Screen Technics ELECTRICINEMA User manual

Other Screen Technics Projection Screen manuals

Screen Technics

Screen Technics ELECTRICINEMA User manual

Screen Technics

Screen Technics CINEMATECH User manual

Screen Technics

Screen Technics CINEMASNAP XL User manual

Screen Technics

Screen Technics CINEMAPRO User manual

Screen Technics

Screen Technics ELECTRICINEMA A User manual

Screen Technics

Screen Technics MASTERFIT IP User manual

Screen Technics

Screen Technics ELECTRICINEMA User manual

Screen Technics

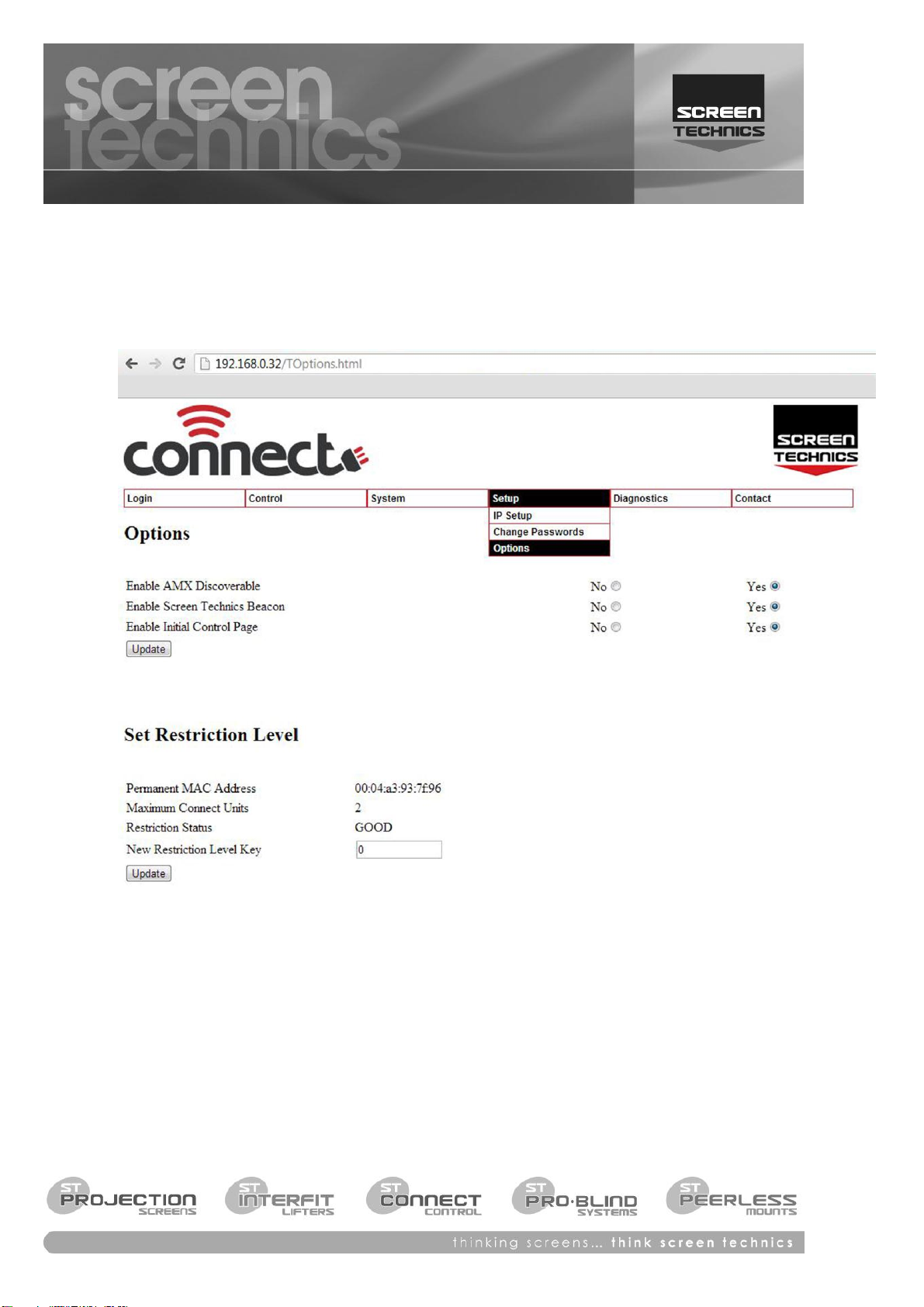

