BecherAir Components BECMATIC 550 User manual

87 West Main Street

Sodus, NY 14551

(315) 483-6923 TEL

(315) 483-6656 FAX

LAST UPDATED: 07 MAY 2015

BECMATIC MODELS 550/600/602/652

OWNER’S MANUAL – BECMATIC SPRING FEEDERS

Spring No.

Revision

MODEL

ID #

SERIAL #

FEED RATE

DATE

2

INDEX

Warranty …………………………………………………………………………….Page 3

Return Information ………………………………………………………………….Page 3

Setup ………………………………………………………………………………...Page 4

Installation of Feed Tube(s) …………………………………………………………Page 4

Mounting …………………………………………………………………………….Page 5

Operation …………………………………………………………………………...Page 10

Optional Equipment ………………………………………………………………...Page 11

Troubleshooting ………………………………………………………………….…Page 13

Preventative Maintenance…………………………………………………………...Page 14

Parts List ……………………………………………………………………………Page 16

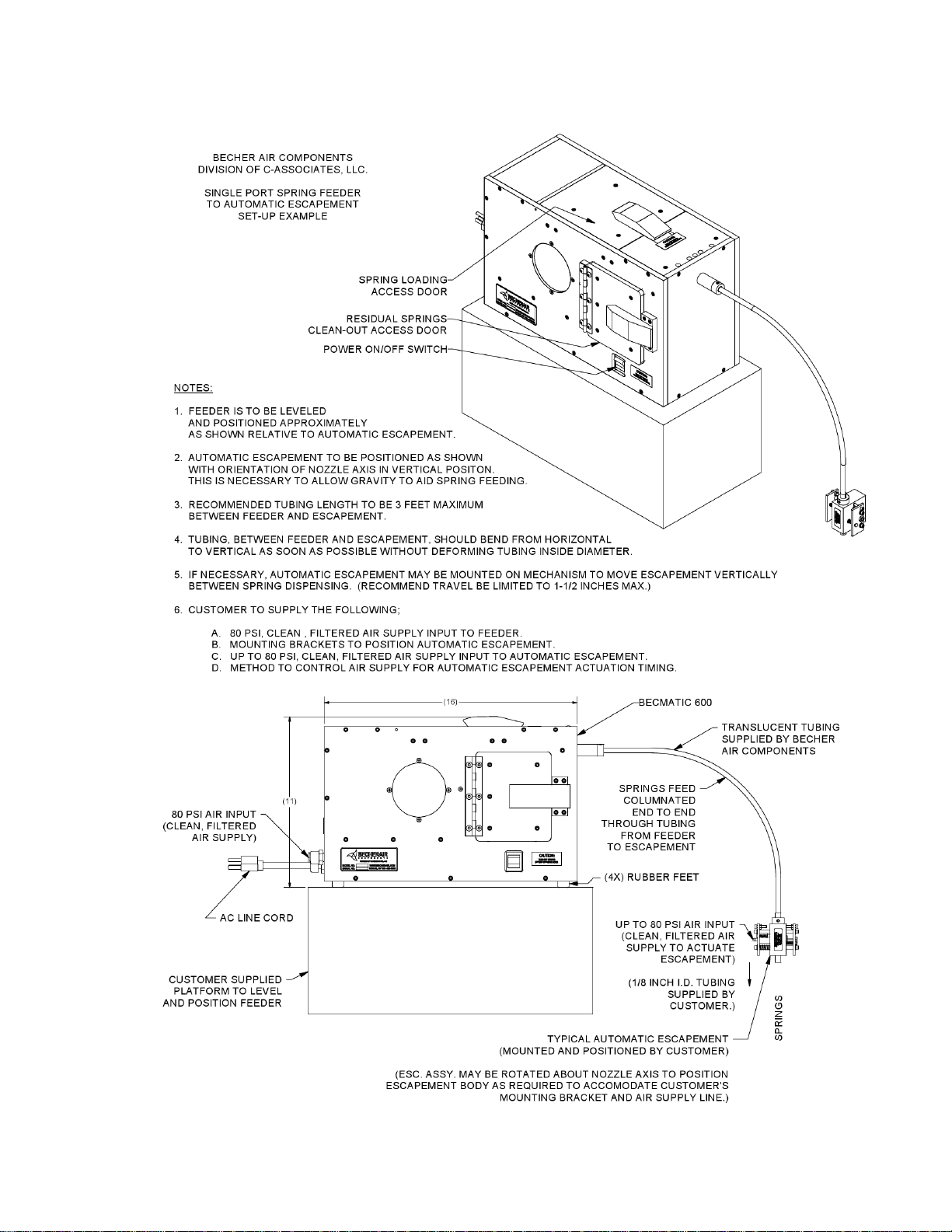

Set-up Example ……………………………………………………………………..Page 17

3

WARRANTY

STANDARD WARRANTY

The seller warrants equipment of its manufacture against defects in workmanship and material

for a period of 12 months from date of shipment from the factory.

This unit has been tooled specifically for your application. Air velocity and volume are preset at

the factory and the case has been sealed to maintain proper airflow. Disassembly or

modifications to this unit may impair operation and/or void warranty.

