BEING BOF Series User manual

Read manual before using this

product. Failure to do so and

observe this information can result

in injury or equipment damage.

Disclaimer

BEING Scientific Inc. makes no representations or warranties concerning this manual and, to the

maximum extent permitted by law, expressly limits its liability for breach of any warranty that may

be implied to the replacement of this manual with another. Furthermore, BEING reserves the right to

revise this publication at any time without incurring an obligation to notify any person of the revision.

The information provided in this documentation contains general descriptions and/or technical

characteristics of the instrument’s performance. This documentation is not intended as a substitute

for and is not to be used for determining suitability or reliability of these instruments for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete

risk analysis, evaluation, and testing of the instruments with respect to the relevant specific application

or use thereof. Neither BEING nor its affiliates or subsidiaries shall be responsible nor liable for

misuse of the information contained herein. Please notify us if you have any suggestions for

improvements or amendments or have found errors in this publication.

All pertinent state, regional, and local safety regulations must be observed when installing and using

this instrument. Repair of BEING instruments SHALL BE PERFORMED IN CONSULTATION

with a BEING technical support representative by the instrument owner or their representative, or a

BEING authorized service technician.

The relevant instructions must be followed when instruments are used for applications with technical

safety requirements.

Copyright © 2023. BEING Scientific Inc.

All rights reserved. No part of this publication may be reproduced, distributed, or transmitted in any

form or by any means, including photocopying, recording, or other electronic or mechanical methods,

without BEING’s prior written permission. For permission requests, write to BEING, addressed

“Attention: Permissions Coordinator,” at the address below.

BEING Scientific Inc.

800 N Haven Ave., Suite 428

Ontario, CA 91764

T: +1 800.278.1390

www.beinglab-usa.com

BEING Scientific Inc.

BOF Mechanical Convection Oven Operating Instructions 3

Before Continuing

Please collect the following information from your unit. You’ll need it to

register the oven and activate its 2-year warranty and when you have to

contact customer or technical support.

Model Number:

Serial Number:

Production Date:

Firmware Version:

Dealer Purchased From:

Purchase Date:

STEP 1: Find the product identification label. STEP 2: Scan the QR code or visit to

https://www.beinglab-usa.com/product-registration

to register your oven(s).

Outside of the cardboard shell.

Back of the oven above the power cord.

2

YEAR

W

A

R

R

A

N

T

Y

Activate

!TODAY

Register Your Unit Today!

See section x.x.x on page xx for finding firmware version.

Thank you for purchasing BEING Scientific’s BOF series mechanical

convection oven.

BEING Scientific Inc. is committed to customer service both during and after the sale. If you have questions oncerning the

operation of your unit or the information in this manual, or the unit fails to operate properly, contact our Technology Support

Department at +1. 800.278.1390, or through the form on our website at https://beinglab-usa.com/technical-support.

Visit www.beinglab-usa.com/warranty for warranty details.

BEING Scientific Inc. BOF Mechanical Convection Oven Operating Instructions

4

Table of Contents

1.0 Safety Messages ............................................................................... 8 - 16

1.1 How to use the Manual........................................................................................ 8 - 9

1.1.1 Introduction ................................................................................................... 8

1.1.2 Chapter Summary.......................................................................................... 8

1.1.3 Model Number Nomenclature ....................................................................... 9

1.2 Safety Notice.............................................................................................................9

1.3 Symbols used in this Operation Instructions ............................................................ 10

1.3.1 Signal Word Panels ..................................................................................... 10

1.3.2 Safety Symbols ........................................................................................... 10

1.3.3 Miscellaneous Non-safety Symbols used in Manual ..................................... 11

1.4 Where to Locate Safety Labels on the Ovens ......................................................... 12

1.4.1 BOF-30T through BOF-200T ....................................................................... 12

1.4.2 BOF-400T ................................................................................................... 12

1.5 Precautions for Your Oven ............................................................................... 13 - 14

1.5.1 Warning Statements .................................................................................... 13

1.5.2 Caution Statements .................................................................................... 14

1.5.3 NOTICE Statements..................................................................................... 14

1.6 Responsibility ...................................................................................................15 - 16

1.6.1 General Responsibility ................................................................................. 15

1.6.2 Operator Responsibility ............................................................................... 15

1.6.3 Maintenance Responsibility ......................................................................... 16

1.6.4 Reporting a Safety Defect ............................................................................ 16

2.0 Functional Description ..................................................................... 17 - 29

2.1 Introduction ........................................................................................................... 17

