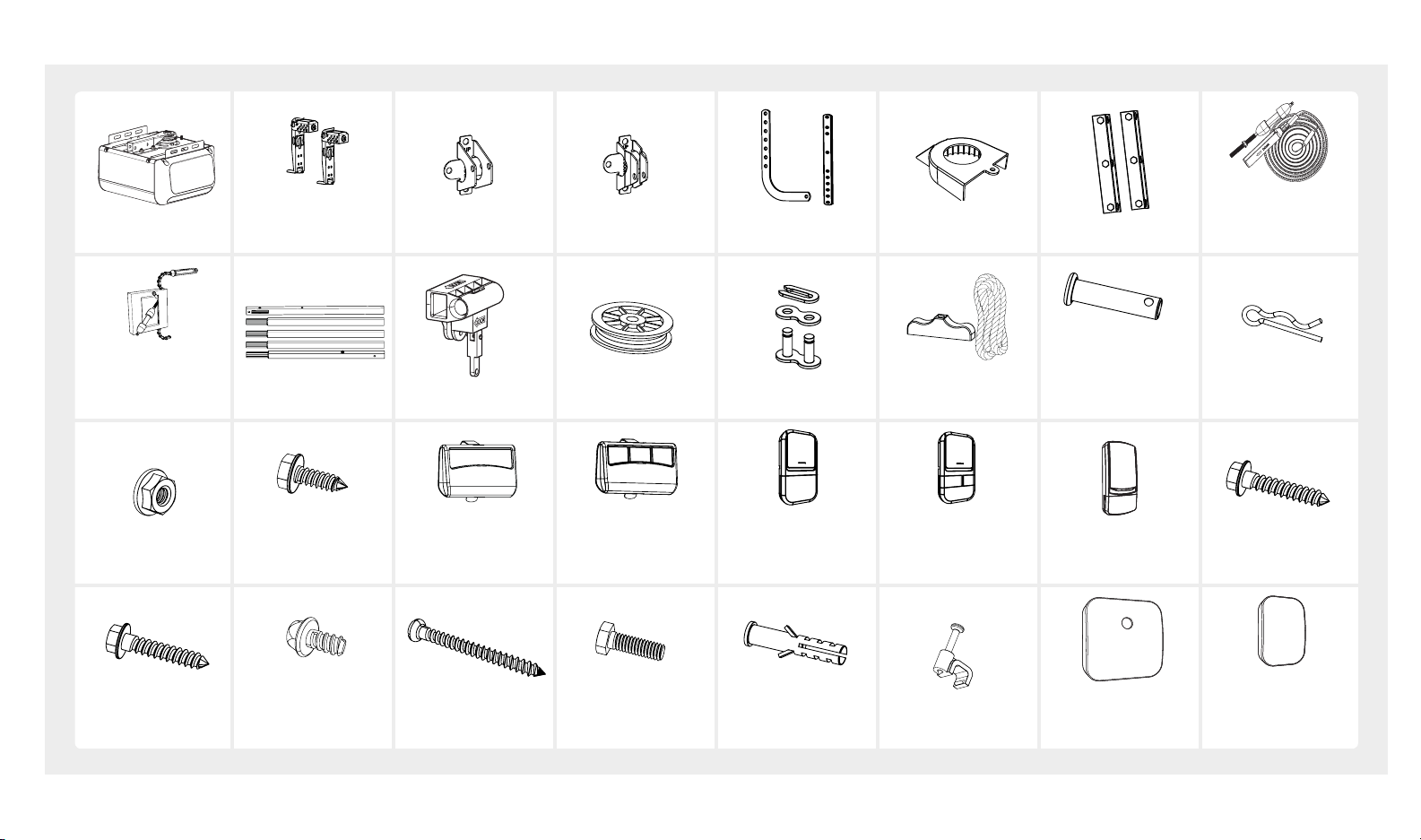

Beam Labs BeamUP BU250 User manual

This manual suits for next models

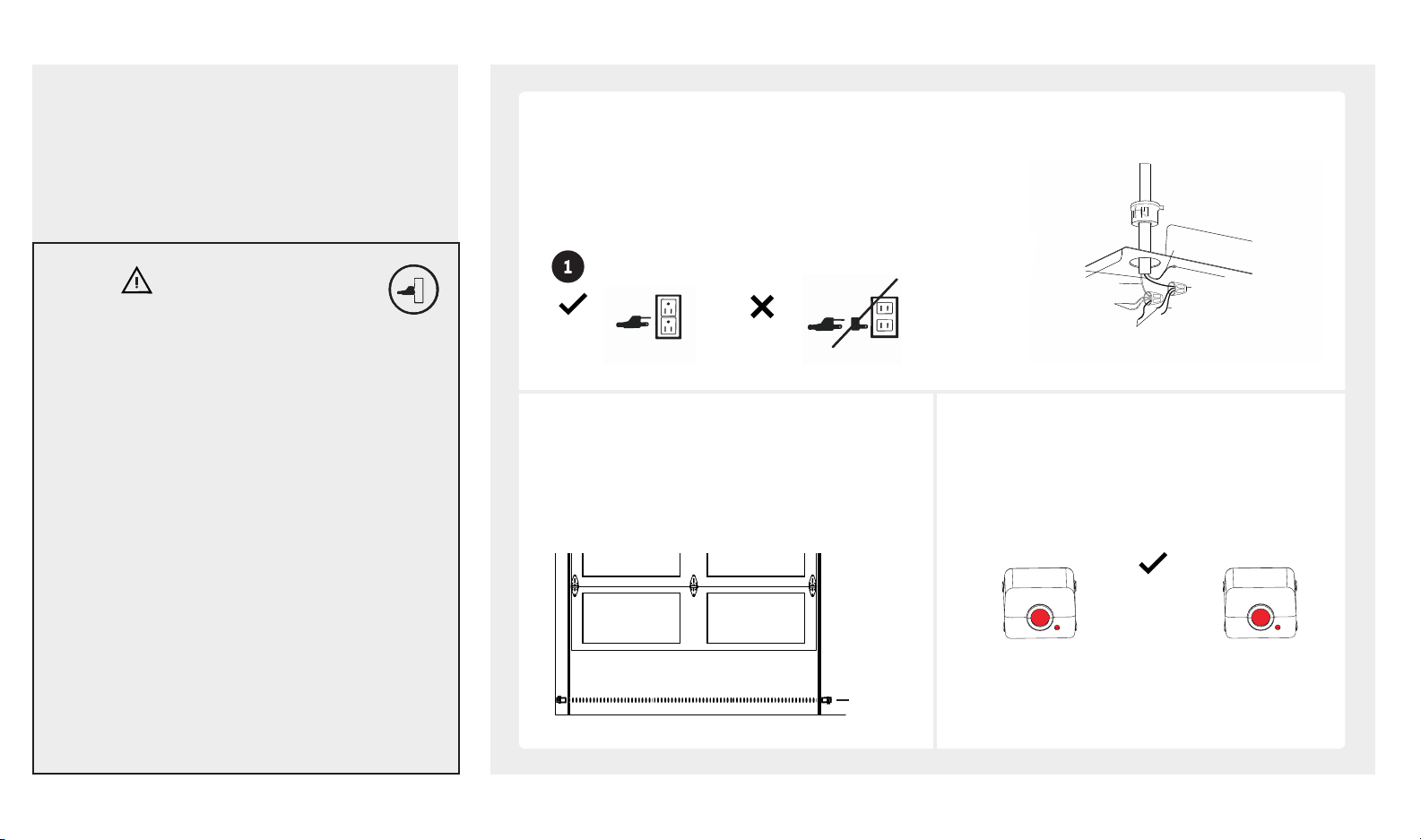

1

Table of contents

Other Beam Labs Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Chamberlain