RETURN INFORMATION

*Call Factory for return authorization.

*Carefully pack unit to avoid damage in shipment. Insure for full value of the unit.

*Include detailed description of problem, name and phone number of the contact person, a

quantity of springs for test operations, and shipping instructions.

4

SETUP & INSTALLATION

SETUP

All models of Becmatic Spring Feeders require a 115 volt grounded electrical outlet and 80 p.s.i.

of clean air. The unit may be plugged into any standard 115 volt outlet, or may be wired directly

to any controller with 115 volt output. In installations where the air supply exceeds 80 p.s.i., a

regulator should be provided.

The feeder should be mounted above the spring escapement to allow gravity feed of the springs

through the feed tube. Feed tube length should be kept as short as possible to eliminate

excess backpressure, (36” maximum).

INSTALLATION OF FEED TUBE(S)

The feed tube is inserted into the outlet nozzle on the front of the feeder. The lock collar should

be adjusted to provide a secure grasp on the feed tube. Over tightening the lock collar will result

in damage to the nozzle and may impair the travel of the springs. Feed tube length should be

enough to allow a transition without kinks or sharp bends that will impede flow.

*230 volt models are not supplied with a plug.

*See mounting instructions.

5

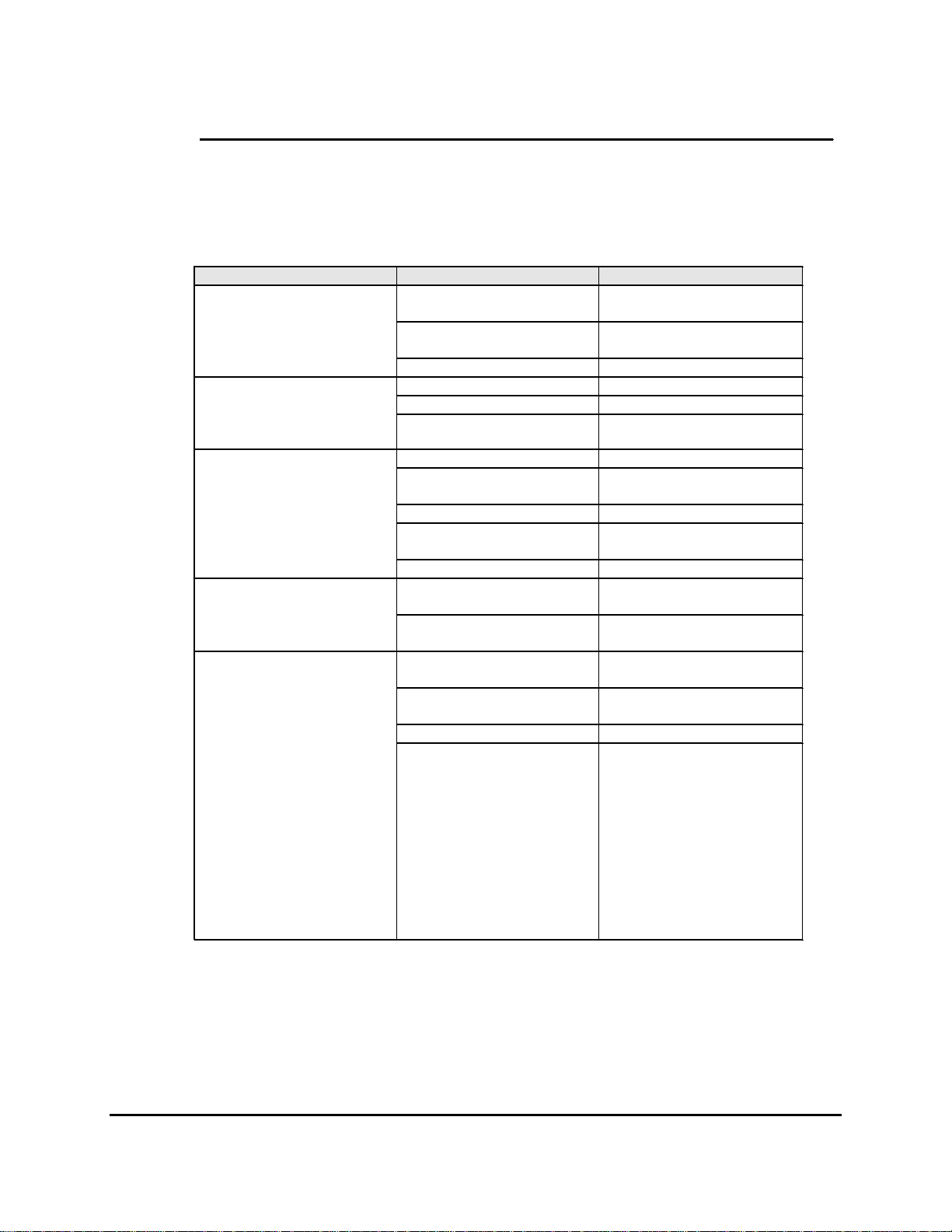

MOUNTING & SPECIFICATIONS

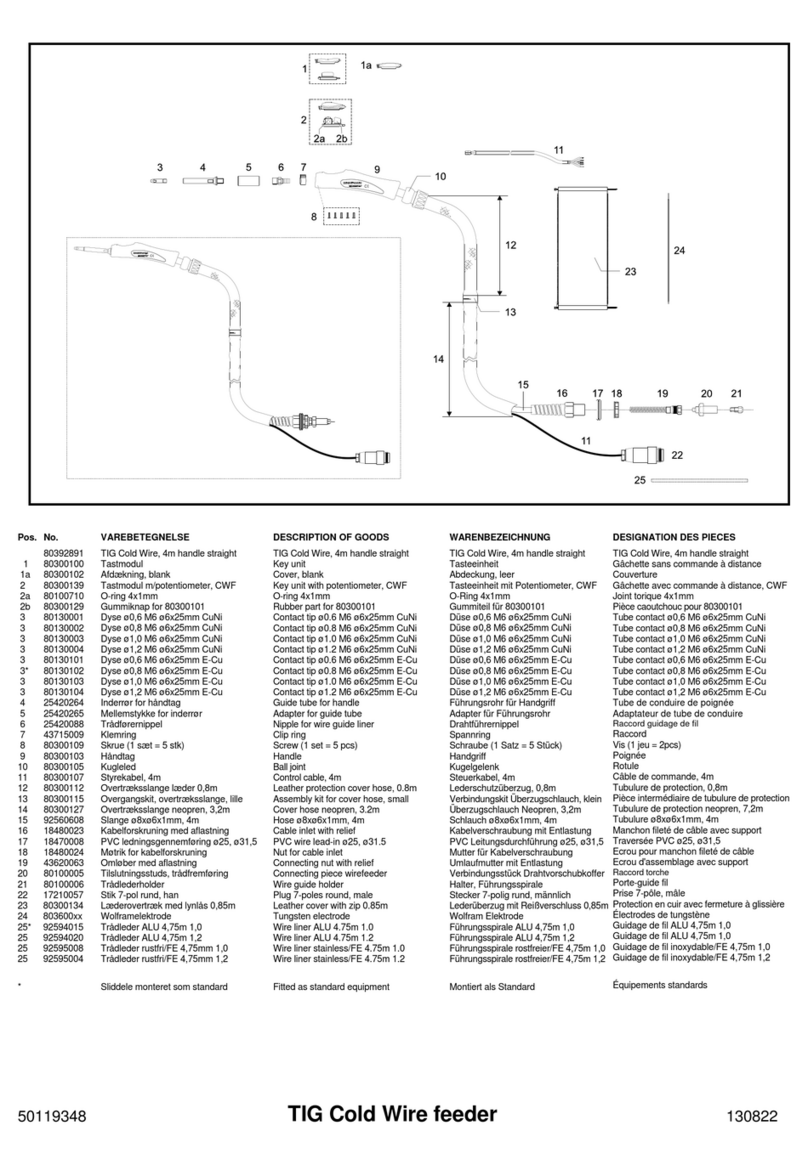

MODEL 550

US Std. Inches

Metric (mm)

Spring O.D.

.040 - .125

1.0 –3.2 mm

Spring Length

.625

16 mm

Capacity (Vol)

.5 qt.

.5 ltr.

Electrical

115 VAC, 1.5A

230VAC, 1A

Air

80 p.s.i.

5.6 kg/cc2

Air Supply

.250 min.

6 mm min.

CLEAN AIR

110V. AC

80-P.S.I.

80 LBS P.S.I.

CLEAN AIR

115VAC 60HZ

GROUNDED

POWER

SUPPLY

(230VAC

OPTIONAL)

ESCAPEMENTS

SPRING

TO

DIVISION OF C-ASSOCIATES, LLC.

MODEL NO.

SERIAL NO.

WWW.BECHERAIR.COM

SODUS, NY 315-483-6923

6

MOUNTING & SPECIFICATIONS

MODEL 600

US Std. Inches

Metric (mm)

Spring O.D.

.125 - .312

3.2 –8 mm

Spring Length

1.250

31.8 mm

Capacity (Vol)

1.5 qt.

1.4 ltr.

Electrical

115 VAC, 1.5A

230VAC, 1A

Air

80 p.s.i.

5.6 kg/cc2

Air Supply

.375 min.

10 mm min.

CLEAN AIR

110V. AC

80-P.S.I.

6.75

16.00

9.75

18.00

OPTIONAL)

115VAC 60HZ

GROUNDED

POWER

SUPPLY

(230VAC

CLEAN AIR

80 LBS P.S.I.

ESCAPEMENTS

SPRING

TO

DIVISION OF C-ASSOCIATES, LLC.

MODEL NO.

SERIAL NO.

WWW.BECHERAIR.COM

SODUS, NY 315-483-6923

~11.00

7

MOUNTING & SPECIFICATIONS

MODEL 602

US Std. Inches

Metric (mm)

Spring O.D.

.125 - .312

3.2 –8 mm

Spring Length

1.250

31.8 mm

Capacity (Vol)

1.5 qt.

1.4 ltr.

