170kg

National II diesel engine: WD615,

WD10, WD618, WD12, WP6 non-road

Stage-II series, etc.

Choose the viscosity of Weichai special engine oil based on the temperature, with reference to Table

2-2.

Table 2- 2 Relationship Table between Viscosity and Environmental Temperature

SAE viscosity grade

Applicable environmental

temperature (ºC)

0W-20 -35-20

5W-30 -30-30

10W-30 -25-30

15W-40 -20-40

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

10

20W-50 -15-45

Note:

1) Before starting the diesel engine, ensure to check the engine oil level within oil pan.

2) Do not check the oil level while the diesel engine is running.

3) Never mix special engine oil of Weichai Power with engine oils of other manufacturers.

For the added volumes of engine oil and numbers of filters of Weichai Power engines. See Table 2-3.

Table 2- 3 Added Volumes of Engine Oil and Numbers of Filters of Weichai Power Engines

Model

Added

volume of

engine oil

(L)

Number of filters

Diesel engine

Engine oil

filter

Diesel filter

Coarse filter Fine filter

4M11 9~12 1 1 1

Remark:

1) The added volumes listed in the table are only for reference. Actual

added volumes shall be decided with the oil dipstick.

2) If the vehicle is equipped a highly-cold-resistant filter or

moisture-removing filter as developed by Weichai Power, they shall also

be replaced when the fuel is replaced.

2.1.3 Coolant

The freezing point specification for Weichai special coolant includes -25ºC, -35ºC, and

-40ºC. Please choose Weichai special coolant of different freezing points based on the local

environmental temperature in such manner that the freezing point is less than local air

temperature by approximately 10ºC, with reference to Table 2-4.

Table 2- 4Weichai Special Heavy-duty Engine Coolant

Variety Product category

Packing

specification

Heavy-duty

engine coolant

HEC-Ⅱ-25

HEC-Ⅱ-35

4kg,10kg

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

11

HEC-Ⅱ-40

Note:

1) Make sure to periodically check the coolant and, to prevent the corrosion and damage,

timely replace depending on actual situation.

2) It’s prohibited to use water or low quality coolant as the engine coolant.

2.1.4 Auxiliary Materials

Table 2-5 Auxiliary Materials

SN. Name Color Purpose and location

1 MolykotePulver Black

Applied on flat and smooth metal surfaces to prevent seize

For example, applied onto outer surfaces of cylinder liners

2 Molykote G-N plus Dark grey

Lubrication before the lubricating oil pressure builds up.

For example, applied onto the intake valve stem

Table 2-6 Reference Table for Sealant Application of Diesel Engine

Mark Main use

List of locations for application of

sealant Supplement

Loctite 242

It’s applied onto the

threads to prevent being

vibrated to looseness, with

moderate strength.

Flywheel cover bolt

Camshaft thrust halfring bolt

Camshaft timing gear bolt

Intermediate idler bolt

Front end cover bolt

Engine oil filter base bolt

Oil cooler bolt

Screw plug, control valve, engine

oil cooler,

Bolt, fuel return pipe fixing device,

fuel pump,

Air compressor shaft end thread

Suction filter bolt

Bolts of sensor and harness fixing

device

Alternatively, the thread

pre-application sealant

DriLoc204 can be

pre-applied.

Loctite 262

Applied onto outer threads

for locking, sealing,

preventing vibration from

causing looseness

Auxiliary bolt, cylinder head

Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

12

Loctite 271 Preventing looseness,

fixing Cup plug, oil drain hole

Loctite 277 For sealing between

element and bore Other cup plug

Loctite 270 Sealing cylinder head top Push rod -cylinder head

Loctite 518

(modified from

Loctite 510)

It’s applied onto shining

metal surfaces for sealing

purpose.

Plates connecting engine body

front end face to front end cover,

and connecting engine body rear

end face to flywheel cover

Interface between water pump rear

cover and engine body front end

face

Interface between flywheel cover

and its connecting plate

Interface between cylinder block

and engine oil cooler cover

Interface between cylinder block

and engine oil filler cap cover

Loctite

KB5910

Junction surface between oil sump

and engine block

2.2 Routine Maintenance

Check the coolant level and temperature.

Observe the coolant level through glass sight hole. If the coolant is insufficient, open the

filler port cap and add coolant.

Note: While opening the filler port cap, make sure to push down the air bleeding button,

in order to prevent the coolant from causing personal injuries under hot state of engine.

Table of contents

Other Baudoulin Engine manuals

Popular Engine manuals by other brands

Briggs & Stratton

Briggs & Stratton 300 series Operator's manual

Fiamma

Fiamma 06536-01T Installation and usage instructions

Siemens

Siemens SIMOTICS S-1FG1 operating instructions

FIALA MOTORS

FIALA MOTORS FM170B2-FS manual

DELTA DORE

DELTA DORE TYMOOV 30FB manual

LinMot

LinMot P01-48-HP-SSCP installation guide