Belitronic BJ5000 Ex User manual

Version 10

Program 1.1834

2018-09-05

English manual for BJ5000 Ex

1 2 3

Softstart

Speed

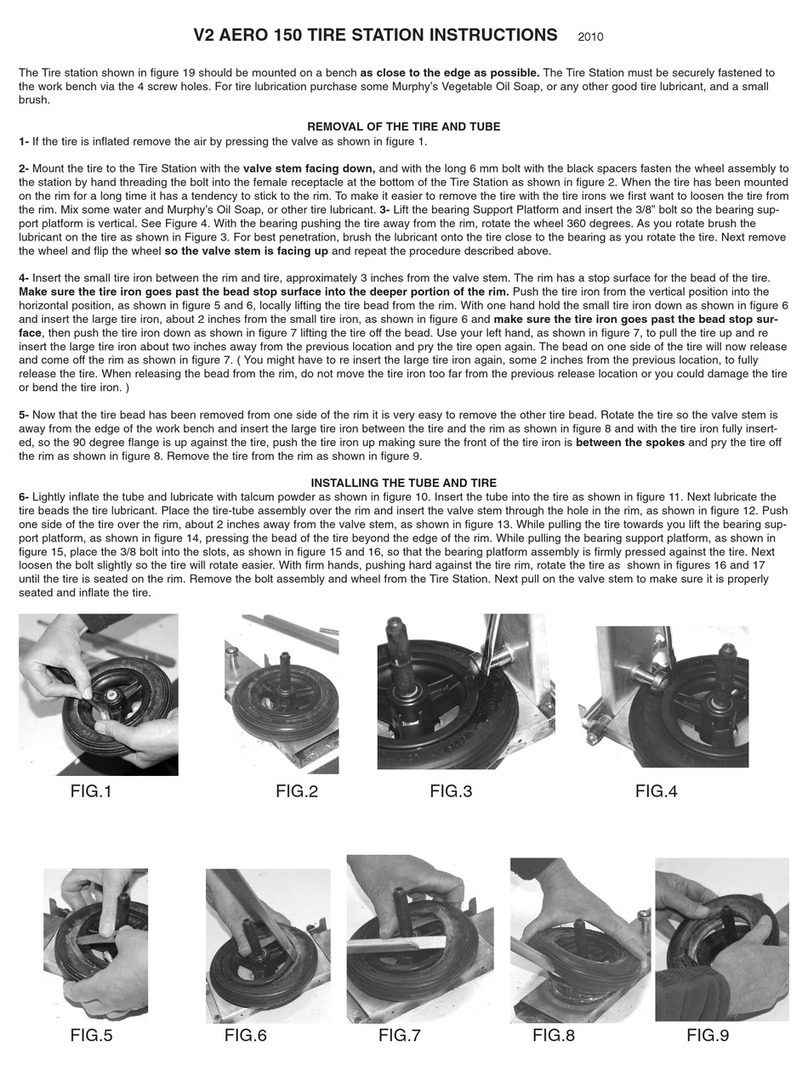

Flowchartshowing how to get from one picture to the other. Detaileddescription of all functionsand display texts are found in the manual. From

Main "Line out" use the Enter key to get in and out of the menu system. Fromthe menu, available submenuswith the buttonsbelow the display

and P-button, Z-button,Drag, Catchand Brake accesseddirectly. Relatedfish program parametersare reached directlywith P-button.The

choice “Ret” returns to the previous menu.

