behr Labor-Technik behrotest R 304 User manual

behr

Labor-Technik

R 304

R 306

R 104 S

R 106 S

R 254

R 256

behrotest®

In-Line Extraction Units

User’s Manual

Please read this User’s Manual carefully before using your new behrotest® In-Line extrac-

tion apparatus!

The User’s Manual provides you with clear and simple instructions for using the apparatus.

Additional information, which is useful and important for an understanding of the operation

of the apparatus is denoted in the manual by a gray stripe in the margin.

In the interest of insuring safe utilization of the In-Line-Extraction apparatus, observe care-

fully the safety warnings in the manual, which are designated by an exclamation mark !

We wish you success and satisfaction in the use of your

behrotest®

In-Line Extraction apparatus

Safety Warnings

Always use the extraction apparatus in a fume hood! Release of solvent vapors is

possible!

To avoid electrical shock risk, insure that no liquids come into contact with the

electrical power cable or get into the inside of the electrical components!

Exercise appropriate caution in working with chemicals! Observe the warnings and

guidance in the Material Safety Data Sheet (MSDS) carefully!

Exercise due care and observe pertinent safety regulations in working with glass

components!

To avoid burn injury, do not touch the solvent vessel or extractor with your bare

hands immediately after an extraction; they will be hot!

To avoid risk of re and explosion, under no circumstances should solvent be

poured on the hot heating unit!

Safety Warnings .................................................................................................. 3

1 Description ............................................................................................... 5

2.1 Completeness and absence of damage ............................................................... 6

2.2 List of Components............................................................................................... 6

Basic unit for four or six samples....................................................................................... 6

R 304 ................................................................................................................................. 6

R 306 ................................................................................................................................. 7

R 104 S.............................................................................................................................. 7

R 106 S.............................................................................................................................. 7

R 254 ................................................................................................................................. 7

R 256 ................................................................................................................................. 8

3 Assembling the behrotest® in-line extraction units ............................ 9

3.1 Attaching the Vertical Support Bars ...................................................................... 9

3.2 Attaching theHorizontal Support Bars................................................................. 10

Bars with Extractor Mountings......................................................................................... 10

Condenser storage standwith cooling water distributor....................................................11

3.3 Installing thehot plate ask adapters ................................................................. 12

3.4 Inserting the glassware....................................................................................... 12

3.5 Connecting the Water Hoses .............................................................................. 14

Cooling Water Distributor................................................................................................. 14

Disconnectingthe quick push-in connections .................................................................. 16

3.6 Using a Model UK 12Circulating Water Cooler................................................... 16

3.8. Connecting to the Mains Power Line.................................................................. 17

3.7 Leak Testing........................................................................................................ 17

4 Using the inline extraction unit ............................................................ 18

4.1 Sample preparation............................................................................................. 19

4.2 Switching the inline heating unit on .................................................................... 19

4.3 Starting the Extraction......................................................................................... 20

4.4 Ending the Extraction.......................................................................................... 20

5 Cleaning the In Line Extraction Apparatus ......................................... 21

Basic Framework and Horizontal Support Bars .............................................................. 21

Round bottomed asks and extractors............................................................................ 21

Reux Condensers .......................................................................................................... 21

5.1 Customer Service ............................................................................................... 21

Appendix............................................................................................................ 22

Replacement parts and accessories............................................................................... 22

Technical Specications.................................................................................................. 23

