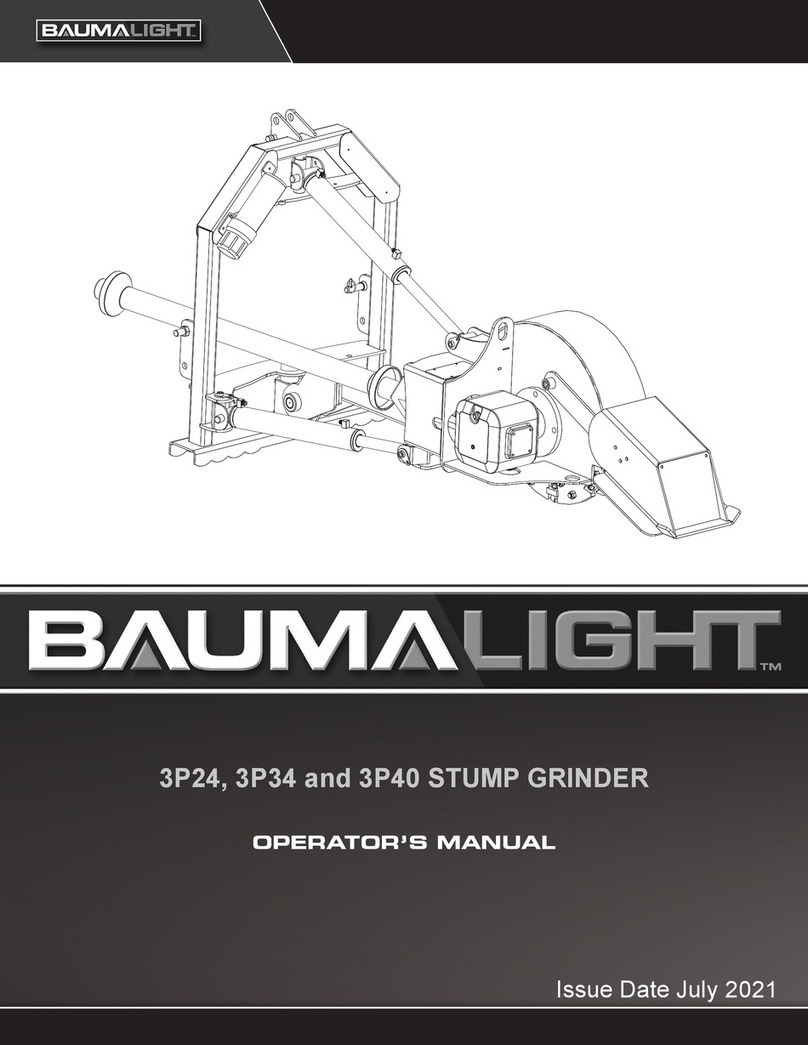

1. INTRODUCTION

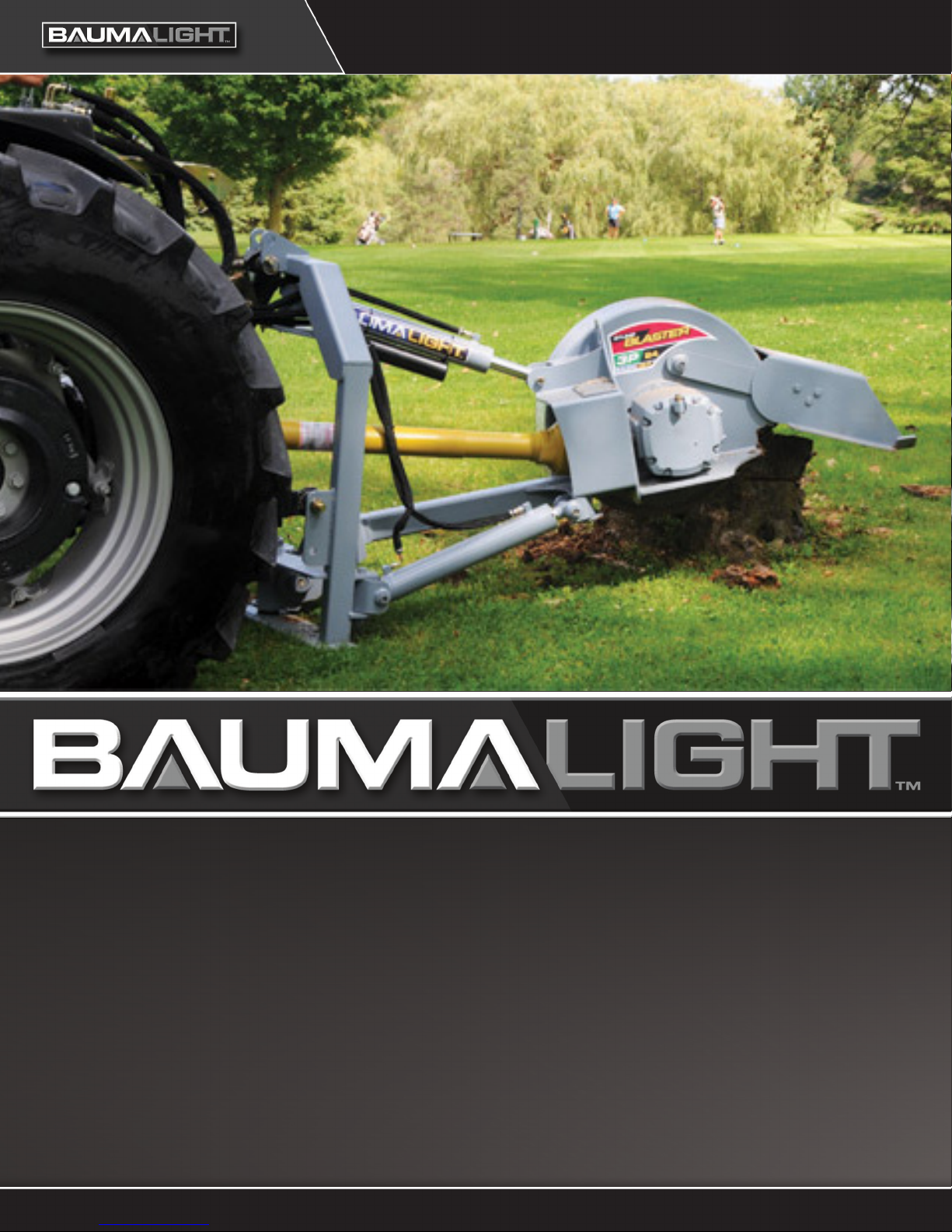

Congratulations on your choice of a Baumalight

3-Point Stump Grinder to complement your stump

grinding operation. This equipment has been

designed and manufactured to meet the needs

of a discriminating buyer for efcient grinding of

stumps.

Model 3P24 has 34 teeth on a 24 in. cutter and

models 3P34 and 3P40 have 54 teeth on a 34

in. cutter. This means less cutting for each tooth

resulting in longer tooth life and smoother cutting

for less wear on the tractor. Heavy tooth population

makes ner mulch and smoother operation.

