ERICH INDUSTRIES 610 Service manual

As with any mechanized equipment, do not install, operate or service this product unless you have

read and understand the safety section, warnings, installation and operating instructions contained in

this manual. Failure to do so could result in property damage, bodily injury or even death.

- WARNING -

Rev. 01/01/13

MODEL 610 AND 310 AUTOMATIC DOOR OPERATORS

UTILIZED ON FLEXIBLE AND SOLID SELF-CLOSING TRAFFIC DOORS

Erich Industries, Inc.

Performance Products Division

550 N. Nine Mound Road

Verona, WI 53593

1-800-882-5839

U.S. Patent #4365-442

U.S. Patent #6138-412

Other Patents Pending

Misc. U.S. Trademarks

• Parts

• Technical

• Sales

• Support

SwingDoorOpeners.com

DETAILS FOR STANDARD PUSH (HEADER) MOUNT CONFIGURATION

NOTE: Roller track is not required or

supplied with 310 or 610 models.

SAFETY DETAILS

Step 2. Install floor mounted stops, if required and supplied, using hardware provided. See figure #2 below for details.

Step 1. Read and understand all directions prior to installation. Install door(s) if required and be sure

they travel freely with the standard spring or V-cam closers operating properly.

Model 610 and 310 Automatic Door Opener

Installation Instructions

Model 610 and 310 Mounting Detail

(angled arm version illustrated)

WARNING - Improper or inadequate

installation could result in premature

product wear or failure and could then

cause property damage, bodily injury

or even death.

or template #15043.

Step 3.

Step 4.

Mount control box to wall using template #14671 with unit mounted adjacent to openers or within 25'. For

distances greater than 25', please contact the factory for assistance.

TIP: As you would with all delicate instruments

and tools, preserve your openers finish by

maintaining the protective oil coating on all

metal bracket components.

REMINDER - Don't forget to mount

the "CAUTION Automatic Door"

stickers on the door(s)!

Step 9.

Follow wiring details and microprocessor programming next in accordance with specifics of your

particular application. Note that typical functions are pre-programmed at the factory so you may not need

to adjust at all. Then move on to the door speed control page before operating.

Example

Step 5.

Step 7.

Step 8.

Step 6.

Install adjustable swivel flow controls to each end of the air cylinder(s). Utilize previous mounting detail

drawing (two pages back) for air line attachment locations.

TIP - If you're opening a single door use the supplied plugs to cap one of the "open"

and "close" air ports.

E-HDEB

Optional sensor extension

bracket. Part # E-HDEB

Erich Industries, Inc.

AIR FORCE®AND DOOR DYNAMICS®DOOR OPENER

ELECTRICAL WIRING DETAILS

Our control box is microprocessor based to insure maximum reliability and flexibility for the user. The system

has been designed to be easy to set up and operate. Directions for setting the proper program are in the Circuit

Board User’s Manual located elsewhere in this manual. The control unit is designed to be connected to a

constant power source of 110VAC 60HZ or 230VAC 50HZ, which powers the control box and a wide variety of

activation devices with 24VAC power.

Activating devices and input signals should be connected directly to the terminal strip located on the left side of

the control board.

N = Power Common Lead

N = Power Common Lead

U = Unused - Auxiliary

R = Remote Proof of Closure Signal

S = Safety Signal

I = Initiate Signal

#1 = Unused - Auxiliary

#2 = Unused - Auxiliary

E = Unused - Auxiliary

D = Safety Signal

F = Fire Signal

P = Proof of Closure Switch Signal

H = 24V Power

H = 24V Power

Notes: Use Terminal strip connection to N and F to lock out opening if maglock is used and active. Door will

remain in open position if receiving input from terminal strip D or S regardless of input from activation device.

Below we provide wiring details for a variety of activation and safety devices available from Erich Industries. In

most cases other manufacturer’s models can also be wired to the system in a similar fashion. Please consult with

the manufacturer of that particular unit with questions or call us.

