Beijing Dahao Technology BECS-D56 User manual

刺绣机电脑

Computerized Control System for Embroidery

Machine

BECS-D56

(General Unit)

Version:2017-01

操作手册

OWNER’S MANUAL

Index

Index

Chapter 1 General Descriptions .....................................................................................................1

1-1 Warnings and Cautions.....................................................................................................1

1-2 Main Features....................................................................................................................3

1-3 Technical Specifications ...................................................................................................6

Chapter 2 Operation Instruction.....................................................................................................7

2-1 Configuration and Direction of the Control Panel............................................................7

2-2 Instruction of Control Panel..............................................................................................8

2-3 Instruction of the Main Screen........................................................................................11

2-4 Notes on Menu Status.....................................................................................................14

2-5 How to Input Numerals, Letters and Symbols................................................................15

2-6 Moving of the cursor.......................................................................................................15

2-7 Procedure of Embroidery................................................................................................15

2-8 Normal Embroidery, Returning and mending.................................................................21

2-9 Relations between Normal Embroidery, Idling and Position Idling...............................21

2-10 Operation Bar and Turn Shaft Button...........................................................................22

2-11 Thread-breakage detection and mending switch...........................................................22

2-12 System's Working Status...............................................................................................23

Chapter 3 Disk Management........................................................................................................24

3-1 Disk Selection.................................................................................................................24

3-2 Design Preview ...............................................................................................................27

3-3 Select One or Several Designs........................................................................................28

3-4 Design import..................................................................................................................29

3-5 Design Export .................................................................................................................30

3-6 Directory Operation ........................................................................................................32

3-7 Deleting Objects in Disk (Including Design Files and Folders).....................................32

3-8 Formatting a Disk............................................................................................................32

Chapter 4 Memory Design Management .....................................................................................34

4-1 Memory Design Management Screen and Other Memory Design Operation Screens ..34

4-2 Select One or Several Designs........................................................................................37

4-3 Selecting a Design for Embroidery.................................................................................37

4-4 Design Preview ...............................................................................................................38

4-5 Copy the memory design ................................................................................................39

4-6 Delete the memory design...............................................................................................40

4-7 Add applique design........................................................................................................41

4-8 Satin stitch compensation................................................................................................43

4-9 Edit packed design..........................................................................................................44

4-10 Design division .............................................................................................................45

4-11 Combine the designs.....................................................................................................46

4-12 “High speed design”......................................................................................................47

4-13 Compile Packed Design................................................................................................47

4-14 Create design from parameter.......................................................................................48

4-15 Move frame to make design..........................................................................................48

4-16 Create outline design from normal design....................................................................49

BECS-D56 computerized embroidery machine owner’s manual I

Index

4-17 Copy design with varied switch length.........................................................................50

4-18 Design parameters operation ........................................................................................50

4-19 Import design from PC .................................................................................................51

4-20 Network Management Function...................................................................................52

Chapter 5 Management of Machine Parameters.......................................................................... 54

5-1 Normal Parameters ......................................................................................................... 54

5.1.1 Design directions...............................................................................................................55

5.1.2 Setting of rotation ..............................................................................................................55

5.1.3 Setting of X-scale...............................................................................................................55

5.1.4 “Rep. Prior” .......................................................................................................................56

5.1.5 “Rep. Mode”......................................................................................................................57

5.1.6 “X&Y Reps”......................................................................................................................57

5.1.7 “X&Y Interval”..................................................................................................................57

5.1.8 “Prior Mode” .....................................................................................................................57

5-2 Setting of other embroidery parameters ......................................................................... 57

5.2.1 Setting Procedure for Other Parameters ...................................................................................58

5.2.2 Introduction of Functions in Other Parameters.........................................................................59

5-3 Set User-defined parameter ............................................................................................ 60

5-4 Purview of Machine Parameter Manage......................................................................... 62

5.4.1 Unlock/Change the administrator password......................................................................63

5.4.2 Machine Administrator cancels machine lock ...................................................................64

5.4.3 Administrator reset (or save) the optimized parameter......................................................65

5.4.4 Change the factory password.............................................................................................66

5.4.5 Unlock the factory password .............................................................................................67

5.4.6 Factory Save/Reset Parameters..........................................................................................67

5-5 Initialize Parameters .......................................................................................................67

5-6 Save all parameter to disk...............................................................................................68

5-7 Read all parameter from disk..........................................................................................69

5-8 Adjust Parameters of X&Y Servo Drivers .................................................................... 70

5.8.1 Set the parameter ...............................................................................................................71

5.8.2 To inquire servo driver status.............................................................................................71

5.8.3 Fix driver parameters.........................................................................................................71

5.8.4 Restore default driver parameters......................................................................................71

Chapter 6 Assistant Operation .....................................................................................................72

6-1 Assistant embroidery operation...................................................................................... 72

6.1.1 Resume Design Start..........................................................................................................72

6.1.2 Save design start ................................................................................................................73

6.1.3 Auto to start position..........................................................................................................73

6.1.4 Stitch stop down.................................................................................................................74

6.1.5 Setting another start ...........................................................................................................75

6.1.6 Set B Point.........................................................................................................................76

6.1.7 Operation onAFC, Sequin and Coiling Devices ...............................................................77

6.1.8 Upper thread hold operation..............................................................................................77