Contents

– 5 –

© behr Labor-Technik 2006

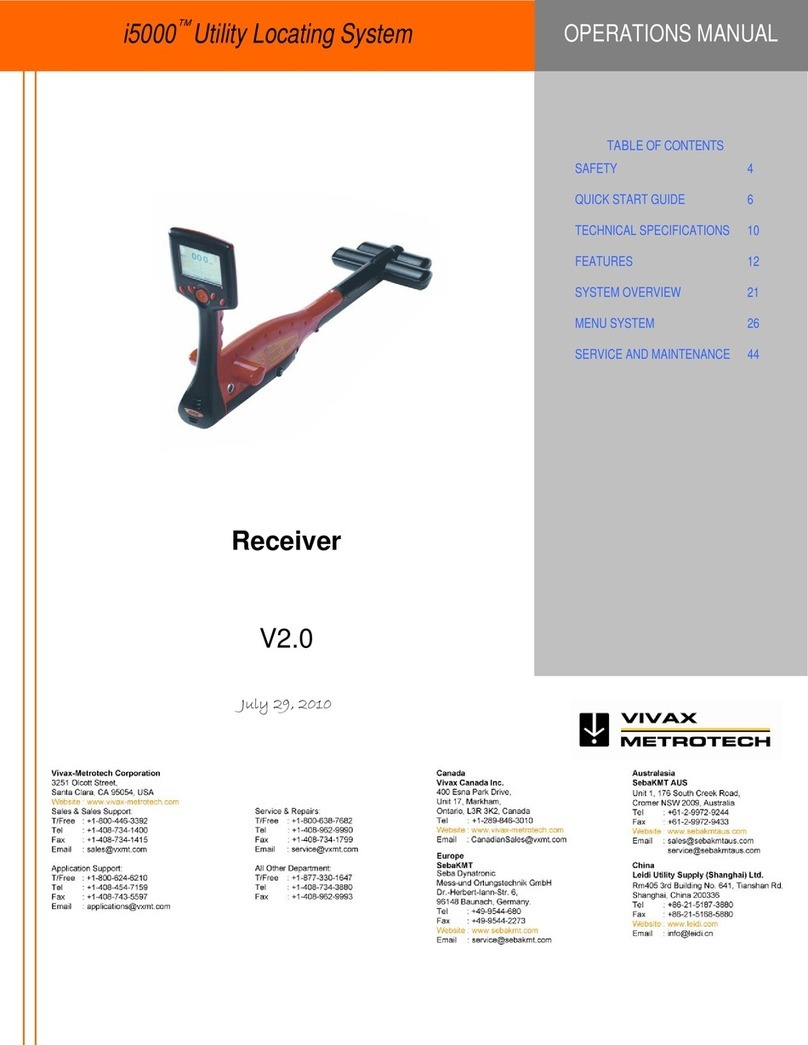

1 Description

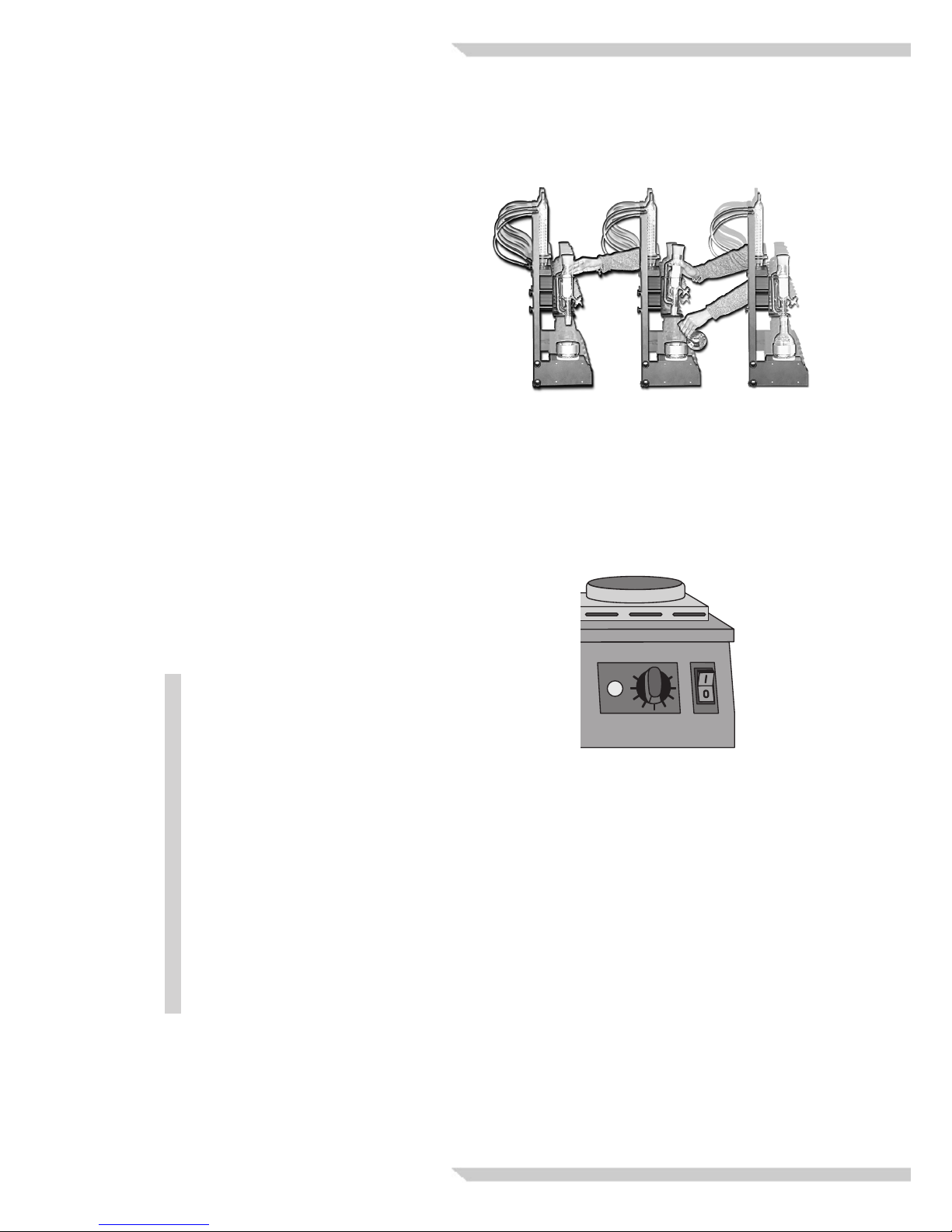

The behrotest® In-Line Extraction Unit is used for Soxhlet extraction, mainly in food, food-

stuffs and soil analysis.

Depending on the model and conguration, the apparatus consists of either four or six

individually adjustable heating positions for round-bottom asks of up to 500 ml volume,

which are used in conjunction with extractors between 30 and 250 ml.