2.2 Oven Generation Comparison ................................................................................ 18

2.3 Oven Features..................................................................................................19 - 29

2.3.1 Compliance ................................................................................................. 19

2.3.2 Construction .........................................................................................20 - 29

2.3.2.1 BOF-30T, BOF-50T, BOF-120T & BOF-200T ...........................20 - 21

2.3.2.2 BOF-400T ............................................................................. 22 - 23

2.3.2.3 Control System .............................................................................. 24

2.3.2.4 Component Functionality .........................................................25 - 29

3.0 Installation and Setup ....................................................................... 30 - 39

3.1 Inspecting and Uncrating ..................................................................................30 - 31

3.1.1 Inspecting Oven’s Packaging Before Removal ............................................. 30

3.1.2 Removing Oven from Shipping Container .............................................30 - 31

3.1.3 Inspect Oven after Packaging Removal ....................................................... 31

3.1.4 In the Event of Shipping Damage ................................................................ 31

3.2 Preparing the Location .....................................................................................32 - 34

3.2.1 Space Requirements ............................................................................32 - 33

3.2.2 Oven Environment ....................................................................................... 34

3.3 Oven Setup ......................................................................................................35 - 39

3.3.1 Stacking Ovens (BOF-50T & BOF-120T only) .............................................. 35

3.3.2 Preparing Oven for Use.........................................................................36 - 37

3.3.3 Setting Controller Date and Time ..........................................................38 - 39

BEING Scientific Inc.

BOF Mechanical Convection Oven Operating Instructions 5

4.0 Operation ........................................................................................ 40 - 61

4.1 Controller Display Overview ..............................................................................40 - 44

4.1.1 Current Conditions................................................................................40 - 41

4.1.2 Buttons .................................................................................................41 - 43

4.1.2.1 Multi-function Buttons..............................................................41 - 42

4.1.2.2 Single-function Buttons................................................................... 43

4.1.3 Data Collection............................................................................................. 43

4.1.4 Setting Entry Methods.................................................................................. 44

4.2 Changing Unit of Measurement ........................................................................45 - 46

4.3 Calibration .......................................................................................................47 - 49

4.3.1 Testing for TV1and TV2.........................................................................47 - 48

4.3.2 The Math ..................................................................................................... 49

4.3.3 Programming the Correction ....................................................................... 49

4.4 Selecting Program Mode ........................................................................................ 50

4.5 Setting Fixed-value Program ............................................................................51 - 52

6.5.1 Temperature ................................................................................................ 51

6.5.2 Program RUN Time ..............................................................................51 - 52

6.5.3 Fan Speed ................................................................................................... 52

4.6 Multi-step Programs.........................................................................................53 - 55

4.6.1 What is a Multi-step Program ....................................................................... 53

4.6.2 Setting Program Steps .........................................................................54 - 55

4.6.3.1 Program Step Temperature Setpoint ............................................... 54

4.6.3.2 Program Step Fan Speed .............................................................. 54

4.6.3.3 Program Step RUN Time ................................................................ 55

4.6.3 Program Cycling ...................................................................................56 - 57

4.6.3.1 Overview ......................................................................................... 56

4.6.3.2 Setting Number of Cycles ........................................................56 - 57

4.7 Setting RUN/START Delay Timer .......................................................................58 - 59

4.7.1 Overview...................................................................................................... 58

4.7.2 Programming RUN/START Delay Timer ................................................58 - 59

4.8 Setting Low-temperature & High-temperature Alarms .......................................60 - 61

5.0 Data Collection ................................................................................ 62 - 66

5.1 Overview .................................................................................................................62

5.2 Storage Capacity ..................................................................................................... 63

5.3 Viewing Data ....................................................................................................63 - 64

5.4 Exporting Data ..................................................................................................64 - 66

5.4.1 File Types ..................................................................................................... 64

5.4.2 Collecting Data During Program Run ........................................................... 65

5.4.3 Collecting Data History by Date.................................................................... 66

5.4.3 Collecting Data History by Number of Program Starts or Power-ons ............ 66

BEING Scientific Inc. BOF Mechanical Convection Oven Operating Instructions

6

6.0 Operational Settings Screens and Parameters .................................. 68 - 85

6.1 Overview (Home Screen) ......................................................................................... 68

6.2 USER Settings .................................................................................................69 - 77

