What to do if Low Water Lockout

Occurs with New Sensor

1. Turn off power to the control.

2. Remove sensor from well and disconnect green

sensor wire. Leave the main sensor cable

connected to the control.

3. Being careful not to allow the sensor or the green

wire to touch anywhere in the terminal area of the

control, restore power to the control. Within 30

seconds the AquaSmart control should enter into

Lockout Water Low.

LOCKOUT

WATER LOW

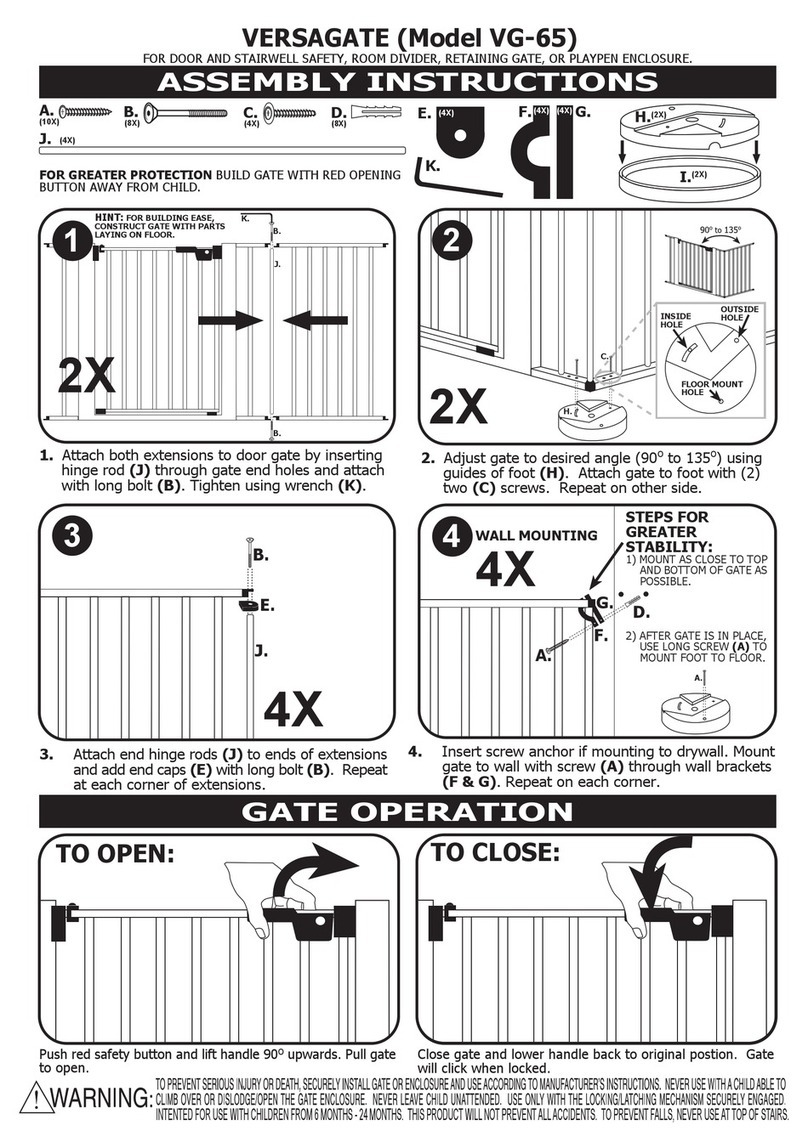

4. Use the 1,000 Ohm resistor attached to this

instruction sheet. Place one resistor lead on the

metal pin of the sensor, the second resistor lead

should be on a metal portion of the connector for

the green wire coming from the sensor (see pictures

below). Hold the resistor in place with ngers.

Within 30 seconds the Lockout Low Water fault on

the display should clear. If the Lockout Low Water

clears, the sensor is operating properly.

Other Possible Causes:

• Poor connections in the LWCO circuit wiring

• Deposit build up on the well or boiler vessel

• Conductivity issues with the water.

5. Recheck the continuity of the LWCO circuit following

the procedure on the previous page.

6. If the sensor is good and the LWCO connection

wiring is good, drain water from the boiler, remove

the well and check for deposit build up on the well.

Clean if necessary and reinstall the well. Rell the

boiler. Check for proper operation of the LWCO

circuit.

7. If the sensor, LWCO connection wiring and well are

good, attempting to measure the resistance through

the water may provide some indication of the

conductivity of the water in the system. Remove the

sensor from the well. Place one of the ohm meter

probes on the metal tube inside the well and place

the second probe on the metal of the boiler vessel.

• 100K ohms or above - water not in contact with

well, deposit build up in boiler vessel

• 5K-100K ohms - intermittent operation could

occur

• 5K ohms or below - LWCO should operate

These are rough guidelines only.

Normal Display Heating Water

HEATING WTR

WTR: 120F

R.W. BECKETT CORPORATION

P.O. Box 1289, Elyria, Ohio 44036

R.W. BECKETT CANADA, LTD

430 Laird, Unit 3, Guelph, Ontario, N1G 3X7

Part No. 62075-001 R00, Printed in the USA 10/15

1K Ohm

Resistor

Here