The full capabilities of the behrotest® In-Line Extraction Unit in daily laboratory utilization

can only be realized if you carefully read and follow all of the guidance in this manual.

Description

Vertical support bars

Drip pan

Adjustable extractor

mounts

Hot-plates with ask

adapters

In-line hot plates

Heating power ad-

justments

On/Off switch

with built-in circuit

breaker

Crossbars for the

extractor mounts

Cooling water

distributor with con-

denser stand

Heating indicator lights

– 6 –

behrotest® In-Line Extraction Unit

2 Contents of Delivery

2.1 Completeness and absence of damage

The individual components of your behrotest® In-Line Extraction Unit have been assem-

bled and packed with the greatest of care.

Please check the contents of the delivery for completeness and absence of damage be-

fore assembling the apparatus. The correct contents of delivery is presented in the follow-

ing list of components.

If you do nd damage, please follow the instructions provided in the leaet entitled

„Transportation Damage? What to do if…“,

Which you will nd included among the shipping documents. If you do have grounds for a

damage claim, please contact:

behr Labor-Technik GmbH

Spangerstraße 8

40599 Düsseldorf/Germany

Telefon: +49 (0)211 7 48 47 32

Telefax: +49 (0)211 7 48 47 48

eMail: info@behr-labor.com

2.2 List of Components

All behrotest® In-Line Extraction Units consist of a

Basic unit for four or six samples

1 In-line hot-plate array R 4 (4 hot plates) or R 6 (6 hot plates)

2 Vertical support bars

1 Cooling water distributor with condenser stand (4 or 6 place) and drip pan,

1 Crossbar with 4 or 6 adjustable extractor mounts

1 Water inow hose, polyamide, Ø 8 mm

1 Water outow hose, PVC, Ø 12 mm

1 Disconnecting tool for Speedt hose connections

1 Connection for “ pipe thread water tap

1 Adapter for “ pipe thread water tap

Depending on the model, the following complete extraction glassware is provided

R 304

4 Aluminium hotplate adapters to t 100 ml round bottom asks

4 Distance parts for 100 ml round-bottom asks

4 100 ml round bottom asks (RK 100)

– 7 –

© behr Labor-Technik 2006

4 Soxhlet extractors, 30 ml (EZ 30)

4 Spiral coil reux condensers for 30 ml Soxhlet (RFK 30)

1 Silicone tube, 6 x 2 mm, 3 m

1 Package containing 25 extraction thimbles to t the 30 ml Soxhlet extractor (EX 30 HS)

1 User’s Manual

R 306

6 Aluminium hotplate adapters to t 100 ml round bottom asks

6 Distance parts for 100 ml round-bottom asks

6 100 ml round bottom asks (RK 100)

6 Soxhlet extractors, 30 ml (EZ 30)

6 Spiral coil reux condensers for 30 ml Soxhlet (RFK 30)

1 Silicone tube, 6 x 2 mm, 3 m

1 Package containing 25 extraction thimbles to t the 30 ml Soxhlet extractor (EX 30 HS)

1 User’s Manual

R 104 S

4 Aluminium hotplate adapters to t 250 ml round bottom asks

4 Distance parts for 250 ml round-bottom asks

4 250 ml round bottom asks (RK 250)

4 Soxhlet extractors, 100 ml (EZ 100/HAHN)

4 Spiral coil reux condensers for 100 ml Soxhlet (RFK 100)

1 Silicone tube, 6 x 2 mm, 3 m

1 Package containing 25 extraction thimbles to t the 100 ml Soxhlet extractor (EX 100 HS)

1 User’s Manual

R 106 S

6 Aluminium hotplate adapters to t 250 ml round bottom asks

6 Distance parts for 250 ml round-bottom asks

6 250 ml round bottom asks (RK 250)

6 Soxhlet extractors, 100 ml (EZ 100/HAHN)

6 Spiral coil reux condensers for 100 ml Soxhlet (RFK 100)

1 Silicone tube, 6 x 2 mm, 3 m

1 Package containing 25 extraction thimbles to t the 100 ml Soxhlet extractor (EX 100 HS)

1 User’s Manual

R 254

4 Aluminium hotplate adapters to t 500 ml round bottom asks

Contents of Delivery

– 8 –

behrotest® In-Line Extraction Unit

4 Distance parts for 500 ml round-bottom asks

4 500 ml round bottom asks (RK 500)

4 Soxhlet extractors, 250 ml (EZ 250/HAHN)

4 Spiral coil reux condensers for 250 ml Soxhlet (RFK 250)

1 Silicone tube, 6 x 2 mm, 3 m

1 Package containing 25 extraction thimbles to t the 250 ml Soxhlet extractor (EX 250 HS)

1 User’s Manual

R 256

6 Aluminium hotplate adapters to t 500 ml round bottom asks

6 Distance parts for 500 ml round-bottom asks

6 500 ml round bottom asks (RK 500)

6 Soxhlet extractors, 250 ml (EZ 250/HAHN)

6 Spiral coil reux condensers for 250 ml Soxhlet (RFK 250)

1 Silicone tube, 6 x 2 mm, 3 m

1 Package containing 25 extraction thimbles to t the 250 ml Soxhlet extractor (EX 250 HS)

1 User’s Manual

optional:

Hydrolysis units – HYDRO 1 for 1 sample or HYDRO 6 for 6 samples

Circulating water coolers for condensers – UK 12/1000 or UK 12/2000

– 9 –

© behr Labor-Technik 2006

3 Assembling the

behrotest® in-line extraction units

Always operate the in-line extraction unit in a fume hood! Solvent vapors may

escape!