Chamberlain Whisper Drive Security+ 182671D owner's manual

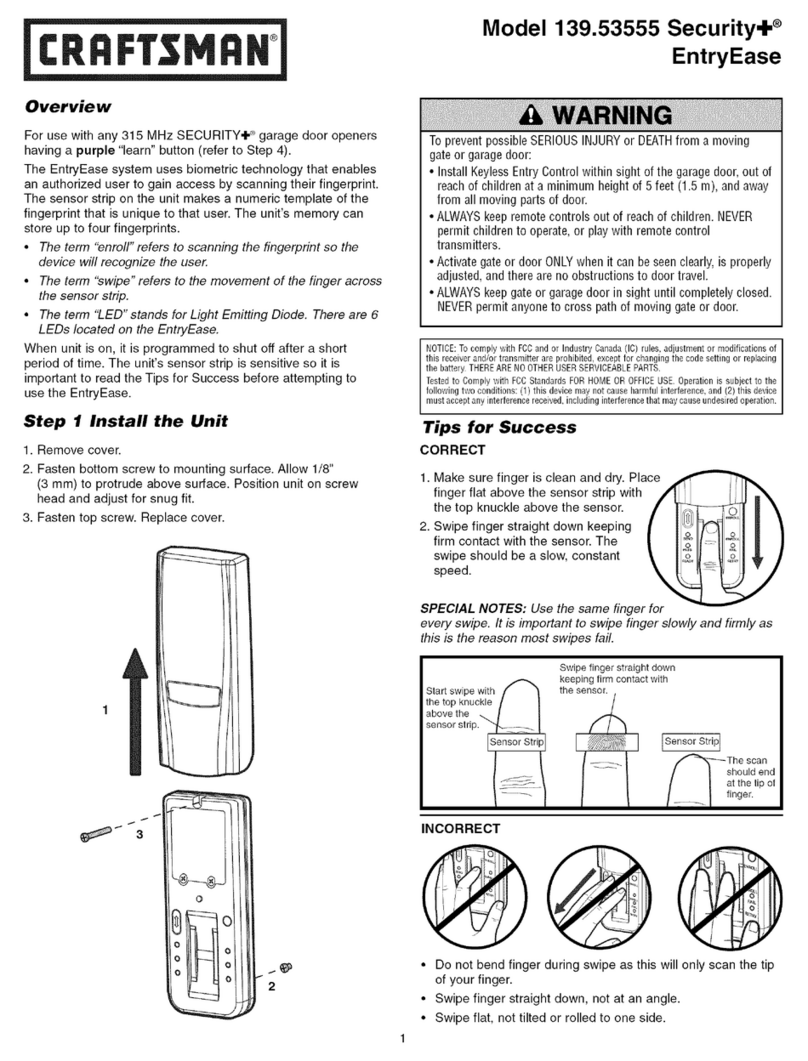

Craftsman

Craftsman 139.53915SRT- 1/2 HP owner's manual

Chamberlain

Chamberlain 3245 1/3 HP owner's manual

BOXER

BOXER 63.002 user manual

Merlin