6.2.1 Screen 0 | USER Home Screen ................................................................... 69

6.2.2 Screen 1 | History - Table ............................................................................. 70

6.2.3 Screen 1 | Present Value vs Setpoint Curve - Real Time .............................. 71

6.2.4 Screen 1 | Alarm History (Generation 3 only) ................................................ 72

6.2.5 Screen 2 | Date and Time Settings .............................................................. 74

6.2.6 Screen 3 | tM, Po, Cycle, Delay Parameters ................................................ 75

6.2.7 Screen 4 | AL, Pb, PK, PA Parameters ........................................................ 76

6.2.8 Screen 5 | 2b, 2K Parameters ..................................................................... 77

6.3 SERVICE Settings ...........................................................................................78 - 85

6.3.1 Screen 1 | P, I, d, t Parameters .................................................................... 78

6.2.2 Screen 2 | CL, Ct, Ht, Lt Parameters ........................................................... 79

6.3.3 Screen 3 | Hp, Co Parameters ..................................................................... 80

6.3.4 Screen 4 | dr, Fn, md, La Parameters .......................................................... 81

6.3.5 Screen 5 | LI, wA, HC, Yu Parameters ......................................................... 82

6.3.6 Screen 6 | ET, CF, F1, F6 Parameters .......................................................... 83

6.3.7 Screen 7 | F7, F8, Mu, Ot Parameters ......................................................... 84

6.3.8 Screen 8 | FA, uC, Mn, 2T Parameters ........................................................ 85

7.0 Troubleshooting and Maintenance .................................................... 86 - 88

7.1 Troubleshooting ...................................................................................................... 86

7.2 Preventive Maintenance ...................................................................................87 - 88

7.2.1 Calibration ................................................................................................... 87

7.2.2 Cleaning ...............................................................................................87 - 88

7.2.2.1 Cleaning the Exterior ....................................................................... 87

7.2.2.2 Cleaning the Chamber .................................................................... 87

7.2.2.3 Cleaning the Electronics ................................................................. 88

7.2.2.4 Cleaning Before Returning Unit ....................................................... 88

7.2.3 Storage ....................................................................................................... 88

8.0 Appendix .......................................................................................... 90 - 98

8.1 Specifications ......................................................................................................... 90

8.2 Electrical Wiring Schematics.............................................................................91 - 93

8.2.1 BOF-30T through BOF-200T (Generation 1)................................................. 91

8.2.2 BOF-30T through BOF-200T (Generations 2 & 3)......................................... 92

8.2.4 BOF-400T (Generations 2 & 3) .................................................................... 93

8.3 Certification and Certificates .............................................................................94 - 96

8.3.1 ISO-9001 Certificate ..................................................................................... 94

8.3.2 ETL Certificate .............................................................................................. 95

8.3.3 Certificate of Calibration ................................................................................ 96

8.4 Statements ............................................................................................................. 97

8.4.1 Oven Ventilation ............................................................................................ 97

8.4.2 California Proposition 65 ............................................................................... 97

8.4.3 Waste Disposal ............................................................................................. 97

8.4.3.1 Packaging....................................................................................... 97

8.4.3.2 Unit ................................................................................................. 97

8.5 Warranty ................................................................................................................. 98

BEING Scientific Inc.

BOF Mechanical Convection Oven Operating Instructions 7

BEING Scientific Inc. BOF Mechanical Convection Oven Operating Instructions

8

1.0 Safety Messages

1.1 How to use These Operating Instructions

1.1.1 Introduction

This manual is intended for individuals requiring information about the use of mechanical (forced air)

convection ovens. Use these operating instructions as a guide and reference for installing, operating,

and maintaining your BEING BOF series, mechanical (forced air) convection ovens (hereinafter “oven”

or “unit”). The purpose is to assist you in applying efficient, proven techniques that enhance

equipment productivity.

These operating instructions covers only light corrective maintenance. No installation, service

procedure or other maintenance should be undertaken without first contacting a service technician,

nor should be carried out by someone other than a service technician with specific experience with

laboratory equipment and electricity.

1.1.2 Chapter Summary

The Installation chapter includes the pertinent information for receiving, unpacking, inspecting, and

setting up the unit. This section contains instructions that should be followed before operating the

oven. These instructions are intended to supplement standard laboratory procedures performed daily

and weekly.

The Functional Description chapter outlines the oven’s standard and safety features.

The Operation chapter includes a description of controller features, temperature, time, and fan speed

setting instructions, multi-segment program setting instructions, and instructions for changing the unit

of measurement and calibrating the oven.

The Data Logging chapter is intended to serve as a source for understanding how the oven’s

controller collects temperature and time information during the oven’s operation and how the user can

collect this data for analysis.

