Identifying and Ordering Parts

Cautions When Using the Machine

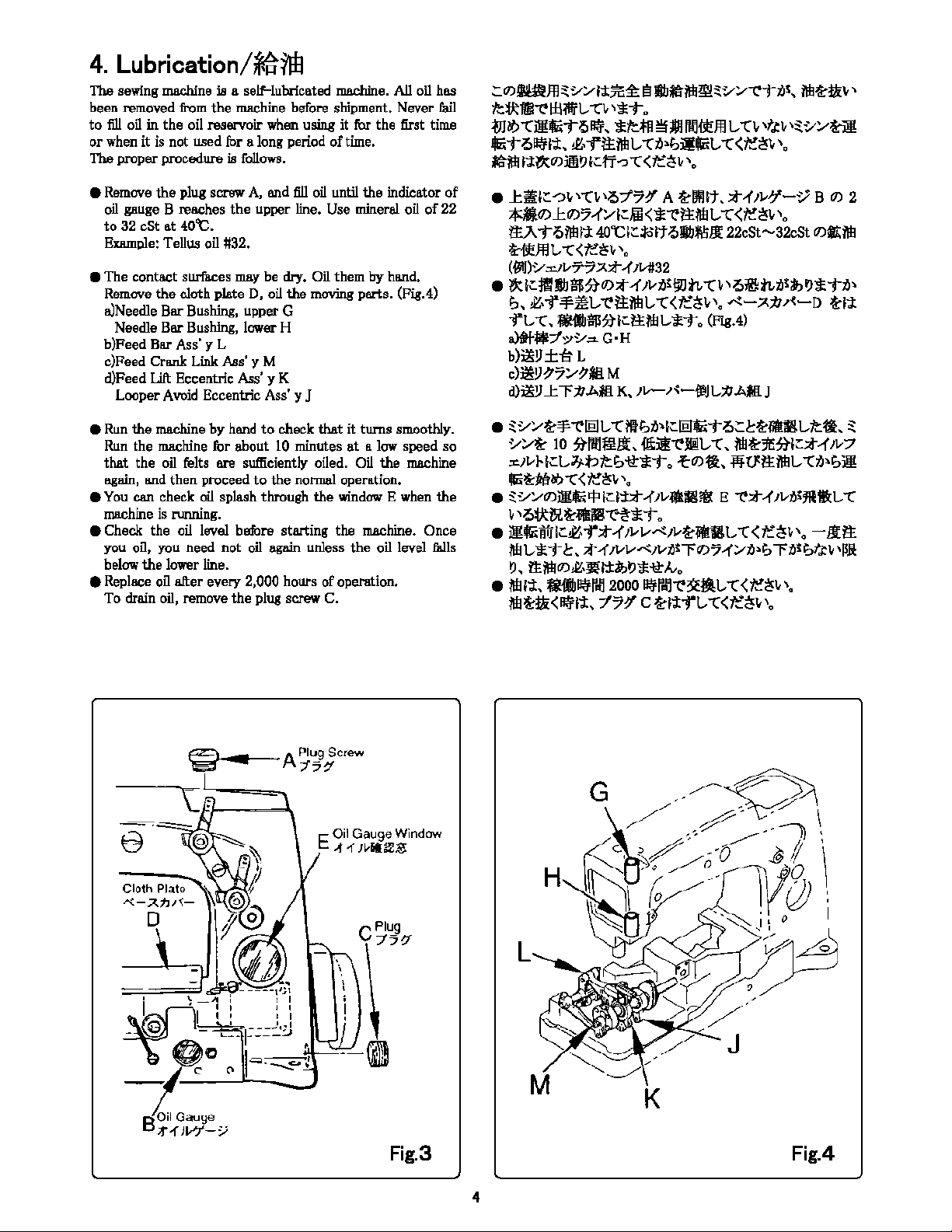

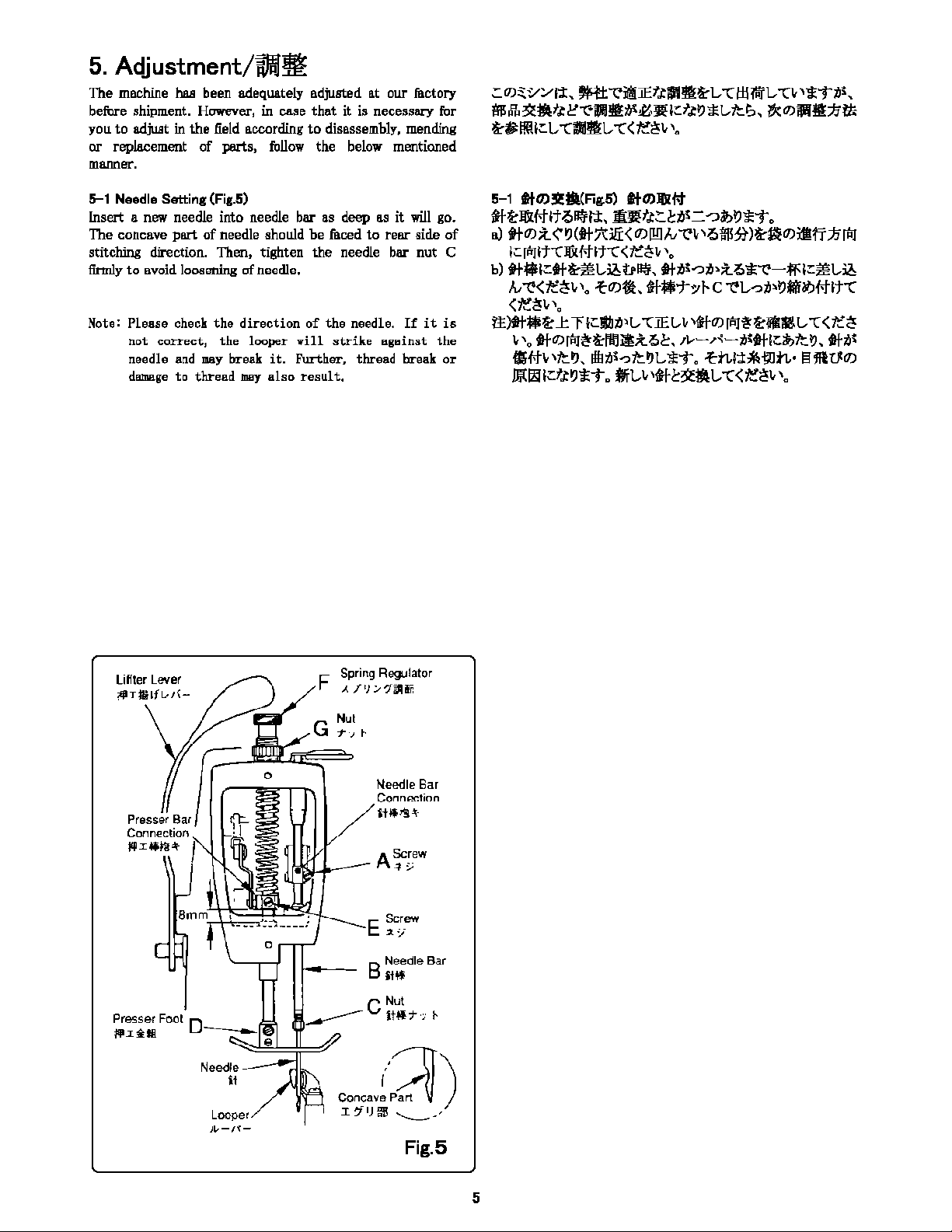

Maintenance

Where the construction permits, each part

is

stamped

with its part

number.

On

all

orders, please include part

number,

part

name

and

model

name

of machine.