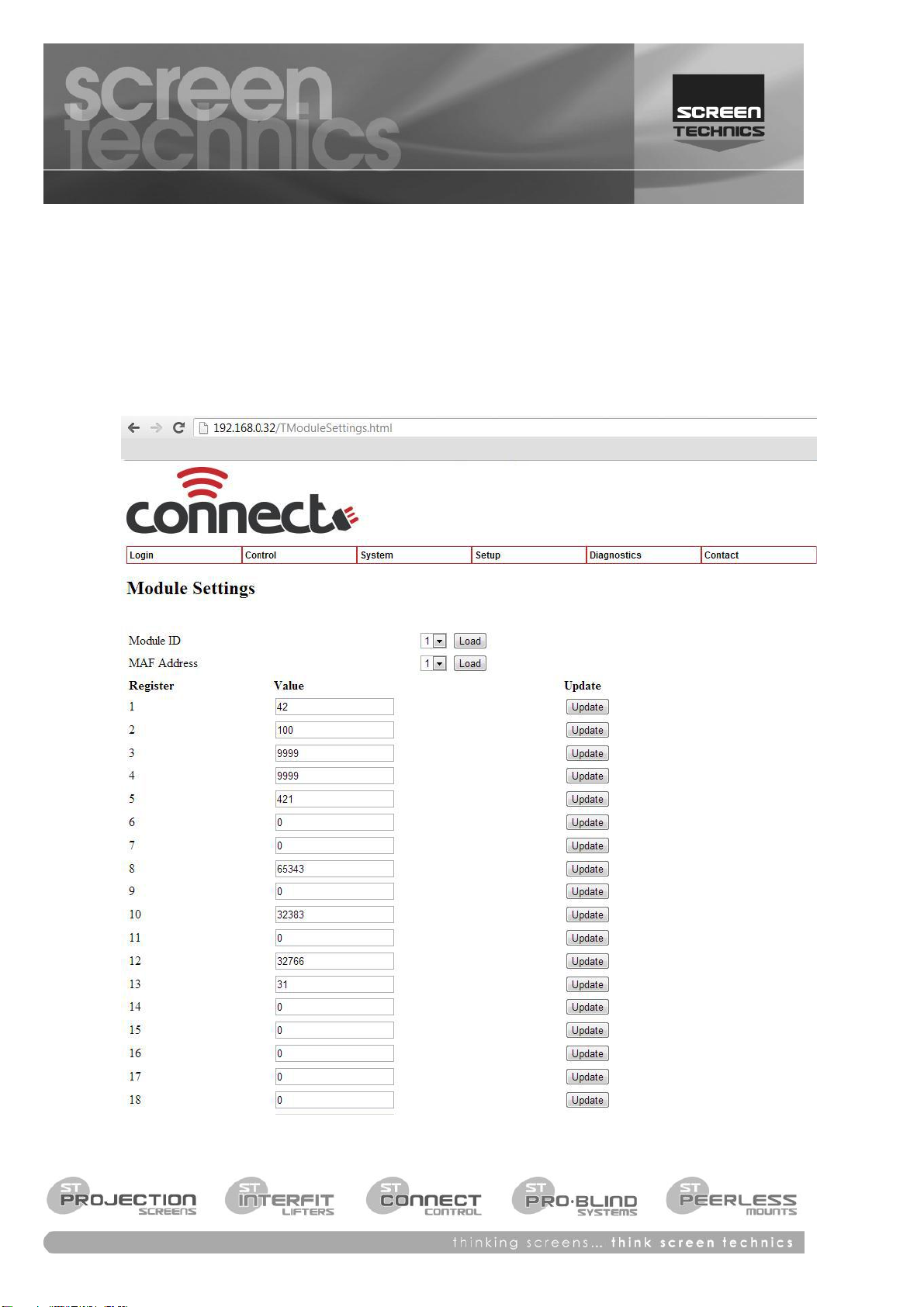

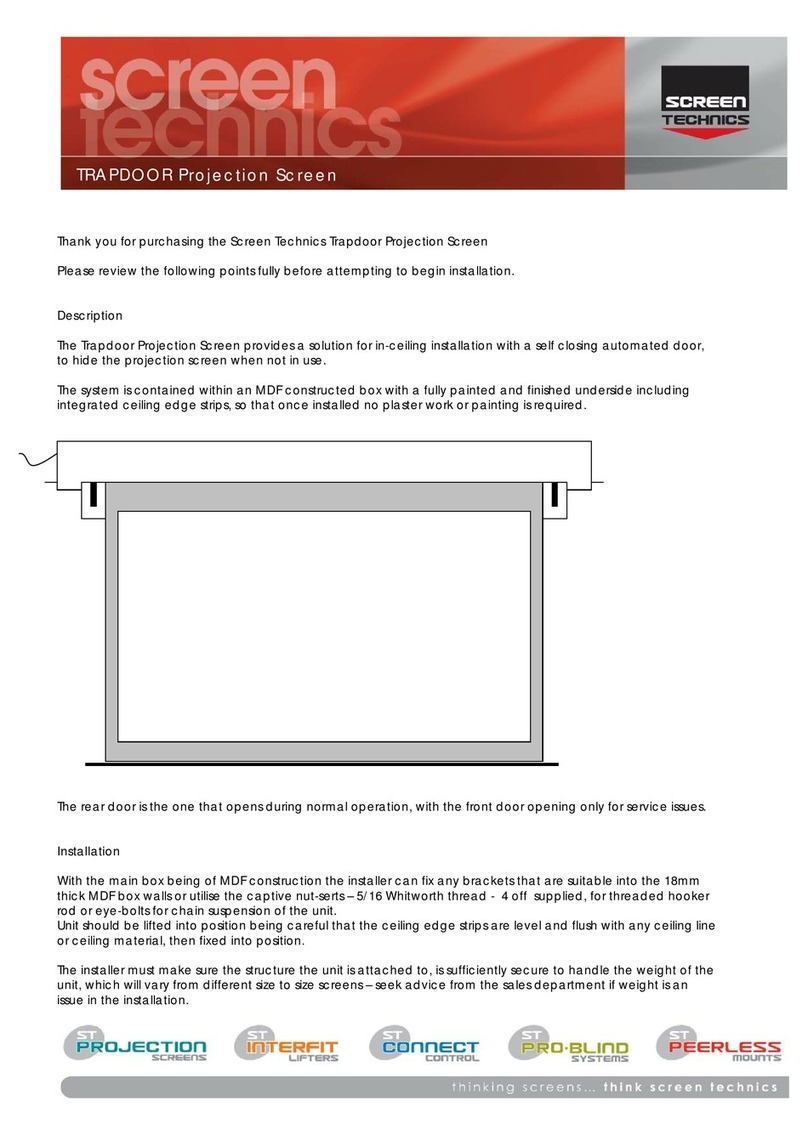

Screen Technics TRAPDOOR User manual

Screen Technics

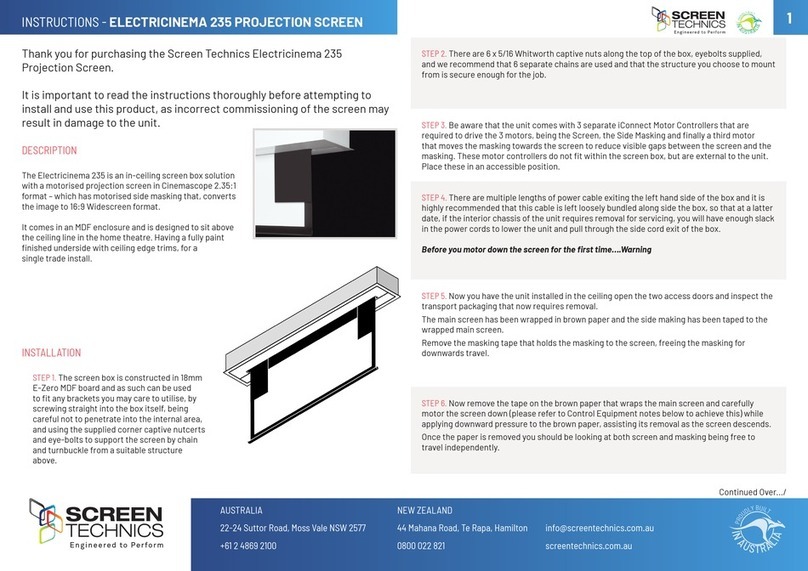

Screen Technics ELECTRICINEMA 235 Guide

Screen Technics

Screen Technics CINEMASNAP 235 User manual