7

BetterOutdoorProducts.com

Maintenance and storage

• Disengagedrives, set parkingbrake, stop engineand

remove key or disconnect sparkplug wire(s). Wait for all

movement to stop before adjusting, cleaning or

repairing.

• Clean grassand debrisfrom cuttingunit,drives,

mufflers, andenginetohelp preventfires. Clean up

oil or fuel spillage.

• Let engine cool before storing and Do not store near

flame.

• Shutofffuel while storing or transporting. Do not store

fuel nearflamesor drainindoors.

• Parkmachine onlevel ground. Setparkingbrake.

Never allow untrainedpersonnel toservicemachine.

• Use jackstandsto support componentswhen required.

• Carefully release pressure from componentswith

stored energy.

• Disconnectthe battery or remove sparkplug wire(s)

before making any repairs. Disconnectthe negative

terminal first andthepositivelast. Reconnect the

positive first and negative last.

• Use care when checking blades. Wrap theblade(s) or

wear gloves, anduse cautionwhen servicing them. Only

replaceblades. Never straighten or weld them.

• Keephandsand feetawayfrom moving parts. If

possible, Do not make adjustmentswith the engine

running.

• Keepall partsingood working conditionandall

hardware tightened. Replace all worn or damaged

decals.

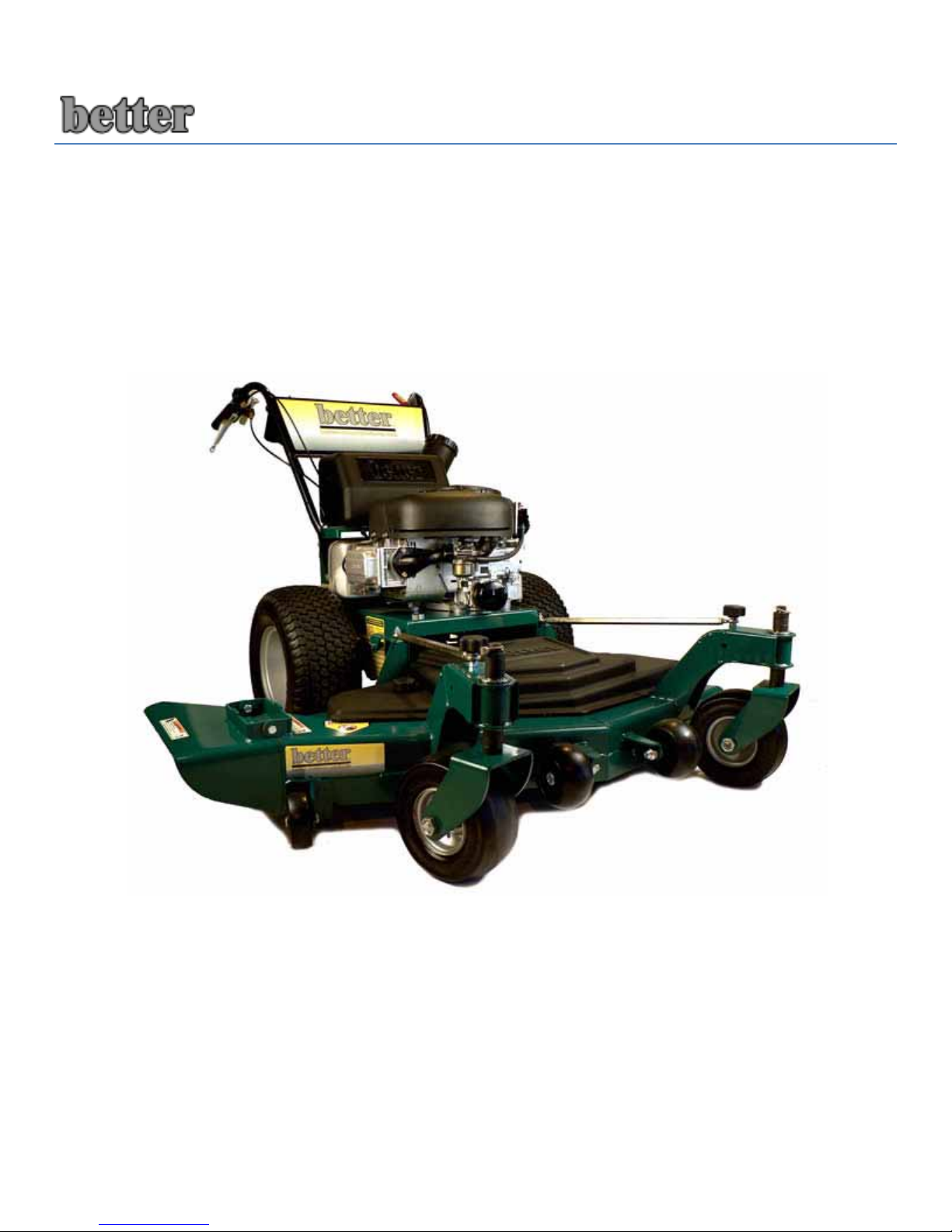

Quick™ MowerSafety

The following list containssafetyinformationspecificto

Better Outdoor Products™ and other safetyinformation

youmust know.Thisproductiscapable of amputating

handsand feet and throwing objects. Alwaysfollow all

safety instructionstoavoid seriousinjury or death.This

productisdesignedfor cutting and mulching grassor,

whenequipped with agrassbagger,for catching cut

grass. Any use forpurposesother than these could

provedangerousto user and bystanders.

General Operation

• Besure the area isclear ofother people before

mowing. Stopthe machineifanyone entersthe area.

• Do not touch equipmentor attachmentpartswhich

maybe hot from operation.Allow to cool before

attempting to maintain, adjust or service.

• Use only Better Outdoor Products™ approved

attachments. Warranty may be voidedif usedwith

