BE Ag & Industrial BE-SBS G Series Application guide

BE-SBSxxG

Snowblower Manual

Operations & Parts Manual

• BE-SBS50G

• BE-SBS60G

• BE-SBS72G

• BE-SBS76G

• BE-SBS7680G

For Models:

Purchase Date

Dealer

Model No. Serial No.

SAFETY PRECAUTIONS BE-SBSxxG

1. Be sure all exposed moving parts such as shafts and adapters are properly guarded and that all coupling

devices are securely attached before applying power. Do not use unless all shields are in place.

2. Do not wear loose fitting clothing in the vicinity of any moving parts.

3. Do not exceed recommended ground speed, recommended PTO speed or recommended horsepower for

the unit which you are using.

4. Keep all persons, pets and livestock away from unit when in use.

5. Do not turn discharge chute towards persons, pets, livestock or buildings when blower is in operation.

6. Before working on, servicing or making adjustments to equipment, disengage power, lower unit to ground

level, shut o engine, make sure all moving parts have stopped and all pressure in the hydraulic system

is relieved.

7. Do not attempt to remove any obstruction from discharge chute until PTO is disengaged and engine is

shut o.

8. Do not stand on auger to service any part of blower, as auger may turn causing either, a serious fall;

or the blower fan to rotate, presenting a danger to fingers, hands or arms in the chute assembly or

blower housing.

9. Keep hands and arms away from cables and turner bar of hydraulic hood turner until engine is shut o.

10. Always look to the rear before backing up.

11. Be aware of the presence of people and objects that may be obscured from vision by blowing or drifted

snow. Be certain that no children have tunneled into snowbanks which are to be removed. Never let

children slide down snowbanks in the vicinity of an operating blower.

Colour: Red

Location: Blower Side

Stones or other objects

may be thrown great

distances by the auger,

especially at higher RPM.

Do not stand in front of

the blower when it is in

operation.

Any debris or stones which are swept into

the fan can be thrown at great distances.

Do not allow any bystanders to stand in

the oath of the discharge chute.

Shields are supplied for your protection.

Do not remove shield and do not operate

the machine unless all shields are in place.

Do not service, adjust or repair until the PTO

has been disengaged, the motor shut o,

the unit lowered to the ground and all parts

have stopped moving. Any moving part has

the possibility of entangling the operator or

his clothing and causing serious injury,

dismemberment or death.

Colour: Red

Location: Blower Side

Colour: Yellow

Location: Blower Back

Do not service, adjust or

repair any equipment

attached to the 3PT

hitch hydraulic, without

lowering the unit to the

ground. If work must be

performed underneath

the unit, block the unit

in a raised position.

Colour: Orange

Location: Blower Back

Do not attempt any

servicing of the blower

while the tractor engine

is running. If the tractor

PTO is accidentally

engaged the serviceman

could become entangled

in moving parts and

seriously injured or killed.

Be certain. Be safe.

Shut o the engine.

Colour: Yellow

Location: Blower Back

Every eort is made to

ensure that a well

constructed high quality

product leaves the

manufacturer. Again the

dealer inspects and

services each unit before

it leaves his lot.

Colour: Orange

Location: Blower Side

Colour: Red

Location: PTO Shaft

Never go near any moving

parts. Because tractor PTO

may be accidentally engaged,

Repair or couple PTO unless

tractor engine is shut o.

Do not remove shields.

Be sure that PTO shield turns

freely and independently of

the driveline. Do not operate

unless all shields are in place.

Be sure that PTO shaft is

attached securely at both

ends before operating.

SAFETY DECALS BE-SBSxxG

To keep your blower in

good operating condition,

please inspect and re-tighten as necessary any loose

nuts or studs after a half hour break in period.

Thereafter periodic checks will ensure that your

blower remains in top working condition.

CAUTION

Lower or block elevated components before

servicing or when leaving the machine.

Elevated components can fail and cause

serious injury.

Abaissez ou bloquez les éléments surélevés

avant de faire l’entretien lorsque vous vous

éloignez de la machine. Les éléments

surélevés peuvent tomber et causer des

blessures sérieuses.