Electrical

115 VAC, 1.5A

230VAC, 1A

Air

80 p.s.i.

5.6 kg/cc2

Air Supply

.375 min.

10 mm min.

CLEAN AIR

110V. AC

80-P.S.I.

6.75

16.00

9.75

~11.00

~18.00

MODEL 602 ONLY

80 LBS P.S.I.

CLEAN AIR

115VAC 60HZ

GROUNDED

POWER

SUPPLY

(230VAC

OPTIONAL)

ESCAPEMENTS

TO

SPRING

11.64

DIVISION OF C-ASSOCIATES, LLC.

MODEL NO.

SERIAL NO.

WWW.BECHERAIR.COM

SODUS, NY 315-483-6923

8

MOUNTING & SPECIFICATIONS

MODEL 652

US Std. Inches

Metric (mm)

Spring O.D.

.250 - .625

6.35 –15.88 mm

Spring Length

1.500

38.1 mm

Capacity (Vol)

3 qt.

2.8 ltr.

Electrical

115 VAC, 1.5A

230VAC, 1A

Air

80 p.s.i.

5.6 kg/cc2

Air Supply

.375 min.

10 mm min.

110V. AC

CLEAN AIR

90-P.S.I.

ESCAPEMENTS

TO

SPRING

(230VAC

OPTIONAL)

115VAC 60HZ

SUPPLY

POWER

GROUNDED

90 LBS P.S.I.

CLEAN AIR

DIVISION OF C-ASSOCIATES, LLC.

MODEL NO.

SERIAL NO.