Merlin SilentDrive Essential Installation and operating instructions

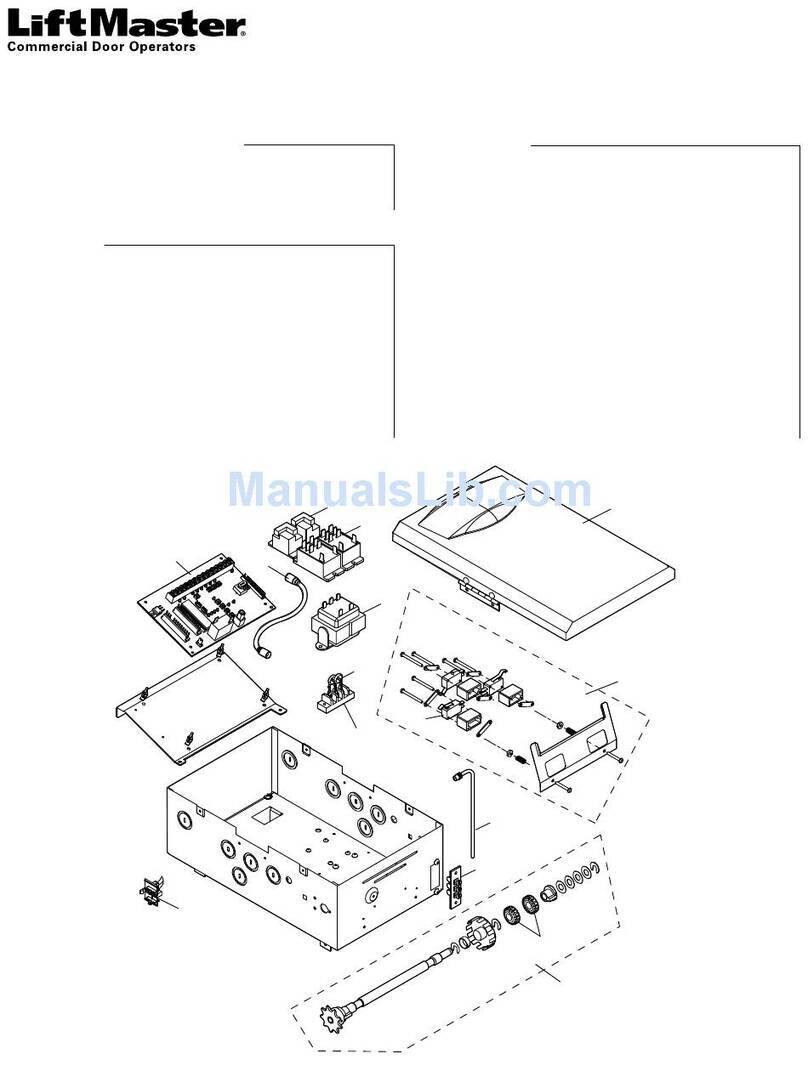

Chamberlain

Chamberlain LiftMaster Professional Security+ 3850 owner's manual

Nice

Nice ROBO RO1040 Instructions and warnings for the fitter

Craftsman