DANGER

Shut off engine before

servicing machine.

Éteindre le moteur avant

de faire l’entrtien.

CAUTION

All nuts and bolts must be

re-tightened regularly.

Consult your Owners Manual.

Tous les écrous et les boulons

doivent être resserrés à

intervalles réguliers. Consultez

le manuel de l’usager.

DANGER

To prevent Serious Injury or Death:

• Keep hands, feet and clothing away

from auger intake

WARNING

MOVING PART HAZARD

To prevent serious injury or death from

moving parts:

• Close and secure guards and shields

before starting.

• Keep hands, feet, hair and clothing away

from moving parts.

• Disconnect and lockout power source

before adjusting or servicing.

• Do not stand or climb on machine when

operating.

DANGER

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT:

• ALL DRIVELINE, TRACTOR AND

EQUIPMENT SHIELDS IN PLACE

• DRIVELINES SECURELY

ATTACHED AT BOTH ENDS

• DRIVELINE SHIELDS THAT TURN

FREELY ON DRIVELINE

DANGER

AVOID BODILY INJURY

PRÉVENTION CONTRE

LES ACCIDENTS

1. OBJECTS MAY BE THROWN GREAT

DISTANCES BY AUGER.

LES OBJETS PEUVENT ÊTRE PROJETER À

GRANDE DISTANCE DE LA VIS HÉLICOïVALE.

2. STAY CLEAR AND WATCH OUT FOR

BYSTANDERS. KEEP ALL SHIELDS IN PLACE.

GARDEZ UNE BONNE DISTANCE ENTRE VOUS

ET LES PERONNES ENVIRONNANTES.

N’ENLEVESPAS LA TÔLE PROTECTRICE.

3. BEFORE WORKING ON MACHINE DISENGAGE

POWER, SHUT OFF ENGINE AND MAKE SURE

AUGER HAS STOPPED ROTATING.

AVANT TOUTES RÉPARATIONS, ENLEVEZ LE

ASSUREZ-VOUS QUE LA VIS HÉLICOïVALE

NE TOURNE PLUS.

SET UP

1. Turn hood to point directly behind blower (PTO side).

2. Lift hood assembly o and spread a light coat of grease on outside of blower mainframe pipe.

3. Replace hood assembly.

4. Install hood turner as per instructions.

5. Grease shear assembly, auger bearings and hydraulic hood turner if installed.

6. Check oil level in gear box.

7. Check all bolts for tightness.

8. Check auger drive chain tension and alignment.

9. Grease PTO universal joints, shield retaining collars and inner tube of PTO.

OPERATION

1. When attaching the blower make certain all guards are in place.

2. Ensure that the fan and auger rotate freely before connecting PTO shaft to the tractor.

3. Use proper pins and ensure that all connections are secure.

4. Engage the PTO at low engine RPM and slowly increase speed to operate level. Operating speed will vary

with snow, weather and ground conditions.

5. Adjust the top link of the 3PT hitch to match the ground and snow conditions. Increasing the length will

cause the blower to cut deeper into compacted snow, but may also cause the blower to scrape gravel or

stones into the fan, which can be a danger to nearby persons, pets, livestock or buildings. Decreasing the

length of the top link causes the blower to ride back on the skid shoes, raising the cutting height, thereby

reducing the possibility of scraping gravel or stones into the blower.

6. Adjust the deflector for the distance of throw required. Moving the adjusting bar, to shorten the distance

between the pins increases the thrown.

7. Be aware of the presence of people and objects that may be obscured from vision by blowing or drifted snow.

Be certain that no children have tunneled into snowbanks which are to be removed. Never let children slide

down snowbank in the vicinity of an operating blower.

SERVICE

1. Before servicing or adjusting, disengage the PTO, lower the unit to the ground and shut o engine.

2. To prevent freezing of hood or other moving parts apply a solution of antifreeze or light oil.

3. Check gearbox oil level on a regular basis. If oil level is low, use a good quality 80W-90 gear oil.

Change oil after 50 hours during break-in period. Change after 700-750 hours or yearly.