WWW.BECHERAIR.COM

SODUS, NY 315-483-6923

9

MOUNTING & SPECIFICATIONS

AUTOMATIC ESCAPEMENT

10

OPERATION

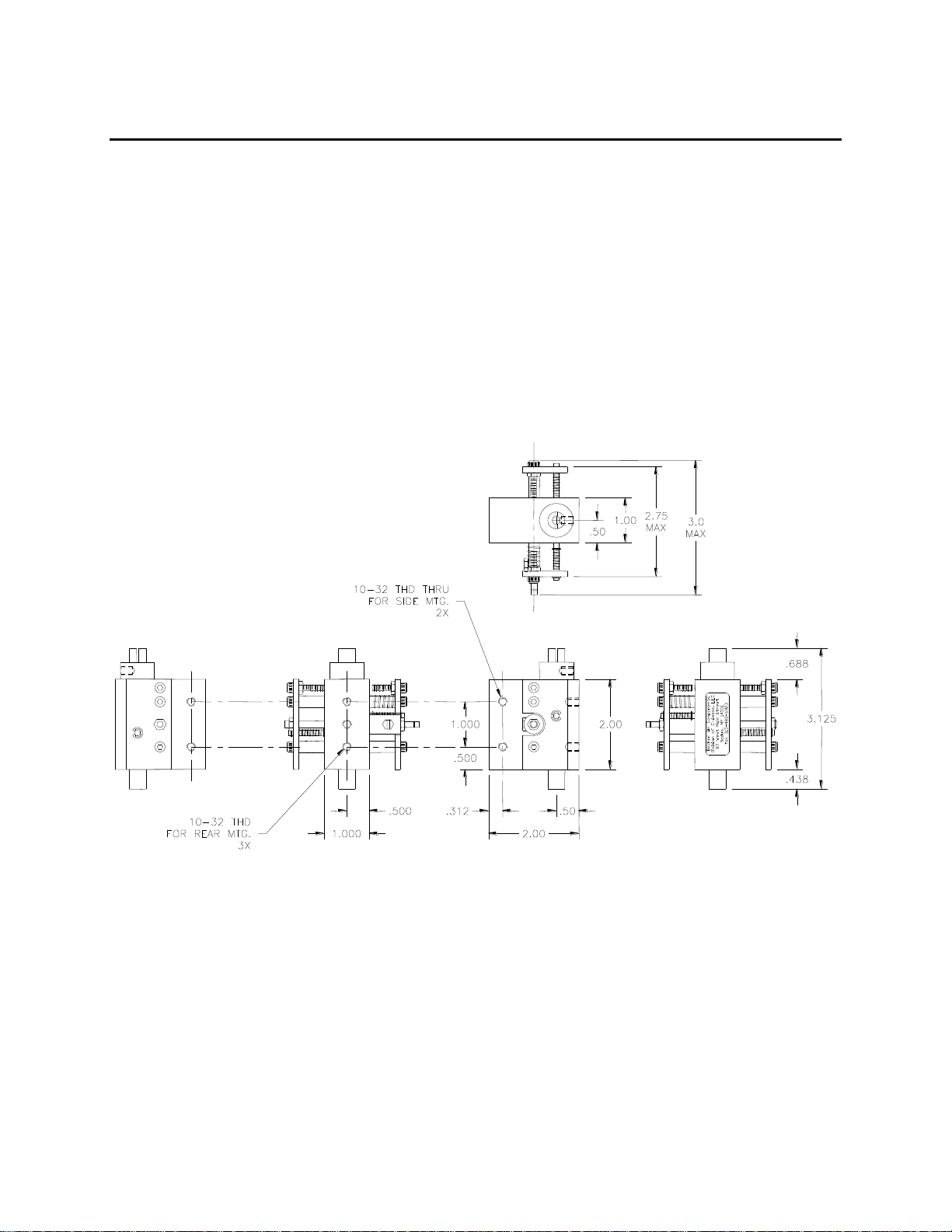

The Becmatic Spring Feeder/ Detangler

takes a quantity of springs from the rear

chamber and feeds them forward to the

spinning chamber where they are

separated, (See Fig.1.) and fed to the

Figure 1

outlet nozzle, (Fig. 2). A cycle timer

provides an air jet to clear the nozzle of

tangled springs (Fig.3). The springs are

then fed down the feed tube to the spring

escapement.

Figure 2

Load springs into the rear chamber of the

spring feeder/detangler. It is

recommended that the quantity be kept to

no more than is necessary to prevent

excessive spinning of springs, which may

result in hooked or damaged parts.

Figure 3

* Severely tangled or hooked springs should be removed from the reservoir prior to adding

new parts.

* Springs should be stored in closed containers to avoid contamination and damage.

* Springs should be clean, dry and free of lubricants or any foreign contamination.

* Foreign debris and damaged parts may cause jamming or impair feed rates.

* Power to the machine should be shut off when the feeder is not in use.

11

OPTIONAL EQUIPMENT

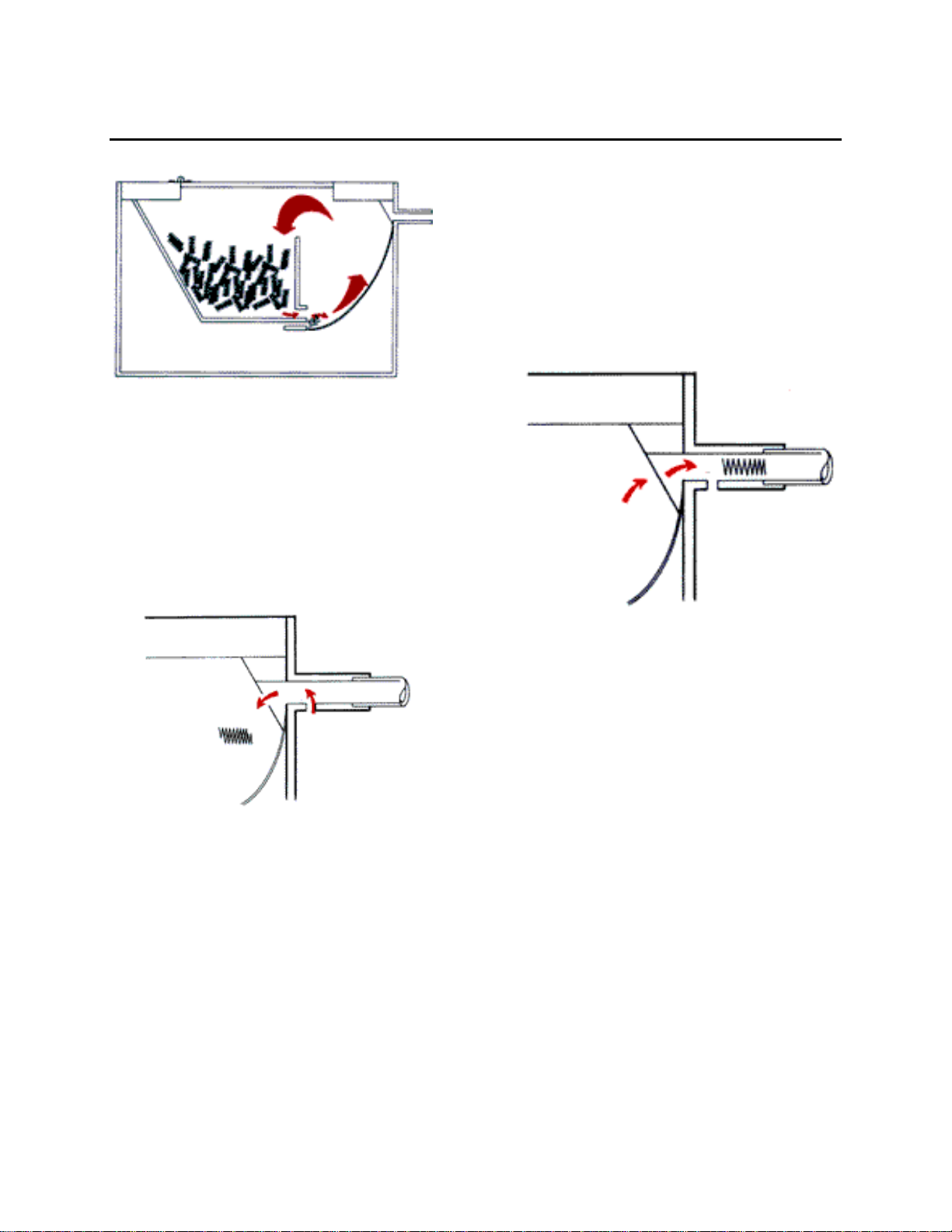

A standard automatic, single station escapement unit can be

supplied for mounting at an assembly station. Four tapped #10-

32 mounting holes are provided. Units with multiple outlet

escapements can be quoted on request.