Craftsman 95355 - EntryEase Fingerprint Keyless Entry... user guide

Chamberlain

Chamberlain GH Replacement parts

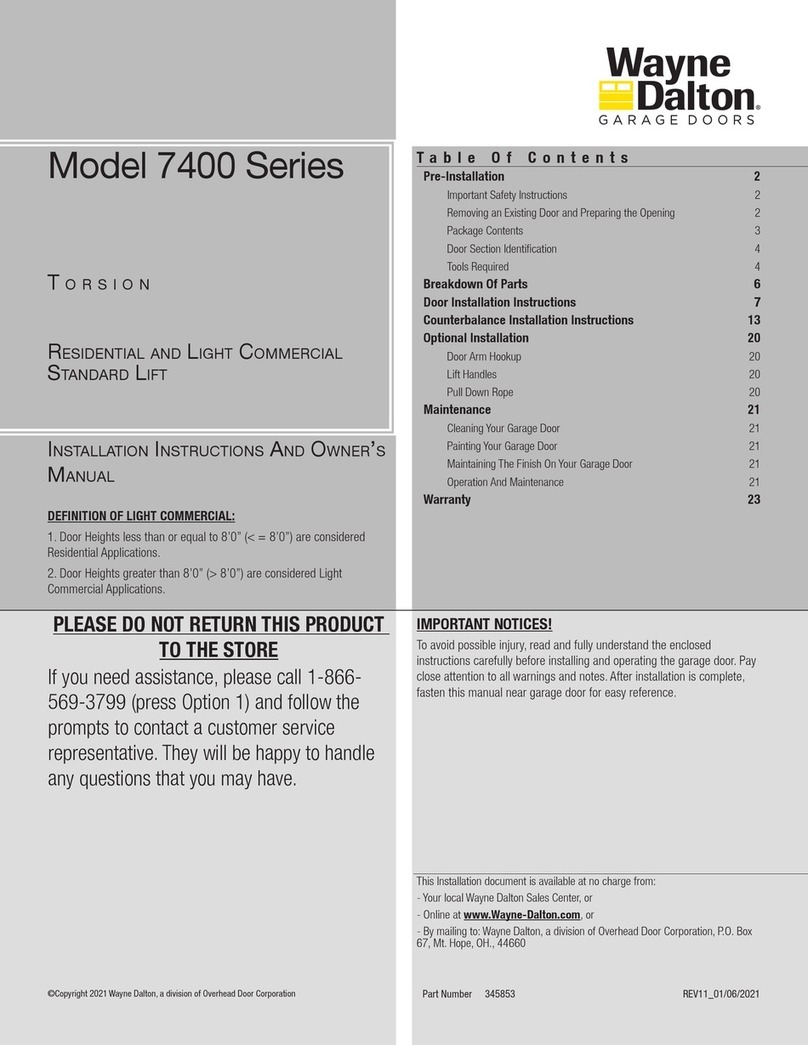

Wayne-Dalton

Wayne-Dalton 7400 Series Installation instructions and owner's manual

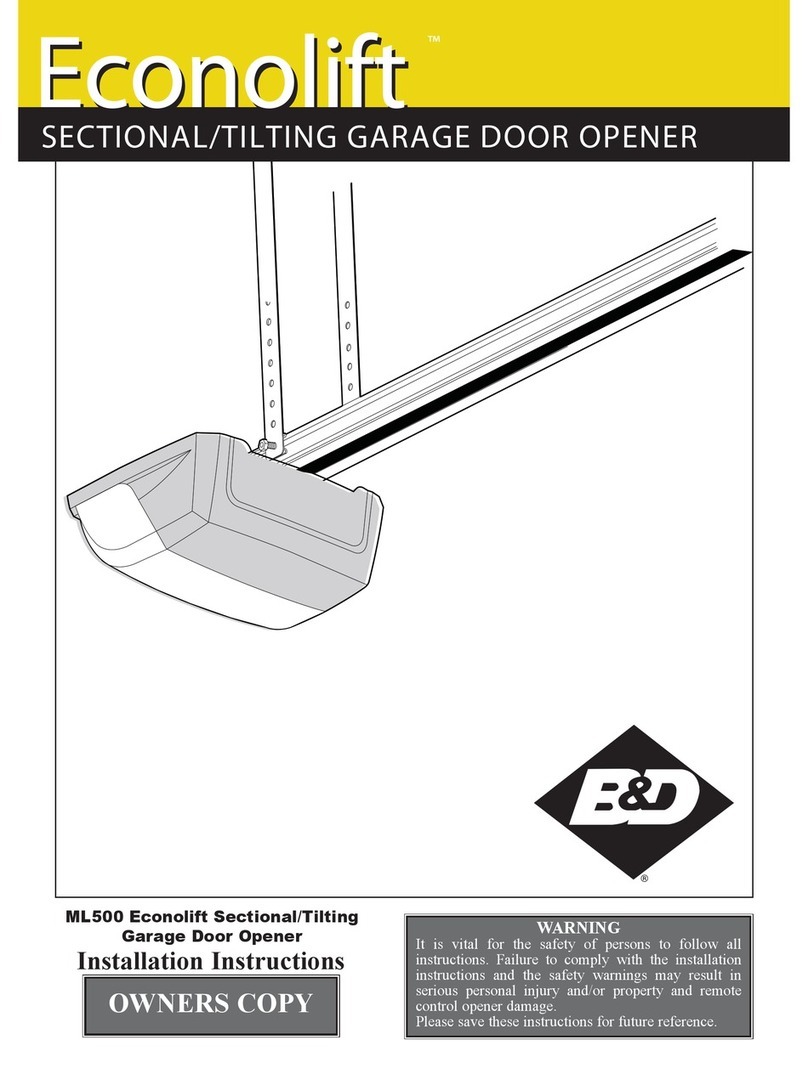

B&D