E-2005 MS Sedco microStar Motion Detector E-3090 MS Sedco DH400 Presence Sensor

Red to H Red to H

White to N Black to N

Brown to I Yellow to S

Black to N White to N

E-3060 MS Sedco GD11S Photoeye Safety Beam E-5010 MS Sedco 216 Touchless Switch

Transmitter: White to H Red to H

Black to N Green to N

Receiver: White to H Red to N

Black to N Blue to I

Gray to D

Green to N

E-3070 BEA Microcell Photoeye Safety Beam E-5020 BEA MS-08 Touchless Switch

#1 to H Red to H

#2 to N Black to N

#3 to D White to N

#4 to N Green to I

Cont.

TIP: If you require

replacement door

sensors go to

DoorSensors.com

E-4020 MS Sedco 99 Push Plate E-6010 VEE CP1 Pull Cord

Normally Open to I Normally Open to I

Common to N Common to N

MS Sedco 614 Piezo Switch MS Sedco DH94 Presence Sensor

Normally Open to I Red to H

Common to N Black to N

Yellow to S

White to N

BEA IS40 and IS40P Sensors E-5030 BEA MS21 Touchless Switch

Red to H Red to H

Black to N Black to N

White to N Green to I

Green to I White to N

White/Black to N Green/yellow to Earth Ground

Green/Black to S (for safety with lockout)

E-5040 BEA MS09 Touchless Switch E-5050 BEA MS11 Touchless Switch

Red to H Red to H

Black to N Black to N

White to N Green to I

Green to I White to N

E-5060 Piezo Push Button Switch E-1010-1EX Explosion Proof Push Button

Plus to H Normally Open to I

Minus to N Common to N

Com1 to N

Normally Open to I

Additional questions can typically be answered by calling the factory technical support staff at

1-800-882-5839.

Revision 01/01/19

Erich Industries, Inc.

Performance Products Division

Automatic Door Opener

Erich Industries, Inc.

Erich Industries, Inc.

NOTE: Most functions are pre-programmed at the

factory so no adjustments may be required here.

Then simply utilize this section for future reference.

Erich Industries, Inc.

NEVER adjust regulators beyond 85 PSI or any

setting that is safe! Door speed will vary depending

on weight of door and any air pressures.

Final Step. Adjust all activating and safety devices in accordance with the manufacturers instructions

and owners preferences.

NOTE: Flexible traffic style doors are typically

light and will most likely require lower settings

of the air regulator and door speed controls.

Start low with PSI adjustments and work up

then fine tune the door movement with the

small flow control knob adjustments mounted

on the cylinder(s).

25 Section 4 - Operation

Erich Industries Performance Products Division Phone 800/305-6736

550N.NineMoundRoad

Verona,WI 53593

OPERATING PROCEDURES FOR OPENERS

A) Start-up(refer toinstallationinstructions fordetails)

1. Make sureairlineshavebeen purged(blownfree ofparticles inairline) priortosupplyline

hook-upto controlenclosure. Attach supplylinetocontrolenclosure.

2. Plug incord orhardwire toelectric (110volt) sourcesinaccordance withlocal codes.

3. Depress ON-OFF switch to turn on.

4. Set activatingdevicesto owner’srequirements.

5. Adjustopening speedwith airpressure controlknob incontrol enclosure. Neverlower more

than 40 PSI or raise higher than 85 PSI.

6. Doorshould not slamopen or closed. If thisoccurs, increase the backcheck on thedoor

closerto a cushioned stopat the end ofthe cycle. Adjust thelatchcheck on thecloser for a

cushionedcloseattheend ofthe closingcycle.

B) Operation

1. Depress ON-OFF switch to activate door operator and turn on.

2. Release ON-OFFswitchto de-activate door operatorand turn off.

3. Allactivatingdevicesmustbepluggedintocontrolenclosuretofunction.

4. Operators willnot bedamaged ifheld inclosed oropen positionwhile activatedforanex-

tendedperiod oftime.