4. Grease the shear assembly and hydraulic hood turner every five hours of operation.

5. Grease the auger bearings every ten hours of operation.

6. Check auger drive chain tension and alignment. Adjust if necessary.

BE-SBSxxG

INSTALLATION

WARNING!

Unfortunately, snowblowers will be faced with forgotten or hidden objects under the snow,

such as chain, tires, stones, pieces of wood, etc.

In spite of all our eorts, machines are not built to resist all those conditions.

DANGER!

It is dangerous to use a tractor which is too big or too powerful. The tractor will always be able to

overload the blower, even if the machine is already at maximum capacity. Tractor being very high,

too large angles at PTO universal joints will result and life of universal joints will be

shortened dramatically.

A proper initial installation will give you years of satisfactory service on your equipment. Please read carefully

following instructions which have been specially made to help you and make you satisfied with your purchase.

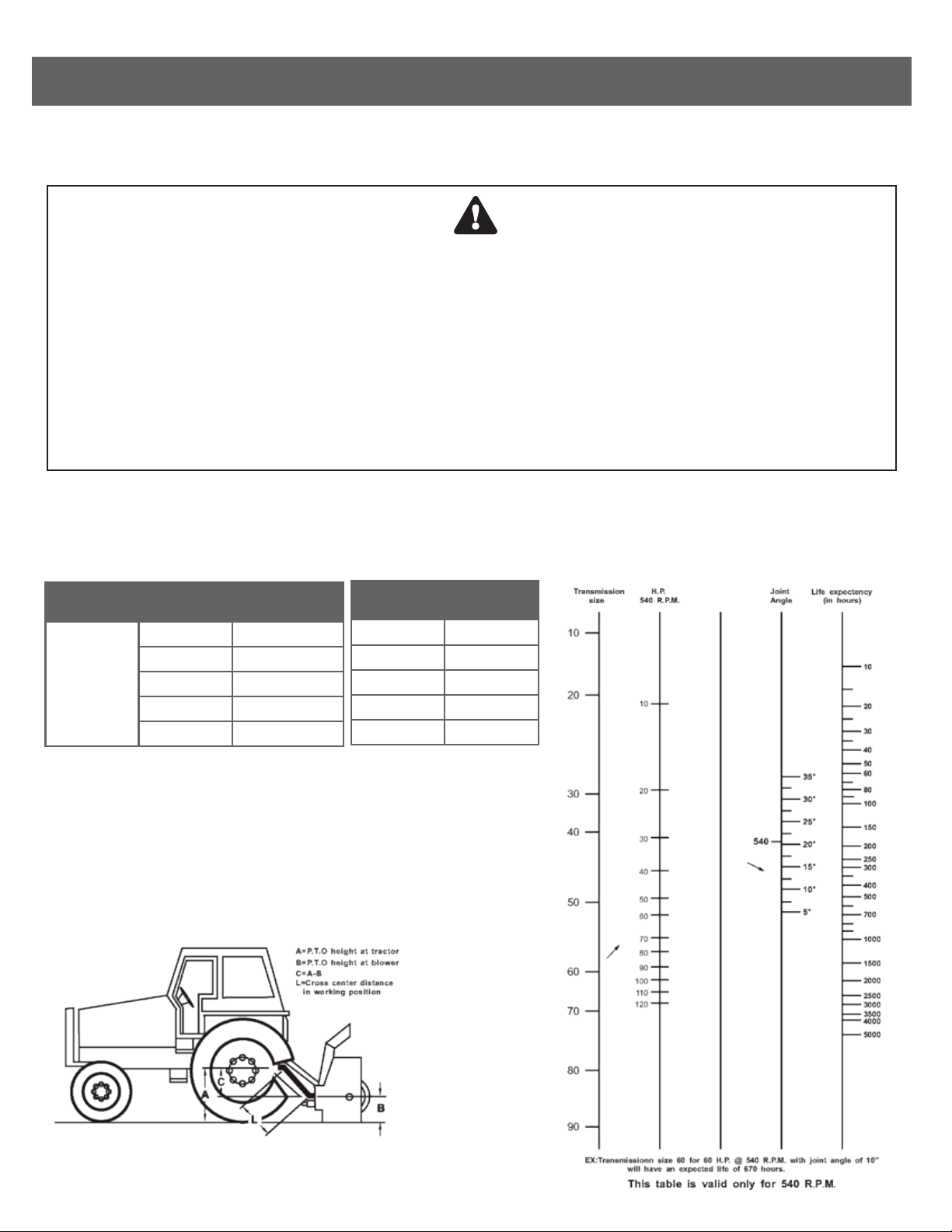

PTO SHAFT ANGLES

PTO Shafts are made to transmit power with angles at universal joints. However, these angles should be kept

to a minimum. Larger the angle, shorter the lift of PTO. For example a snowblower sold for a tractor capacity

of 60-70 HP, which would be attached to a 60 HP Tractor, operating at maximum capacity (60 HP Continuous).

HOW TO DETERMINE PTO ANGLE

1) Lower blower on ground

2) Take measures A, B and L

3) Subtract B of A (A-B=C)

4) Divide L by C (L/C=F)

5) Compare F factor in table to find

PTO angle (interpolate, if necessary).

HP PTO ANGLES ESTIMATED

LIFE (HOURS)

450 Hours5°60 @ 540 RPM

195 Hours10°Using #50 PTO

90 Hours15°

40 Hours20°

20 Hours25°

F FACTOR

6

3.75

2.75

2.15

1.75

ANGLE

10°

15°

20°

25°

30°

BE-SBSxxG

INSTALLATION (CONT.)

Previous examples clearly demonstrate that universal joint angle is directly related with life of PTO in order to

reduce angle, it is necessary to increase the distance between snowblower and tractor.

It is impossible to increase the distance between snowblower and tractor, in order to maintain a reasonable

angle at PTO, it is recommended to use a large size of PTO, That is a greater capacity PTO, (please refer to

