Beiyuan BQS-1H User manual

Page 1of 17

Instruction Manual

For

e-Shear Mace Electric Handpiece <BQS-1(H)>

Xinjiang Beiyuan-Tyree Mechanical Engineering Co. Ltd

Page 2of 17

Contents

II. Overview...............................................................................................................3

2.1 Product features................................................................................................3

2.2 Technical parameters........................................................................................3

III. Installation ...........................................................................................................4

3.1 Installing combs and cutters..............................................................................4

3.2 Comb selection.................................................................................................5

3.3 Chickenfeet.......................................................................................................5

3.4 Remove and replace the fork body assembly and the roller .............................6

3.6 Adjusting tension...............................................................................................7

IV. Operation.............................................................................................................8

4.1 Pre-work inspection and preparation ................................................................8

4.2 Pre-use and in-use safety and precautions.......................................................8

4.3 Using the handpiece.........................................................................................8

V. Maintenance and Repair....................................................................................11

5.1 Regular checks...............................................................................................11

5.2 Repair and maintenance.................................................................................12

Troubleshooting Guide..........................................................................................13

Page 3of 17

1. Please read this manual carefully before operating.

Thank you for choosing BEIYUAN e-Shear Mace electric handpiece, we hope you

will find full satisfaction with its shearing performance. Although every individual

handpiece is rigorously tested before leaving our factory, in order to ensure safety

during operation, and to maintain good working condition and extend its service life,

please read this manual carefully before use.

II. Overview

2.1 Product features

The e-Shear Mace BQS-1(H) electric handpiece consists of the electric handpiece

assembly and handpiece power supply. Its main features are:

1. a 48V DC power supply with power saving provides 2 speeds 2900 and

3200rpm.

2. ergonomically designed barrel for more comfort and flexibility during

operation.

3. smooth running, low vibration and low noise.

4. small size, light weight, compact, easy to operation, easy to carry.

5. driven by a powerful and durable brushless electric motor, it is suitable for

general and professional shearing.