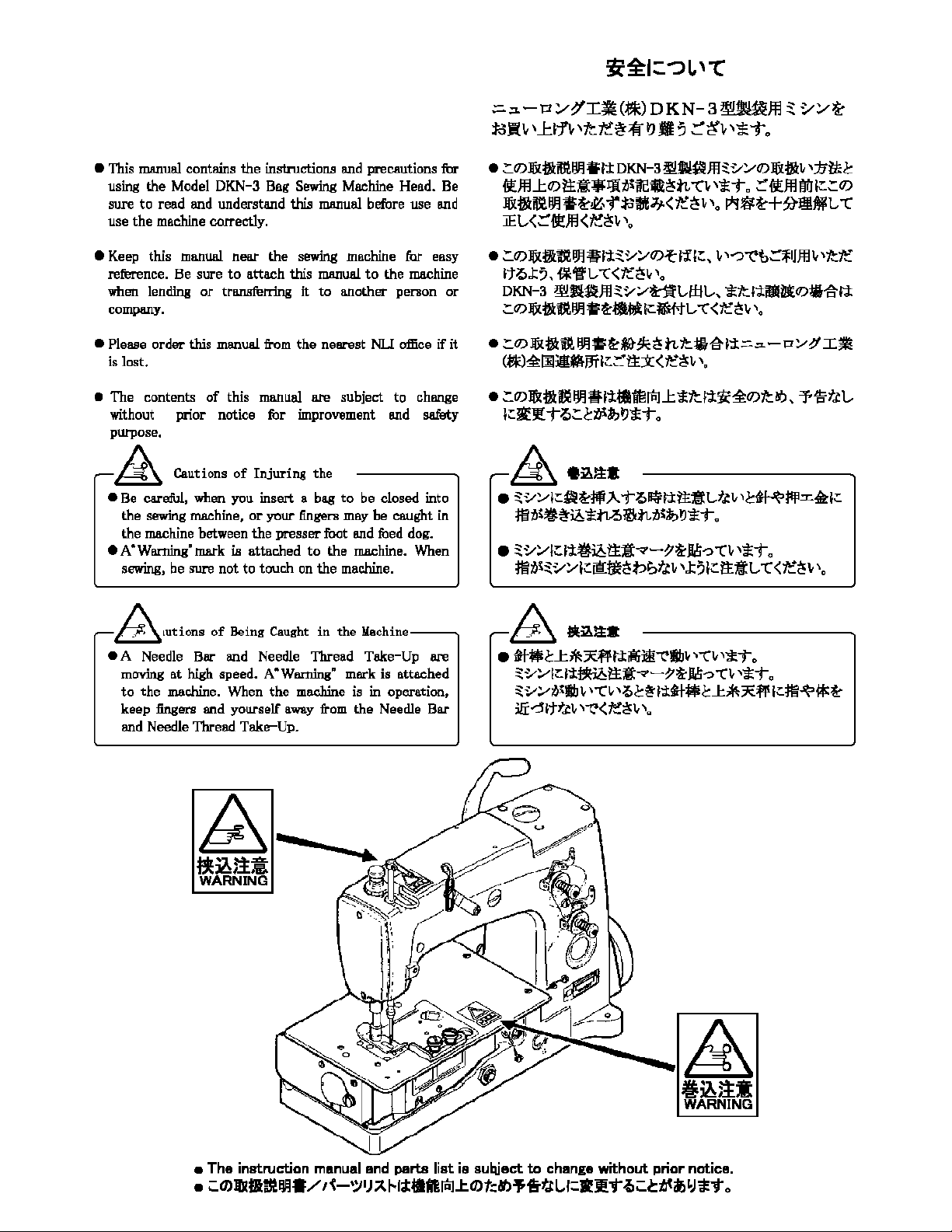

Safety

Rules

To prevent personal injury:

•

All

power sources

to

the machine must be turned

off

before threading, oiling, adjusting or replacing parts.