C) EmergencyOperation

1. Incase of apower outageorif turnedoff,the doorswill openandclose manually. Theopera-

torwillnot bedamagedwhen operatedmanually.

2. Always turnoperators offduring a poweroutage andturn onwhen powerisrestored.

D) Shutdown

1. Use ON-OFFswitch on thecontrolenclosure to de-activatethe operator. Turn off.

WARNING - Be sure all safety devices and

activators are working properly before putting into

service. If you are having any problem with these

devices, turn off the opener and contact the

manufacturer of the sensor or Erich Industries.

Model 610 and 310 Operating Procedures

IF THIS OCCURS REFER TO SPEED CONTROL PAGE OF THIS MANUAL.

26

Section 5 - Maintenance

Erich Industries Performance Products Division Phone 800/305-6736

550N. Nine Mound Road

Verona, WI 53593

MAINTENANCE PROCEDURES FOR “KWIK-OP”

A) Maintenance-AirSource (as applicable)

1. Service compressors,filters,etc. aspermanufacturer’sinstructions.

2. Service shouldbecarried outin3monthintervals,oras required. Consultthismanual for

details.

B) Maintenance-Operators

1. Manually opendoors to check for“freeswing”. Adjustand/or lubricatehinges.

2. Checkactuator armsforexcessive play. Ifrequired, loosenset screwor lock nutand tighten

bolttoremove play. Donotover tighten,whichwillcausebinding. After tighteningsetscrew

orlock nut,check againto insurethat theunit hasfree action.

3. Check cylinderjambnut andtighten(ifrequired)withthecylinder ventonthe bottom.

4. Lubricatebearingpointswith spraylube.

5. Checkair filteronsupplyairline. Clean, drain,or replaceas required.

6. Check,air hoses andconnections forleaks, kinks, orcontact with movingparts. Correct as

required.

7. Checkair pressureandopening speed. Adjustper instructionsasrequired.

8. Checkcloser back check,closing speed, andlatch speed. Adjust perinstructions as required.

9. CheckTimeDelay period. Adjustperinstructions asrequired.

10. Service shouldbecarriedoutin3month intervalsalongwithcompressor servicing,orasrequired.

If any parts are worn or need replacing, consult this manual for parts listing.

WARNING - Be sure all safety devices and

activators are working properly before putting into

service. If you are having any problem with these

devices, turn off the opener and contact the

manufacturer of the sensor or Erich Industries.

Model 610 and 310 Maintenance Procedures

WARNING - Be sure all safety devices

and activators are working properly before

putting into service. If you are having any

problem with these devices, turn off the

opener and contact the manufacturer of

the sensor or Erich Industries.

Troubleshooting

Model 610 and 310 Parts List

Exploded View

630 Model / 14787 300 Model

DD-3000

DD-3003

630 Model / 14964 300 Model

DD-3007A Flat Head Cap Screw

DD-3007A

DD-3033

DD-3032

DD-4000630 630 Model / DD-4001 300 Model Air Cylinder

DD-4000630

or DD-4001

300 Model

DD-7002 Universal

NOTE: Part numbers

detailed are for both the 310

and 610 models unless

noted otherwise. On some

parts obsolete and current

part numbers are shown for

reference purposes.

Required for

630 Model

DD-7004 Cylinder Bracket 630 / DD-7014 300 Model

DD-7004 630

DD7014 300

Included with Cylinders

DD-8526

DD-8527

DD-8526

DD-8527

DD-8505630

DD-8506630

Questions? 1-800-882-5839

14002

14002

Arm with

30

degree

bend (not

shown)

