Bei automation Laminar XL User manual

720 Middle Ground Blvd. ●Newport News, VA 23606 ●Tel: 757-873-6602 ●Fax: 757-873-0212 ●Email: [email protected] ●Web: www.beiautomation.com

Installation Instructions - Laminar XL Motorized Projection Screen

1. Carefully remove the screen from its shipping container. If you are using a knife or blade to cut open the box, take care

not to cut or otherwise damage the contents inside. Inspect the screen carefully looking for possible concealed shipping

damage. Make sure you have removed additional accessories from the box before discarding.

2. When mounting the screen housing make absolutely sure that it is installed level to insure proper and reliable operation.

3. Wall mount: To mount the Laminar XL on the wall (see figure 1) you must attach the mounting buttons (included) to the

wall using a 1/4" lag screw, toggle bolt or machine screw (not included). For safe and reliable mounting be sure to use

the proper fasteners and anchors according to the mounting substrate. The mounting substrate should be able to support

at least 100 pounds. The spacing between the buttons should be per the dimensions shown on the attached diagrams.

4. Ceiling mount: To mount the Laminar XL on the ceiling you must drill two 1/4" holes in the top of the housing 1-1/2"

from each end. On the top of the housing you will find a centering line. This is there to show you where to drill and also

serves to center your drill bit. The housing should be mounted to the ceiling using 1/4" lag screws, toggle bolts or

machine screws. For safe and reliable mounting be sure to use the proper fasteners and anchors according to the

mounting substrate. The mounting substrate should be able to support at least 100 pounds.

5. The motor is mounted on the left end of the housing as you face the screen from the audience. The motor has a 6' wiring

lead. If this is not long enough make sure that there is a junction box within 4' of the motor end so that additional wiring

can be connected.

6. Make wiring connections per the respective diagrams according to the method of control. See attached wiring diagrams.

7. If you need to reset the motor limits see the limit setting instructions.

Reverse Roll Conversion

If proper screen operation is impeded by an object mounted on the wall, such as a white board, then the fabric can be

reverse-rolled by resetting the motor limits so that the screen fabric rolls up and down on the front of the roller instead of the

back of the roller.

1. You will need the limit setting instructions to perform this operation.

2. Remove the bottom closure panel by grasping with both hands, lifting and removing from the housing.

3. You will need to re-set the motor limits according to the limit setting instructions.

4. CAREFULLY lower the screen until the metal roller is exposed. Allow the screen to continue to roll down until it rolls back

up on the front of the roller. Run the fabric up until the bottom of the screen is flush with the bottom of the housing and

stop. Set the motor "up" limit.

5. Lower the screen until it is at the desired down position and stop. Set the motor "down" limit.

6. Replace the bottom closure, reversing it so that it hooks on the side of the housing closest to the wall. This will allow the

screen fabric exit opening to be at the front of the housing.

Removing the Screen Roller Assembly

There may be some cases where you may have to remove the screen roller assembly from the housing if you are mounting

the housing to the ceiling.

1. To remove the roller assembly you must remove the steel retaining ring that holds the motor in the bracket. The

retaining ring has a small loop in it so that you can grip and pull with pliers.

2. The idle end of the roller has a spring loaded steel pin that mounts in a nylon ball bearing. Grip the motor end of the

roller and while holding the motor and roller with one hand push the roller towards the idle end, compressing the spring

loaded pin.

3. When the motor end has cleared the mounting bracket pivot the roller away from the housing and then remove the idle

end from the bearing. Be sure to hold the motor in place with your hand at all times to insure that it does not

fall out of the roller.

HOUSING WIDTH IS EQUAL TO

VIEWING AREA WIDTH PLUS 1212"

12" BLACK DROP

FIGURE 6

LAMINAR

FIGURE 1

FIGURE 2

720 Middle Ground Blvd. ●Newport News, VA 23606 ●Tel: 757-873-6602 ●Fax: 757-873-0212 ●Email: [email protected] ●Web: www.beiautomation.com

Low Voltage Wiring For XL Motors

The control method for the XL series motor is entirely low voltage. The primary low voltage wiring topology is 4C modular

cable using RJ-22 modular connectors. The motor limits are set from the wall switch. The limit settings are stored in non-

volatile RAM inside the motor. Once the limits are set the wall switch can be safely disconnected without losing the limit

settings. If you don’t want to use the wall switch the screen will continue to operate properly without it as long as one of the

other control methods is used such as contact closures or IR remote. The motor can be commanded to move to the up

position, the down position or the intermediate position. This can be done by using the standard 3 button wall switch, (2)

momentary contact closures or optional IR remote. The diagrams below illustrate how to control the XL series motor using

these methods.