6-2 Other assistant operation................................................................................................. 77

6.2.1 View Embroidery Parameter..............................................................................................78

II BECS- D56 computerized embroidery machine owner’s manual

Index

6.2.2 View Statistics Information............................................................................................... 79

6.2.3 Power resume setting/ frame start setting.......................................................................... 79

6.2.4 Power resume.................................................................................................................... 80

6.2.5 Set embroidery scope in software...................................................................................... 81

6.2.6 Set system clock................................................................................................................ 82

6.2.7 Language Choice............................................................................................................... 83

6.2.8 Machine Soft Information ................................................................................................. 83

6.2.9 Help................................................................................................................................... 84

6.2.10 Machine Test ..................................................................................................................... 84

Chapter 7 Other Operation...........................................................................................................86

7-1 Operation on color-changing order.................................................................................86

7.1.1 Input Color Line................................................................................................................ 86

7.1.2 Modify color line............................................................................................................... 87

7.1.3 Replace a needle................................................................................................................ 87

7.1.4 Set color of showing design .............................................................................................. 88

7-2 Design border operation..................................................................................................89

7.2.1 Check the boundary of a design ........................................................................................ 89

7.2.2 Move the frame along the boundary of a design............................................................... 90

7.2.3 Create design from outline................................................................................................ 91

7.2.4 Frame to generate design, then embroider back................................................................ 91

7.2.5 Embroider a “+” in current position.................................................................................. 92

7.2.6 Frame and embroider back for one line............................................................................. 93

7.2.7 Embroider the boundary of current design........................................................................ 94

7.2.8 Embroider true boundary of current design....................................................................... 95

7-3 Positioning Idling............................................................................................................95

7.3.1 Go ahead stitches............................................................................................................... 96

7.3.2 Go back stitches................................................................................................................. 96

7.3.3 Next Color Code................................................................................................................ 97

7-4 Reset X/Y Displacements ...............................................................................................97

Chapter 8 Memory Design Edition ..............................................................................................98

8-1 Start Editing Design........................................................................................................98

8-2 Design Edition Operation................................................................................................98

8.2.1 Summary ........................................................................................................................... 98

8.2.2 Document and View Operation......................................................................................... 99

8.2.3 Key for Positioning Stitch and Editing Stitch.................................................................... 99

Chapter 9 Letter Design .............................................................................................................101

9-1 Enter Letter Design Operation......................................................................................101

9-2 Input Char String and Basic Parameter.........................................................................101

9-3 Character Pattern Save..................................................................................................106

Chapter 10 JF Type Sequin Embroidery....................................................................................107

10-1 Brief Introduction on Sequin Embroidery ..................................................................107

10-2 Embroider sequin........................................................................................................108

10-3 Input sequin design .....................................................................................................108

10-4 Sequin design edition..................................................................................................109

10-5 Parameter about multi-sequin embroidery..................................................................113

BECS-D56 computerized embroidery machine owner’s manual III

Index

10-6 Change color order and set sequin mode....................................................................117

10-7 Manual operation of sequin embroidery..................................................................... 120

10-8 Debugging multi-sequin embroidery..........................................................................121

10-9 Sequin mending..........................................................................................................122

Chapter 11 Directions on Coiling, Taping and Zigzag Embroidery..........................................123

11-1 Function Introductions................................................................................................123

11-2 Main Technical Specification.....................................................................................123

11-3 Parameters and setting................................................................................................124

11-4 Relative Operations of Special Embroidery ...............................................................126

11.4.1 Shift between Flat Stitch Head and Special Head.................................................................126

11.4.2 M Axis Operation of Special Embroidery.............................................................................128

11.4.3 Operations of Clamp Foot.....................................................................................................129

11-5 Debug Special Embroidery.........................................................................................129

11-6 Steps on Special Embroidery......................................................................................130

11-7 Mechanical Category and Driving Mode Selection for Special Embroidery Machines130

Chapter 12 Instruction on Operating High-Efficiency System..................................................133

12-1 Descriptions of Parameters in High- Efficiency Mode...............................................133

12-2 Setting of Software for High-Efficiency Mode.......................................................... 133

Chapter 13 Updating Control Program......................................................................................137

13-1 Update Data Software (Upper Machine)....................................................................137

13-2 Updating Control Program (Down Machine).............................................................140

Chapter 14 Updating Peripheral Equipment Program ...............................................................144

Appendix ⅠParameter Setting List........................................................................................ 147

Appendix ⅡDirections on USB operations............................................................................ 162

Appendix ⅢError Information & Instruction of System Level Mistake................................163

Appendix ⅣMake Special Multi-Sequin Design ................................................................... 167

Appendix ⅤNetwork Connection of Embroidery Machines .................................................178

All rights reserved. Beijing Dahao Technology Corp., Ltd.

IV BECS- D56 computerized embroidery machine owner’s manual

Chapter 1 General Descriptions

Chapter 1 General Descriptions

Thanks for using the Computerized Embroidery Control System produced by

Beijing Dahao Technology Corp., Ltd. User are recommended to read this manual

carefully, so as to operate the machine correctly and effectively. Besides, user

should keep this manual for future use.