The Automatic Escapement is mounted below the spring feeder

and will dispense one (1) spring when activated by an air signal.

The factory supplies this unit with a restricting fitting installed

on the air cylinder. If this fitting is removed, the air signal provided

by the customer must be controlled air. Full line flow/pressure

will damage the unit.

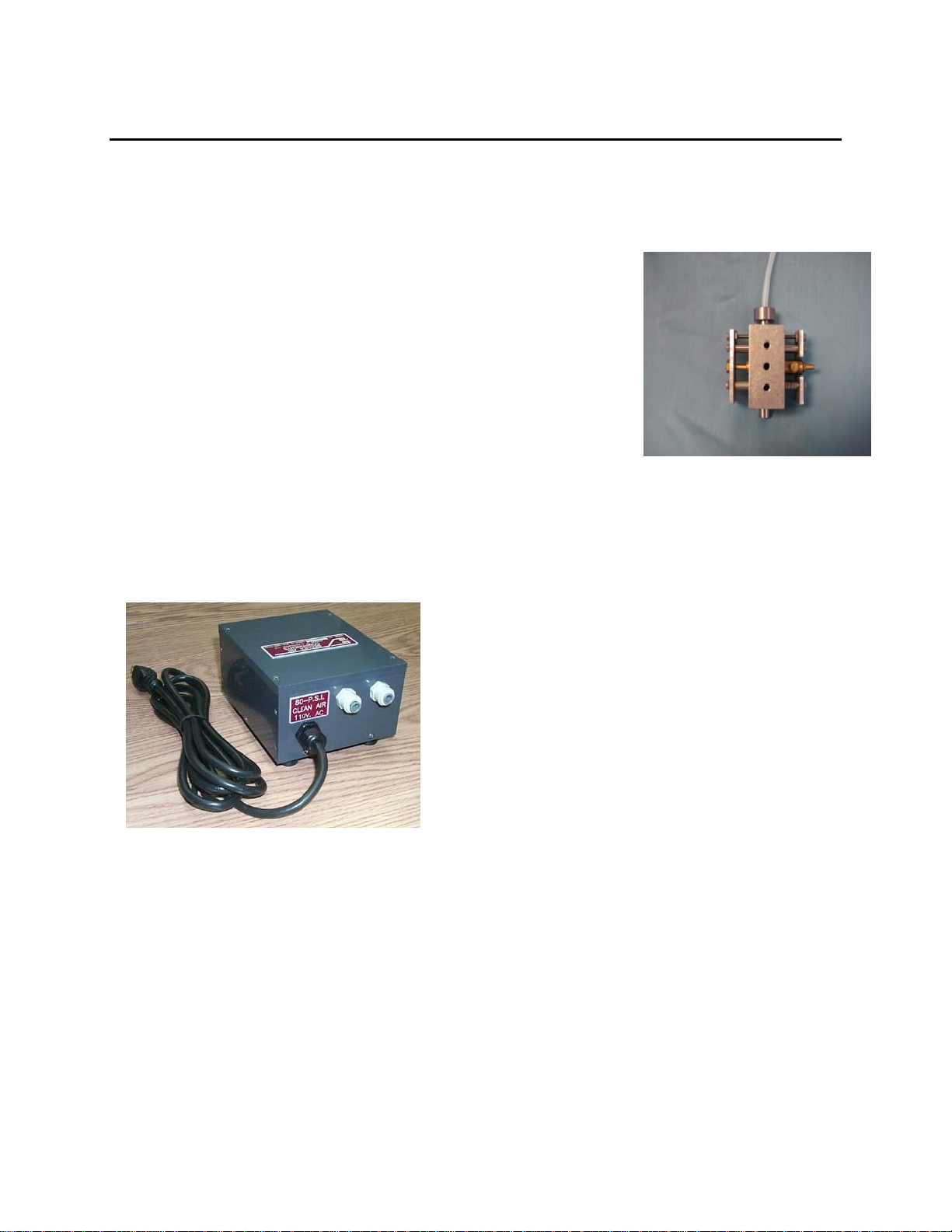

An Automatic Escapement Timer (PN: 69000-775)

may be used to automatically actuate the escapement

at a pre-determined time interval. The time interval

may be varied allowing the customer to dynamically

adjust their spring dispensation rate.

The automatic escapement can also be actuated via an optional Air Operated Foot-Pedal (not

shown). This unit allows the user of an auto escapement to manually dispense a spring as desired

by stepping on the foot-pedal. Depressing the pedal allows air to pass though to the escapement

and thus actuate the solenoid.

12

OPTIONAL EQUIPMENT

A Pen-type Escapement is available for manually releasing one spring at a time into position.

Units are tooled for specific spring sizes up to .250 inch diameter and .500 inch long.

The Bench-type Escapement provides for dispensing of one

spring at a time for manual pickup and placement.