MOTOR PAUSE CATCH

WHEEL BREAK MORE

JIG CATCH HAUL

MANU MORE RET

L.MESS TORQ STOP

MINSPEED RET

DIM LINECOUNTER

STOP-P RP RET

Time

Speed

Extra torque

Time

Speed

Extra torque

Softstart

Speed

Detect value

Speed

Time

Distance

Torque start

Min torque

Soft stop time

Minimum speed

Auto

Depth

Time up

Time down

Catch –On speed brake

Catch - Wheel pulses

Brightness

Restart

Show catch depth

Width

Diameter

Outer diameter Unit

Direction

Sensor A B

Magnets

ZERO SEA PULLEY

SOFTS. PAUSE RET

Stop at zero Time

Time

Above depth

Restart

Auto zero

Automatic

Manual

Activation

Wheel laps

Time

Laps

Num. of Pulses

Pulse length

Pulse pause

Pulse strength

SPEED DEPTH AIR

RET

Power

Time

Speed

Power

Time

Speed

Speed

Above depth

E

E1

E11

E12

E13

E14

E15

E151

E152

E153

E154

E4

E2

E3

E42

E41

E43

E44

E441 E442

E443

E444

E445

E45

E5

E51 E52 E53

Motor

menu

Advanced

Motor menu

Wheel

menu

Menu for

Wheels stop point

Brake

menu

4 5 6

1 2 3

4 5 6

1 2 3

4 6

1 2 3

4 5 6

1 2 3

4 5 6

1 2 3

Fast

push

Chapter E

MENU AND SCREEN FLOWCHART

Program firmware 1.1834

EX1 EX2 EX3

EX4 EX5 EX6

EX1 EX2 EX3

EX4 EX5 EX6

EX1 EX2 EX3

EX4 EX5 EX6

EX1 EX2 EX3

EX4 EX5 EX6

EX1 EX2 EX3

EX4 EX5 EX6

LINE OUT: XXX

<XX

DISP INFO BEEP

CODE RET

MORE

DISP BAR BIG

SHOW HELP RET

Brightness

Light time

Contrast

Language Configuration

Time

Upper bar

Lower bar

DRAG, CATCH & BRAKE Time

Show status

Boat voltage

Internal voltage

Temperature

Motor current

Humidity lower sensor

Humidity upper sensor

Wheel speed

Motor speed

Serial number

Program version

Pressing button

Number beeps at catch

Pause between beeps surface)

Code at.

Code xxxxxx

DRAG CATCH BRAKE

Normal fishing

X

X

-

-

-

-

-

-

-

-

-

-

X

X

X

X

-

-

-

-

-

-

-

-

X

X

-

-

X

X

X

X

X

-

-

-

X

X

X

X

X

X

X

X

X

-

-

-

X

-

-

-

-

-

-

-

-

X

X

-

Step jig fishing

Bottom fishing

Bottom + Step jig fishing

Mackerel fishing

Pictures in fishing program

E6

E61

E612

E613

E614 E615

E62

E63

E64

MAIN PICTURE

Display

menu

Menu

various

1 2 3

4 5 6

1 2 3

4 5 6

NETWORK

MENU RET

Level

E654

1

4

Mode

Address

Group

Coworking

Wait for hooks

E651

Mackerel with jig

Trolling

Fish finding program

X

X

--

-

-

-

-

-

X

X

X

-

X

-

-

-

-

-

-

-

-

-

-

X

X

X

-

-

-

-

-

-

-

X

X

-

EX1 EX2 EX3

EX4 EX5 EX6

Groups 1- 6

EX1 EX2 EX3

EX4 EX5 EX6

EX1 EX2 EX3

EX4 EX5 EX6

EX1 EX2 EX3

EX4 EX5 EX6

EX1 EX2 EX3

EX4 EX5 EX6

EX1 EX2 EX3

EX4 EX5 EX6

EX1 EX2 EX3

EX4 EX5 EX6

Group settings 1- 6

1 second

press

4

second

press

LOAD SAVE

FACTORY RET

Chapter Z

E65

E611

Depth

Jig

Step length

Step pause

Bottom pause

Bottom distance

Max depth

Hauling up

Number of jigs

Depth reduction

Minimum depth

Wheel laps

Chapter P

MENU AND SCREEN FLOWCHART

Program firmware 1.1834

Chapter Page i chapter

Menu flowchart First pagespread

Contents This side.

Foreword page

•How to understand this manual

•Dictionary

Installation pages

•Approval 1

•Mechanical installation 1

•Electric installation 1-2

•Startup 2

•Install fishingline 2

Machine pages

•Frontpanel (Overlay) 1

•Main screen (Line out) 1

•Push buttons (Z,P,E,A,U,S) 2-3

•Push buttons (1,2,3,4,5,6) 3

•Symbols Drag Catch, Brake 2

•Catch registration 4

•Catch depth memory 5

Communication pages

•Quick start. 1

•Settings in software 1

•View other machines in network. 1

•Activate/Deactivate machines. 1

•Group screens 1-2

•Remote controll machines 3

Chapter Page i chapter

Chapter [P]rog button (Fish programs)