1-1 Warnings and Cautions

In order to reduce the occurrence of the fire, electronic shock and personal injury at using this product, user

shall strictly follow the basic security prevention measures at below:

Matters forAttention at Usage

Danger

During the operation, do not try to open the machine box. The high voltage

contained in some parts can be deadliness. Rotating parts may cause serious

injury.

Forbidden Don't expose the machine to humidity gas, poisonous gas, water, and dust.

Forbidden Don’t store or operate the machine in vibrating area, which may cause

trouble to the machine.

Caution Please abide all the warnings and safety requirements to ensure the security

of person and property

Caution LCD is fragile item. Do not use hard materials to click on the screen.

Caution

Before plugging in, user has to pay attention to the direction of the floppy

disk and the U disk. Don’t attach force when the inserting direction is

wrong, or it may cause the damage of the floppy driver, disk, U disk and

USB port. When the indicator on floppy driver is on, please don’t insert or

pull out the disk.

Caution We will add appendix if necessary, if there is any difference between the

manual and appendix, please the appendix will take precedence.

In Transportation

Caution Don't hold the cable when moving..

Caution Please abide all the warnings and safety requirements to ensure the security

of person and property

BECS-D56 computerized embroidery machine owner’s manual 1

Chapter 1 General Descriptions

Compulsory

Overloading may cause serious loss. P

lease load according to the

instruction on the box..

Installation

Caution

Don't jam the vent on the device. Don’t plug up the machine, or it may

cause fire or electronic shock.

Caution Make sure the installation direction is correct..

Caution Don't expose the machine to humidity gas, poisonous gas, water, and dust.

Cable Connection

Forbidden Don't test the insulation of the circuit loop.

Forbidden Never try to connect overloading electronic device on the connector or the

power socket.

Caution Make sure the insulation cover of each cable is fine.

Caution Communication cable and power cable should be separated.

Caution

All the cables should be well fixed. Don’t put any strength on cables. Make

sure the turning point of cable is well protected. Add pipes to increase

insulating capability.

Caution

Machine should be grounded. The resistance should be no larger than 10

Ω.

Operating Direction

Danger

Don't operate the machine when there is any damage on the protection

shell.

Forbidden When machine is running, do not touch any running part.

Caution

Make sure the configuration of power supply in normal. Use stabilized

voltage power supply when the voltage rebound is between -10%~10%.

Caution In case of warning, please check out the problem. Operation can only be

carried out again when problem is solved.

Caution

The power supply has over-currency protection function. There is a 3 mins

time lag before the function can be used again.

2BECS- D56 computerized embroidery machine owner’s manual

Chapter 1 General Descriptions

Maintenance

Warning

If you need to open the machine cover, cut out the power supply first. Due

to the capacitance after power off, operator must wait for one minute before

opening the machine cover.

Caution Circuit boards can be damaged by static. Non-professional technician can

not disassemble circuit boards.

Caution

If machine is inactive for a while, users must power on the machine

regularly (once in 2 or 3 days, more than an hour for each time).

Caution If machine is inactive for a long time, users should hav

e the machine

checked before power on.

Rejection

Caution Rejection should obey the rules and regulations set by national industrial

electronic standards.

1-2 Main Features

1. LCD Displayer

It offers delightful operation and easy learning. The beautiful screen display turns everyday

work into joyful experiences.

2. Timing Turn-off of LCD Displayer

Following measures were taken to extend the LCD life: LCD will turn off automatically in case

of no operation in 15 minutes (the time can be changed in parameter setting). A touch of the

screen or any key will reboot the LCD.

3. Super-Large Memory Capacity

The memory capacity reaches 100 million stitches, in which 800 designs can be stored. Its

super-large memory capacity can meet demands of different customers.

4. Maximum One Million Stitches for Single Design

At present a single design in the system has the maximum of 1,000,000 stitches and 980 times

of automatic color changing.

5. Multi-Task Parallel and Free Shift among Tasks

During embroidering, actions like design input & output, preparation for the following designs

and modification of parameters can be carried out. Flexible shift among tasks can be realized by

using the task-shifting key.

BECS-D56 computerized embroidery machine owner’s manual 3

Chapter 1 General Descriptions

6. Storage of Frequently Used Parameters and Color-Changing Order for Each

Design

Design will be saved along with its parameters, color-changing orders and needle bar colors.

System can memorize the operational details for each design. Users can set parameters for a

design during the embroidery process of the previous design, which will save time and improve

the efficiency. More importantly, it is one basis to realize network management.

7. Group Management of Parameters

Parameters can be divided into groups based on their functions and embroidery types. The

system can also save and recover the parameters used by technician at end-user and the

parameters used by the manufacturer of machine. And for the machine with password-setting

function, user can set password on the machine.

8. Design Input & Output with USB

Except for DOS, FDR and ZSK format floppy disk, users can use USB disk for data transfer.

USB disk supports DIR operation, which is easy for design management. For each directory,

system supports the storage of 800 designs or the sub-directory operation. There is no limitation

on directory levels. Design formats like DSB, DST, ZSK and FDR can be loaded.

9. Input of Several Design Files at One Time

Both floppy and USB disks support multi-design input under one directory.

10.Input design through network, color-changing order, etc.

Network connector is available, which help user input design, color-changing order, applique,

etc.

11.Network Function

A surveillance LAN can be built with connectors and linked to the factory LAN, which realizes

network management, improves production efficiency and reduces possible mistakes. It’s the

best choice of embroidery equipment for enterprises to take the modern enterprise management.