The Operational Settings Screens and Parameters chapter provides the user with all the screens for

viewing real-time temperature and time performance data and data and alarm history. Additionally, it

includes information on navigating the screens and settings that affect the oven’s accuracy, efficiency,

and effectiveness, along with changing the unit of measurement.

The Troubleshooting and Preventive Maintenance chapter serves as a guide for identifying the most

common problems. Potential problems are listed, along with possible causes and related solutions.

The Appendix contains technical specifications, schematic drawings, warranty, certification certificates,

instructions for requesting a certificate of calibration and for end-of-life disposal of the unit, and BEING

technical support contact information.

BEING Scientific Inc.

BOF Mechanical Convection Oven Operating Instructions 9

1.2 Safety Notice

Be sure that you are completely familiar with the safe operation of the BEING BOF series oven. Improper use can

cause serious or fatal injury.

Installation and repair procedures require specialized skills with laboratory equipment and electricity. Any person

that installs or repairs this unit must have these specialized skills to ensure that this unit is safe to operate.

Contact BEING Scientific Inc. or your local authorized distributor for repairs or any questions you may have about

this unit’s safe installation and operation.

The precaution statements are general guidelines for the safe use and operation of these instruments. It is not

practical to list all unsafe conditions. Therefore, if you use a procedure that is not recommended in these operating

instructions, you must determine if it is safe for the operator and all personnel in the proximity to the instrument.

If there is any question of the safety of a procedure, please contact BEING Scientific before starting or stopping

the instrument.

This equipment contains high voltages. Electrical shock can cause serious or fatal injury. Only qualified personnel

should attempt the startup procedure or troubleshoot this unit.

• Documentation must be available to anyone that operates this equipment at all times.

• Keep non-qualified personnel at a safe distance from this unit.

• Only qualified personnel familiar with the safe installation, operation, and maintenance of this unit should

attempt startup or operating procedures.

• Always stop the instrument before making or removing any connections.

1.1.3 Model Number Nomenclature

These operating instructions covers all five (5) models of the BEING BOF series. The following

describes the model number nomenclature used throughout these instructions.

B O F - 30 T

BEING

Instrument

O = Oven

Instrument Type

F = Mechanical (forced air) convection

Controller

T = Touchscreen

Chamber Size

30 = 30L

50 = 51L

120 = 121L

200 = 211L

400 = 400L

BEING Scientific Inc. BOF Mechanical Convection Oven Operating Instructions

10

1.3 Symbols used in These Operating Instructions

The following signal word panels, safety symbols, and non-safety symbols are used to alert you to potential per-

sonal injury hazards or information of importance. Obey all safety messages that follow these symbols to avoid

possible personal injury or death.