•Overview Fishing programs [P]

•Normal Fishing [P]1

•Step Jig Fishing [P]2

•Bottom Fishing [P]3

•Bottom With Step Jig [P]4

•Mackerel (Also Squid) [P]5

•Mackerel With Jig [P]6

•Trolling [P]7

•Fish Finding [P]8

Chapter [Z]ero button)

•SAVE, LOAD, FACTORY, DISPLAY

Information pages

•Troubleshooting, error messages 1

•Guarantee, Warranty info. 2

•Technical specifications 3

•Accessories 4

•Underhåll 4

Alphabetical wordlist Last pagespread

GDPR Backside

Warnings Backside

CONTENTS

Contents

Menu systemet (Chapter E reached with [E]nter button)

MAIN MENU [E] MOTOR [E1] PAUS[E2] CATCH [E3]

WHEEL[E4] BRAKE[E5] MORE[E6]

MOTOR [E1] JIG [E11] CATCH [E12] HAUL [E13]

MANU [E14] MORE [15]

MOTOR-MORE [E15] L.MESS [E151] TORQ [E152] STOP [E153]

MINSPEED [E154]

WHEEL [E4] DIM[E41] LINE [E42] COUNTER[E43]

STOP.P[E44] WHEEL [E45]

STOP.P [E44] ZERO [E441] SEA [E442] PULLEY [E443]

SOFTS, [E444] PAUS[E445]

BRAKE [E5] SPEED [E51] DEPTH [E52 AIR [E53]

MORE [E6] DISP [E61] INFO [E62] BEEP [E63]

CODE [E64] MORE [E65]

DISP [E61] DISP [E611] BAR [E612] BIG [E613]

SHOW [E614] HELP[E615]

DISP-MORE [E65] NETWORK [E651]

MENU[E654]

Menues and submenues

Congratulation on a great choice of Jigging Machine!

Belitronic has produced electronic jigging machines since 1972, something we were first in the world with.

Since then, we have sold thousands of machines to about 100 countries. Especially Norway, Iceland,

Faroe Islands, Denmark Canada, USA and Australia.

HOW TO READ THIS MANUAL

The manual now refers to the chapter with sub pages (instead of current page number). Chapter can be

specified as "installation", but can also be displayed by the [ ] characters, and simultaneously shows how

to press the buttons in the display's menu system to find the function. All keys have symbols for primary

functions, but also have small letters or numbers printed in the front panel for navigation purposes. For

example, [E12] is a reference to Chapter [E12] of the manual and navigation of the menu system. In this

example, the [E]nter, Button [1] and then button [2] must be pressed. In the manual, the chapters are

sorted by number starting from left and not as whole numbers. That is, Chapter [E123] comes after [E1]

and [E12] but before [E2].

Bold text such as MOTOR written in capital letters refers to the menu system where up to six choices can

be displayed and selected with corresponding buttons [1] - [6] below the display. Choices leads directly

to screens or to submenus with additional menu choices in smaller loops which roll back to previous

menu. To display more screens repeat press the [P]rog button. [PP] means, for example, press twice,

and [PPP P] press four times. Sometimes it may be, for example, [P]2[PP], which means that you must

first press the [P]rog button once. The screens showed must be set to value “2”. Then two more press on

the [P]rog button. Bold text with gem characters are features. Values for a picture are written inside italics

(“ “).

DICTIONARY

•Brake: A constant braking force on the wheel when the line is going down.

•Depth: Fishing depth, and maximum fishing depth in Bottom Fishing Programs.

•Factory reset: Loading values previously Stored, or Factory set values.

•Fishing area: Is the area between set Depth and Jig length.

•Step: Part of Jig Length. Followed by a short stop Step Pause before continue with next Step length

•Jig length: Length of line drawn up from set Depth.

•Line out: Line length pulled out in Fathoms, Feet or Meter.

•Max depth: Special function in Bottom Fishing for straightening up line if the boat drifts away.

•Softstart: Acceleration time for the motor when starting, or changing speed.

•Catch registration: When a sensor detects catch, it sets Ex in Catch or Haul up mode.

•Catch LED: Four LED’s flashes at catch registration.

•Zeropoint: Is the point of fishingline when Line out is zeroed bypressing [Z]ero button.

