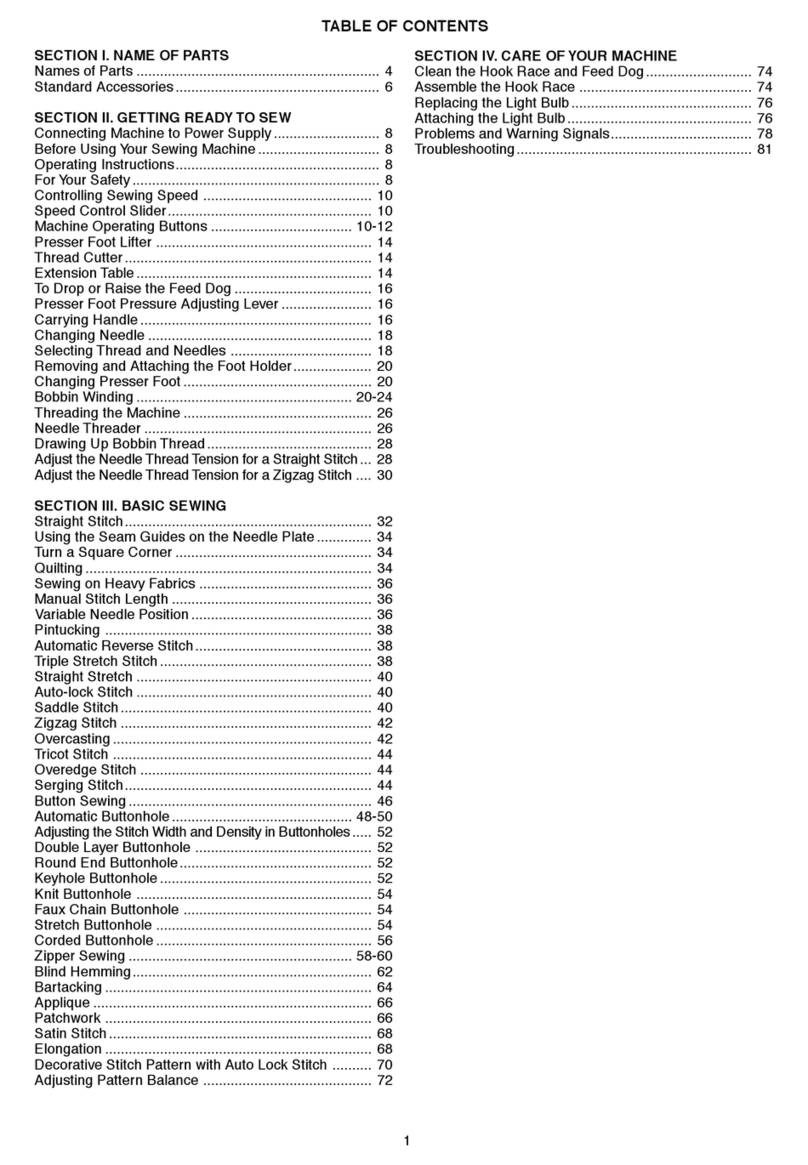

INDEX

WHAT TO DO WHEN.......................................................................................................................... 1-3

CHANGING EXTERNAL PARTS

FACE COVER .........................................................................................................................................4

FREE-ARM COVER ...............................................................................................................................5

FRONT COVER ......................................................................................................................................6

REAR COVER.........................................................................................................................................7

MECHANICAL ADJUSTMENT

PRESSER BAR HEIGHT ........................................................................................................................8

NEEDLE DROP POSITION.....................................................................................................................9

ADJUSTMENT OF HOOK TIMING .......................................................................................................10

ADJUSTMENT OF NEEDLE BAR HEIGHT..........................................................................................11

CLEARANCE BETWEEN NEEDLE AND TIP OF ROTARY HOOK ......................................................12

FEED DOG HEIGHT .............................................................................................................................13

TOP TENSION ......................................................................................................................................14

STRETCH STITCH FEED BALANCE ...................................................................................................15