Available for spring sizes .250 to .500 inch diameter.

13

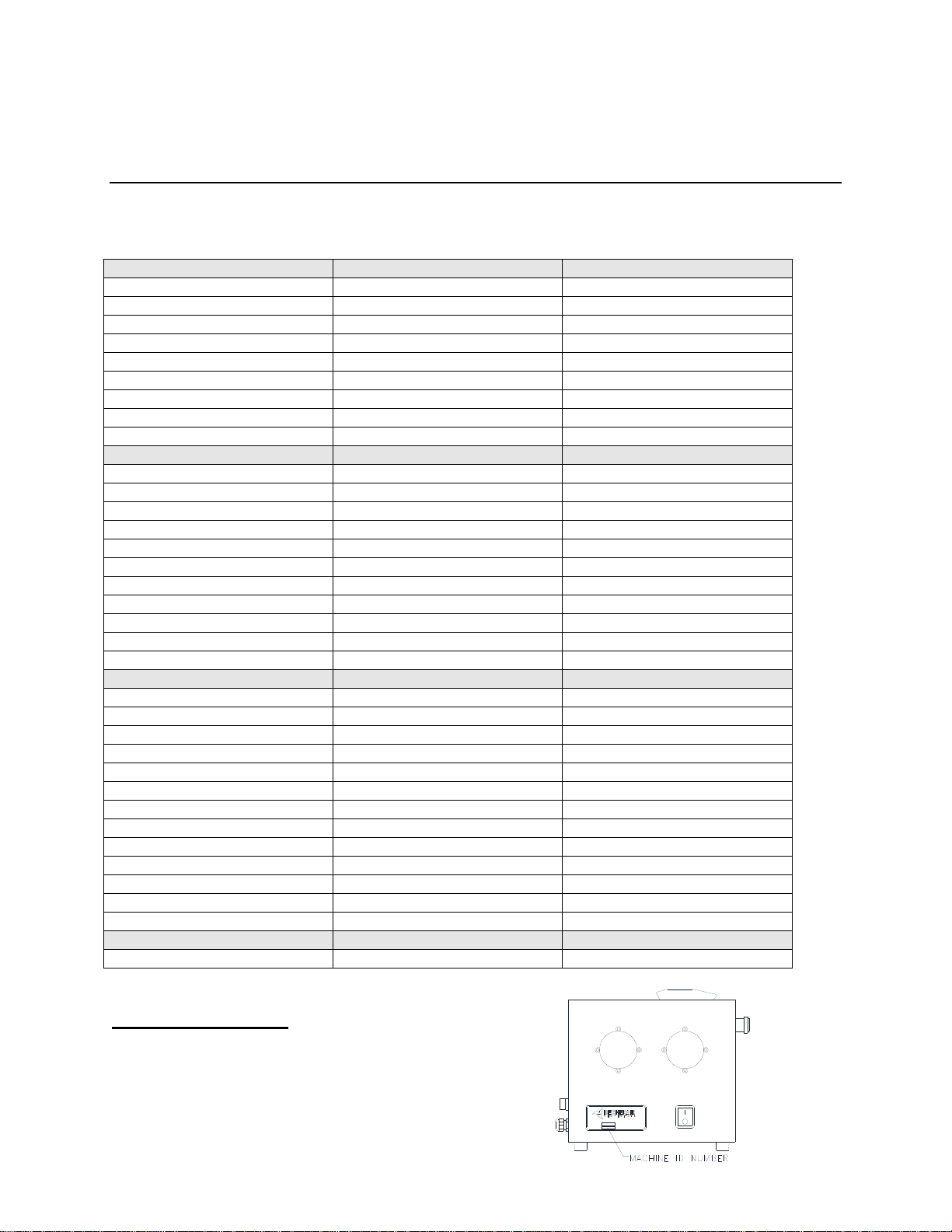

TROUBLE SHOOTING

PROBLEM

CAUSE

SOLUTION

No Power

Check power source, restore

as necessary

Fuse Blown

Remove Base Panel, replace

inline fuse

Unit will not operate,

ON/OFF, Switch does not

light.

Faulty Switch

Replace On/Off Switch

No air to unit

Restore air supply

Timer not cycling

Replace timer

Unit will not operate –

ON/OFF Switch is lit

Air valve not shifting

Replace air valve

Nozzle obstructed

Remove and clear nozzle

Springs oversized or

damaged

Replace springs

Inadequate air supply

Restore supply to 80 p.s.i.

Air leaking around door(s)

Adjust door latch/replace

gasket

Unit runs –will not feed

springs

Window(s) leaking

Replace windows

Supply reservoir over filled

Remove springs to restore

operating level

Unit runs –feed rate

inadequate

Insufficient volume in supply

reservoir

Add springs to restore

operating level

Feed tube kinked, worn or

obstructed

Replace feed tube

Springs have been

magnetized

Remove and degauss springs

Springs dirty or oily

Remove and clean springs

Springs will not feed down

tube

Static charge

Small, light springs are

subject to static charge

buildup. This may become

worse in low humidity

conditions. An occasional

shot of anti-static aerosol can

eliminate this problem. Take

care to not saturate the

springs. Any liquid –water,

oil or solvent will impair

spring feed rates.