•Hauling up: multiple meanings.

▪Settings of the motor when hauling up to Zeropoint (Speed, Force and Acceleration).

▪Length of line hauled up in special function Max depth, see the list above.

▪How much line allowed to pulled out before Ex hauls back to Stoppoint again.

•RP: Short for Reverse Polarity for demagnitization of the electromagnetic clutch.

•Rpm: Speeds in the manualen are described as RPM (which is not any unit for speed) of the motor

and wheel rather then line length per time unit e.g m/s or knots.

•Drag: Basic force applied to motor/wheel when stopped or motor runs.

•Bar: Displays sometimes shows vaules as animated analogue bars. Easier to read sometimes.

•Line mess: Function to prevent Line mess when the lines tangles.

•Stoppoint: Value of Line out when motor stopps.

•Beep: Built in sounder/speaker for various attention and confirmations.

•Counter: Register for the number of wheel laps payed out. Recalculated and shown as Line out.

•Reset: Loading Factory set values or user previously saved values.

•Work mode: Ex has 3 different modes. Manual mode is when not used. Auto mode is when machine

works automatically with any of the FishIng gprograms, with Catch detection possibillity. Pause

mode is used while moving between fishing spots when line is in water, allowing the motor to start if

line is pulled out.

FOREWORD

Foreword

APPROVAL

This machine BJ5000 is produced by Belitronic Sweden AB in Lunde Sweden in accordance with the

appropriate rules for CE approval and marking within EU and the EEC. The serial number is printed on

the outside label and also on the label under the gearbox. The machine is only meant for fishing. It must be

mounted in such a way that no danger occurs when in use. It is very important that the spool, line and

hooks cannot come in contact and injure the operator of the machine.

The emergency stop button must be easily accessible. Check daily that the emergency stop is working.

The machine must be connected to either a 12 or 24v DC, the power source should be a Lead Acid

Battery or equivalent ( see the chapter ELECTRICAL INSTALLATION)

The machine shall only be used by those who have read and accepted the contents of this user manual.

INSTALLATION

Upon installation, take particular care with the

mechanical, but most importantly the electrical

connections. If you are in doubt, contact a

qualified electrician. Mount your BJ5000Ex with

the supplied 40mm U-Bolts and brackets. The

brackets can be attached to either side of the

machine. Mount the brackets first on the

machine with the supplied M8 bolts, washers

and rounded nuts. Do not over tighten.

Secondly use the supplied U-Bolts around the

tubing with washers and nuts. Now check

tightness of all the nuts.

Details for pole mount.

AC/DC

ELECTRICAL INSTALLATION

Make sure that the EMERGENCY STOP button is pressed before connecting the machine to the battery.

For the warranty to apply, Ex must be connected to lead battery or battery type that can be charged from a

traditional generator found on most boats and cars. The reason for this is that Ex must be able to get rid of

the energy that arises from tough driving as the engine acts as a generator, which can lead to lead batteries.

However, power supplies AC/DC or DC/DC may not be used. They do not receive the power from Ex and

results in overvoltage that will damage Ex. The power cable should be connected directly to the battery

system. Possibly via a fuse and / or main switch. Ex is made for 12volt DC and 24volt DC battery system

with charging. Under 10 volts and over 30 volts can cause damage to Ex.

Avoid damaging the cable and bundling it with other cables. Cables bundled up together increases the risk

of interference between Ex and other instruments onboard. The rule “Use as less cable and joints as

possible". Maximum length of supply cable 4x2,5mm² at maximum motor load at 12 volt battery pole voltage

is around 15 meter. If charger is used (battery pole voltage 14,5volt) 35 meter is okay. Running at 24 volt

power supply longer length then 35 meter might be okay.

Interference may occur in other instruments or devices, look over cables and possibly move the machine if

problem occurs.

+

_

The two red wires are connected to the battery + and

the two blue to the –regardless of 12V or 24v.

INSTALLATION

Installation - 1

10v12v 24v

30v

Volt DC

STARTUP

The machine is started by turning the EMERGENCY BUTTON clockwise until it pops out. Now

the machine has power. The display provides some information at startup. If the display is not lit,

the machine may be incorrectly connected to the battery. Check the cables on the battery!

