3

Contents

1Overview of this machine............................................................................................................ 5

2Before use....................................................................................................................................... 5

3Operating precautions................................................................................................................. 6

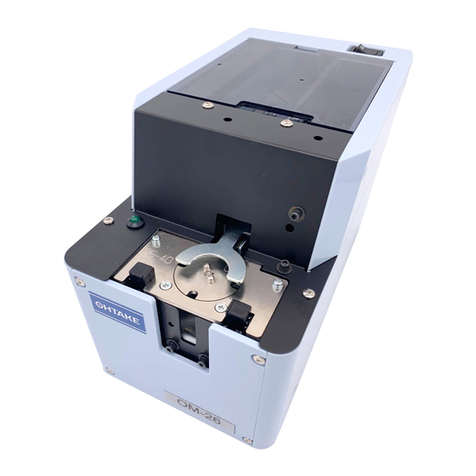

4Name of Machine parts................................................................................................................ 9

5Adjustments and checks before use ......................................................................................10

5.1 Checking the model number of the body ......................................................................... 10

5.2 Basic operation...................................................................................................................... 12

5.2.1 Amount of screws to be loaded ............................................................................... 12

5.2.2 Loading the screws..................................................................................................... 13

5.2.3 Turning ON the power ............................................................................................... 13

5.3 Checking and adjusting the brush...................................................................................... 14

5.4 Checking and adjusting the passing plate ........................................................................ 15

5.5 Checking and adjusting the rail vibration ......................................................................... 16

5.6

Checking and adjusting the holding plate

..................................................................... 18

5.7 Checking and adjusting the front/rear sides of the rail ................................................. 19

5.8 Checking and adjusting the timer ...................................................................................... 20

5.9 Installing the additional “Nejikura” Screw hopper .......................................................... 21

6Maintenance.................................................................................................................................22

7Parts adjustments and replacements ....................................................................................23

7.1 Replacing and Adjusting the Brush .................................................................................... 24

7.2 Replacing the main motor ................................................................................................... 25

7.3 Operation Timing After Replacing the Main Motor ........................................................ 26

7.4 Replacing the rail................................................................................................................... 27

7.5 Replacing the passing plate ................................................................................................ 28

7.6 Replacing and adjusting the escaper and the robot escaper guide ............................. 29

7.6.1 Replace the escaper and robot escaper guide....................................................... 30

7.6.2 Check and adjust the position of the robot escaper guide. ................................ 31

7.6.3 Adjust the escaper notch position........................................................................... 32

7.6.4 Explanation of the escaper movement before adjusting the sensor ................ 34

7.6.5 Checking and adjusting the sensor.......................................................................... 36

8Operational check.......................................................................................................................37

9Application with Robotic System............................................................................................38

9.1 Installation with Robotic System........................................................................................ 38

9.2 External output signals ........................................................................................................ 39

9.3 Robotic operations ............................................................................................................... 40

10 Miscellaneous...............................................................................................................................41

10.1 Overload Protective Circuit.......................................................................................... 41