To avoid the risk of electrical shock, insure that no liquid comes in contact with

the power cable or gets into the inside of the apparatus!

Follow carefully safety regulations and exercise due caution in working with glass

components!

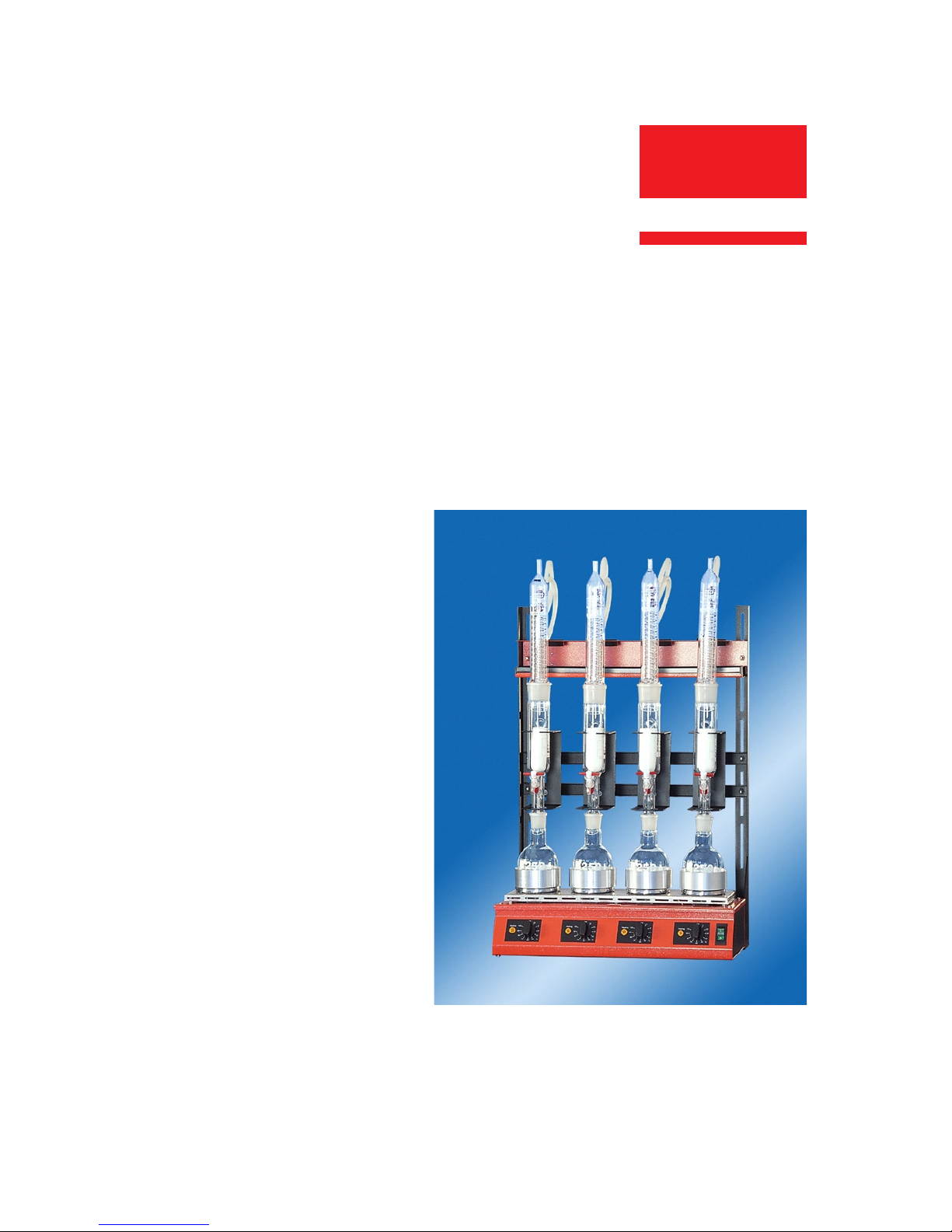

3.1 Attaching the

Vertical Support Bars

1. Place the in-line heating unit on a at level

surface.

Assembling the in-line extraction unit

2. Attach both vertical support bars to the side of

the in-line heating unit using the four knurled

screws provided.

Insure that the lower ends of the sup-

port bars, which are to be attached to the

heating unit, are resting on the bench top.

The angle bracket for attaching the sup-

port bars has elongated slots for inserting

the screws. This allows you to adjust the

vertical height of the support bars. Angle brackets

with elongated

slots

– 10 –

behrotest® In-Line Extraction Unit

3.2 Attaching the

Horizontal Support Bars

Bars with Extractor Mountings

Insert the bars with the extractor mountings from

below between the internal track formed by the

horizontal support bars. The extractor mountings

must be oriented with the slotted opening on top,

facing forward.