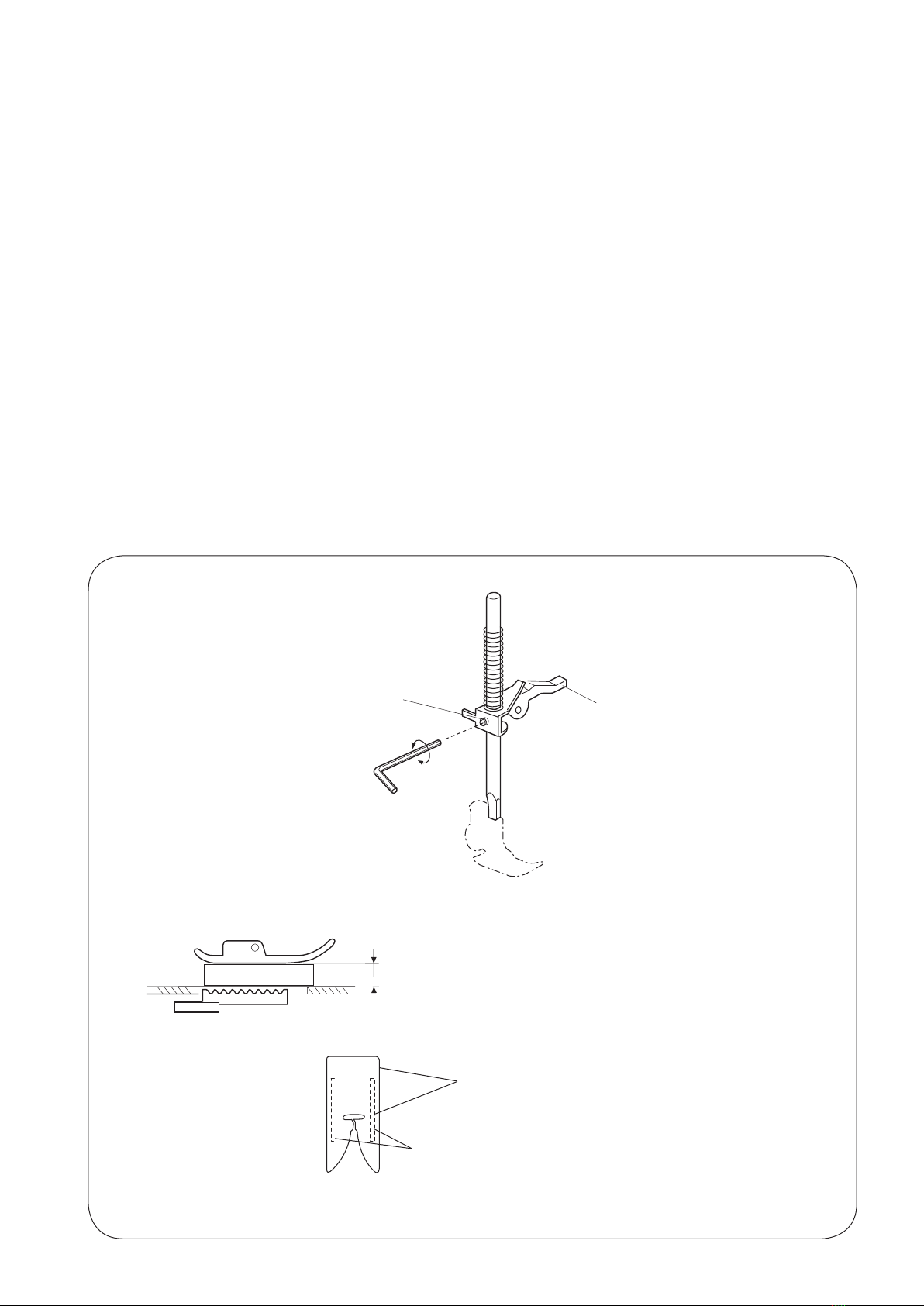

REPLACEMENT AND ADJUSTMENT OF THE NEEDLE THREADER PLATE....................................16

ADJUSTING BUTTONHOLE LEVER POSITION..................................................................................17

SELF-DIAGNOSTIC TEST

SELF-DIAGNOSTIC TEST.............................................................................................................. 18-23

TO DISPLAY THE VERSION OF THE PROGRAM...............................................................................23

REPLACING THE ELECTRONIC COMPONENTS

PRINTED CIRCUIT BOARD A CONNECTION .....................................................................................24

PRINTED CIRCUIT BOARD A ..............................................................................................................25

PRINTED CIRCUIT BOARD F2 ............................................................................................................26

PRINTED CIRCUIT BOARD F1 ............................................................................................................27

PRINTED CIRCUIT BOARD L...............................................................................................................28

DRIVING MOTOR (DC MOTOR) ..........................................................................................................29

SWITCHING REGULATOR UNIT..........................................................................................................30

PARTS LIST .................................................................................................................................... 31-45