INSTALL FISHINGLINE

Reduce Drag to minimum value. To do this…

1. Press the [4] key until the display bar disappears.

2. Press the [U]p button. The motor starts but without traction on the wheel. Note the direction

of rotation of the motor.

3. Press [S]top. If the desired direction of rotation of the motor is correct, jump to step 7. If not,

proceed to item 4.

4. Press the [E]button when LINE OUT is displayed . The display now shows the MENU.

5. Press [4] for WHEEL.

6. Press [3] for COUNTER and then once on the [P]rog button. Display shows “Direction”

Change the "Normal" or "Reverse" selection to the opposite using the button [3] and [6].

Jump to point 2.

7. Attach the line to the wheel.

8. Press [U]p so the motor starts.

9. Increase Drag by pressing button [1] until tight traction is obtained on the wheel. Reduce

power with button [4] if desired.

10. When all the line is mounted on the wheel press the [S]top.

Now all line is mounted. In order for the machine to count correctly, some settings need to

be made. This is described in Chapter [E41], E [42], E [42P] and E [43].

Installation - 2

INSTALLATION

Continuing…ELECTRIC INSTALLATION

Communication between machines.

Ex can communicate with other Ex’s and share information about where the fish are, or to prevent all

machines pulling the line to the surface at the same time. For this, two wires are used in the power

cable. The Brown and the White. The installation is done so that all white cables of the machine (one

from each Ex) are connected together, in the easiest way is twisted together or with a screw terminal.

Connect the Brown in the same way. DO NOT connect Brown and White together. Note that all of the

machines in the network must be powered from same battery system (at least the battery minus pole).

Now the machines are mechanically prepared. What remains is to set up the values for the

communication in the display menu. Take a look at the Communication-1 and special sections. To

easily get started, step-by-step instructions are given. Machines with software older than 1.1834

must be upgraded with new software for this to be available.

An example with 3 Ex connected in network

The front panel of the BJ5000Ex (from now on called Ex) is equipped with a graphic display, 12

push buttons, with backlighting, and four red LEDs in the corners for catch indication. All buttons

have more than ONE function. Below are the buttons name and primary function. From now on,

push buttons in the manual will refer to what is inside the characters [ ]. [Z] for [Z]ero, [P] for

[P]rog and so on. Se picture below.

4st LEDs in the corners

indicate catch.

Buttons for Auto or

Manual running Ex

Keys for setting

values, program

selection and

Reset Line Out

Drag +

[1]

[A]uto. For

automatic mode.

[U]p. Start and stop of

motor in Manual mode

and for Pause mode.

[S]top/Down. Stops

motor and Automatic

mode. Returns to

Manual or Pause mode.

[E]enter

[P]prog

[Z]ero

Brake +

[3]

Drag –

[4] Catch –

[5] Brake –

[6]

Figure 1. Name of the buttons.

Buttons 1-6 have many functions

depending on what appears in the

display. See Chapter Pushbuttons. Page

Machine 2.

Catch +

[2]

FRONT PANEL

MAIN SCREEN

The display shows the most common text in 4 lines with 16 characters in each row. The Main screen, is

partially configurable and shows multiple information.

•Row 1 shows:

•Status field for various temporarily information. see list of symbols in Chapter [E615].

•Released line length(Line out) in Fathoms, Meters or Feet with minus sign "-" if negative (when

line is above Zeropoint).

•Row 2 shows:

•Selected Fishing program (Chapter [P]).

•Catch depth memory (se machine - 5).

•Machine mode symbols ([E445]).

•Row 3: Can show optional values (See BAR [E612]) in both analog and digital form. This row also

shows the temporary value of DRAG, CATCH and BRAKE when they are changed.

•Row 4: Can show optional values (See BAR [E612 P]) in both analog and digital form.

Figure 2. Main screen

Chosen Fishing program

Chosen upper value

Chosen lower value

Analoge display (Bar) of chosen values Digital display of chosen

values

Line length payed outStatus field with symbols

Machine - 1

Buttons [P]rog [E]enter [Z]ero [A]uto [U]p [S]stop

The [P]rog button is used in all display screens to get to the next display in chapter [P]. Since

Ex has more than 180 images, all images are grouped into smaller loops. Pressing the [P]rog

from the Main screen will first show the choice of Fish program. Future press then shows

screens for the selected Fish program.