B&D Econolift ML500 installation instructions

Chamberlain

Chamberlain 8100M owner's manual

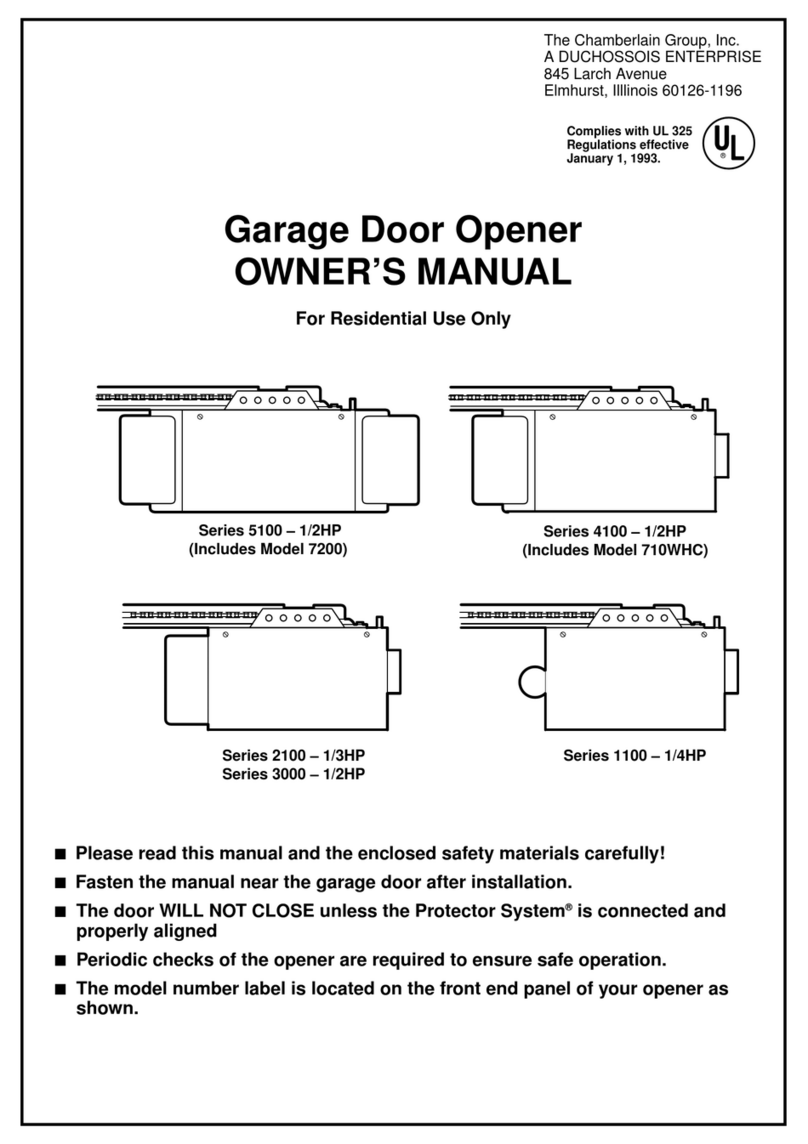

Chamberlain

Chamberlain Series 1100 owner's manual

ERICH INDUSTRIES

ERICH INDUSTRIES 610 Installation instructions & owner's manual