For details, please refer to appendix Ⅴ.

12.Patch Embroidery (Applique)

This function can set a patch code after the color code or stop code, and when the machine

embroiders to the patch code, it will halt and move frame out for patching. After sticking a

patch, user would pull the operation bar to let the frame move back and continue embroidering.

4BECS- D56 computerized embroidery machine owner’s manual

Chapter 1 General Descriptions

13.Starting Point Saving

This function can save the start point of each design and waive the work of user to repeat

moving frame manually to find the design origin when user selects the same design.

14.Maintenance and Test of Machine

This function is to easily judge the malfunctions at maintenance and test, which consists of

encoder testing, main shaft speed testing, machine parts testing and the main shaft stopping at

any position, etc.

15.Multi-Language Support

The system supports Chinese / English /Spanish/Turkish and other languages.

16.Design Output

Design can be output and saved into floppy disk or USB disk. Adoption of TAJIMA’s binary

system enables user to enjoy the advantage of data transmitting through the World Wide Web

(other formats may not be transmitted directly).

17.Repetition Embroidery

The machine can increase embroidery productivity by repetition embroidery, which can also be

used with cyclic embroidery.

18.Cyclic Embroidery

The user also can increase embroidery productivity by using cyclic embroidery function, by

which the machine automatically returns to the origin point and starts the same embroidery

design again when finishing the design one time.

19.Design Compiling

(1) Compile the Data of Selected Design to Generate New Design

Users can compile any design according to zoom ratio, rotate angle, normal repetition or partial

repetition to generate a new design and save it in the memory card. The newly generated design

can be used for embroidery, output or other operations.

(2) Compile the Combined Design

System can compile the pre-set combined design to generate a new one and save it to the

memory card. The newly generated design can be used for embroidery, output or other

operations.

20.Letter Design

There are altogether 28 letter-bases. Users can make groups and change the letter order

according to different tasks. This operation is simple and easy managing.

BECS-D56 computerized embroidery machine owner’s manual 5

Chapter 1 General Descriptions

21.Design Editing

By using this function, users may insert, modify or delete certain stitch at the selected point.

New designs can be created by this function too.

22.Speed Adjusting

The highest speed for embroidering can be set. During the process of embroidering, speed

changes automatically when the needle interval changes.

23.Thread Trimming

Thread trimming can be manually controlled. Trimming acts automatically at the end of

embroidery process or color changing.

24.Thread Breakage Detection

In case of thread breakage or run-out of bottom thread, machine stops and warning lights start

to blink.

25.Color Changing

At the color changing point, user can either act color changing manually or let the system do

according to the preset order automatically.

26.Special Embroidery

BECS-D56 computerized embroidery has special embroidery functions (coiling, taping and

Zigzag embroidery).

1-3 Technical Specifications

1. Maximum design saving quantity: 800 designs

2. Memory capability: 100 million stitches

3. Screen resolution: 800*480

4. Network transfer speed: 10Mbps

5. Data transfer mode supported: floppy disk, USB disk and network

6. Stepping Precision: minimum stepping precision is 0.1mm

7. Stitch range: 0.1mm to 12.7mm

6BECS- D56 computerized embroidery machine owner’s manual

Chapter 2 Operation Instruction

Chapter 2 Operation Instruction

2-1 Configuration and Direction of the Control Panel

A. Configuration of the Control Panel

1. LCD Screen

D56 adopts high-luminance LCD display.

2. Main USB Interface

USB disk can be plugged in for data input/output. The external floppy driver is also

connected by USB interface.

3. Serial Port to Mother Board

4. Power Port

B. Direction in Using the Floppy Disk

This external floppy driver uses USB port. Make sure the plug-in direction is correct. Try to

avoid using force with incorrect plug-in direction, or it may destroy the floppy driver and disk.

C. Direction in Using the USB Disk

Please pay close attention to electrostatic phenomenon. Don’t forget to discharge before

plugging in/out the USB disk.

BECS-D56 computerized embroidery machine owner’s manual 7

Chapter 2 Operation Instruction

USB disk features plug-in direction. Users should avoid plugging out during writing or loading

data, because it may result in loss of data. We highly recommend users to check the data

integrality in case of data missing.

Note: During the process of USB format, sudden loss of electricity or plugging out the disk may

break down the USB.

D. Direction of Network Connection

Preset the network parameters before the connecting. Otherwise other machines in the network

maybe can’t communicate.