•

All

cover and guards must be

in

position before operating

machine.

•

Do

not tamper with safety cover, guards, etc.,

while

machine is

in

operation.

Safety Precautions

•

Always

turn power off before threading, oiling, and

adjusting the machine or replacing parts.

• Wear safety glasses.

• Make sure, before starting the machine,

that

all

covers

and shields are

in

place and closed.

•

Do

not touch on the machine when it

is

run.

• Turn power off and make sure the

cutter

does not

operate before you put your fingers under the

cutter

blades and the needles

to

adjust.

•

Do

not touch on the machine when it

is

run.

• Please keep

in

mind

to

handle the machine carefully and

to

maintain the machine

in

good condition.

• Thread fuzz or dust must be cleaned with air or brush on

throat plate,

in

the groove of feed dog or around looper

after the day's work.

• Wipe the area easy

to

rust with oilcloth.

• Check the machine for loose screws and tighten them,

if

any, once a month.

•

Good

maintenance

will

prolong

the

machine

life.

ii

•

:=.::i.

-n1/:1'I:~

(~)

~00i!l!if4tffl'l;:.fj:

DKN-1

O)KuliIEI~

8'1=1:a:-'M-uml.,

-C:t3VJ~To

• :::·r±xO)~l'i,

/';-o/D7.J--O)/-/;-o/:ffi:%t1;~--c-:::·m~

<tc~'v'o

•~fflL~~~~~&O~ffl~O)~-~~-~~,~

O){ili.1/f'Vlnftt·--c-MVJ

f;:.<1v

'~1?i-l'i,

:t3J'lv

'Liiv

,t~tc't5~

L,t~:=.::i.

-n1/:1'I~(~)~OOJ!i!if4tffl'l;:.:::·J!!!if4t<

tc~v

'a

r,!;j~O)~,

~f.11;' ~~:ffi:%' ~y1/)mf~1;'

~y1/:ffl:%

:a:-~m~<tc~v

'~T

J::5:td!ffiv

'v

,t~t.,~-t"a

• ~~~VJ·*-wJnO)tr::O)*ifill.,,

*0)3t~,

~rm,

w.ollf,

$8'1=13t~,

1:Ji1:"r,¢.e~f'f~O)trJf;:.~,--r•n»::a:--wJ0-c<tt~

V

\o

•

w.Bliff'f~O)t't51'i'tc~}jj-*O)~ffl:a:-:t3-t"-t"0')L,~-t"o

• jJ/'{-ftt·7'.J~M~0-Cv,;s::.t:a:-$~L,

-c7'.J~G3ffi'.~L,

-c<tc

~V\o

•

jj-O)r/;:.-¥:a:-J-..n'5t't51'i,

~,--rtn»::a:-'WJ0-C<tc~'v'o

f~;E!l!w.ffl/f

O)

t't5l'i,

~,

i"ffl:il»::a:-'WJ

VJ~y1/7'.J~ll17'.J~ftv

,::.t

:a:-$~L,

-c7'.J~G1t~:a:-fi0-C<tc~v

'a

•

~y1/Jljf~l'i~-\tft1J,~ft$

8'1=17'.J~Gt±H[~L7'.J~0

-Cv

'~Ta

r±Jt~<

J&:lJk5

ttt

f;:.

m

1;:.1/f-um

f;:.,tAtHt-c

<tc~v

'a

• - a

O)f'f~7'.J~~TL,~L,t~G,

ittJitO)L,

j!!J~0)7$\:0)

~,

1v-/';-O)~:bVJ1;:.~~0tdl::.VJ~l'i't5nv

,1;:.J&VJ

~1v,-c<tc~'v'o

•

-¥

J-.;h,O)

~

Ull

L,

l'i~~

0)

~~

f;:.~9

L,

~TO)

--c-

:::·

r±tt

<tc~'v'o

From the Library of Superior Sewing Machine & Supply LLC