your dealer for more details).

For snowblowers of 100 HP an additional gearbox is also available that can be mounted on existing snowblower

gear box, which increased the input shaft height, reducing angle at PTO joints. This gear box also has a an

input speed of 1000 RPM, which greatly increases PTO capacity.

ANGLES AT EACH END OF PTO

A popular habit is to change snowblower angle in order to obtain a better scraping eect. This practice can

become harmful to the PTO, angle at each end being unequal. There will be a fan speed variation as well as a

drastic increase of load on cross and bearings. To avoid, it is recommended to keep tractor PTO Shaft and

snowblower input shaft always parallel.

SHEAR BOLTS

Shear bolts are built to break under shocks on the fan or on the auger. However, under certain circumstances,

this security is not adequate. Example: a sudden high impact shock on the fan may, in some cases, break the fan

shaft without breaking the shear bolt.

If the shear bolt breaks, make sure to always replace it with a same category bolt (grade 8.8). It is necessary to

always maintain this bolt very tight, in order to keep the eciency of the shearing mechanism.

WARNING: The gear box fan shafts are made with special allow steel. Moreover, they are case hardened

to increase capacity to shock load. These shafts cannot be broken under normal snow loads.

However, undesirable objects may enter the fan and either bend or break gear box shaft. It is understood that

gear box cannot be built to resist every possible overloads and consequently, gear box fan shafts will not be

replaced under warranty. Therefore, the user of the snowblower must be very careful.

BE-SBSxxG

SET UP INSTRUCTIONS

1. Un-crate items and compare with the parts breakdown found in the Operator’s Manual.

2. Bolt on left and right skid shoes according to Image 1.

3. Assemble the chute. Following manner of assembly in Image 2 and Image 3. Refer to the snowblower

diagram in the diagram in the operator’s manual for exploded view.

Image 1: Assembled Skid Shoe.

Image 2: Chute Assembly.

Image 4: Chute Bearing.

Note: Shims (#24 in parts list) for

bearings must be installed on the top

bottom of bearings.

The bolts must be oriented with the

threads down, see Image 4.