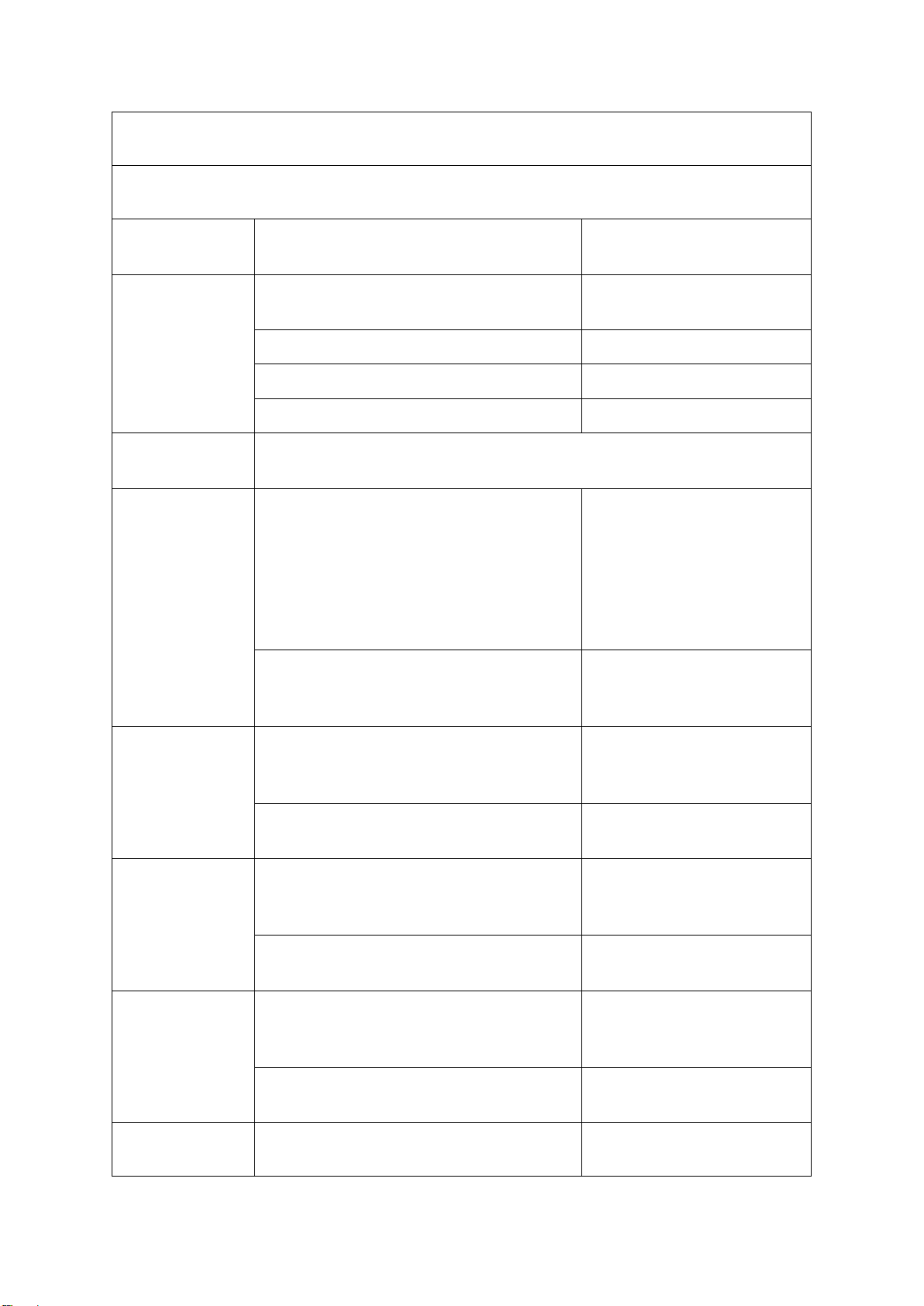

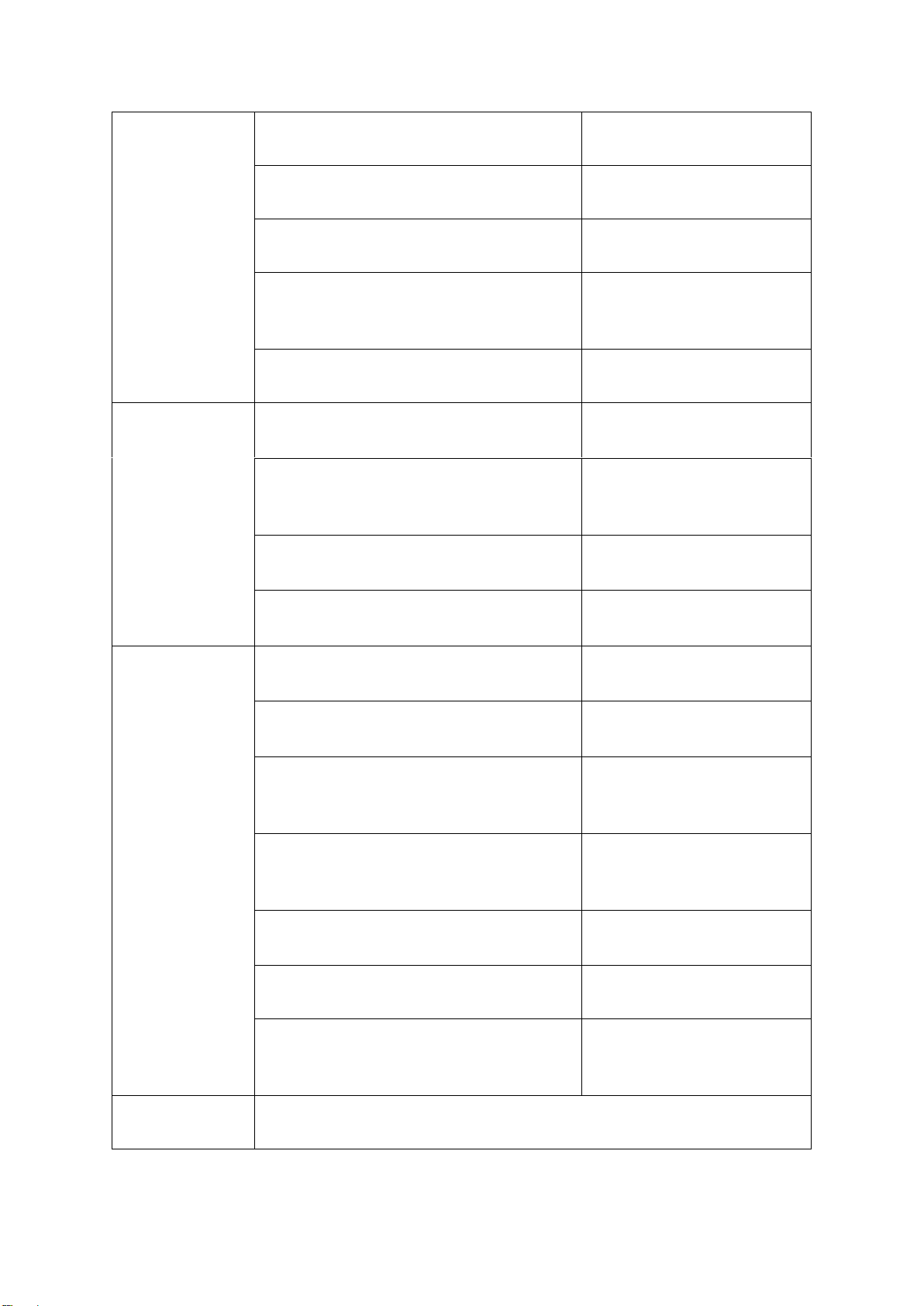

2.2 Technical parameters

Item

Parameter

Supply voltage

90 –260 V AC

Output voltage

48 V DC

Motor power output

350 W

Cutting speed

2900/3200rpm

Page 4of 17

III. Installation

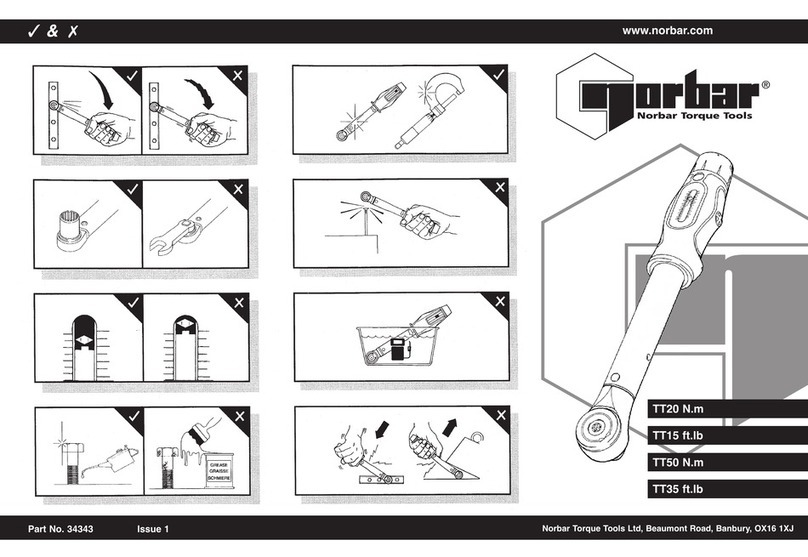

3.1 Installing combs and cutters

3.1.1 Combs

Place the comb on the cutting head of the handpiece, make sure the comb and the

cutting head is properly aligned and symmetrical. At this stage do not tighten the

comb screw, apply limited pressure just enough to hold the comb in place.

3.1.2 Cutters

Insert cutter then tighten the tension nut, until the tips of the chickenfeet fit firmly into

the two holes on both sides of the cutter.

3.1.3 Adjusting and securing comb

Adjust the relative positions of the comb and cutter, ensure the point at which the

bevel of the comb begins is 1.5 to 2 mm from the tip of the middle tooth of the cutter

(see fig.1). Also ensure that the comb and cutter is symmetrically positioned, then

secure the comb firmly using the provided spanner.