The correct height of attachment for the

horizontal support bars depends on the

glassware being used. For example, in

the case of the 100 ml Soxhlet extrac-

tion, locate the screw holes of the upper

horizontal support bar at the lower ends

of the third elongated slots in the vertical

support bars. The height can be readjust-

ed as needed at any time in the future.

Fasten the horizontal support bars with the

four knurled screws provided.

Slotted openings

– 11 –

© behr Labor-Technik 2006

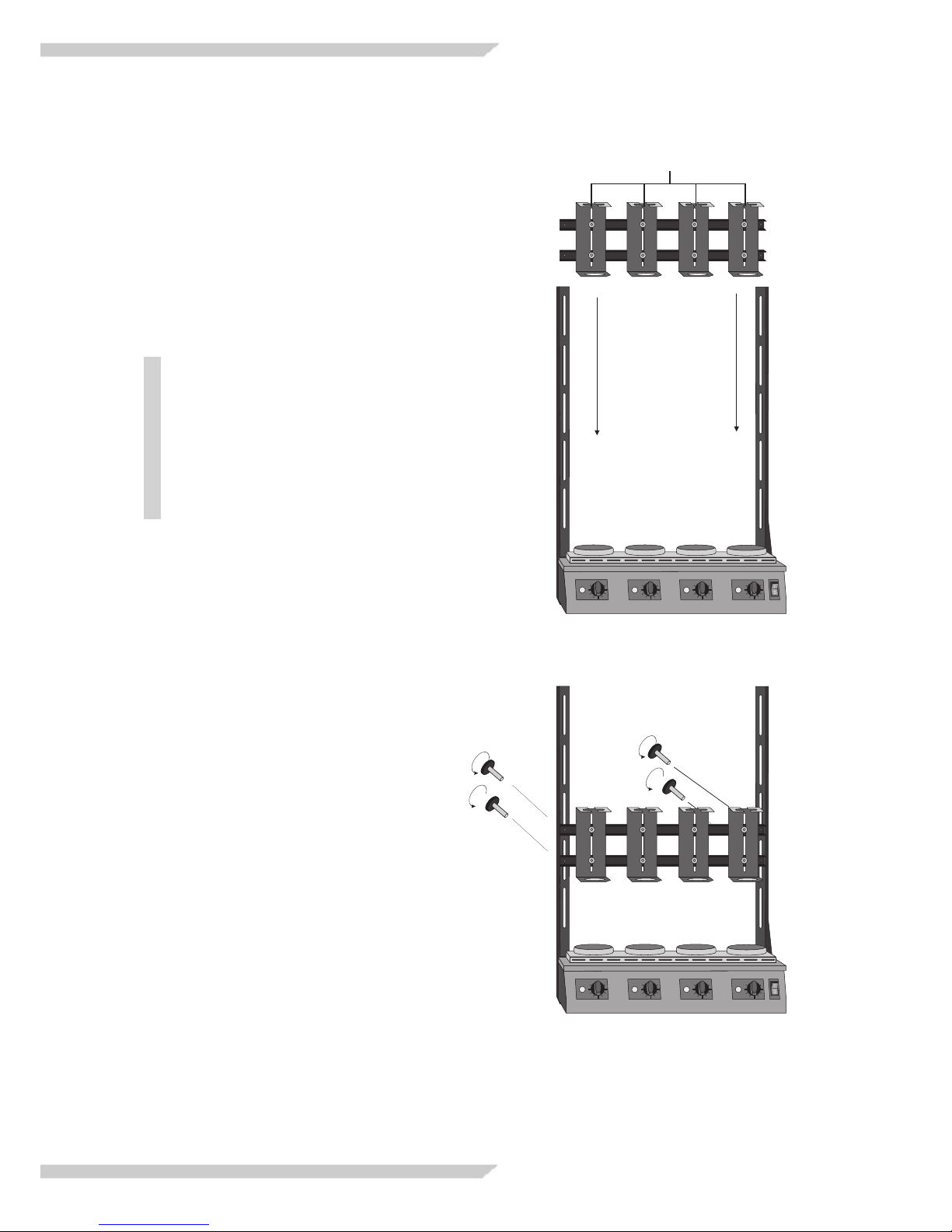

Condenser storage stand

with cooling water distributor

Insert the condenser storage stand from above

between the internal track formed by the horizon-

tal support bars.

Position the screw hole of the condenser stand at

the lower ends of the uppermost elongated slots

in the vertical support bars.

Fasten the condenser stand in place with

the pair of knurled screws provided.

Assembling the in-line extraction unit

Insert the drip tray into the condenser storage

stand.

