2V1.2 | 14/03/2022 | 11700928

Table of Contents

1. General Information ................................................................................................. 3

2. General Safety Instructions..................................................................................... 5

3. Housing Set Models ................................................................................................. 6

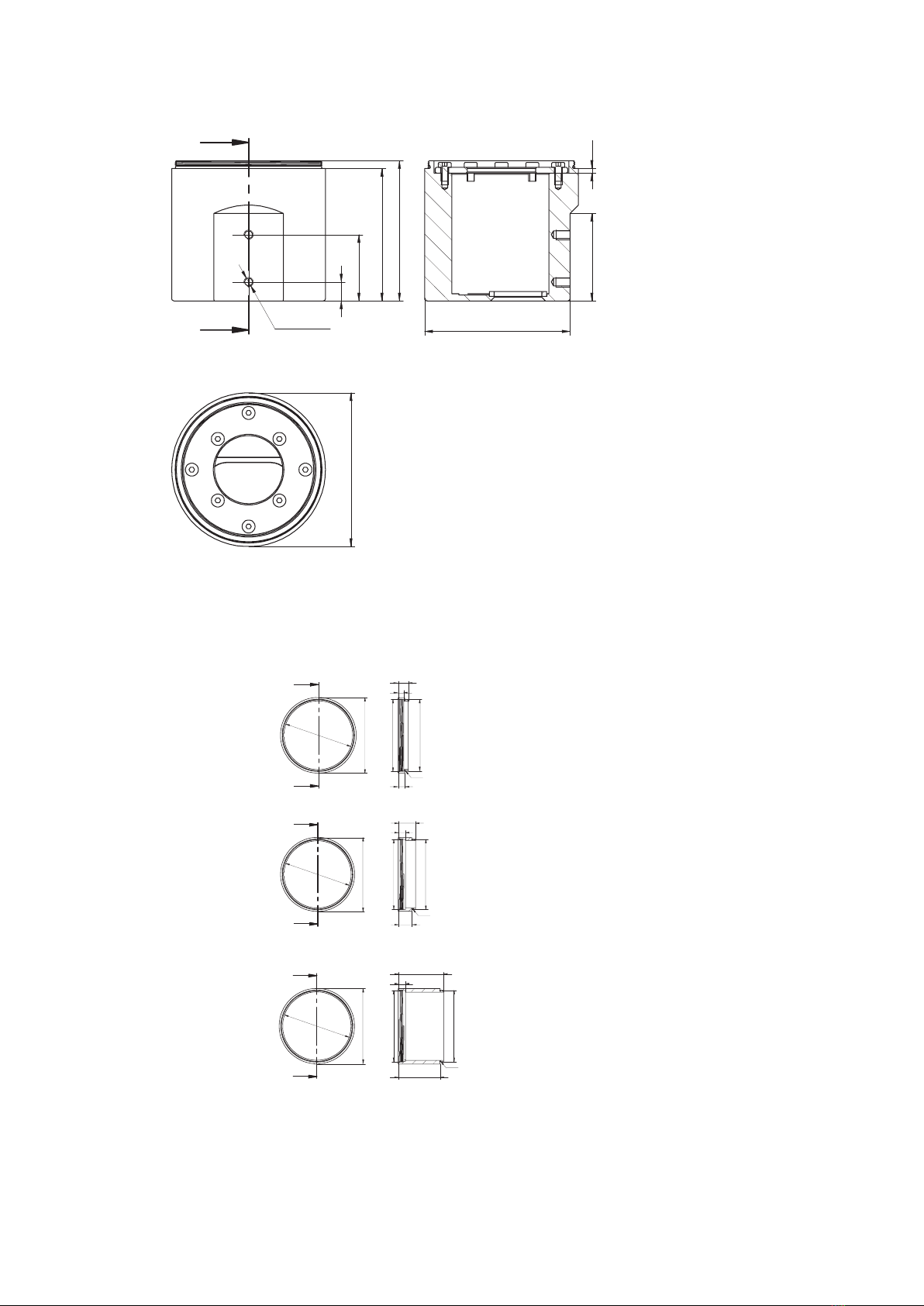

3.1 Housing Base Set A VCXG.I r IP65/67 HA.............................................................. 6

3.1.1 Environmental Requirements ........................................................................... 9

3.1.2 Tube assembly ................................................................................................. 9

3.2 Housing Base Set B V4A VCXG.I r IP69K .............................................................11

3.2.1 Environmental Requirements ......................................................................... 13

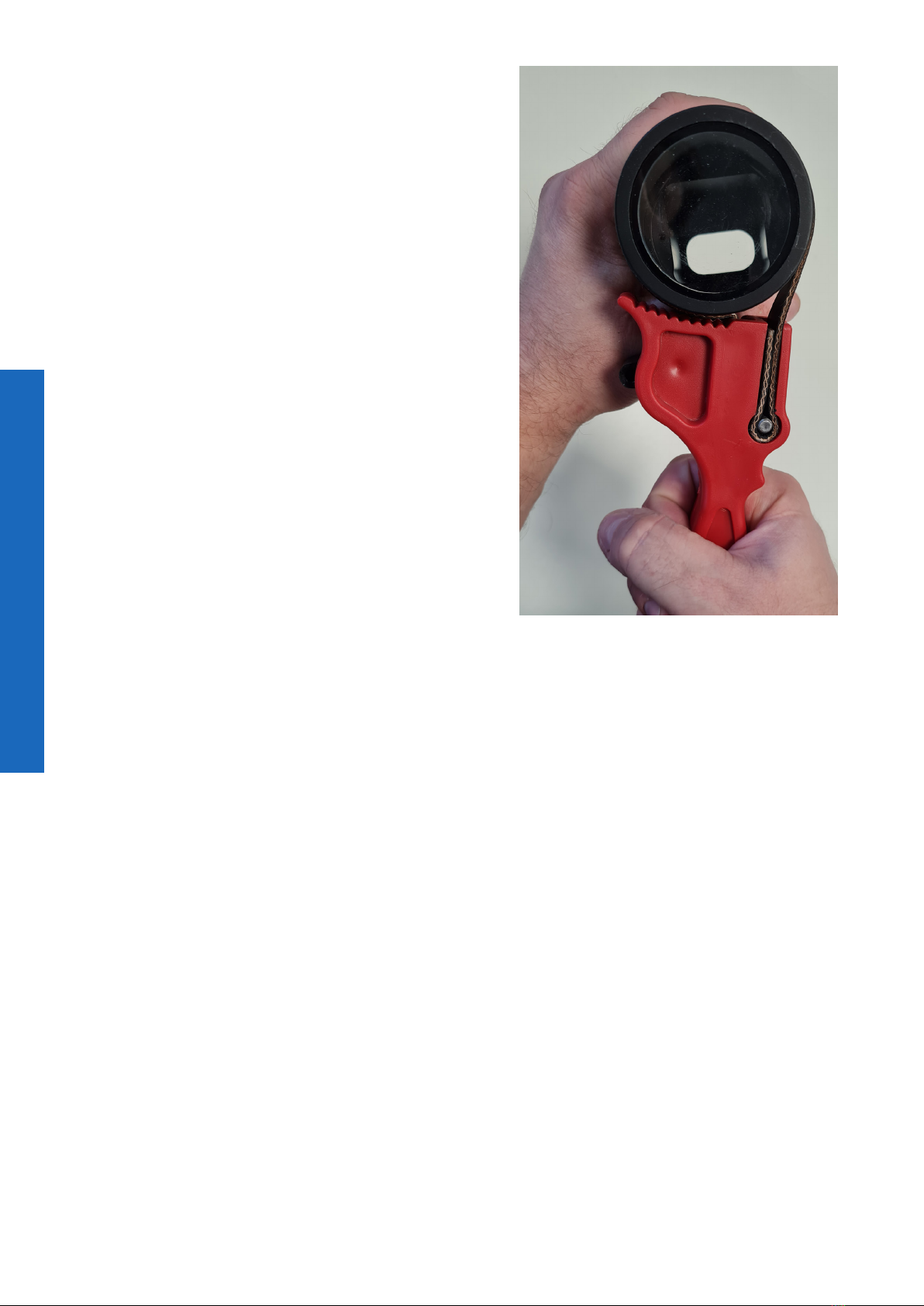

3.2.2 Clamp elements assembly ............................................................................. 14

3.2.3 Cable gland .................................................................................................... 17

3.2.4 Rear wall assembly ........................................................................................ 19

3.2.5 Tube assembly ............................................................................................... 22

3.2.6 Approved cables............................................................................................. 23

3.3 Housing Base Set C V4A VCXG.I r IP65/67 ......................................................... 24

3.3.1 Environmental Requirements ......................................................................... 28

3.3.2 Tube assembly ............................................................................................... 29

4. IP rating and chemical resistance ........................................................................ 30

4.1 IP Protection Classes (EN 60529) ........................................................................ 30

4.2 Chemical resistance of sealing materials.............................................................. 31

4.2.1 EPDM, TPE .................................................................................................... 31

4.2.2 Flouroprene®XP............................................................................................. 32

4.2.3 Acrylic glass.................................................................................................... 33

4.2.3.1 Alcohols, mono- and polyhydric................................................................ 33

4.2.3.2 Organic solvents, fuels ............................................................................. 34

4.2.3.3 Acids (organic and inorganic) ................................................................... 36

4.2.3.4 Leach........................................................................................................ 37

4.2.3.5 Salts, inorganic and organic (saturated solutions).................................... 38

4.2.3.6 Inorganic compounds ............................................................................... 40

4.2.3.7 Organic compounds ................................................................................. 40

5. Cleaning .................................................................................................................. 41

5.1 Cleaning and care of acrylic glass (Tube M60 / M62)........................................... 41