14

MAINTENANCE

NOTE 1: It is very important that a clean air supply is maintained. Change all air line filters at

3-month intervals or as required to ensure a continuous clean air supply.

NOTE 2: Never oil any parts on the feeder or escapements, adding oil or lubricants can have a

negative impact on feed rates and could void warranty.

FEEDER MAINTENANCE:

* Once/month. Wipe out inside of feeder using non-ammonia based cleaner to remove

excess dust/dirt buildup. (Required less often if using passivated springs.)

* Once/month. Wipe spring slide ramp with Armor All or Pledge to reduce friction and

ensure springs slide freely. More frequent applications may be required depending on the

cleanliness of the springs be fed.

* Every 3 months. Check/tighten paddlewheel assembly mounting screws if applicable.

* Once/year. Check paddlewheel inserts for wear. Insert should protrude from

paddlewheel body by at least 0.75 inches. (New insert extends 0.84 inches.) If paddlewheel

inserts are excessively worn feeder may have difficulty keeping up with required feed rate. (See

parts list.)

* Once/year. Check door gasket for damage or wear which may cause air leaks at

door/feeder interface. Replace if necessary. (See parts list.)

* Once/year. Check for air leaks around windows. Repair using clear RTV. If a window

is cracked it should be replaced to prevent air leakage. Any air leaks could affect the feeder’s

ability to keep up with the required feed rate. (See parts list.)

TUBING FROM FEEDER TO ESCAPEMENT:

* The tubing, which carries the springs from the feeder to the escapements, will get worn to

a point where the springs have difficulty sliding down to the escapements. The replacement rate

varies depending on spring configuration and feed rate. Monitor system to determine the

required replacement interval.

15

ESCAPEMENT MAINTENANCE:

* Every 3 months. Check all air fittings and tighten if necessary.

* Every 3 months. Check all hardware and tighten if necessary. (If hardware is tightened

on slide rods be careful not to over torque as this could induce twist into assembly causing it to

bind when actuated. Tighten screws on each end of the slide rods to a snug condition then

actuate the escapement by hand to verify freedom of movement throughout the actuation range.

Complete the tightening in a rotational fashion until all screws are tight. After all hardware is

tight verify freedom of movement throughout actuation range.)

16

PARTS LIST

MODEL 550

115 VOLT

230 VOLT

AIR VALVE (2)

69000-406

69000-406-01

TIMER

69000-404-05

69000-404-06

ON/OFF SWITCH

69000-403

69000-403

PUSHER CYLINDER

69000-412

69000-412

CYLINDER CLEVIS

69000-576

69000-576

DOOR LATCH

69000-415

69000-415

DOOR SEAL

69000-442

69000-442

WINDOW (4)

69000-572

69000-572

MODEL 600/602

115 VOLT

230 VOLT

AIR VALVE (SM)

69000-406

69000-406-01

AIR VALVE (LG)

69000-405

69000-405-01

TIMER

69000-404-05

69000-404-06

ON/OFF SWITCH

69000-403

69000-403

PUSHER CYLINDER

69000-410

69000-410

CYLINDER CLEVIS

69000-496

69000-496

DOOR LATCH

69000-415

69000-415

DOOR GASKET

69000-442

69000-442

SIDE DOOR GASKET

69000-490

69000-490

WINDOW (4)

69000-616

69000-616

MOTOR

69000-439-01

69000-439-02

MODEL 652

115 VOLT

230 VOLT

AIR VALVE (SM) (2)

69000-406

69000-406-01

AIR VALVE (LG)

69000-405

69000-405-01

TIMER

69000-404-05

69000-404-06

ON/OFF SWITCH

69000-403

69000-403

MOTOR

69000-439-01

69000-439-02

PUSHER CYLINDER

69000-411

69000-411

CYLINDER CLEVIS

69000-496

69000-496

PADDLE WHEEL (5)

69000-694

69000-694

PADDLE WHEEL INSERT (10)

69000-695

69000-695

DOOR LATCH (2)

69000-415

69000-415

DOOR GASKET

69000-442

69000-442

WINDOW (2)

69000-616

69000-616

WINDOW (2)

69000-616-02

69000-616-02

ESCAPEMENT

N/A

N/A

AIR SOLENOID

69000-012

69000-012

Ordering Information

Before calling for parts or service, please have your

machine serial identification number ready.

DIVISION OF C-ASSOCIATES, LLC.

MODEL NO.

SERIAL NO.

WWW.BECHERAIR.COM

SODUS, NY 315-483-6923

17

This manual suits for next models

3

Table of contents

Popular Wire Feeder manuals by other brands

OHTAKE

OHTAKE NSRI Series user manual

MK Products

MK Products Cobramatic Pro Series owner's manual

ESAB

ESAB Origo Feed 304 PIPE instruction manual

Abicor Binzel

Abicor Binzel ABIDRIVE V2 Operating instruction

Afag

Afag HLF12-P Operating and installation instructions

Lincoln Electric

Lincoln Electric DLF-72 Operator's manual