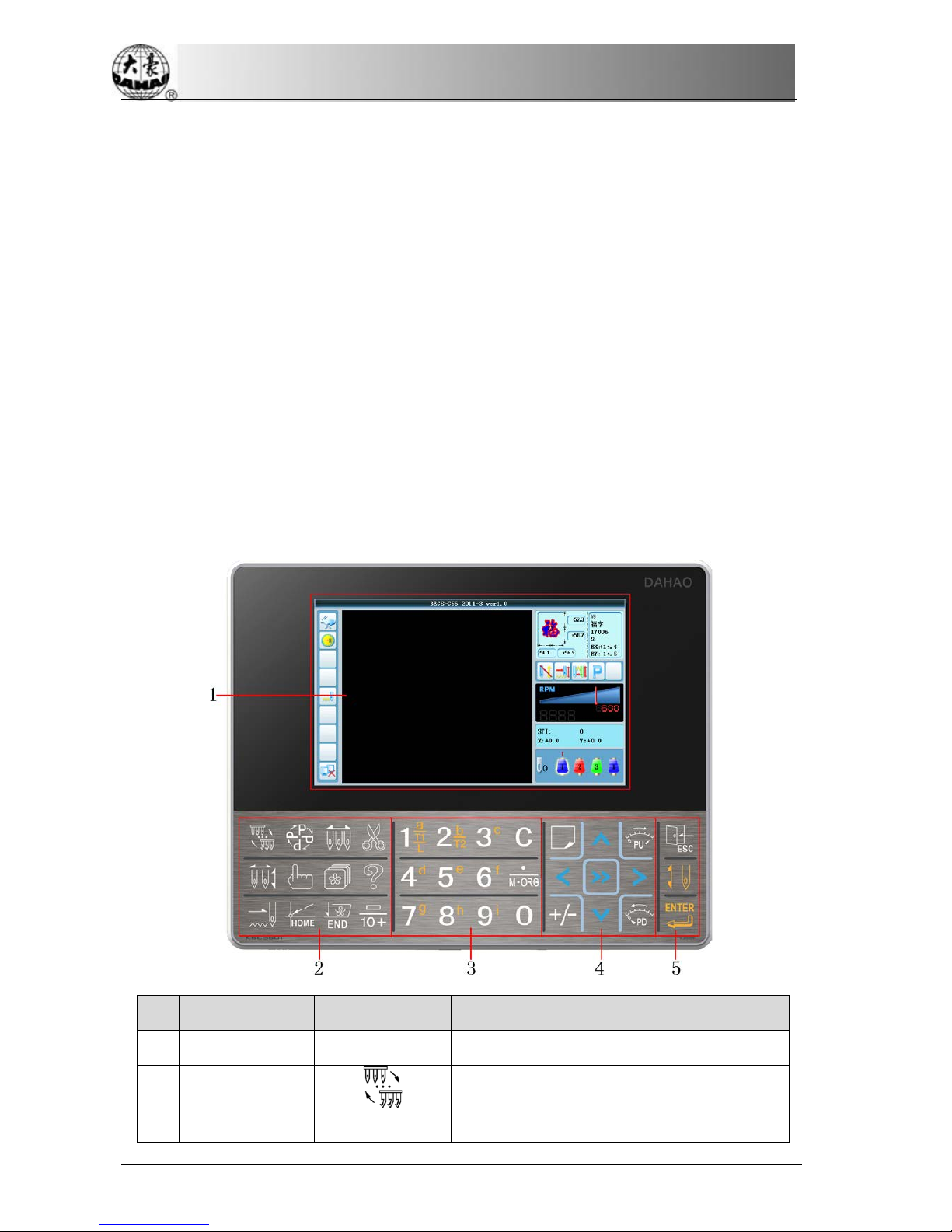

2-2 Instruction of Control Panel

The key on the keyboard can be used along with LCD. If you want to operate function in any

menu on the LCD, just press relative shortcut key on the keyboard. The status of that key will

be shown on the screen.