Micanan

Micanan PRO-LJ Installation and instruction manual

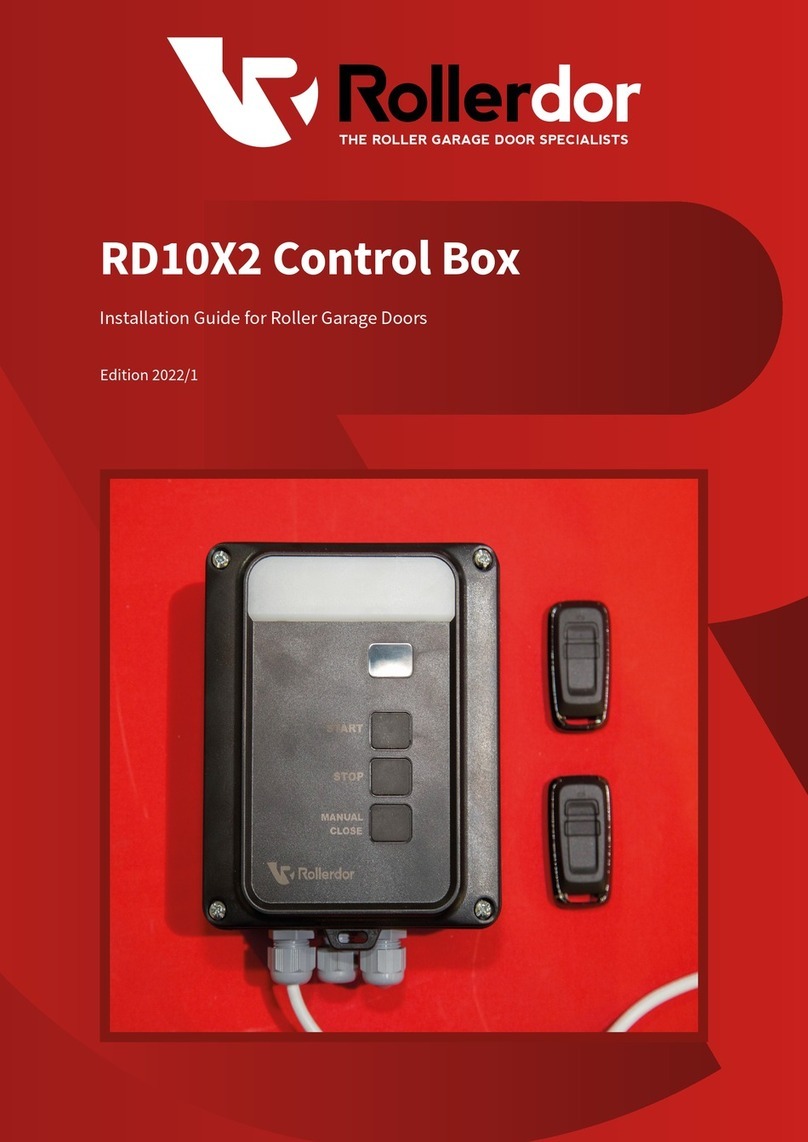

Rollerdor

Rollerdor RD10X2 installation guide

Craftsman

Craftsman 139.53985DM owner's manual

FAAC

FAAC 844 ER 3PH Translation of the original instructions