Fig. 1

Page 5of 17

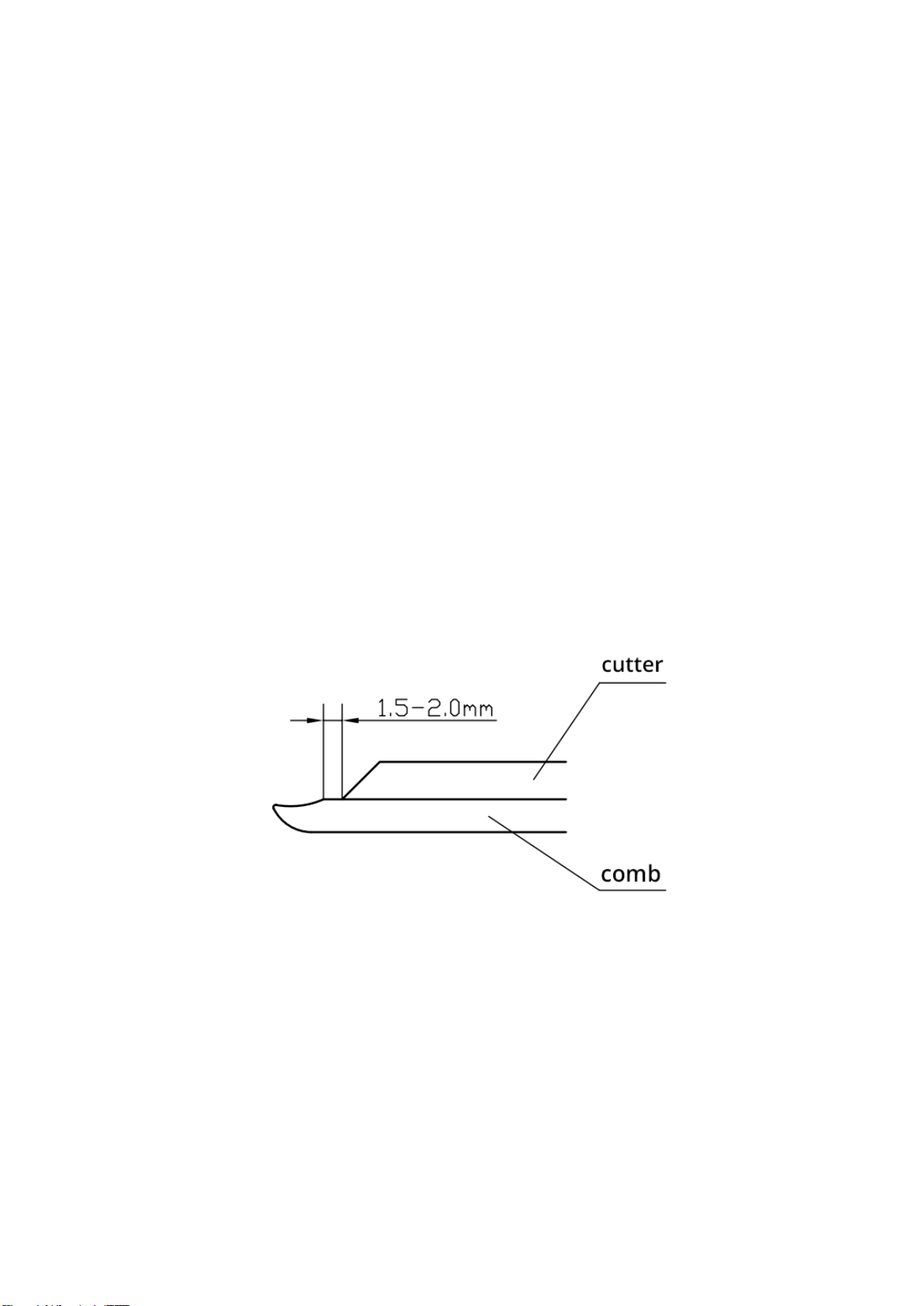

3.2 Comb selection

Choosing the right comb for the job is a vital part of preparation for shearing.

Selection of comb should consider shape of the tip, bevel and width. (see fig. 2)

Fig. 2

In general:

•Short bevel is principally used when shearing is at its best and the stock are in

top condition.

•Medium bevel is the most widely used comb and suitable for the majority of

crossbred shearing.

•Long bevel is particularly suitable for fine wool sheep when the wool is dense

and sticky.

Width selection should take into account the user’s level of experience with shearing.

For more information on comb and cutter selection, please visit:

www.beiyuanshearing.com.au

3.3 Chickenfeet

Before mounting chickenfeet, apply a small amount of grease to the two mounting

holes on the forkbody, then insert the left and right chickenfeet into the left and right

holes respectively, make sure the safety spring falls into the groove of the

chickenfeet.

To take out the chickenfeet, twist the chickenfeet 180° then pull outward.