No. Name Figure Description

1 LCD Displayer Displays the operation interface.

2 Function Area

Reserved

Functions

Unused Temporarily

8BECS- D56 computerized embroidery machine owner’s manual

Chapter 2 Operation Instruction

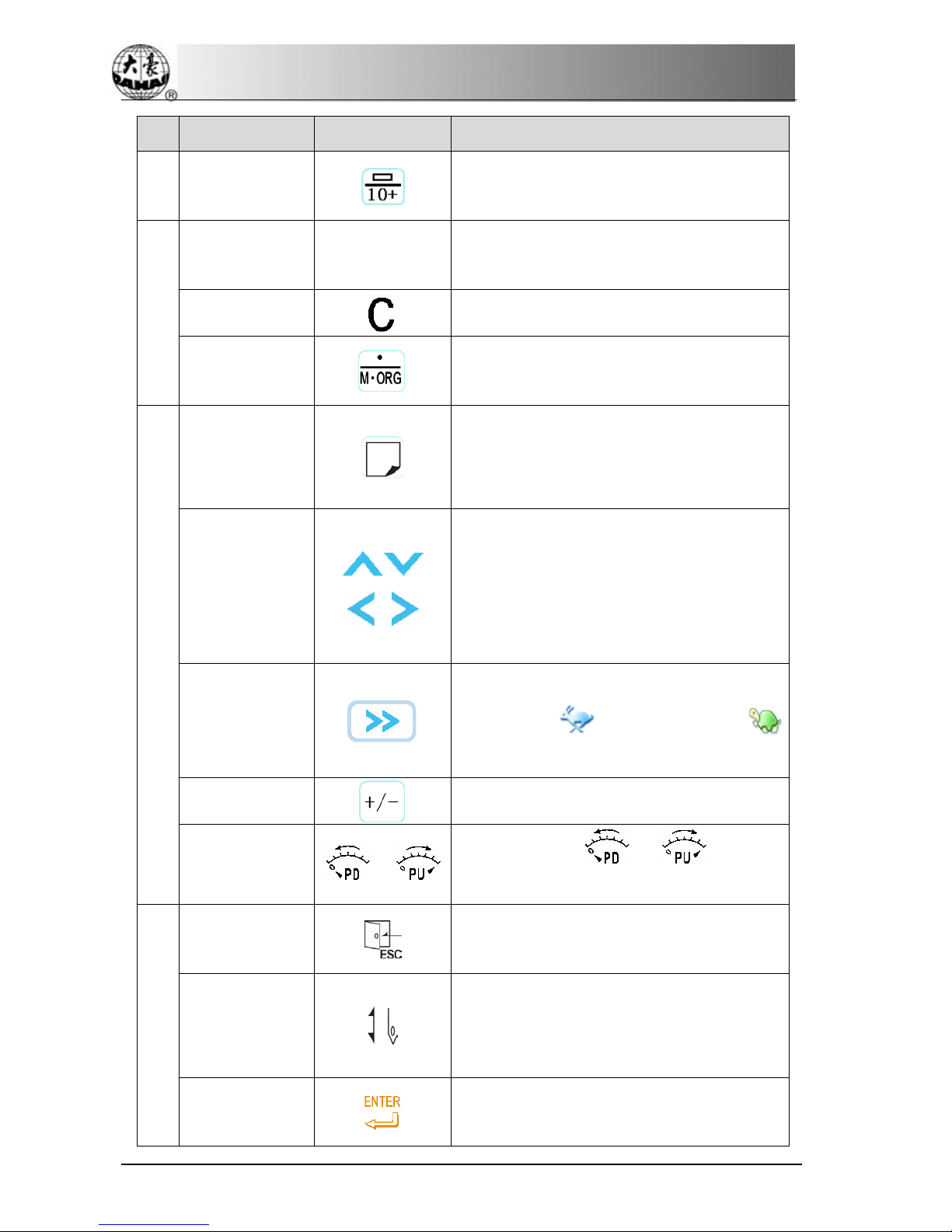

No. Name Figure Description

Pattern Direction

T

his key can turn the pattern among eight

directions.

Color-changing

Press this button to enter the color-changing

operation

Thread-trimming

After stop, press this button to enter the

interface for selecting upper thread-trimming

or upper& bottom thread-trimming

, where

user can select the corresponding

thread-trimming method.

Color-chang

ing &

Start Method Shift

Button

P

ress this button to shift among Manual

Color, Auto Start/Auto Color, Manual Start/

Auto Color and Auto Start

Other Management The operations about parameters and patterns

Management of

Pattern and Disk

Operation a

bout pattern edition and disk

management

This button can be available only when the

main control software supports the special

embroidery function

Embroidery/ Idling

Shift Button

Press this button to shift among embroidery,

high speed idling and low speed idling

Return to start

point

After stop, press this button to let frame

return to the start point of the current pattern

automatically

Return to stop

point

A

fter stop, user can press the manual

frame-

moving to move the frame (like

applique), then press this button to have the

frame to return to the

stop point

automatically

BECS-D56 computerized embroidery machine owner’s manual 9

Chapter 2 Operation Instruction

No. Name Figure Description

It is used for editing design or input needle

number.

3

Number keys T

hey are used to select menu items or set

parameters

used for deleting the last letter you typed in

Manual Moving

I

t is used for manual moving or inputting

point

4

Task Shifting

When user activates several interfaces, he can

use this button to shift the activated interface

in order

Manual

Frame-moving

Press it to move the frame. T

he manual

frame-moving keys support the combining

direction (pressing two neighboring direction

buttons can move the frame along the

45degree to the pressed directions).

Manual

Frame-moving

Speed

Press this button to shift the frame-moving

speed among (High speed)and

(Low speed).

To show plus & minus of inputted number.

Speed

Adjustment 、Press the button or

to reduce

or increase the embroidery speed.

5

ESC

Press this button to quit the corresponding

operation

Embroidery

Confirm

(Release)