Image 3: Chute Assembly.

BE-SBSxxG

SET UP INSTRUCTIONS (CONT.)

Image 5: Crank Support Bracket

Image 7: A Frame Top Assembly

Note: Hand crank support bracket must be

installed on the bottom of chute flange.

Image 6: Hitch Frame

4. Assemble hitch, see Image 6.

5. Assemble the hitch top assembly and chute crank support brackets as shown in image 7.

6. Refer to page 2 of the operator’s manual for final service and installation of snowblower.

BE-SBSxxG

SNOWBLOWER DIAGRAM BE-SBSxxG

SNOWBLOWER PARTS LIST BE-SBSxxG

REF NO. PART NO. DESCRIPTION QTY

Main Frame1300011 1

Lock Nut M101300022 13

Bearing SAPF-206-20 C/W Flange1300033 1

Nut M61300044 1

Bolt M10x201300055 3

Lock Nut M121300066 17

Skid Plate1300077 2

Bolt M12x301300088 4

Bolt M16x901300099 1

Washer 1613001010 4

Bearing 6203-2RS.5/813001111 1

Idler Sprocket13001212 1

Spacer13001313 1

Lock Nut M1613001414 1

Bolt M12x4013001515 8

Bearing HCFS207-23 C/W

Cast Flange

13001616 2

Washer 1213001717 8

Lock Washer 613001818 1

Connector Link #6013001919 1

Roller Chain #60 (56-1/2”)13002020 6

Bolt M10x3013002121 1

Auger Drive Sprocket13002222 1

Auger for 50”13502323-50” 1

Auger for 60”13602323-60” 1

Auger for 72”13722323-72” 1

Turning Screw13002828 1

Bolt M6x4013002929 1

Lock Nut M613003030 1

Hand Crank13003131 1

Mounting Plate for Handle13003232 1

Auger for 76”13762323-76” 1

Fan13002424 1

Flat Washer 3/8”13002525 1

Bolt 3/8”x1-1/4”13002626 1

Lock Pin 6x4013002727 1

REF NO. PART NO. DESCRIPTION QTY

Nylon Washer13003333 1

Special Washer ø12x0.213003434 10

Bearing 6301-2RS113003535 5

Lock Nut M813003636 3

Mounting Plate for Chute13003737 1

Lock Bolt13003838 2

Bolt M12x4513003939 5

Chute (W/O Deflector)13004040 1

Bolt M8x3013004141 1

Bolt M6x3013004242 1

Adjusting Arm13004343 1

Deflector Hinge Pin13004444 1

Cotter Pin ø213004545 2

Deflector13004646 1

Lock Plate13004747 1

Mounting Bracket

for Crank Handle

13004848 1

Cross Shaft for 50”13504949-50”

49-60”

49-72”

49-76”