The [E]nter button leads from Main screen to the menu system (Chatpter [E]) with a variety

of settings for both Fishing programs and everything else in the machine, such as Display

Contrast, Light and Sound. Inside the menu system, press the [E]nter button directly back to

the Main screen. In network, the button is used to access Group screens (hold button in).

[Z]ero button has two functions: A short press resets Line length, which will then become

Zeropoint. If the button is pressed for three seconds, a Reset menu will appear. See chapter

[Z] for more details.

To the right of the panel there are three buttons to "drive" the machine.

[A]uto button. A short press puts Ex in the Machine mode called Automatic mode. The

machine starts working according to the selected Fishing program (delayed start of

Autopause [E2]) and records catch according to set criteria. If the button is

held in, the line runs out without any brake at all. If the button is pressed repeatedly within 1

second in Auto mode, the Catch depth memory is cleared.

[U]p button is used to set Ex in the Machine mode called Manual mode. (Depends on

PAUSE MODE –Activates when [E445]) A short press starts or stops the motor. If the

button is pressed, the motor will run continuously until it is released. The motor also stops if

the counter comes to Zeropoint or if the wheel is stopped by Stop At Pulley [E442] or Stop

At Sea [E443]. In Auto mode, the button can be used to enable Pause mode.

[S]top / Down button is used to set Ex in the Machine mode called Manual mode (Depends

on PAUSE MODE –Activates when [E445]) and always stops the motor. As long as the

button is pressed, BRAKE force is applied to the wheel, which now should be easy for the

sinker to pull out. When the button is released, the DRAG force is applied on wheel which

should stop.

The buttons below the display [1] - [6] have five different functions, but primary function is

marked with symbols above for them. Directly accessed from Main screen.

The symbol means DRAG. Refers to the force

applied to wheel when the line is stopped (in

pause, or manual mode) or pulled by motor.

The symbol means BRAKE and is the constant

braking force on the wheel to prevent line tangle

when line is released. A significantly weaker

power than DRAG.

The symbol means CATCH. A measure of how

heavily the engine must pull before the machine is

to register catch and start dragging the catch.

Read more in chapter Machine - 4

Figure 1. The symbols…..

DRAG CATCH BRAKE

Button [1]-[6] (DRAG, CATCH och BRAKE)

PUSHBUTTONS

Machine - 2

Function 4. To change huge numbers such as

the theft code, each digit is changes individually.

As shown in the illustration, Button [2] and [5] is

used to change the digit position, which is

indicated by an arrow. Buttons [3] and [6] are

used to increase or decrease the selected digit

value. To confirm the value, press [P]rog.

Function 3. For setting and changing the values. By

changing the three digits (100s, 10s and 1s)

individually. Decimal numbers such as Times,

changes in the 10's, 1's and 0.1's.

For 4 digit numbers, the first digit (1000's) changes

with 100-digit buttons.

Example of setting a value

Code screen

Shows Unit

Function 2. The buttons are used for menu

navigation. Each one corresponds to one of the

options shown in the display. MORE and RET

option found in several menus leads to and from

additional menus.

Machine - 3

Example MENU [E]

Increase with 1

Decrease with 1

Step one digit

to the left <

Step one digit

to the right >

Main screen shows nothing on upper row as

default setting.

These six buttons under the display have several different functions.

Function1. From Main screen, the buttons DRAG, CATCH and BRAKE are reached directly with the

buttons below the display. The first press shows the desired value as shown in row 3. Another push or

held in will change the value. After a set time Showtime [E614], chosen “Value for upper row” will

return on row 3. In this example, the engine torque "Nm"

Screen when DRAG buttons are pressed Screen when CATCH buttons are pressed Screen when BRAKE buttons are pressed

Buttons [1]-[6] (DRAG, CATCH och BRAKE)

Group screen

Function 5. In group screens, the six buttons

correspond to machines in the group. Each press of

the button switches the machine in or out to control.

Machines being control are surrounded by a black

frame.

4

12 3

5 6

Machine

addresses

PUSHBUTTONS

CATCH REGISTRATION

Catch registration can be done in 5 different ways.

•High load. Perhaps the most common way to register catch in Ex is how heavy it is to pull the line.