Press this button to confirm or release the

embroidery

Enter

Press this button to conform the relating

operation

10 BECS- D56 computerized embroidery machine owner’s manual

Chapter 2 Operation Instruction

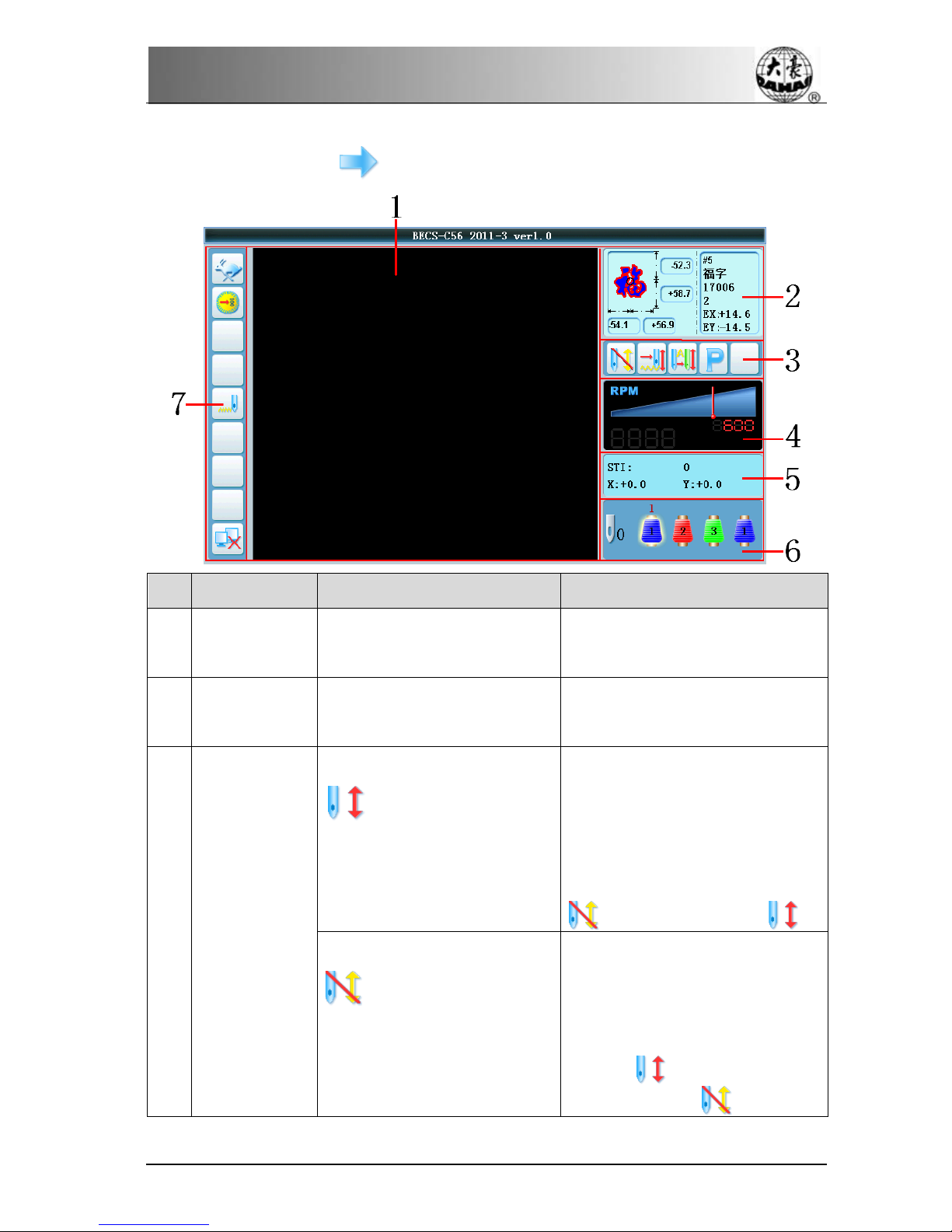

2-3 Instruction of the Main Screen

Note: Press the button can shift between the following two pages.

No. Name Figure Description

1 Real time

tracking

Stitch forms or patterns are

displayed in this area.

2 Pattern

information

R

elated pattern information is

displayed in this area.

3 Current status

Embroidery confirmation

status

(Embroidery can be cancelled)

In embroid

ery preparation status,

you can select pattern, set

parameter and etc. Press this key

and confirm, then machine status is

changed from preparation status

to confirmation status .

Embroidery preparation

status, user can confirm the

embroidery

In e

mbroidery confirmation status,

you can pull bar to embroider.

When machine stops, press this key

to confirm to cancel confirmation

status

and back to

preparation status .

