Beck EPD Driver Board User manual

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 1 of 12

Quick Start Guide

EPD Driver Board

August 2019

About This Manual

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 2 of 12

This User’s Guide describes the characteristics, operation, and use of the

EPD-Driver board. This EPD-Driver is designed for driving of electrical panel

displays.

Power supply

There are three possibilities for the power supply on the board: over USB only,

external power supply 5V DC and from LiPo battery. The LiPO battery

capacity should not be less as 300mAh.

Depending on the supply variant there are two different jumper settings:

Jumper is assembled: the power supply can be realized over USB or

external power supply with 5V DC via the battery connector.

Connection of the LiPo battery can lead to the battery damage!

Jumper is not assembled: the LiPO battery have to be used. USB

connection is used for battery charging only and not for power supply of

the board.

Power LEDs (USB, Char)

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 3 of 12

There are two power status LEDs on the EPD board.

The USB LED indicates the presence of 5V power on the EPD board.

The Char LED indicates charging of the battery. If the LED is off the charging

is complete.

These LEDs do not light, when the jumper for USB power is assembled.

Mounting EPD-Driver and Display

Before connecting the board to a USB or battery, it is necessary to connect the

display to the correspondent port and set the basic power settings in

accordance with the requirements, specified in the display documentation.

Incorrect display’s connection or incorrect voltage setting may cause the

display’s damage.

Note: use the actual displays and driver documentation only!

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 4 of 12

To connect the EPD there are three connectors on the board (see Figure 1):

“ADA” - universal connector, “16 BIT” – connector for the EPDs with 16 data

bus and “8 BIT” – connector for EPDs with 8 bit data bus. It is allowed to use

only one connector for one display connection.

Figure 1: Top View of Typical Board Configuration

Before connecting an EPD to one of the ports on the driver board it is

important to check the conformity of the signals, defined in the specification of

the EPD driver and the display‘s documentation.

Note: in case of inconformity of the signals on the EPD driver board,

please contact the producer. It is possible to provide a suitable

connector.

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 5 of 12

All EPD connectors are lock types. Please be sure that before display’s

connection the lock is open. When connecting the display to the connector on

the EPD driver board, make sure that the contacts on the display's cable are

located at the bottom side. See figure below.

After connecting the display, fix the cable with the lock, pressing it down.

Display Voltige Settings

To install the EPD gate supply voltages, the micro switch block SW1 is used.

The necessary parameters for EPD gate supply voltages can be found in the

characteristics of the display. Using Table 1, set the Gate negative supply and

Gate Positive supply voltage by SW1 according to the display documentation.

Figure 2: SW1 Jumpers for gate voltage setup

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 6 of 12

The supported values for the gate supply voltage of EPDs are shown in the

table below.

To display a graphic information on the display from a memory card, you must

use a card with a size of up to 32 GB. The card must have a 32-bit FAT32 file

system. At the same time, the memory card should contain not only graphic

information, but also a configuration file, without which the driver does not

boot. This file must contain display information and additional driver settings.

Creation of the configuration file

The file of configuration allows to set the board’s output parameters according

to the driving EPD display. The config.ini file is placed in the main folder of SD

card. If there is no any config.ini file or any mistake takes place the board

shows an error by LED Error lightning.

There are several main settings, which can be critical for the panel usage. The

example below describes the configuration for ED133UT2. The comments (#) explain

the command lines.

## Config File v1.0

#Display Resolution in Pixel

DISPLAY_RES_X=1600

DISPLAY_RES_Y=1200

#Number of the grades of grey can be defined.

#It influences the update speed and image quality.

#Possible settings:

#2 (black and white)

#4

#8 (e.g. ES133TT3)

#16 (e.g. ED133UT2)

#Default: 2

GRAYSCALE=16

Jumper

Function

1

+28V

2

+27V

3

+25V

4

+22V

5

customized value (optional)

6

-20V

7

-22V

8

Boot

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 7 of 12

#Display bus setting

#According to the datasheet of the panel.

#Possible settings:

#8 (e.g. ED133UT2)

#16 (e.g. ES133TT3)

#Default: 8

BITS_NR=8

#VCOM in Millivolts

#VCOM Value is to find on the label of the display. It varies from unit to unit.

# -2.84V *1000 = -2840

# example on the picture below

#Default: -2000

VCOM=-2840

#Contrast of the image

#Possible settings:

#0-100

#Default: 50

CONTRAST=50

#Timer for slide show. Can be set ON/OFF

#Default: OFF

TIMER=ON

#Delay time for slide show in milliseconds

#min. 20000

TIME=60000

#Sleep mode settings

#ON/OFF

#Default: OFF

SLEEP=OFF

#END of file

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 8 of 12

Figure 3:Example of the Vcom voltage on the EPD

The config.ini has to be prepared by means of a PC in advance and saved on

the flash memory. If the config.ini is not found in the SD memory, EPD driver

does not start and LED Error lights constantly with red. In case of incorrect

configuration of the file config.ini the LED Error blinks and EPD driver can

show fault information.

Graphic files

The graphic files have to be configured according to the using panel and

requirements of the EPD driver. The EPD driver supports BMP-files as 24 bits

true color image. The resolution of the picture must not exceed the resolution of

the EPD. The smaller images will be centred and displayed in the native

resolution without scaling.

Names of the files have to be no longer as 11 signs, e.g. “004Plan.bmp”. The

number of the files is limited by 65563 and the volume of the using SD memory.

The image files are to save as separate files in the main folder on the memory

card.

Note: In case of any questions or problems with files configuration, please

contact the distributor or EPD driver’s producer.

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 9 of 12

Getting Started

1. Connect the EPD ribbon cable to the correspondent connector on the EPD

driver board.