– 12 –

0

l

behrotest® In-Line Extraction Unit

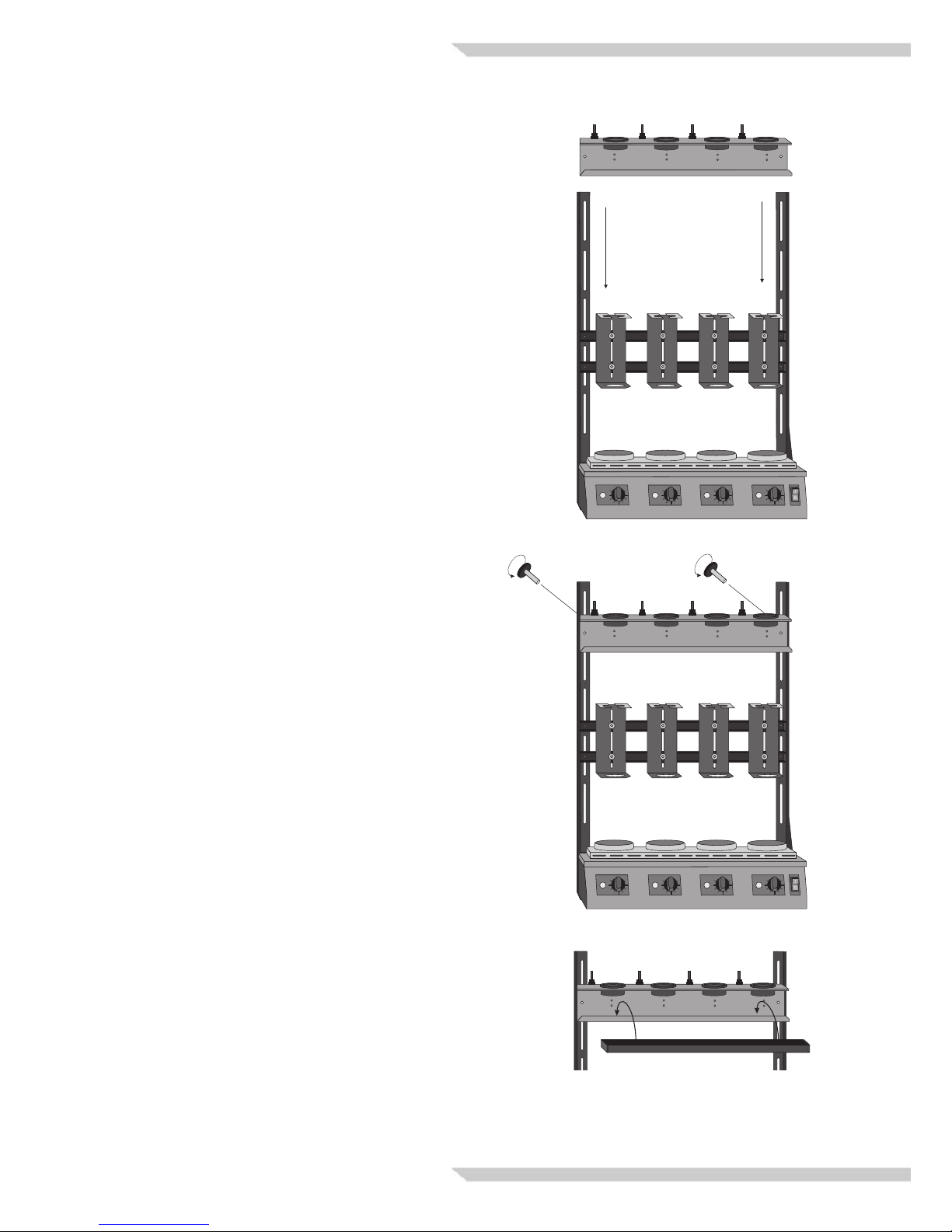

3.4 Inserting the glassware

To minimize the risk of breakage, always

hold all glassware in the vicinity of the

standard taper joint! Never use grease on

the standard taper joints!

1. Place the distance parts into the ask adapt-

ers.

The asks must not be placed directly

into the adapters; otherwise they might

break on heating. Never use your in-line

extraction unit without the distance parts!

2. Place the round bottom ask in the ask

adapter on the hotplate.

Check once more the height of the cross-

bars with extractor mounts. The upper

end of the neck of the round bottom ask

must protrude several millimeters into

the lower opening of the extractor mount.

This will secure the ask against tipping

over.

If necessary, adjust the height of the

crossbars.

3.3 Installing the

hot plate ask adapters

Place the hot plate ask adapters on the hot-

plates.

Take care that the adapters are seated securely

on the hot plates and cannot slip off sideways.

– 13 –

© behr Labor-Technik 2006

3. Insert the extractors from above into the ex-

tractor mounts and seat them on the round

bottom asks.

The upper horizontal segment of the extrac-

tor mounts have a slot in front. In the event

that you are using an extractor with spigot (for

example, the behrotest® EZ 100/HAHN), then

guide the extractors with the spigots carefully

through these slots.

Assembling the in-line extraction unit

4. Insert the reux condensers onto the extrac-

tors.