This manual suits for next models

1

Table of contents

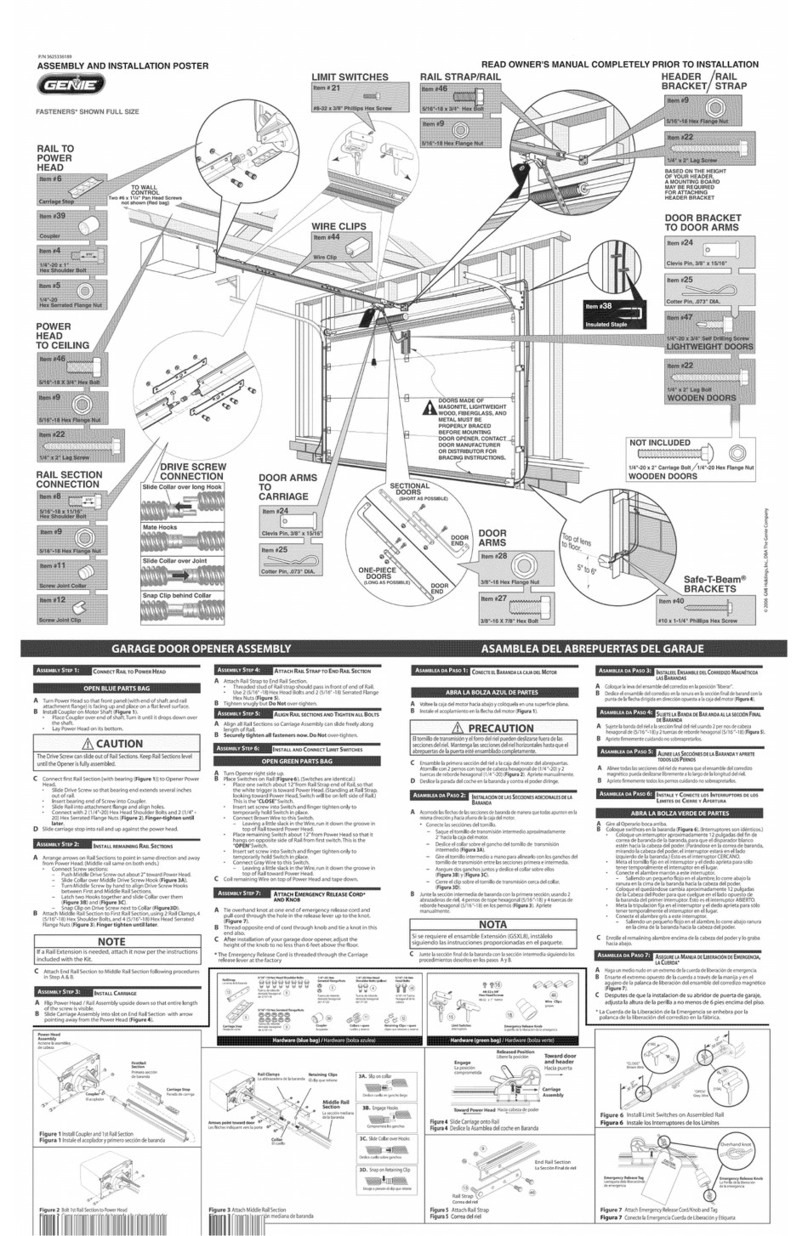

Popular Garage Door Opener manuals by other brands

Chamberlain

Chamberlain LM50 Assembly and operating instructions

Linear

Linear LDC0801 Homeowner's instructions

Roger Technology

Roger Technology F70/IPU36 Instruction and warnings for the installer

Homentry

Homentry HERDO1 Installation and operating guide

Linear

Linear LD 033 Homeowner's instructions

Chamberlain

Chamberlain Whisper Drive WD822K owner's manual

Chamberlain

Chamberlain LM800A instructions

BFT

BFT EOS 120 VENERE D Installation and user manual

tau

tau SPIN Use and maintenance manual

Merlin

Merlin Commander Elite MS105MYQ Installation and operating instructions

Craftsman

Craftsman CMXEOCG781 owner's manual

Force Technology

Force Technology FS 1500 Installation instructions and user guide