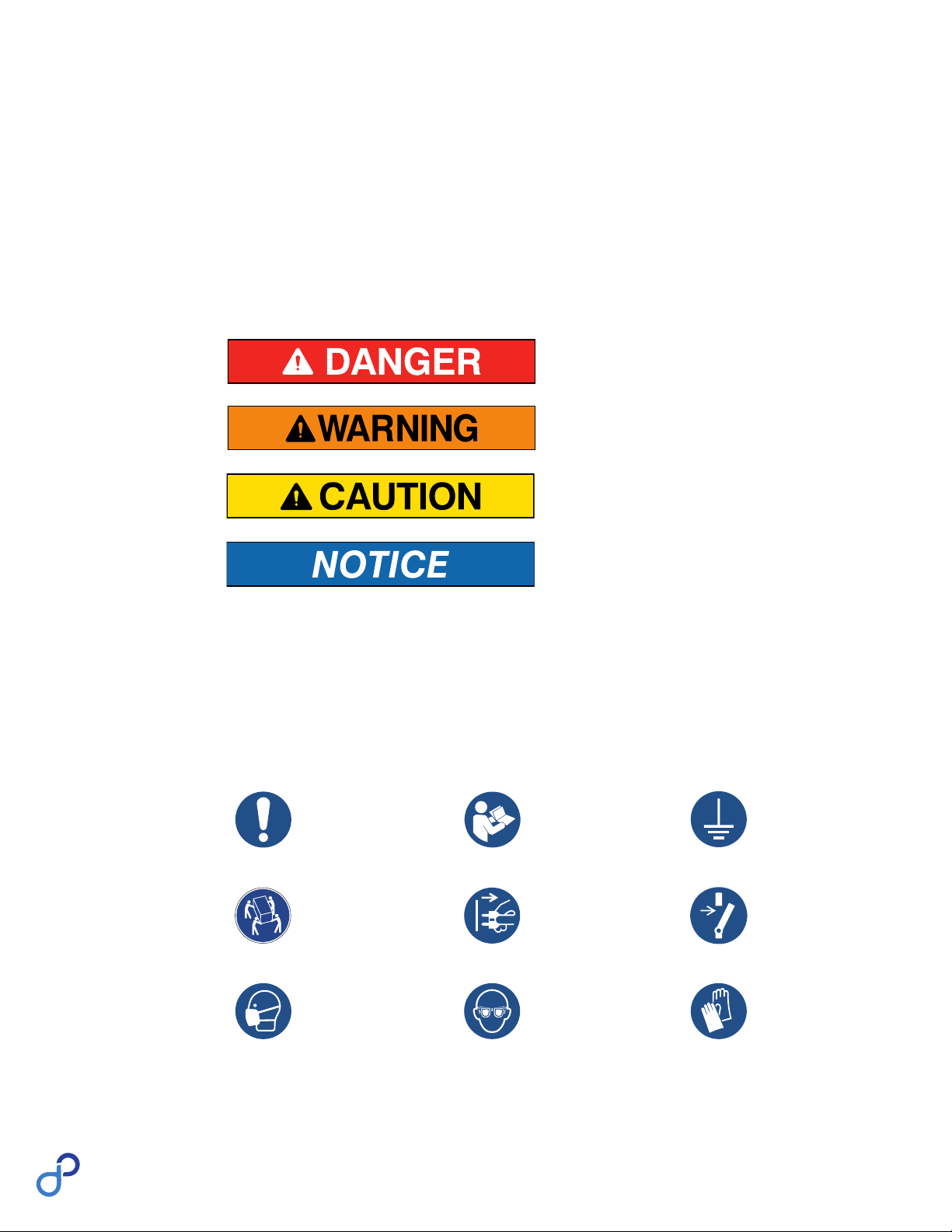

1.3.1 Signal Word Panels

Signal word panels are a method for calling attention to a safety messages or property damage

messages and designate a degree or level of hazard seriousness. It consists of three elements: a

safety alert symbol, a signal word and a contrasting rectangular background. The following signal

word panels are in accordance with ANSI Z535.4-2111 (R2017) and ISO 3864 standards.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury.

Indicates a property damage message.

1.3.2 Safety Symbols

Safety symbols are graphic representations—of a hazard, a hazardous situation, a precaution to avoid

a hazard, a result of not avoiding a hazard, or any combination of these messages—intended to

convey a message without the use of words. The following safety symbols are used in these

operating instructions.

Mandatory

General Mandatory Symbol

General Notice Symbol Read Manual Earth Ground

Multi-person Lift Disconnect Electric Plug

From Outlet

Disconnect Before

Maintenance or Repair

Wear Face Mask Wear Eye Protection Wear Protective Gloves

BEING Scientific Inc.

BOF Mechanical Convection Oven Operating Instructions 11

1.3.3 Miscellaneous Non-safety Symbols used in Manual

The following graphic representations are intended to convey a message without words or to bring

your attention to important information about the use of the oven or a feature.

Warning

Prohibition

Read Information Ambient Temperature Atmospheric Pressure

Relative Humidity Airborne Pollution ETL Certification

Waste Electrical and

Electronic Equipment

No Direct Sunlight No Radiant Heat Exposure No Corrosive

Fuids or Cleaners

No Explosive Gases No Flammable Gases No Water

General Warning Symbol

Safety Alert Symbol Electrical Shock Hand Crush or Pinch

Lifting Hazard Hot Surface

BEING Scientific Inc. BOF Mechanical Convection Oven Operating Instructions

12

The safety labels are attached to the ovens to provide important information about potential hazards and how

to avoid them. The following photos show where the safety labels should be attached to the oven until service

of the product is discontinued. If the safety labels are damaged, please contact BEING or your local distributor

to request new labels.

1.4 Where to Locate Safety Labels on the Ovens

1.4.1 BOF-30T through BOF-200T

1.4.2 BOF-400T

1

2

1

2

12

Figure 1.1 Figure 1.2

Figure 1.3 Figure 1.4

Figure 1.5

Figure 1.6

BEING Scientific Inc.

BOF Mechanical Convection Oven Operating Instructions 13

1.5.1 Warning Statements

The improper use of this unit may cause death or serious injury. Observe all statements.

DO NOT remove warning labels.

Check the voltage, phase and capacity of the power supply and connect properly.