unapproved attachments.

Slope Operation

All slopesand rampsrequire extra caution.If youfeel

uneasy on a slope, Do notmowit.

• Remove obstacles such as rocks, tree limbs, etc. from

themowingarea.

• Watch forholes, rutsor bumps. Tall grasscan hide

obstacles.

• Use caution neardrop-offs, ditches, or embankments.

Themachine could suddenly turn over if awheel goes

over the edge of a cliff orditch,orif an edge cavesin.

• Use extra care withgrasscatchersor other

attachments. These can change the stabilityof the

machine.

• Keepall movementon slopesslow and gradual.Do

not make sudden changesinspeed or direction.

• Mow slopesside to side.

• Do not mow slopesgreater than 15 degrees.

Service

• Never store the machine or fuel containerinside where

there isan open flame, such asnear a water heater or

furnace.

• Keepnutsandboltstight,especiallytheblade

attachment bolts. Keep equipment in good condition.

• Never tamper with safetydevices. Checksafety

systemsfor proper operation before each use.

• Understand service procedure before doingwork. Keep

the workarea clean and dry.

• Engine exhaust fumescan cause sicknessor death.

ONLY start engine outdoorsor in awell ventilated place.

• Keepcigarettes, sparksand open flamesaway from

the fuel system and the battery.

• Alwayshave an approved and fully charged fire

extinguisher near your workarea.

• Wear personal eye protection when using compressed

air for cleaning purposes.

• Neverlubricate, serviceoradjust mowerwhileitis

moving. Keep all safety devices in place and in working

condition.

• Keephardware tight.

Topreventthem from getting caught, keep hands, feet,

clothing,jewelryand long hair awayfrom anymoving

parts.

• Before servicingmachine, disengage all powerand

stop the engine. Let engine cool.

• Securely support anymachineelementsthatmust be

raised for service work.

• Keepall partsingood condition and properlyinstalled.

Fix damage immediately. Replaceworn or brokenparts.

Remove anybuildup of grease, oil ordebris.

• Unauthorized modificationsto themower mayimpairits

function and safety and will void any warranty.