1

Cross Shaft for 60”136049

50

1

Cross Shaft for 72”137249

51

1

Cross Shaft for 76”137649

52

1

PTO130050

53

1

Bolt M18x130130051

54

1

Lock Nut M18130052

55

1

Bolt M10x130130053

56

4

Hitch Pin ø22x120130054

57

2

Right Tube Hitch Frame130060

63

1

Connecting Bracket130061 1

Rear Brace130062 1

Bolt M18x45130063 2

Lock Pin ø8130055

58

2

Keystock 1/4 Sq. x 1-1/2130056

59

1

Gearbox130057

60

1

A-Frame130058

61

2

Left Tube Hitch Frame130059

62

1

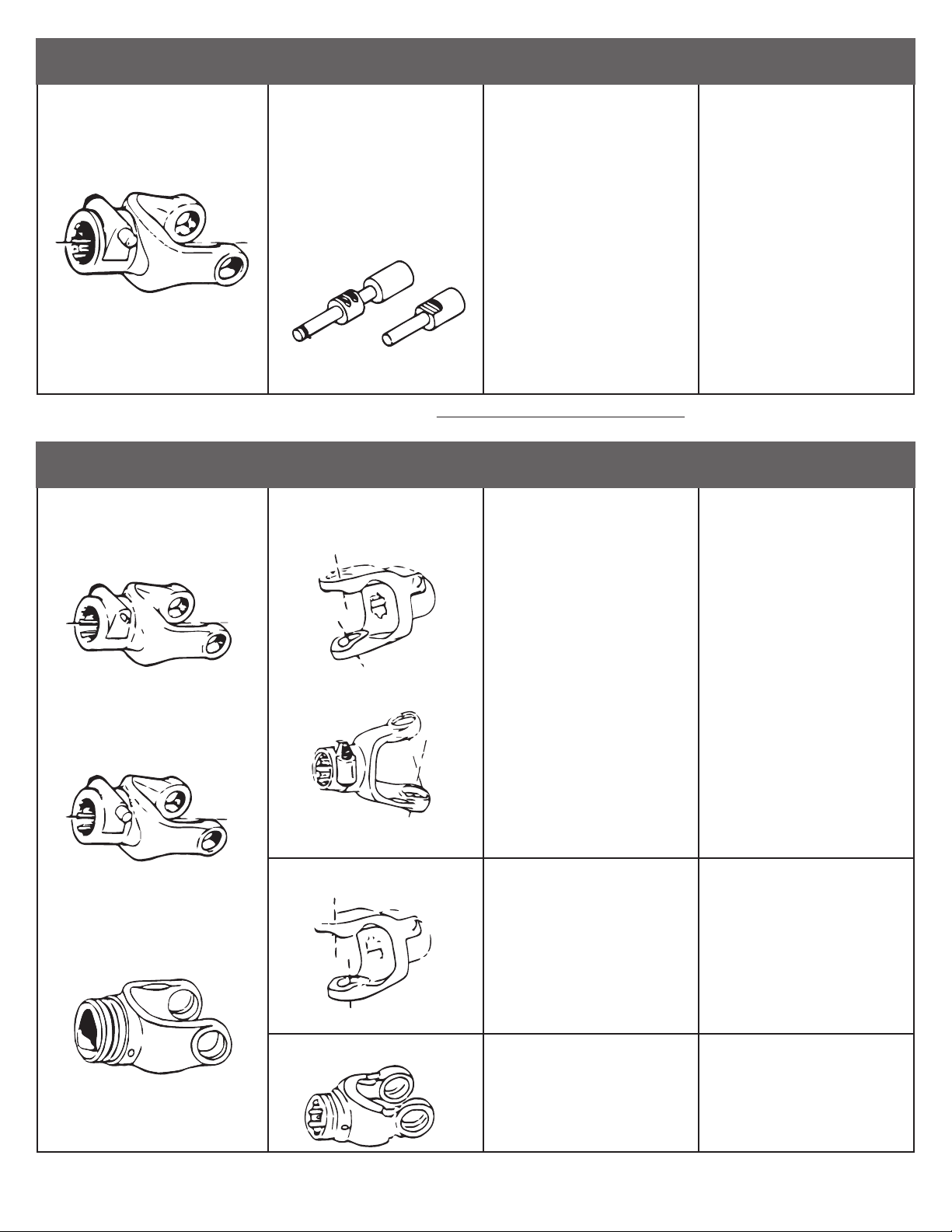

SHIELD ASSEMBLY

Plastic Shield Assembly #69.888.998

Complete PTO - Bondioli Type Series 4 # 69.888.400

Tractor Yoke

# 21-10-00

Shearbolt Clutch

Series 4

# 57-117-18

Shearbolt # 01.008.045

M8 x 45x1.25 (GR8.8)

Nut # 09-000.008

Nyloc M8x1.25

BE-SBSxxG

SHIELD - Excessive wear of shield

bearings.

- Insucient lubrication

- Incorrect chain mounting.

- Shield interfering with

implement.

- Follow lubrication instructions

- Mount chain to allow maximum

angularity.

- Avoid contact of the shields

with xed parts of the machine

or tractor.

- Replace shield bearings.

- Chain moving or failure. - Shield interfering with

implement

- Incorrect chain mounting.