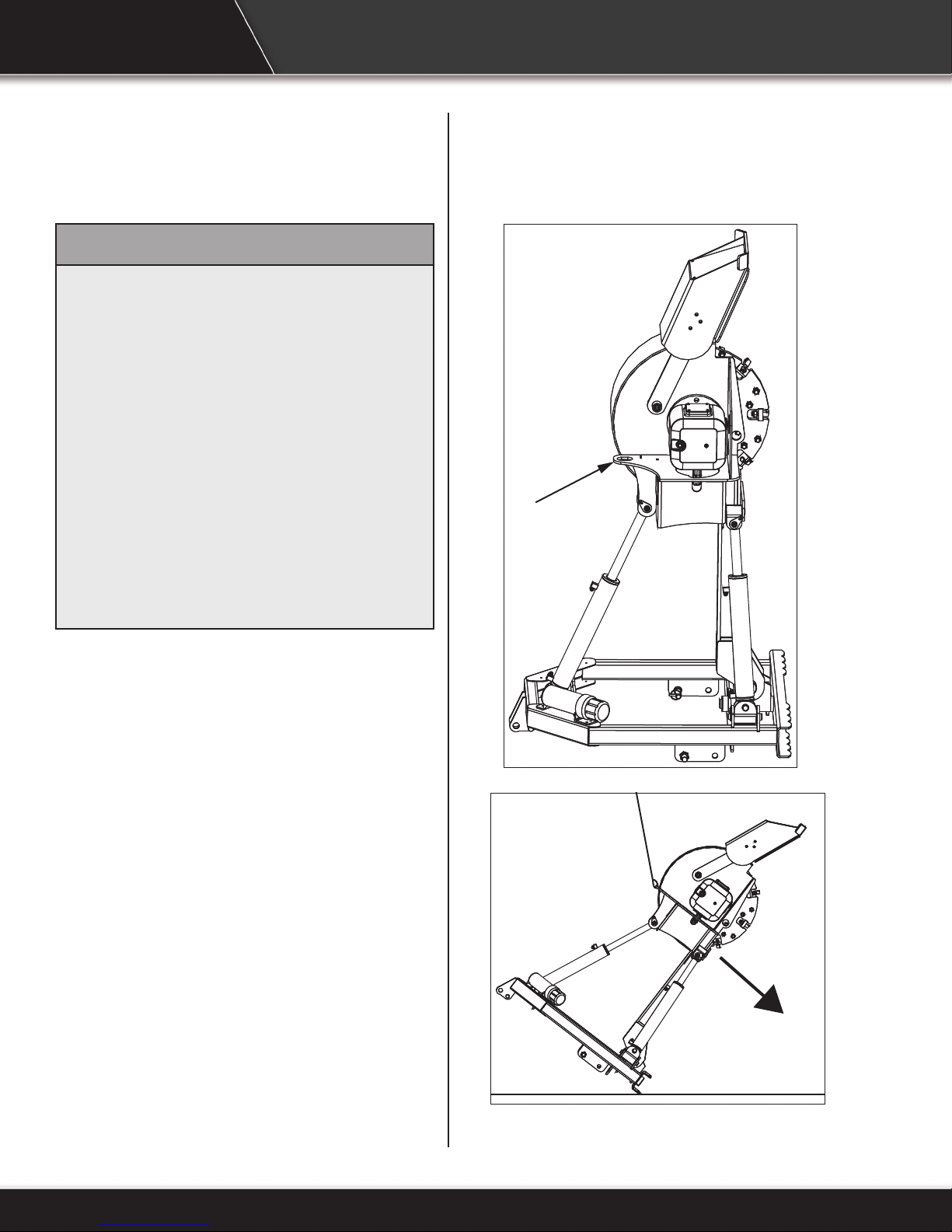

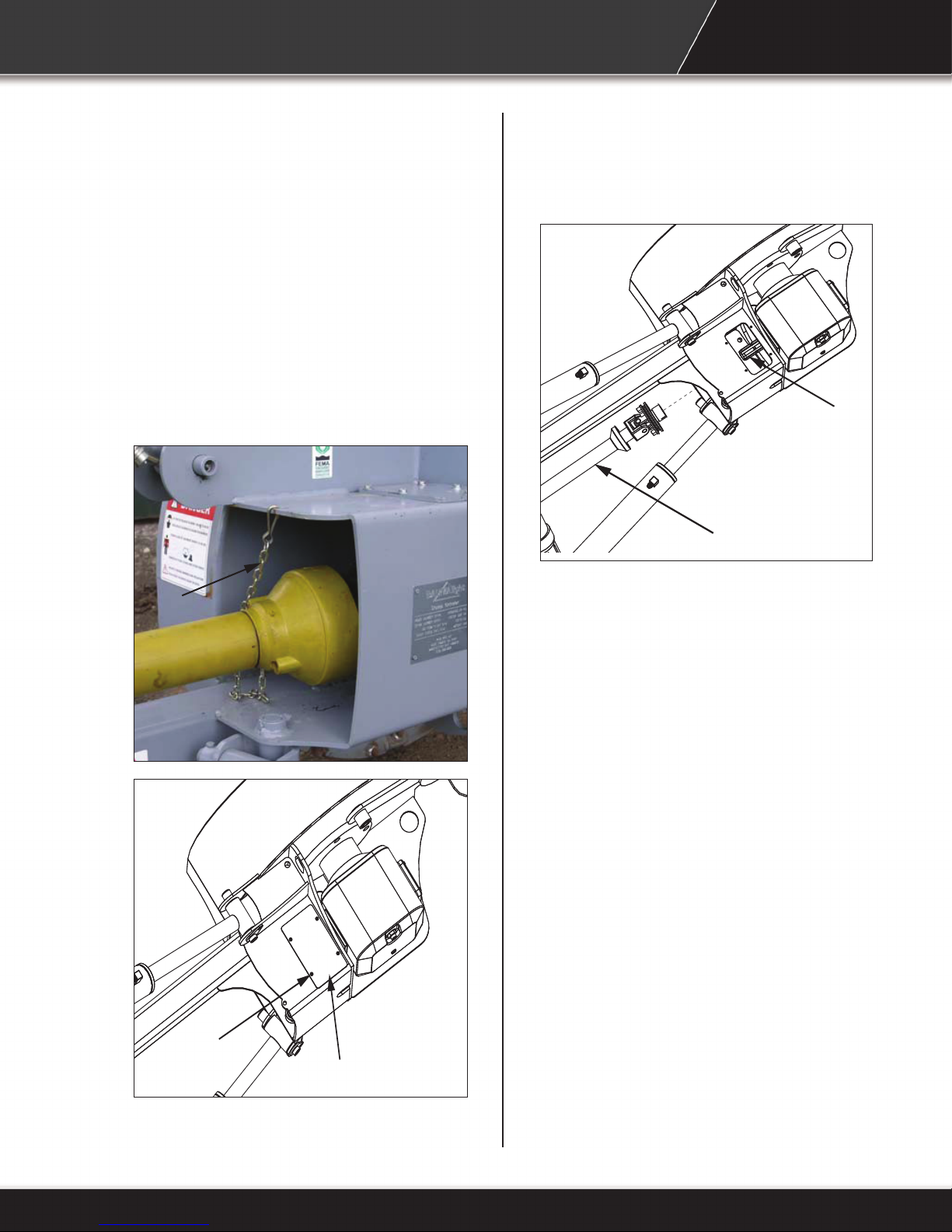

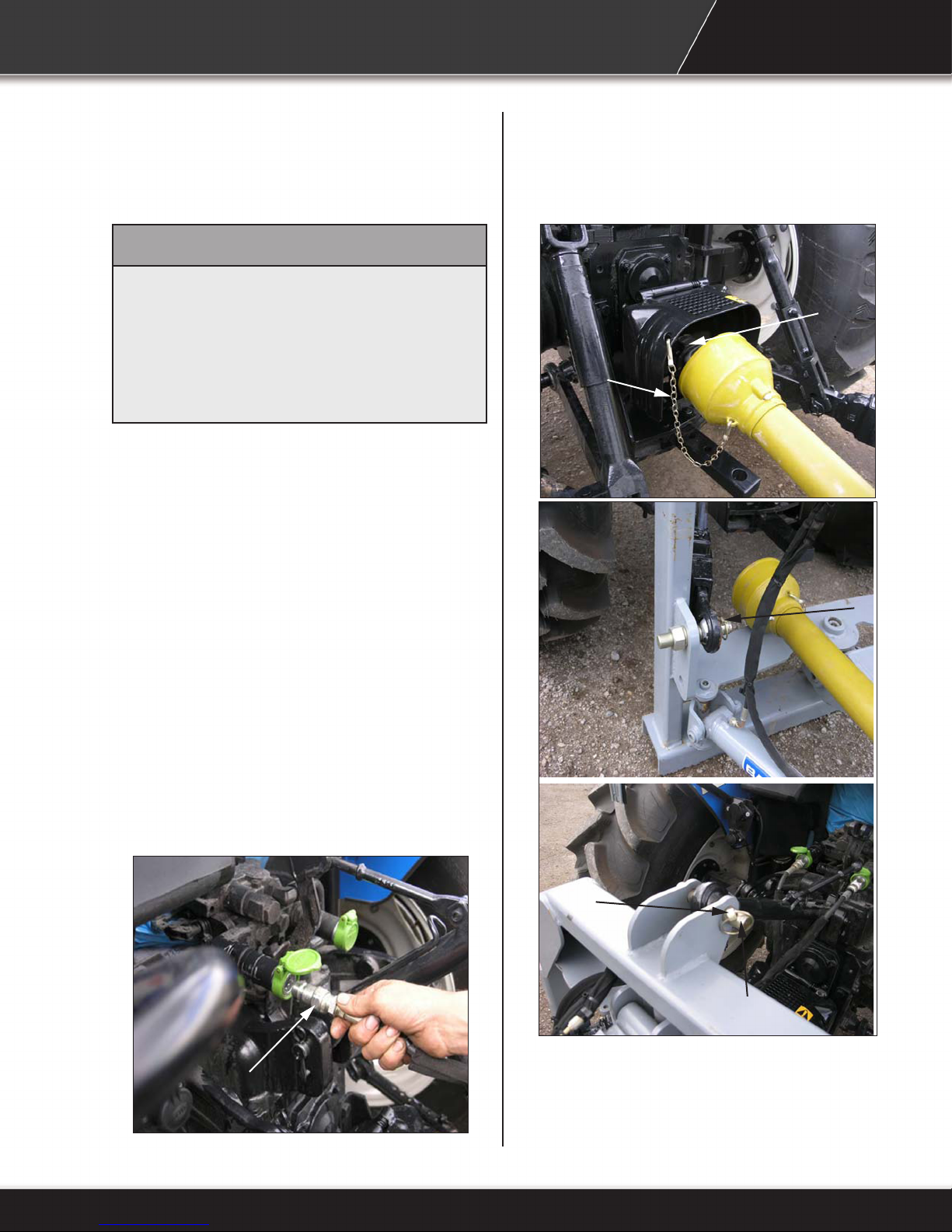

The cutting wheel is powered by the PTO (540)

on your tractor with the swing and lift cylinders

activated by the standard remote hydraulic

connectors on the tractor.

Grease zerks and replaceable brass bushings are

provided at major pivot points for extended service

life.

The debris shields is standard equipment on all

stump grinders. It is recommended that the stump

grinder never be operated without one.

Safe, efcient and trouble free operation of your

Stump Grinder requires that you and anyone

else who will be operating or maintaining the

Stump Grinder, read and understand the Safety,

Operation, Maintenance and Troubleshooting

information contained within the Operator’s

Manual.

This manual covers the Baumalight 3-Point Stump