Control Wiring Options

A – Part# 19.100.104

(1) 3 Button Wall Switch

is included with the

screen. An additional

wall switch is Optional.

B – Part# 19.102.100

IR Remote Control

Optional

CORREC

T

(

PIN 1 TO PIN 1

)

INCORREC

T

(

PIN 1 TO PIN 4

)

Low Voltage Connections to Interface

B

Installing the modular connectors

A

Low voltage connection interface

located inside screen housing

120 VAC / 1 amp

Up

Common

Down

Connect to momentary contact closures

Timing = 500 ms

To

moto

r

To wall switches

and/or IR receiver

Connection Interface

(located inside of screen housing)

720 Middle Ground Blvd. ●Newport News, VA 23606 ●Tel: 757-873-6602 ●Fax: 757-873-0212 ●Email: [email protected] ●Web: www.beiautomation.com

Power supply wiring for “XL” type motors

M

WIRING LEAD FROM MOTOR IS 72” LONG

3 CONDUCTOR CABLE, 18 GAUGE STRANDED

MOTOR REQUIRES 120 VAC, 60 HZ, 1 AMP

GREEN

WHITE

BLACK

GROUND

NEUTRAL

LINE

720 Middle Ground Blvd. ●Newport News, VA 23606 ●Tel: 757-873-6602 ●Fax: 757-873-0212 ●Email: [email protected] ●Web: www.beiautomation.com

Setting the motor limits for the XL motor system

*** DAMAGE TO THE SCREEN MAY RESULT IF OPERATED WITHOUT PROPERLY SETTING THE MOTOR LIMITS ***

1. Setting the [DOWN] motor limit

Set SW1-ON and SW2-OFF. Press the [DOWN] button on the

switch to move the screen to the desired lower limit. If the

screen moves in the opposite direction, release the [DOWN]

button and momentarily press the [STOP] button. This will

reverse the operation of the [UP] and [DOWN] buttons. Move

the screen to the desired lower limit and set both SW1 & SW2

to OFF to record the position.

2. Setting the [UP] motor limit

Set SW1-OFF and SW2-ON. Move the screen to the desired

upper limit by pressing the [UP] button on the switch. Set both

SW1 & SW2 to OFF to record the position and return to normal

operation.

3. Setting the intermediate stop position

To set an intermediate stop position for an additional aspect

ratio, move the screen to the desired position and press the

[STOP] button. Press and hold the [STOP] button for at least

three seconds to record the position.

4. Normal operation

Momentarily pressing the [UP] button on the switch will move

the screen to its upper limit.

Momentarily pressing the [DOWN] button will move the screen

to its lower limit.

While the motor is in motion, momentarily pressing the [STOP]

button for less than two seconds will stop the screen at its

present position.

Once the motor is stopped, momentarily pressing the [STOP]

button will move the screen to its intermediate stop position or

additional aspect ratio.

When the motor is at rest, pressing and holding the [STOP]

button for at least three seconds will record a new intermediate

stop position or additional aspect ratio.

