OM1004 ISSUE 20 PAGE 5 OF 30

1 INTRODUCTION

This manual describes the operation of the Mag-03 range of three axis magnetic field sensors.

These compact high performance sensors with integral electronics provide measurements of

static and alternating magnetic fields in three axes. The sensors, alternatively described as

magnetometers, convert magnetic flux density, measured in three axes, into a bipolar analog

voltage. Analog output voltages Vx, Vy and Vz are in linear proportion to the flux density.

In designing the Mag-03 series, the policy has been to provide a high performance sensor

having a flat amplitude response and a small, predictable phase lag over a wide bandwidth.

In order to offer maximum flexibility and not degrade the performance, the sensor has no

internal filters. The analog outputs may require external filters to optimise the performance

depending on the application. The Mag-03PSU power supply contains simple filters which

may be sufficient, but for more stringent requirements the Mag-03SCU signal conditioning

unit may be appropriate.

The sensors are available in a variety of enclosures, as detailed below, with five measuring

ranges. A low noise version can be supplied in all packages with a measuring range of

±70μT or ±100μT.

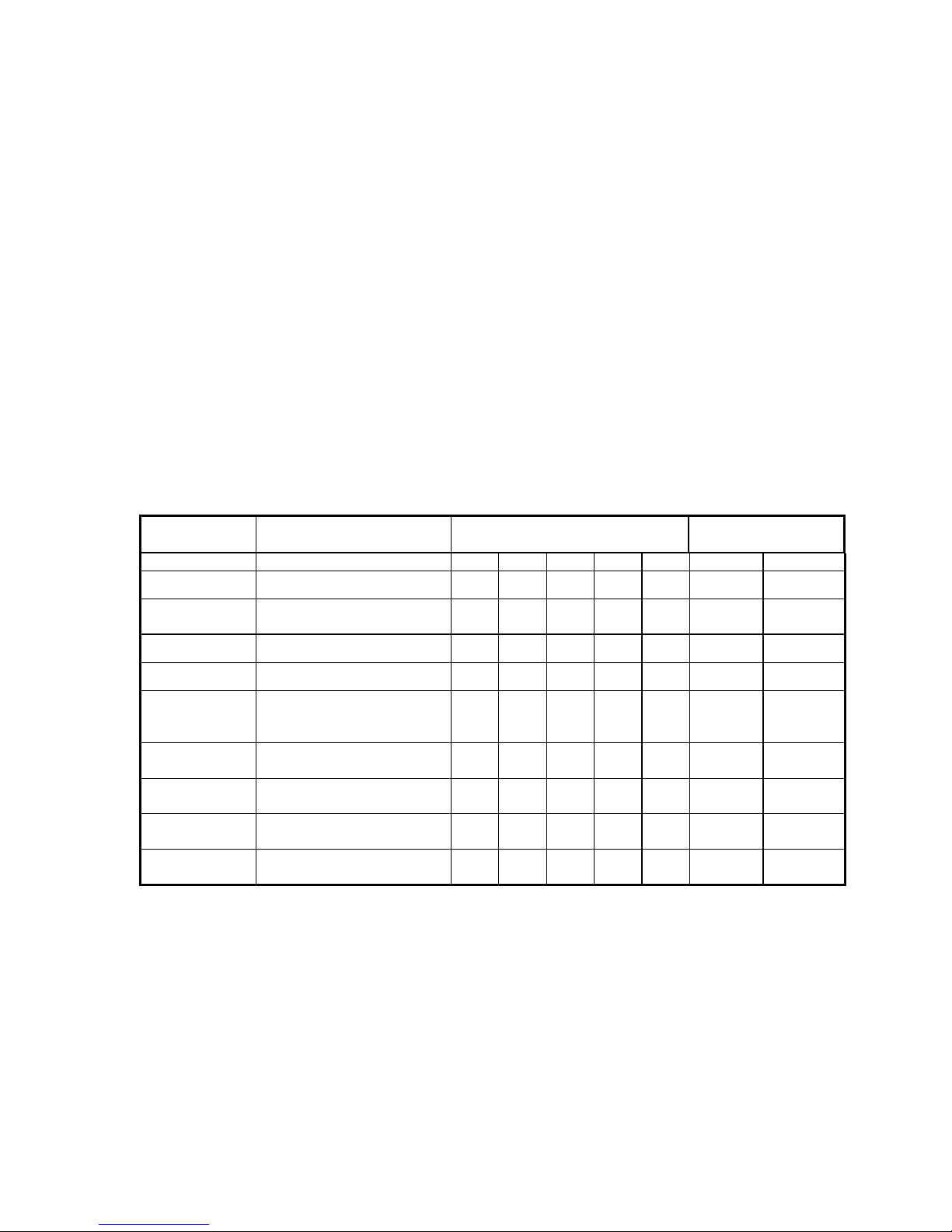

TYPE ENCLOSURE MEASURING RANGE (μT) ORTHOGONALITY

ERROR (°)

70 100 250 500 1000 0.1 0.5

Mag-03MC Cylindrical ***** *

Mag-03MCES Cylindrical - environmentally

sealed connector ***** *

Mag-03MCFL Cylindrical with flying leads ***** *

Mag-03MS Square section ***** *

Mag-03MSES Square section -

environmentally sealed

connector

***** *

Mag-03MSS Square section submersible to

100 metres ***** *

Mag-03IE Cylindrical with independent

elements *****

Mag-03MCTP

(to special order) Cylindrical - two part

construction ***** *

Mag-03MCUP

(to special order) Unpackaged ***** *

TABLE 1. Mag-03 SENSORS

Products are specified as Mag-03 followed by the enclosure code (MC, MCES, MCFL, MS,

MSES, MSS or IE) followed by L for the low noise version only, then the measuring range

(70, 100, 250, 500 or 1000μT).

e.g. Mag-03MSL70 is a square section low noise sensor with a range of ±70μT

Mag-03MC1000 has a cylindrical enclosure and a range of ±1000μT

A re-calibration service is available which is traceable to international standards.