- Avoid contact of the shields

with xed parts of the machine

or tractor.

- Mount chain to allow maximum

angularity.

- Replace defective parts.

- Guard cone damaged. - Guard cone in contact with

components on the tractor

and/or implement.

- Excessive Angularity.

- Eliminate interference between

guard cones and any part on

the tractor and/or implement.

- Avoid excessive angle during

cornering or when lifting or

lowering the implement.

- Replace damaged guard cones.

- Eliminate interference between

guard cones and any part on

the tractor and/or implement.

- Replace damaged tubes.

- Adjust guard tubes length with

longer tubes.

- Guards in contact with

components on the tractor

and/or implement.

- Guard tubes overlap too short

or no overlap at all with

extended P.T.O. Drive shaft.

- Guard tubes damaged

(deformed and split at one side).

*Note: Shield bearing must be greased every 8 working hours.

For any additional details (capacity, angle, length), please refer to catalogue.

Sold by:

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

16hr 8hr 8hr

16hr 16hr

BE-SBSxxG

Cross Kit

Telescopic Tube

- Cross arms broken. - Extreme torque peak or chock

load.

- Axial Loads too high.

- Use appropriate safety device.

- Change to a larger P.T.O. size.

- Shorten P.T.O. shaft

- Replace defective cross

bearings.

- Bearing caps turning in their

cross journal.

- Overheated bearing caps.

- Telescopic tubes failure or

twisting.

- Extreme torque peak or shock

load.

- Short tube engagement.

- Use appropriate safety device.

- Change to larger P.T.O. size

- Replace the P.T.O. drive shaft

with one having adequate

length.

- Replace defective tubes.

- Change to a P.T.O. drive shaft

with one having adequate

length

- Replace the P.T.O. drive shaft

with one having adequate

length.

- Carefully follow greasing

instructions.

- Replace defective tubes.

- Extreme load when sliding.

- Short tube engagement.

- Inadequate greasing.

- Continuous (sand, etc.).

- Accelerated wear of telescopic

tubes.

- Excessive continuous torque

and/or excessive working angle.

- Inadequate greasing.

- Verify compatibility between

shaft and working conditions.

- Carefully allow greasing

instructions.

- Replace aective cross

bearings.

- Excessive continuous torque

and/or excessive working angle.

- Inadequate greasing.

- Verify compatibility between

shaft and working conditions.

- Carefully follow greasing

instructions.

- Replace defective cross

bearing.

*Note: Cross bearing must be greased every 8 working hours.

*Note: Telescopic tubes must be cleaned and greased every 16 working hours.

- Accelerated wear of cross kit.