Check the voltage and frequency of the power supply and ensure they are compatible with the oven

power requirements prior to use. The fluctuations of the supply voltage SHALL NOT exceed ±10%

of the nominal supply voltage.

This unit MUST use the included electrical cord with a dedicated electrical circuit with a confirmed

electrical ground connection.

The unit MUST BE properly electrically grounded (The Hot line or the Neutral line SHOULD NOT be the

grounded connection, adhere to the product’s requirement before using).

Please use the receptacle connecting with the ground connection to prevent electric shock. If the

receptacle does not have the ground connection, the earth ground wire must be installed by a qualified

electrician. DO NOT conduct the ground connection through the gas pipe, water pipe, telephone line

or lightning rod! This kind of ground connection may cause electric shock due to the incomplete loops.

DO NOT insert multiple plugs into the outlet at the same time.

Power switch and circuit breaker MUST be in the “OFF” position when connecting or disconnecting

the unit’s power cord to or from the power supply.

The power cord MUST BE removed from receptacle when any of the following occur:

• When the product is waiting for overhaul due to faults.

• When the product goes out of service for a long time.

• When the product is being moved.

DO NOT operate oven with damaged power cords.

DO NOT arbitrarily lengthen or shorten the power supply connection wire.

DO NOT modify the power cord in any way.

DO NOT put flammable, explosive, volatile, and corrosive substances in the oven chamber for drying

and baking.

DO NOT touch the chamber door, the chamber body or the surrounding surface when the set

temperature is over 176°F (80°C)!

DO NOT put fingers, hands or objects into the air intake or exhaust ports.

The unit should have routine inspections and should be serviced by a qualified service technician

when needed.

Our oven is designed to provide safe and reliable operation when installed and operated within design

specifications. Make sure you read and understand all instructions and safety precautions listed in this

manual before installing or operating your unit. If you have any questions concerning the operation of your

unit or the information in this manual, contact our Technical Support Department.

To avoid possible personal injury or equipment damage when installing, operating, or maintaining this oven,

use good judgment and follow these safe practices:

1.5 Precautions for Your Oven

BEING Scientific Inc. BOF Mechanical Convection Oven Operating Instructions

14

1.5.2 Caution Statements

The improper use of this unit may result in minor or moderate injury.

DO NOT use doors, handles or knobs to lift or stabilize the unit.

DO NOT place heavy objects on the power cord.

DO NOT put the oven on the power cord.

DO NOT tension the power supply cord when plug in.

DO NOT operate oven when water may be in the unit. Immediately disconnect the main power

supply and request service.

DO NOT sprinkle insecticide or flammable spray on the oven.

1.5.3 NOTICE Statements

The improper use of this unit may result in damage to the unit or your facility.

The oven should be located on a strong solid surface.

Take care when opening and closing the door to prevent damage to delicate internal components.

DO NOT make the oven wet while cleaning.

DO NOT pour water or put liquid on the oven when cleaning the unit.

DO NOT clean the oven with a strong cleanser (e.g., solvent type) and use a soft cloth.

304 stainless steel material is not acid resistance, please pay attention to the corrosion prevention

measures. DO NOT place corrosive materials inside the unit to prevent damage.

In addition to the safety warnings listed above, safety messages are posted throughout the manual.

These safety messages are designated using a signal word panel followed by text and a safety symbol

where applicable. Read and follow these important instructions. Failure to observe these instructions

can result in permanent damage to the unit, significant property damage, personal injury or death.

BEING Scientific Inc.

BOF Mechanical Convection Oven Operating Instructions 15

Our ovens are constructed for maximum operator safety when used under standard operating conditions and

when recommended instructions are followed in the maintenance and operation of the machine.

All personnel engaged in the use of the oven should become familiar with its operation as described in these

operating instructions.

Proper operation of the unit promotes safety for the operator and all workers in its vicinity.

Each individual must take responsibility for observing the prescribed safety rules as outlined. All caution,

warning and danger labels must be observed and obeyed. All actual or potential danger areas must be

reported to your immediate supervisor.

1.6 Responsibility

1.6.1 General Responsibility

No matter who you are, safety is important. Owners, operators, and maintenance personnel must

realize that safety is a vital part of their jobs every day.

If your primary concern is loss of productivity, remember that production is always affected negatively

following an accident. The following are some of the ways that accidents can affect your production:

• Loss of a skilled operator (temporarily or permanently)

• Breakdown of lab morale

• Costly damage to equipment and laboratory samples

• Downtime

An effective safety program is responsible and economically sound.