– 14 –

1

2

3

behrotest® In-Line Extraction Unit

3.5 Connecting the Water Hoses

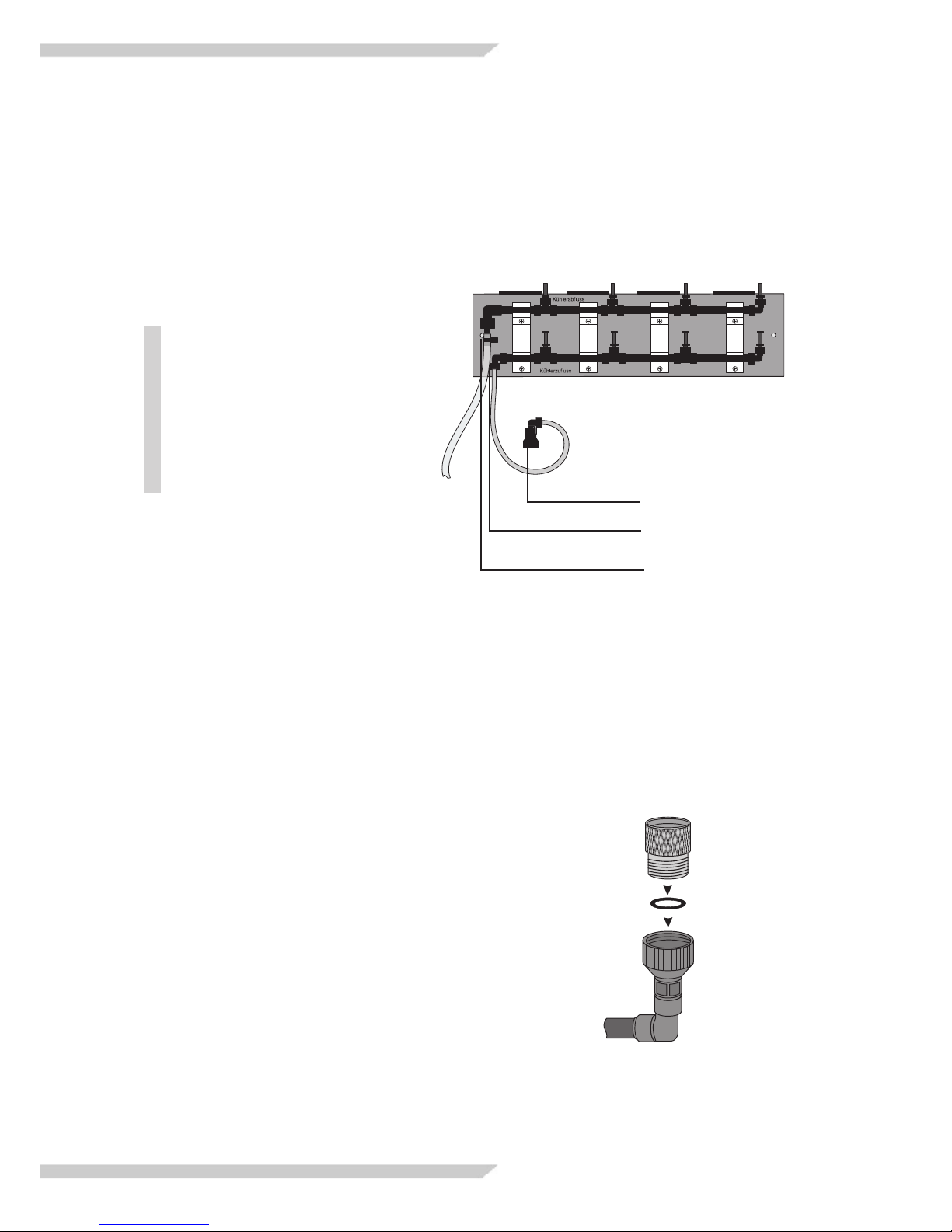

Cooling Water Distributor

1. Cooling water supply

The cooling water supply hose is made of polya-

mide and is 2 meters long. If necessary,

shorten it as required.

Use only a very sharp blade,

such as a scalpel or box cutter

to cut polyamide hoses. The cut

end must be free of burrs and at

a sharp right angle. Avoid defor-

mation of the hose. By following

these procedures a leak-free

seal will be guaranteed in the

push-on tting.

The connection (2) for the cooling water sup-

ply hose is found on the rear of the condenser

stand.

• Push one end of the water supply hose as

far as it will go into the connection.

• In the same manner, attach the “ water tap

connection (1) to the other end of the hose.

• Bring the water supply hose to a laboratory

water tap.

Water tap with “ pipe thread

Insert a washer in the connector and screw

the fasten the water supply hose to the water

tap by screwing the connector onto the “

pipe thread of the water tap.

Water tap with “ pipe thread:

Use the “ to “ adapter.

Place a washer in the connector and screw

the adapter and connector together. Then

screw the adapter onto the “ pipe thread of

the water tap.

– 15 –

© behr Labor-Technik 2006

2. Cooling water outow

The connection for the cooling water outow (3, gure on pre-

vious page) is likewise located on the rear of the cooling water

distributor with condenser stand.

Insert the black tubing segment of the outow (drain) hose as

far as it will go into the hose receptacle.

Lay the hose to a sink or other drain.

Insure that there are no tight curves or kinks in the

hose. If necessary, shorten the hose to prevent

constrictions of this nature.

3. Connections to the Condensers

• Cut appropriate lengths of the silicone tubing included in

the delivery.

The lengths of the

tubing segments

should be such as to

permit comfortable

unhindered operation

of the work station.

The segments must

not be so short that

they are under tensi-

on, nor should they

be so long that they

tangle or kink as a

result of hanging

down too far.

• Attach the silicone tubing

segments to the tubing nipples on the cooling water distri-

bution unit identied as „Kühlerabuss“ (outow) and „Kühl-

erzuuss“ (inow).