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

BE-SBSxxG

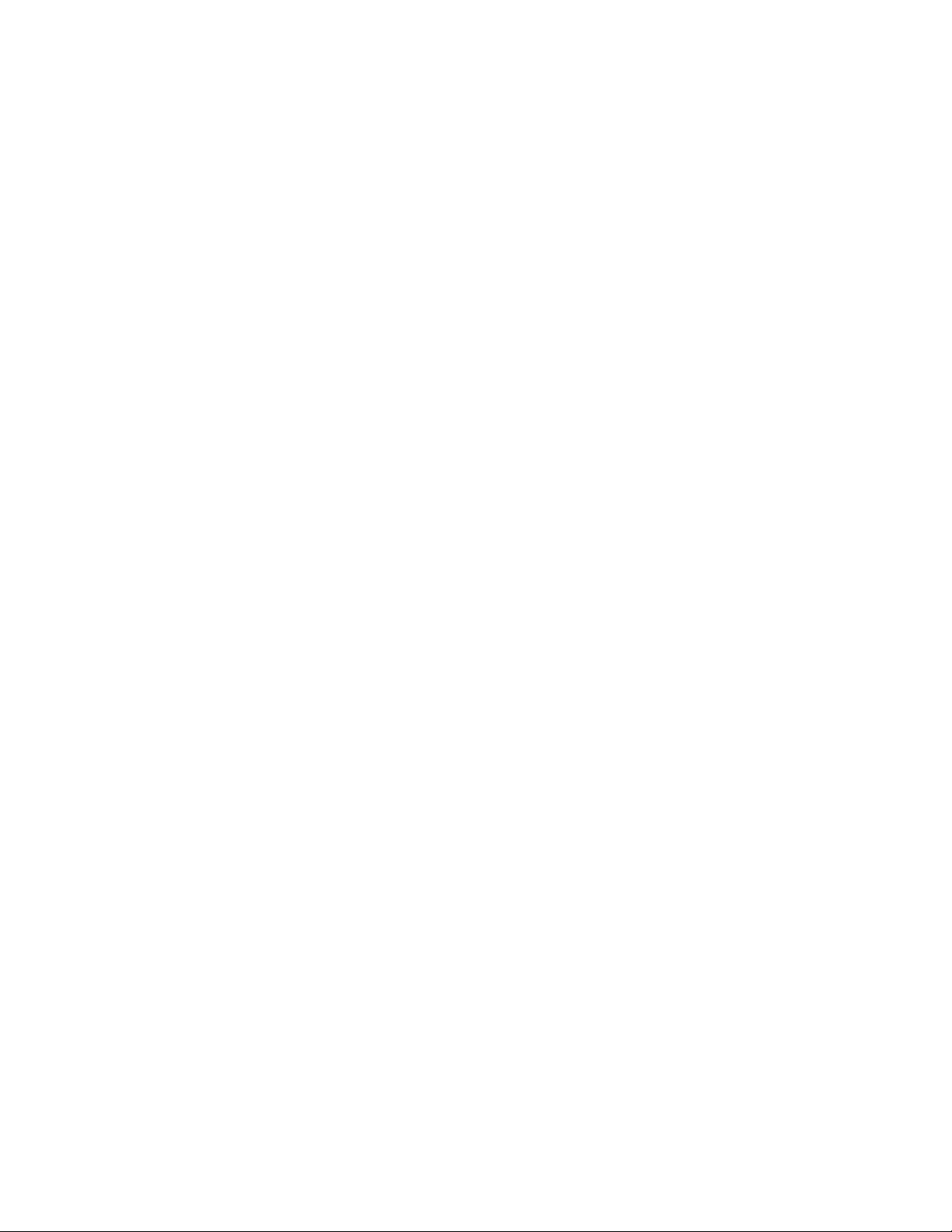

Quick-disconnect yoke

Yoke

- Quick-disconnect pin tight or

completely seized.

- Quick-disconnect pin damaged

(broken or bent).

-Quick-disconnect pin damaged

in the locking portion.

- Quick-disconnect pin dirty

(insucient maintenance).

- Quick-disconnect pin defective

(forced engagement, incorrect

handling).

- Excessive shaft length.

- Axial loads too high.

- Clean, oil and follow service

instructions.

- Replace quick-disconnect pin.

- Shorten shaft length (cut both

telescopic tubes as well as

shields and remove burrs).

- Replace quick-disconnect pin.

- Clean and grease telescopic

tubes and replace both tubes,

if necessary.

- Replace quick-disconnect pin.

- Yoke ears deformation.

- Yoke ears distorted.

- Yoke ears worn or pounded.

- Excessive shaft length.

- Axial loads too high.

- Excessive working angle and

torque.

- Overload caused by high

starting and peak torques.

- Excessive working angle.

- Shorten shaft length (cut both

telescopic tubes as well as

shields and remove burrs).

- Replace defective yokes.

- Clean and grease telescopic

tubes and replace both tubes

if necessary.

- Replace defective yokes.

- Verify compatibility between

shaft and working conditions

- Disengage tractor P.T.O. during

cornering or when lifting or

lowering the implement.

- Replace defective yokes.

- Engage P.T.O. more carefully.

- Use appropriate safety device.

- Replace defective yokes.

- Avoid excessive working angle.

- Disengage tractor P.T.O. during

cornering.

- Replace defective yokes.

*Note: Quick-disconnect pins must be cleaned and greased every 16 working hours.

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

BE-SBSxxG

This manual suits for next models

5

Table of contents