SW1 SW2 FUNCTION

ON OFF Set LOWER

limit

OFF ON Set UPPER

limit

OFF OFF

Record Position

-

Normal

Operation

STOP

ON

OFF

SW1 SW2 RJ22

(View from back of switch)

Table of contents

Popular Projection Screen manuals by other brands

Da-Lite

Da-Lite ExecutiveElectrol Instruction book

LAWSON PHILIPS

LAWSON PHILIPS OutStanding Screens OSS Drive-in 16 owner's manual

STILFORD

STILFORD JBSCR751BK Assembly instructions

Euroscreen

Euroscreen Diplomat Electric manual

Celexon

Celexon Professional Plus installation guide

Da-Lite

Da-Lite TENSIONED COSMOPOLITAN ELECTROL Instruction book

Beamax

Beamax In-Ceiling Atmosphere Tensioned user manual

Elite Prime Vision

Elite Prime Vision Polar Star Series user guide

Euroscreen

Euroscreen Diplomat TabTension user manual

Screen Innovations

Screen Innovations Solo 3 Indoor 575 External installation instructions

DeskMakers

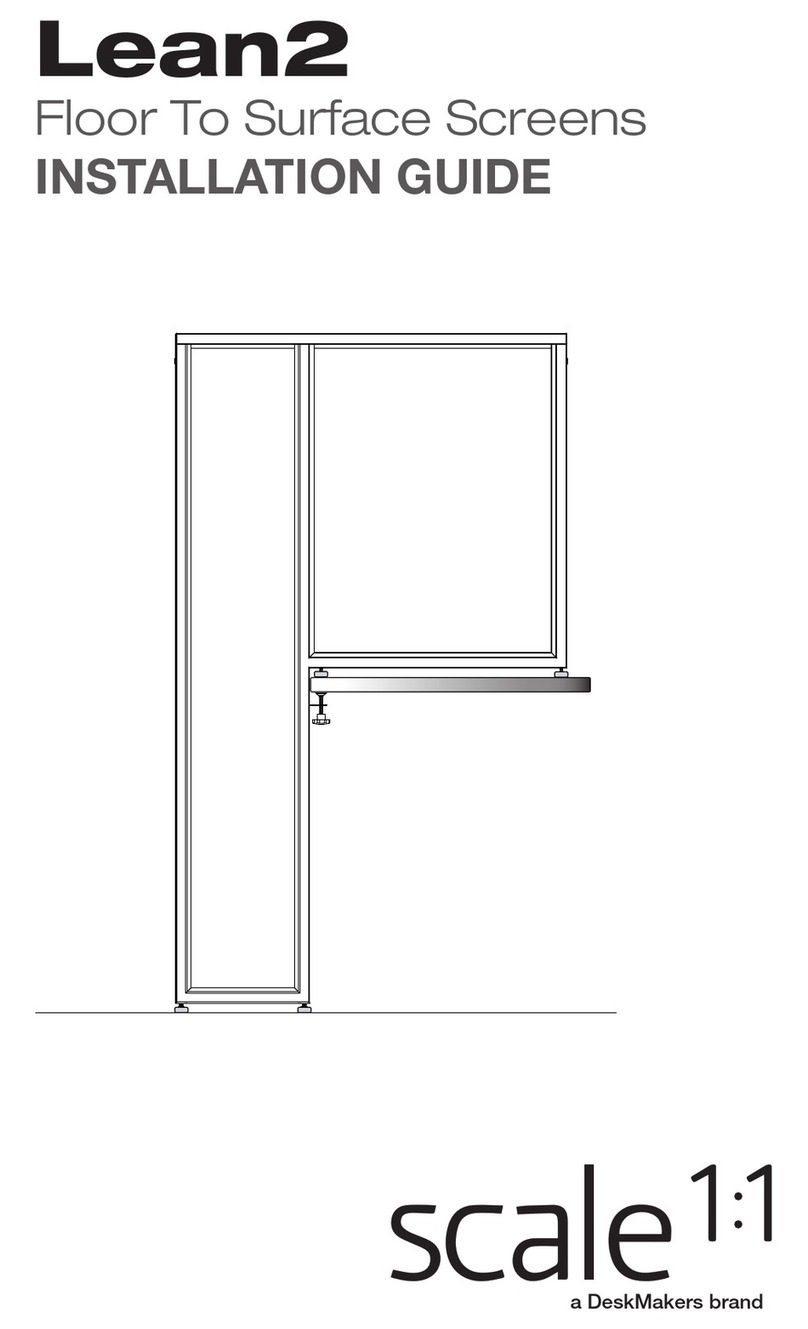

DeskMakers Scale 1:1 Lean2 installation guide

Panoview

Panoview DS-9092PM installation guide