• Attach the tubing segments to the condensers.

The lower nipple on the reux condenser is for water inow.

Connect the tubing segments coming from the lower „Kühl-

wasserzuuss“ panel of the cooling water distributor to the-

se nipples. Connect the upper nipples of the condensers

in the same manner with the upper „Kühlwasserabuss“

panel of the cooling water distributor.

Assembling the in-line extraction unit

– 16 –

behrotest® In-Line Extraction Unit

Disconnecting

the quick push-in connections

If needed, the connections of the polyamide tub-

ing or the tubing nipples can easily be discon-

nected. Use the special tool provided for this

purpose.

Use the narrow slot of the tool for the nip-

ples and the inow tube and the wide slot

for the outow tube.

1. Tubing nipple quick push-in connector

• Place the tool in front of the annular rim of the

quick connector.

• With the other hand, grasp the tubing nipple.

• Press the annular rim inwards with the tool while

simultaneously pulling the tubing nipple forwards

and out of the cooling water distributor.

2. Inow/Outow Quick Connector

• Place the tool in front of the annular rim of the

quick connector of the hose.

• With the other hand, grasp the hose.

• Press the annular rim inwards with the tool

while simultaneously pulling the hose for-

wards and out of the quick connector.

3.6 Using a Model UK 12

Circulating Water Cooler

Follow carefully the instructions in the UK

12 User’s Manual.

The hose set of the circulating water cooler con-

tains an adapter for connection to the inow and

outow hoses of the cooling water distributor.

Attach the free end of the inlet hose with an

adapter. Insure that you push the end of the hose

into the connector as far as it will go. Connect the

inlet hose to the water outow outlet of the circu-

lating water cooler.

Complete the circuit by collecting the outlet hose

of the cooling water distributor to the inlet of the

circulating water cooler.

Disconnect

tubing nipple

Press

annular rim

inwards

Press annular rim inwards

Pull out hose

– 17 –

© behr Labor-Technik 2006

3.8. Connecting to the Mains

Power Line

First insure that the local mains (electrical) power

is of the same voltage as that indicated on the

model label of your behrotest® inline apparatus.

Insure that the power switch on the front of the

inline apparatus is set to „0“.

Insert the plug of the electrical power cable com-

ing from the back of the inline heating unit into a

mains power socket.

3.7 Leak Testing

You can now check the hose and tubing connec-

tions for leaks.

Turn on the water tap and make any necessary

changes to the hose and tubing connections.

Assembling the in-line extraction unit

– 18 –

behrotest® In-Line Extraction Unit

4 Using the inline

extraction unit

Always use the in line extraction unit in a

fume hood!. Escape of solvent vapor is

possible!

Before inserting the round-bottom asks

always make sure the distance parts

are laid out properly and smoothly in the

ask adapters. Never use your inline

extraction unit without the distance parts.

If the asks are inserted without the

distance parts directly into the adapters

they might break on heating - danger of

re or explosion!

To avoid risk of electrical shock, insure

that no liquids come in contact with the

power cable or get into the apparatus

housing!

Employ due care in working with chemi-

cals and follow the precautions cited in

the Material Safety Data Sheets!

Employ due care in working with glass

components!

Never touch the solvent vessel with your

bare hands immediately after an extrac-

tion; it will be very hot and painful burns

may result!

To avoid risk of re or explosion, avoid

spilling solvent under any circumstances

on the hot heating elements!

– 19 –

© behr Labor-Technik 2006

1 2 3

4.1 Sample preparation

Prepare the sample for extraction.

Place the sample material into the extrac-

tion thimble. Close the top of the thimble

with fat-free cotton wool and insert the

closed thimble into the extractor.

Insert the extractor into the extractor

mounting (1).

Make sure the distance parts are laid out

properly and smoothly in the ask adapters.

Now ll solvent into the round bottom

ask. Place the ask on the hotplate ask

adapter (2) and insert the extractor into the

mouth of the ask (3).

Attach the reux condenser to the extractor

and start the ow of cooling water.

4.2 Switching the inline

heating unit on

Turn the power switch on the front of the

inline heating unit to the „I“ position.

The power switch of the behro-

test® inline heating unit fullls

two functions. It serves to turn

the apparatus on and off and also

contains a built in electrical circuit-

breaker.

The circuit-breaker operates simi-

larly to those in household appli-

ances – it shuts off the electrical

power supply.

Since this safety feature (circuit-

breaker) requires cocking a spring,

turning the power switch of the in-

line heating unit to the on position

will require somewhat more force

than a simple on/off switch.

Using the inline extraction unit

– 20 –

behrotest® In-Line Extraction Unit

4.3 Starting the Extraction

Adjust the heat level for the individual sample po-

sitions with the power level knobs.

Adjust the power levels so that the solvent boils

uniformly in all positions and condenses in suf-

cient amounts to uniformly extract all of the

samples.

The yellow „HEATING“ indicator lamps of each

heating position indicate heating activity.

4.4 Ending the Extraction

After the solvent has been all evaporated or

separated, turn the power level knobs down and

switch the inline heating unit off with the MAIN

SWITCH.

This manual suits for next models

5

Table of contents