BECS-D56 computerized embroidery machine owner’s manual 11

Chapter 2 Operation Instruction

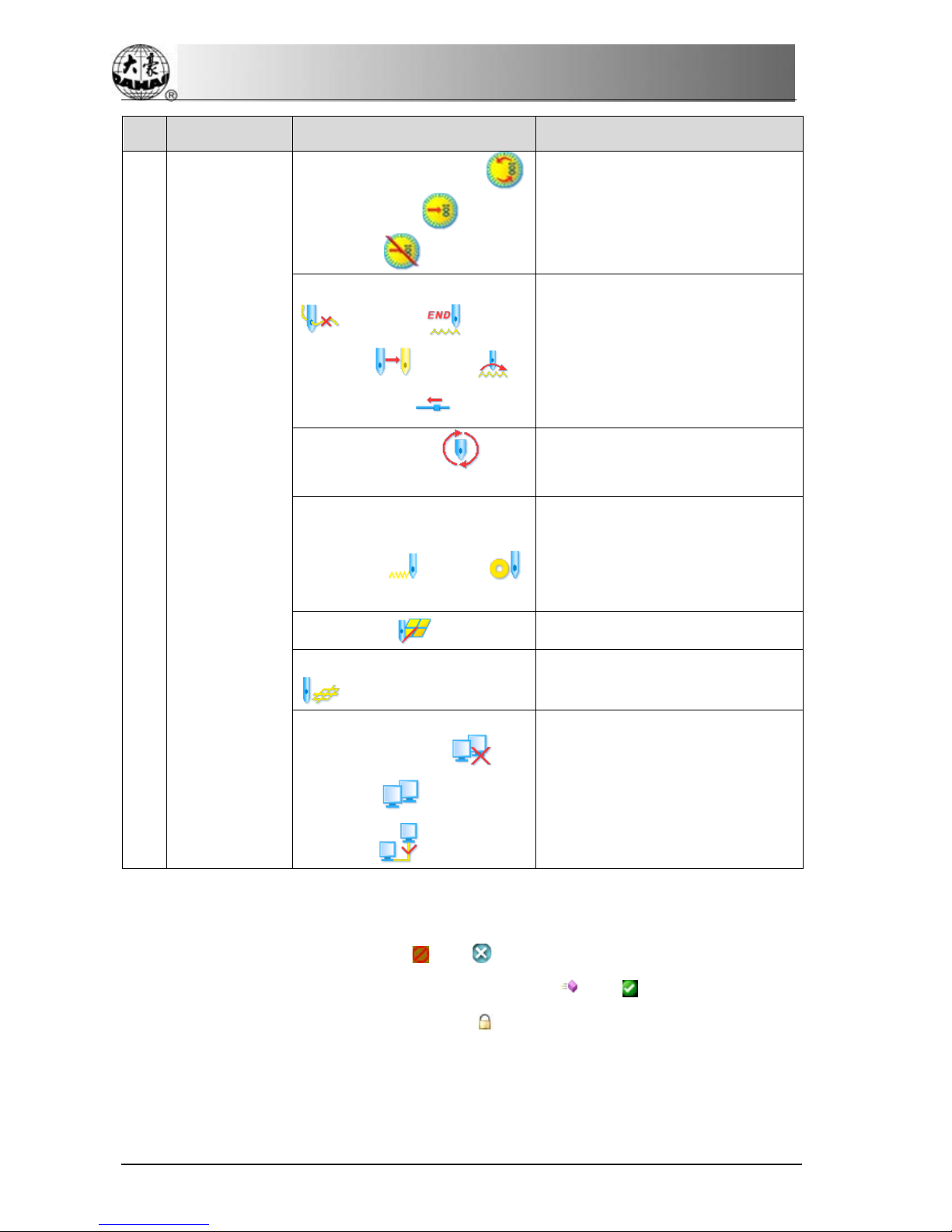

No. Name Figure Description

Normal embroidery

System is now in normal

embroidery status. W

hen you pull

ba

r, the main shaft rotates and

frame moves along the pattern

trace. Pull bar to go back, machine

idles back in low speed. When

machine stops, press this key to

shift to low speed idling .

Low-speed Idling

The machine is currently in

low-speed idling status. When user

pulls

the bar for normal

embroidery, the main shaft remains

inactive and the frame advances

along the stitch trace. When pulling

the bar for returning, the main shaft

remains inactive and the frame

returns along the stitch trace. When

the machine stops, click this key to

switch to high-speed idling status

.

High speed idling

System is now in high speed idling

status. P

ull bar but main shaft and

frame don’

t move and stitch

number increases; pull bar to stop,

the frame goes to the real position

of the current stitch. P

ull bar to

back, main shaft and frame don’t

move. Stitch number decreases as

well. P

ull bar to stop, the frame

goes back to the real position of

current stitch. When machine stops,

press this key to change to

Embroidery Status .

Manual color-changing

manual start

In this status, press related needle

position key to select a position.

P

ull bar to start embroidering.

When meeting the color-changing

code, system stops the machine

automatically and displays .

12 BECS- D56 computerized embroidery machine owner’s manual

Chapter 2 Operation Instruction

No. Name Figure Description

Then you should act manual

color-

changing. Input the position

you need, pull bar to start

embroidering

(

manual start

)

Auto color-changing

manual start

If you set machine to

auto-color-

changing, you should

first set needle color-changing

order. D

uring embroidery, no

matter where the current needle

locates, system will act

color-changing according to this

order. When you meet

color-changing code, machine will

stop automatically and change to

the needle position that already has

been set. I

f you set auto start,

machine will start automatically; if

you set to manual start, pull bar to

start.

Auto color-changing

auto start

Change pattern direction P

ress this key to shift the pattern

direction.

4

Main Shaft

Speed

Display the set speed and actual

speed of main shaft

5

Current Stitch

Information

Display the current stitch

information

6

Color-changing

Order and

Current stitch

position

7

M

achine status

information

(In the order of

left to right,

top to bottom)

Frame moving speed(use

to shift between low

speed

and high

speed )

BECS-D56 computerized embroidery machine owner’s manual 13

Chapter 2 Operation Instruction

No. Name Figure Description

Main shaft status(running ,

stop in position ,

not stop

in position )

Embroidery status

(

thread break

、finish 、color

changing 、jump 、

pull bar to stop

)

Cyclic embroidery

, none

cyclic embroidery

Assistant embroidery status/

lockstitch/special embroidery

(lockstitch , sequin ,

etc.)

Off-set point

Assistant embroidery mode

Network status

(disconnected 、

connected 、successfully

registered

)

2-4 Notes on Menu Status

If one menu is labeled with the mark “ ” or “ ”, this indicates that this menu can not be

accessed and modified. While if one menu is labeled with “ ” or “ ”, it indicates that this

menu can be accessed and modified. If there is a “ ”, then this parameter can be modified only

if the user relieves the password at first.

14 BECS- D56 computerized embroidery machine owner’s manual

Table of contents

Popular Sewing Machine manuals by other brands

Duerkopp Adler

Duerkopp Adler FLP Series Additional guide Additional accessories guide

Bernina

Bernina Bernette 410 Instruction book

MATRI

MATRI Matrimatic Silver manual

Janome

Janome MEMORY CRAFT 5200 - instruction manual

Husqvarna Viking

Husqvarna Viking 90 operating manual

Singer

Singer 300wl03 instructions