Figure 4:EPD ED133UT2 is connected

2. Put the prepared SD card into the slot as it is shown on the picture.

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 10 of 12

3. Connect an external power supply: a battery or USB

4. Power Up. Switch on the main supply. The board should boot up immediately.

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 11 of 12

5. Check that the green LED “Aktive” blinks. (if not, see the light indication

table in the EPD driver board specification)

6. Manage the slideshow by buttons or wait for the display update by timer.

Beck GmbH & Co. Elektronik

Bauelemente KG

Eltersdorfer Str. 7

90425 Nürnberg

Germany

Tel.: +49 –(0)911 –9 34 08 –0

Fax: +49 –(0)911 –9 34 08 –28

E-Mail: info@beck-elektronik.de

Internet: www.beck-elektronik.de

Preliminary

Product Specification

EPD Driver Board

Page 12 of 12

7. If the settings are correct, the display should show an image.

Before turning to the Support Hotline, please make sure that your query is not

answered in one of these manuals or “Datasheet” documents.

Table of contents

Other Beck Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Link electronics

Link electronics SDI to Analog Composite & Y/C DigiFlex 1159 Specification sheet

Lenovo

Lenovo ThinkCentre M53 Hardware Maintenance Manual

Renkforce

Renkforce 4500 Series user manual

ThermoKey

ThermoKey EPS Technical manual

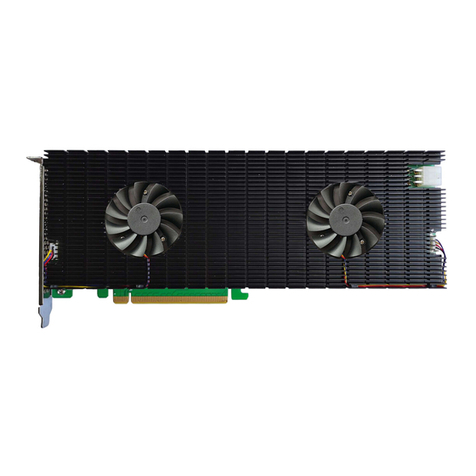

HighPoint

HighPoint SSD7540 Quick installation guide

Key Digital

Key Digital HD Leeza KD-HD1080P operating instructions

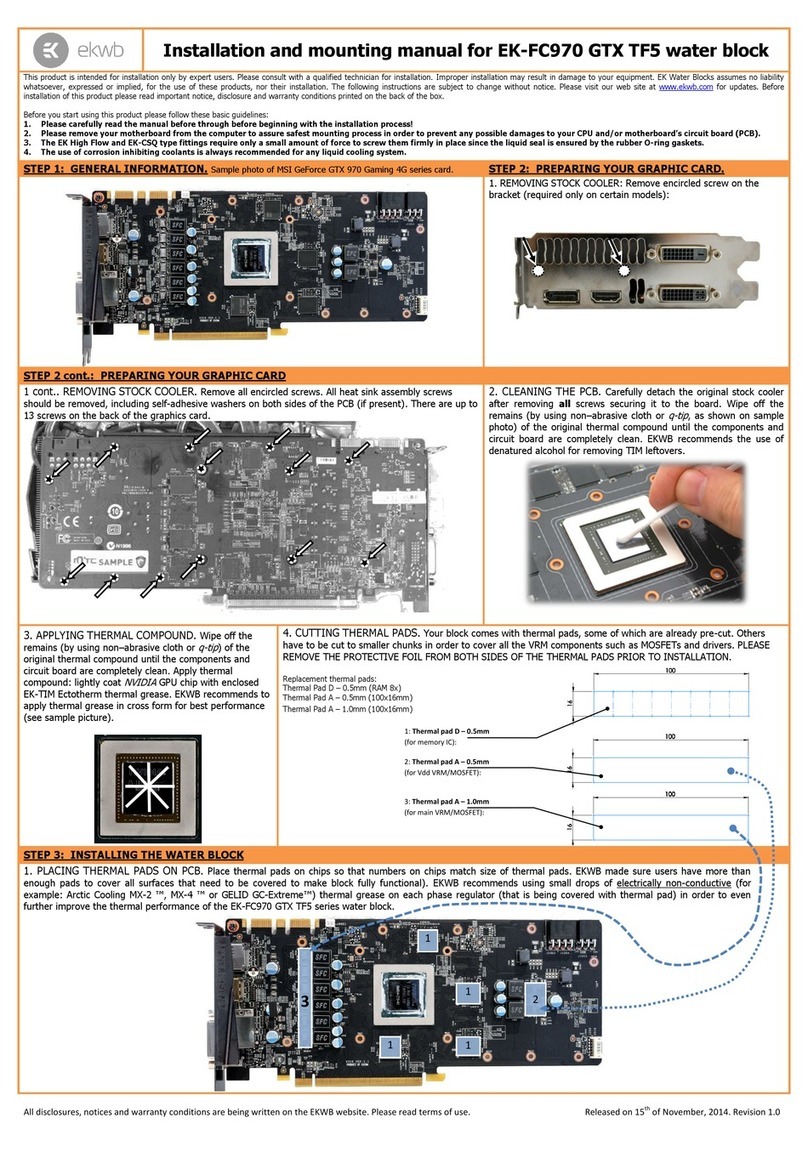

ekwb

ekwb EK-Quantum Reflection2 PC-O11D EVO D5 PWM... user guide

IBASE Technology

IBASE Technology MPT-1000V user manual

Zmotion

Zmotion EIO16084 manual

Renesas

Renesas R-IN32M4-CL2 TESSERA Application note

EK-Quantum

EK-Quantum Momentum2 ROG Strix X570-i Gaming D-RGB user guide

ekwb

ekwb EK-FC970 GTX TF5 INSTALLATION AND MOUNTING MANUAL