Organize a safety committee or group and hold regular meetings. Promote this group from the

management level. The safety program can be continually reviewed, maintained, and improved through

this group. Keep minutes or a record of the meetings.

Hold daily equipment inspections in addition to regular maintenance checks. You will keep your

equipment safe for production and exhibit your commitment to safety.

Please read and use these operating instructions as a guide to equipment safety. These instructions

contain safety warnings throughout, specific to each function and point of operation.

1.6.2 Operator Responsibility

The operator’s responsibility does not end with efficient experimentation and production. The operator

usually has the most daily contact with the equipment and intimately knows its capabilities and limitations.

Plant and personnel safety is sometimes forgotten in the desire to meet incentive rates, or through a

casual attitude toward laboratory equipment formed over a period of months or years. Your employer

probably has established a set of safety rules in your workplace. Those rules, these operating instructions,

or any other safety information will not keep you from being injured while operating your equipment.

Learn and always use safe operation. Cooperate with co-workers to promote safe practices. Immediately

report any potentially dangerous situation to your supervisor or appropriate person.

BEING Scientific Inc. BOF Mechanical Convection Oven Operating Instructions

16

REMEMBER:

• NEVER place your hands or any part of your body in any dangerous location.

• NEVER operate, service, or adjust the equipment without appropriate training and first reading

and understanding this manual.

• Before you start the portable drying/conveying system check the following:

Remove all tools from the oven.

Be sure no objects, samples or chemicals are laying on the oven.

• If your oven has been inoperative or unattended, check all settings before starting the unit.

• At the beginning of your shift and after breaks, verify that the oven is functioning properly.

• Report the following occurrences IMMEDIATELY:

unsafe operation or condition

unusual oven action

leakage

improper maintenance

• DO NOT wear loose clothing or jewelry, which can be caught while working on the equipment. In

addition, cover or tie back long hair.

• Clean the equipment and surrounding area DAILY, and inspect the machine for loose, missing or

broken parts.

• Shut off power to the oven when it is not in use. Turn the power switch to the OFF position, or

unplug it from the power source.

1.6.3 Maintenance Responsibility

Proper maintenance is essential to safety. If you are a maintenance worker, you must make safety a

priority to effectively repair and maintain equipment.

Before removing, adjusting, or replacing parts on this oven, remember to turn off all electric supplies

and all accessory equipment at the machine, and disconnect and lockout electrical power. Attach

warning tags where possible.

Be sure the oven is correctly connected to an earth grounded electrical outlet that

complies with current codes.

When you have completed the repair or maintenance procedure, check your work, and remove your tools.

DO NOT restore power to the oven until all persons are clear of the area. BEFORE you turn the oven

over to the operator for production, verify the unit is functioning properly.

1.6.4 Reporting a Safety Defect

If you believe that your oven has a defect that could cause injury, you should immediately discontinue

its use and inform BEING Scientific or your local authorized distributor.

The principle factors that can result in injury are failure to follow proper operating procedures

(i.e. lockout/tag out), or failure to maintain a clean and safe working environment.

BEING Scientific Inc.

BOF Mechanical Convection Oven Operating Instructions 17

The BEING BOF Series mechanical (forced air) convection ovens are engineered for heavy workloads and

continuous, 24-hour operation in a wide variety of chemistry, clinical, light industrial, pharmaceutical, and

research laboratory applications, such as.

• Age testing of electronic components and devices, AKA product age acceleration

• Annealing

• ASTM testing

• Baking

• Conditioning

• Curing

• Dehydrating

• Die-bonding

• Dry sterilization

• Evaporation

• Drying - glassware and part

• Heat treating

• Heated storage

• Life cycle testing

• Moisture and stability tests

• Polymerization

• Pre-heating

The mirror-finish 304 stainless steel chamber provides a strong, corrosion-resistant, inert, and easy-to-

clean environment and prevents sample contamination for any application. The wire shelves provide

maximum air circulation for uniform heating. Their design prevents shelf-tilting and sample spillage. The

wire’s surface tension minimizes or eliminates sample- or part-slide.

The microprocessor-based PID temperature controller and 3-speed, forced convection heating system

provide uniform temperature regulation without overshoot, eliminating potential sample damage. The

controller provides for the programming and storage of fixed-value and multi-segment programs. (See

Section 4.0 for controller programming.)

The adjustable exhaust allows the user to control chamber temperature uniformity by allowing humidity

to escape.