The chickenfeet is secured onto the forkbody by a safety spring, ensure the screw

holding the safety spring in place is not loose.

Page 6of 17

3.4 Remove and replace the fork body assembly and the roller

3.4.1 Method of removal

The fork body assembly can be removed without removing the center post.

First unscrew the tension nut, then remove the tension pin and tension sleeve.

Remove the safety screw behind the tension nut and remove the fork body with the

roller attached.

3.4.2 Replacing fork body

Remove the oil hole cap on the top of the handpiece. Place a small amount of

grease onto the roller (ball) and ball race of the fork body. Place the ball onto the

crankshaft using a pen, screwdriver or other suitable method (make sure that the flat

side of the roller is facing the crank spindle). Place the crank and roller in the bottom

position in the handpiece. Insert the fork body from the front of the handpiece and

over the ball. After it is confirmed that the center post cup is sitting onto the center

post correctly, replace and tighten the safety screw.

3.5 Adjusting center post

The center post has been adjusted to the correct position when leaving the factory, it

can suit cutters of different thicknesses. Do not re-adjust the center post unless

necessary.

If adjustment is necessary, first, use a worn cutter (approx.. 3.5mm in thickness), and

a comb of any thickness, set the comb in place (see adjusting and securing comb

above), then adjust the roller on the crank spindle to the highest position.

3.5.1 Adjusting roller to the highest position

(1) first remove the cover cap on top of the handpiece, check to see if the roller is

positioned at the top of the groove of the fork body. If its position is at the top, go to

step (3).

(2) If the roller is not positioned at the top of the groove on the fork body, then start

and stop the handpiece, until the roller is positioned at the top of the groove.

Caution: before starting the machine, ensure the comb and cutter are fitted

and tension applied.

(3) With the roller positioned at the top, turn off the power supply, disconnect the

cord between the handpiece and power supply.

Caution: before carrying out repair work, ensure power is disconnected!

(4) Loosen tension, hold the front of the fork body and move horizontally back and

forth, until the roller is at its highest position. (Note: use care when adjusting the

Page 7of 17

forkbody, excessive movement may cause the roller to slide down, if this happens,

repeat step (2).

3.5.2 Adjusting center post

Loosen the center post nut and insert the post gauge as per illustration, keeping it at

90 degrees to the handpiece. Turn the center post until the center of the gauge is

level with the gauge top. Retighten the center post nut (Fig).

Fig.3

3.6 Adjusting tension

3.6.1 Installing tension retaining spring

When installing, first make sure that the larger curved tip of the spring points to the

clockwise direction (viewed from the top) as it is inserted into the thread bush, then

insert the smaller curved tip into the small hole. Apply force to press the retaining

spring into the grooves of the thread bush.

Caution: not installing the tension retaining spring could cause loss of tension

capacity, resulting in damage to the handpiece!

3.6.2 Tension problems

Be aware that the size of each end of the tensioning pin is different, ensure the

larger end sits in the tension pin cup. Also ensure that the downward tips of the

chickenfeet are pressed firmly into the holes on the cutter. To apply tension,

smoothly rotate and tighten the tension nut. Do not apply too much pressure as it

may cause overheating and accelerate blade wear. When cutting is not smooth, first

check the sharpness of the blades.

Caution: the downward tips of the chickenfeet must be pressed firmly into the

holes on the cutter, otherwise tension cannot be applied properly.

Page 8of 17

IV. Operation

4.1 Pre-work inspection and preparation

(1) Check that the comb and cutter are properly installed, and tension is correct.

(2) Check if the gearbox has been greased as required, other lubricated parts have

been greased as required.

(3) Check if the voltage of the main power supply and the special power supply

(Controller) for the handpiece is correct.

4.2 Pre-use and in-use safety and precautions

(1) The power outlet must be reliably grounded.

(2) Before turning on the power, the switche on the handpiece must be set to OFF.

(3) After the power is connected, with the handpiece in hand, turn on the switch at

the back of the handpiece.

(4) During shearing, the cutting head of the handpiece should always maintain a safe

distance from the operator.

(5) During shearing, the lead of the handpiece should be kept free and unobstructed

to avoid tangling with sheep.

(6) While on break, the handpiece should be turned off to prolong its service life.