Grinder, models 3P24, 3P34 and 3P40. Use the

Table of Contents as a guide to locate required

information.

Keep this manual handy for frequent reference

and to pass on to new operators or owners. Call

your Baumalight dealer, distributor or the factory

if you need assistance, information or additional

copies of the manuals.

1.1 Overview

When this machine is worn out and no longer in

use, it should be returned to the retailer or other

party for recycling.

OPERATOR ORIENTATION - The directions left,

right, front and rear, as mentioned throughout this

manual, are as seen from the tractor driver’s seat

and facing in the direction of travel.

1.2 Intended Use And Foreseeable

Misuse

The stump grinding tool is designed to be used

by experienced operators, trained in the safe

operation of a tractor and trained in the hazards

related to using the stump grinder and the safe use

of the grinder for the intended purpose. Operators

will require personal protective equipment to

reduce the risk from some hazards that cannot be

completely eliminated or controlled by the design

of the tool.

Each model in the family is intended to be used

within the stump size limits shown in the catalog

and in the implement specications in the manual.

Care is required to ensure that the stump grinding

tool will not come across metallic objects, stones

or other materials harder than a typical stump

while grinding.

The Stumpblaster stump grinding tools are not

designed for use in hazardous atmospheres

where there is a risk of re or explosion due to

ammable gases or vapors. Use in hazardous,

explosive atmospheres is prohibited.

Serious injury or death of the operator or

bystanders may be caused if the tool is misused.

Misuse may also cause damage to the tractor

carrying the implement.

1