4

SAFETY RULES

PLEASE BE CAREFUL – READ THE OPERATOR’S MANUAL CAREFULY IN ORDER TO

PROTECT YOURSELF AND OTHERS FROM DANGER.

The machine should be used with respect to the basic work safety rules and the following precautions:

• NEVER allow any unauthorized persons, unfamiliar with the Operator’s Manual or underage per-

sons, especially children, to use the machine.

• ALWAYS check the physical condition of the machine, especially its wear and whether the operating elements

of the cutting system are properly secured.

• YOU MUST replace the worn out or damaged parts with new ones.

• THE MACHINE may be operated only with the recommended tractors equipped with the required front axle

load.

• DURING the time of aggregating the machine with the tractor, special care should be exercised, and it is

prohibited for any persons to be present between the machine and the tractor while the engine is on.

• IT IS UNACCEPTABLE to operate the machine without the shields and a guard, it is also prohibited to

operate the machine with damaged shields and lifted guard.

• IT IS UNACCEPTABLE to operate the hydraulic lift lever externally.

• PRIOR TO ANY OPERATION activities performed on the mower, it is necessary to disengage the power

take-off drive and the engine of the tractor, pull out the key from the ignition, and allow the operating drums and

the blades to come to a complete stop.

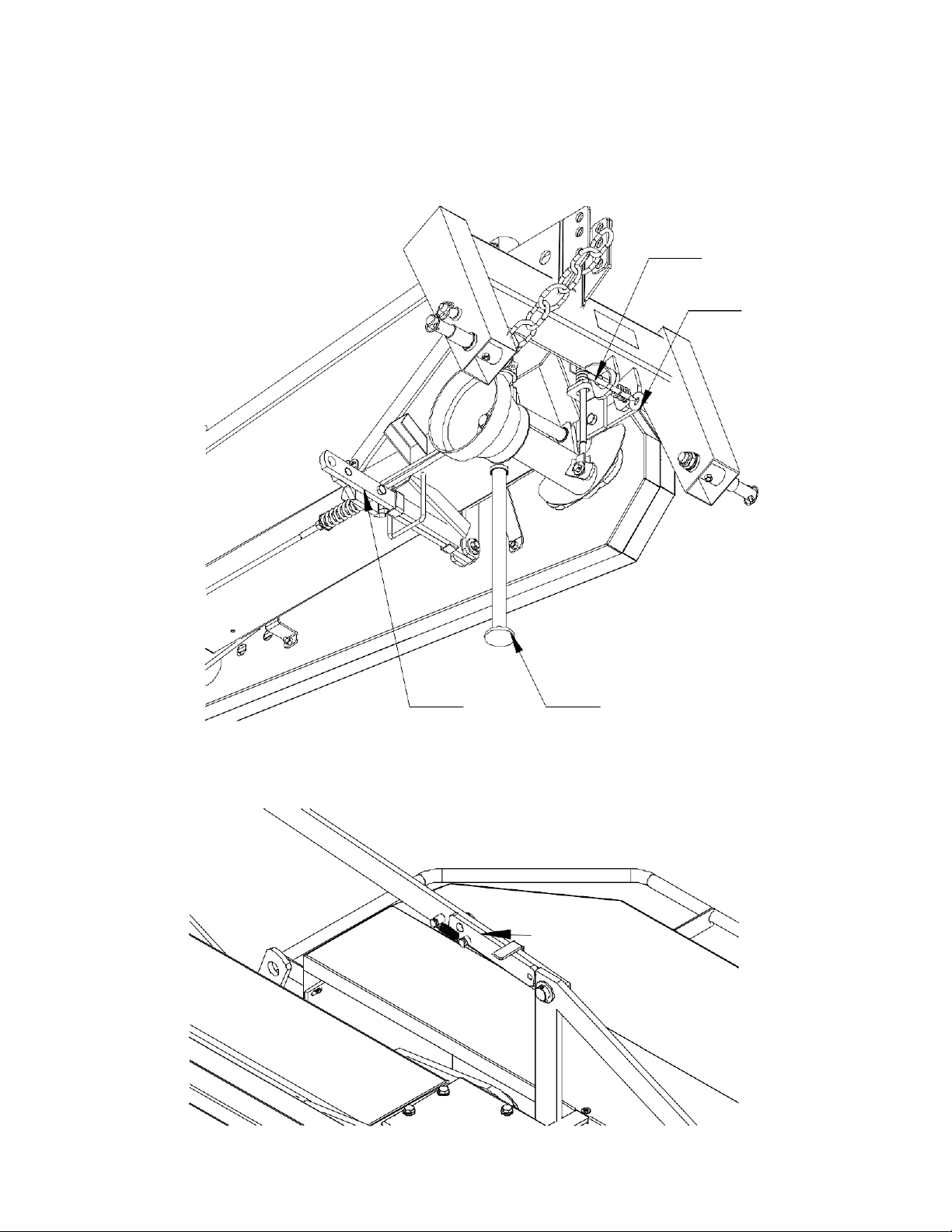

• WHILE performing necessary operation activities required for the purpose of lifting the mower on the three-

point suspension system, it is very important to secure it additionally to prevent from detaching by a support or a

chain.

• IT IS PROHIBITED to lift the mower with the power drive turned on and the cylinders rotating.

• IT IS NECESSARY to check whether there are any persons or animals within the danger zone prior to turning

the driving power on or during operating the mower.

• IT IS PROHIBITED to operate the machine with any bystanders present within less than 50m perimeter.

• THE FIELDS AND MEADOWS TO BE MOWED should be free from any foreign and hard objects.

• IT IS PROHIBITED to mow on the sides of the streets, public roads, public places (parks, schools, etc.) or

places with stones in order to eliminate the risk of the hard objects thrown out.

• THE MOWER SHOULD BE turned on only when in the operating position.

• THE MOWING may be started only when the power take-off engine speed of 540 rev/min. is reached; it is

prohibited to surpass 600 rev/min.

• IT IS PROHIBITED to operate the mower while driving backwards.

• FOR TRANSPORT the mower should be in a transport position.

• CHANGING the mower’s position from the transport position to the operating position should be performed on

a horizontal and even surface, with the blades lifted above the ground.

• IT IS UNACCEPTABLE to carry on board any persons or any load while the machine is being transported or

while operating it.

• WHILE on the public road, applicable provisions of the Traffic Regulations should be obeyed, and the mower

should be equipped with required lighting and warning devices in accordance to the local laws of a particular

country, where the machine is used.