(7) Keep the vents of the handpiece motor free from blockage, any wool or debris

blocking the vents should be promptly removed.

(8) If a problem occurs during shearing, first shut off the handpiece and cut off the

power supply, then proceed to perform inspection and maintenance.

(9) Ensure the handpiece is turned off and the power is cut off before loosening the

tension nut.

(10) Do not turn on the handpiece without first installing the comb and cutter.

Caution: power must be completely unplugged before performing maintenance

on the handpiece!

4.3 Using the handpiece

(1) Plug in the power cord into the power supply and ensure it is secure.

(2) Hang or fix the control box at a height of approximately 1.4 –1.7 meters above

ground.

(3) Connect the control box to the main power supply with its 3 points plug.

(4) To start or halt operation, use the switch located at the back of the handpiece.

Caution: the handpiece must be started under zero load before every

operation.

Page 9of 17

Caution: in the event that an emergency stop is required ( e.g. sheep tangling),

press the button and pull out the plug at the bottom of power supply.

Fig. 4

(5) Toggling the switch under the control box by a screwdriver, available speed 2900

or 3200 rpm (See fig. 5 showing the position).

Power supply

Cord connector

Button

Connected

Disconnected

1.4 –1.7m

to the ground

Page 10 of 17

Speed selection

Fig. 5

Page 11 of 17

V. Maintenance and Repair

5.1 Regular checks

5.1.1 Lubrication of cutting parts

(1) add oil every half hour

Add #32 mechanical lubricant between the comb and cutter, tension pin cup and the

roller (by opening cover cap on top of the handpiece). Loosen the tension nut, place

the handpiece in a near upright position, then drip oil onto tension sleeve. Lift the

forkbody, then drip oil to the inner side of the forkbody until oil reaches the center

post cup.

(2) add grease once a day

Take out the tension sleeve and apply a suitable amount of grease.

(3) add grease once a week

Take out both chickenfeet, apply grease into the chickenfeet holes on the forkbody.

Caution: make sure grease is not trapped between the thread bush and tension nut.

This may affect the proper functioning of the tensioning system.

5.1.2 lubricating gear box

(1) Only use special quality synthetic grease for lubricating the gearbox.

(2) The amount of grease inside the gear box should be between 2 to 3.5 ml.

Insufficient lubrication could negatively affect the operation of the gearbox and may

cause damage. Over-application could lead to leakage and overheating.

(3) It’s suggestion that adding grease into gear box in 30 running hours (or shorn 600

sheep) .

(4) if the rear section of the handpiece overheats, check whether there is a problem

with gearbox lubrication, add or replace grease if necessary.

(5)It’s required to refill grease after having stored for more than 6 months prior to

use.

5.1.3 Check for worn parts

After shearing 3000-4000 sheep, it is recommended to inspect the handpiece

thoroughly to see if there is noticeable wear on any small parts. Small parts should

be replaced after being worn out. This could help prolong the service life of major

parts.

5.1.4 Storage

For longer term storage, the parts that need to be replaced should be replaced,

various parts of the handpiece should be re-filled with lubricating oil. Put the

Page 12 of 17

handpiece and control box into its bag and store in a dry place for reuse in the

coming year.

5.2 Repair and maintenance

This machine is a precision power tool, it is not advised to disassemble any part of

the drive and electrical components. Please read this manual carefully and follow

procedures to disassemble and re-assemble this machine for ordinary maintenance.

When carrying out maintenance work, the handpiece should be placed on a dry,

clean wooden board or held tightly in the hand. Do not use a vise or clamp

mechanism to hold the handpiece. Use special tools for disassembly.

In the event of a fault, the following methods can be used to determine and eliminate

it. If you cannot resolve it by yourself, please contact us or your local distributor.

Page 13 of 17

Troubleshooting Guide

Issue

description

Troubleshooting

Suggested solution

Handpiece

does not start

Power cord is disconnected

Reconnect and ensure the

cord is secure

Switch is not responsive

Replace switch

Wire broken to the switch

Reconnect

Control board issue

Replacement

Handpiece

overheating

First, find out accurately which part of the handpiece is overheating. Do

this by restarting the handpiece after letting it cool down.

Front portion

overheating

May be due to build-up of dust or debris

in the front portion of the handpiece.