System risks, like voltage spikes, short circuits, over temperature, etc., are monitored by a safety system

that runs independently of the performance controller. Audible and visual alarms are set off, and the oven

will shut down if a risk is identified.

The BOF Series ovens have a USB communications port for data logging. (See Section 5.0 for extracting

data information.)

2.0 Functional Description

2.1 Introduction

BEING Scientific Inc. BOF Mechanical Convection Oven Operating Instructions

18

Since the introduction of the BOF Series mechanical (forced air) convection ovens with

a touchscreen controller display was introduced in 2021, it has gone through several

improvement cycles. The following table shows the differences in the oven generations.

The feature descriptions and operational instructions in this document cover the three

generations of ovens.

Feature Generation 1 Generation 2 Generation 3

Manufacturing Date - Start Jan 2023

Electrical

Integrated electrical panel with easy access cover •••

Circuit breaker over-current protection - power switch

combination •––

Circuit breaker current protection –••

Illuminated power switch –••

Resistive heating element •••

Controller

Touch capactive display •••

PID automatic control •••

Automatic power on/off •••

USB data collection •••

Firmware updatable •••

Programmable functions

Unit of measurement •••

Oven temperature calibration •••

Fixed-value programs •••

Multi-step programs •••

Program cycling •••

Timed & untimed •••

Fan speed - adjustable •••

RUN delay •••

Alarm notification

On display •––

Alarm history in operational settings –••

Heating element on indicator ––•

User interface version ––•

Safety

Resettable over-temperature switch

Reset button inside electrical panel ••–

Reset button outside electrical panel ––•

Temperature limit protection •••

Power off memory •••

Anti-scalding protection •••

2.2 Oven Generation Comparison

BEING Scientific Inc.

BOF Mechanical Convection Oven Operating Instructions 19

2.3 Oven Features

2.3.1 Compliance

The BEING BOF series mechanical (forced air) convection ovens have been

tested and found to be in compliance with the requirements defined in IEC

61010: Medical Laboratory Equipment Testing.

Compliance can be identified by the ETL INTERTEK mark on the product

identification label above the power cord. The testing has demonstrated.

5000103

CONFORMS TO:

UL 61010-1:2012 | Edition 3.1 | R2019: Safety requirements for electrical equipment for measure-

ment, control, and laboratory use – Part 1: General requirements

UL 61010-2-010:2019 | Edition 4: Safety requirements for electrical equipment for measurement,

control and laboratory use – Part 2: Particular requirements for laboratory equipment for the heating

of materials

CERTIFIED TO:

CAN/CSA 22.2 61010-1-12:2012 | Edition 3+ U1; U2; A1: Safety requirements for electrical

equipment for measurement, control, and laboratory use – Part 1: General requirements

CAN/CSA 22.2 61010-2-010:2019 | Edition 4: Safety requirements for electrical equipment for

measurement, control and laboratory use – Part 2: Particular requirements for laboratory equipment

for the heating of materials

BEING Scientific Inc. BOF Mechanical Convection Oven Operating Instructions

20

2

3

8

9

5

6

10

11

17

16

18

15

9a

19

14

20

13

12

Front View

Front Left Isometric View

Back View - Generation 3

2 Chamber door

3 Door handle/latch

5 Top door hinge & hinge cover

6 Bottom door hinge

8 Touchscreen controller display with

USB data collection port

9 Feet

1 Body

10 Electrical components access panel

11 Power switch (Generation 2 & 3 units only)

9a Stacking feet (BOF-50T & BOF-120T only)

12 Power cord

13 Circuit breaker (Generations 2 & 3)

Circuit breaker/power switch

(Generation 1)

14 Over-temperature switch reset

button (Generation 3, see Section 2.3.2.3 for

Generations 1 & 2.)

15 Chamber air intake

16 Chamber exhaust vent

17 Back panel

18 Fan vent

19 Electrical panel vent

20 Product identification label

2.3.2 Construction

2.3.2.1 BOF-30T through BOF-200T

20

13

12

Back View

Close-up

Generations 1 & 2

Figure 2.1

Figure 2.2

Figure 2.3

1

This manual suits for next models

5

Table of contents

Popular Convection Oven manuals by other brands

turbofan

turbofan E9311 Installation & operation manual

Wolf

Wolf ML-136825 owner's manual

turbofan

turbofan 30D Series Installation and operation manual

Electrolux

Electrolux air-o-convect LPG Gas Hybrid Convection Oven... Short form specification

Healthy Choice

Healthy Choice PR4225 manual

GE

GE Advantium CWB713 installation instructions