Start the handpiece whilst

pressing and sealing the oil

hole with your thumb, fill in

oil from the front of the

handpiece into the body,

then flip the handpiece and

drain thoroughly.

Check to see if the comb and cutter are

sharp, and proper tension was applied

Re-grind the comb and

cutter, lessen tension

pressure

Thumb and

index finger

portion

overheating

Check the center post and center post

nut, ensure there is no foreign object in-

between

Lift the crank spindle, flush

out the foreign object with

lubricant

Check for signs of wear on the center

post or center post nut

Replace with new parts

Tension nut

overheating

Check the tension pin and tension pin

cup, ensure there is no foreign object in-

between

Remove dust and debris,

apply new grease

Check for signs of wear on the tension

pin or tension pin cup

Replace with new parts

Middle finger

or ring finger

portion

overheating

Check to see if the roller is installed

correctly (make sure the flat side is

facing the crank spindle)

Reinstall the roller

May be due to wool getting caught in the

roller

Remove the wool

A lack of lubrication for cogs in gearbox

Apply lubrication

Page 14 of 17

Rear portion

overheating

Use of unsuitable or dirty grease

Replace grease

Excessive grease in gearbox

Remove excessive grease

Check for signs of wear in the gearbox

Replace parts

Check to see if the comb and cutter are

sharp, and proper tension was applied

Re-grind the comb and

cutter, lessen tension

pressure

Blockage in ventilation holes

Remove blockage

Cannot apply

tension to

comb and

cutter

Check to see if there is grease in

between the thread bush and tension nut

Clean thoroughly to remove

grease from this area

Check to see if there is a retaining circlip

installed, and for any signs of wear

Replace with new retaining

circlip, ensure correct

direction when replacing

Check for signs of wear on the tension

pin, tension pin cup or tension sleeve

Replace with new parts

The thread inside the tension nut is

slipping

Replace with new parts

Cutting issues

Check to see if the comb and cutter are

sharp

Re-grind the comb and

cutter

Check to see if the tips of the cutter

display any irregularities

Check to see if the comb is too thin

which causes the chickenfeet to be in

contact with the comb screws.

Replace comb or grind off a

part of the thread on the

comb screw

Has there been a change of center post?

Readjust the center post

according to instructions

above

Check for signs of wear on the tension

pin, tension pin cup or tension sleeve

Replace with new parts

Damaged comb screw

Replace comb screw

Check to see if the cutter is too thin

which causes the tips of the chickenfeet

to be in direct contact with the comb

Replace cutter

Abnormal

vibration and

First determine in which portion of the handpiece the issue occurs.

Page 15 of 17

operational

issues

Occurs in the

front portion

Check to see if the chickenfeet are fitted

properly onto the fork body

Replace chickenfeet

Check if the comb is set securely

Tighten comb screws

Check to see if the centre post is loose

Readjust and tighten

according to instruction

above

Check if the comb is too thin which

causes the fork body to be in contact

with the comb screws

Replace the thread portion

on the comb screw

Check for signs of lockups in the comb,

and see if there is any crack on the fork

body

If there is crack,

immediately replace fork

body

Check for damages on the comb screw

Replace comb screw

Check for excessive wear at the tips of

the chickenfeet

Replace chicken feet

Occurs in the

middle portion

Check to see if the roller and the pin on

the crank spindle are working properly

Replace roller

Check to see if the roller is able to move

freely within the groove on the fork body

Replace fork body

Check to see if readjustment to centre

post was made incorrectly which causes

the fork body to be in contact with the

crank spindle

Re-adjust centre post

according to instruction

above

Occurs in the

rear portion

Excessive wear in the gearbox, which

emits an abnormal noise when operating

Replace gearbox parts as

necessary

Motor not

running

properly

Wire breakage

Check wirings and

reconnecting

Switch issues

Motor malfunction

Replace motor

Page 16 of 17

Diagram of

connections at

back of motor

Page 17 of 17

Table of contents

Popular Tools manuals by other brands

SGS

SGS SAT205 owner's manual

Makita

Makita HR007G instruction manual

Jonker Sailplanes

Jonker Sailplanes JS1 Revelation Flight manual

The Siemon Company

The Siemon Company Multi-Pair Termination Tool S110 Specifications

Bosch

Bosch GST 160 CE Professional Original instructions

Glastar

Glastar Foiler user manual