This is done by measuring motor current (shown as Weight in Ex) while it runs, and therefore

available only when motor is working. The Weight to be exceed for starting Catch registration is

called CATCH (See Machine - 3, Function 1). How long time the Weight must remain above

CATCH before entering Catch mode is determined by Catch -Time up [E3]. This makes it possible

to determine whether Catch mode should occur early for fast bites on the bait, or if fishes need to

bite on for a long time. The Status symbol [E615 P] can provide detailed information in Main

screen if the limit is exceeded for fine tuning the Catch registration or for troubleshooting. Status

symbol [E615 P] is disabled in factory setting.

•Low load. If motor current gets below what’s needed for just turning the motor with hooks and

sinker, like when sinker/hooks are lost or held up by another machine or fishes, Catch mode can be

triggered. See the L.MESS [E151] function for more information. Also here the motor must run and

the Status symbol [E615 P] can show detailed information for fine tuning and Troubleshooting.

•Low wheel speed. Catch - Time down [E3P] can be used to enter Catch mode if line rolls out too

slow. For example by fishes holding the hooks or hitting the bottom. The time is the maximum time

allowed for one wheel laps to pass. NB that too high setting of BRAKE or sluggish clutch or wheel

might trigger this when it also slows down the wheel. Default CATCH-Time down [E3P] is not used.

NB CATCH –Time Down [E3P] can not be combined with any Bottom Fishing program.

•High wheel speed. If large catch pulls out the line too fast, Speed brake [E51] is activated and will

slow down the wheel speed, and can also activate Catch mode.

•Pulled out line. Wheel pulses are monitored during fishing and detects at any time if line and wheel

is pulled backwards. If wheel is pulled out more laps than set Catch - Wheel laps [E3 PPP] the Ex

is put into Catch mode.

Machine - 4

Sensors

Fish program High

load Low

load High wheel

speed Low wheel

speed Pulled

out line

[P]1 Normal Fishing Yes Yes Yes Yes Yes

[P]2 Step Jig Fishing Yes Yes Yes Yes Yes

[P]3 Bottom Fishing Yes Yes Yes No Yes

[P]4 Bottom Fishing With Step Jig Yes Yes Yes No Yes

[P]5 Mackerel Yes (1) Yes Yes Yes Yes

[P]6 Mackerel With Jig Yes (1) Yes Yes Yes Yes

[P]7 Trolling Yes Yes Yes Yes Yes

[P]8 Fishfinding Yes Yes Yes Yes Yes

Table 1. Shows which Catch registrations sensors are aviliabel for each Fishing programs.

(1) Catch mode i Mackerel program works as in other fishing programs but generates no indication in

display, sounder or Catch LED. In Mackerel program Ex makes automatic restart when Zero point is

reached.

CATCH DEPTH AND CATCH DEPTH MEMORY

Catch depth. In all Fishing programs except the mackerel [P]5 and Mackerel With Jig [P]6

programs, the Catch depth might be displayed while Ex is in Catch mode. This is optional and is

controlled by Show Catch depth [E3PPP PPP]. If enabled, the Catch depth screens and Main

screen is displayed alternately every 3 seconds during Catch mode. At the same time, the buzzer

may sound for audible notice, depending on BEEP –At catch [E63] setting.

Catch Depth Memory.

Registered Catch depth is memorized during a time Cooperation time [E651 PPP PPP P] from

time catch occurs. This time is shared to the entire network and is therefore located in MENU -

MORE - NETWORK. As long as the time and memory has not ran out of time, a "M" appears in the

display next to the Auto Symbol, for “Catch Memory”

Catch depth memory affects the machine in such a way that the machine's original Fishing

depth and Jig length is replaced with a calculated value so that the Fishing area is centered

around the Catch area. For example, if the Catch detection occurred at 50 meters and the Jig

length is 10 meters, the machine’s Fishing depth will change to 55 meters. Future jigging will take

place between 55-45 meters, and Catch detection depth 50 is in the middle. When the next

Catch registration is made, the memory is replaced with a new calculation and the Cooperation

time [E651 PPP PPP P] restarts. When the Cooperation time [E651 PPP PPP P] runs out, the

machine returns to its original settings for Fishing depth, and Jig length.

If the Catch depth memory is not interesting, for example, false catch, then the [A]uto button can

be pressed a second time within 1 second. This will restore the original settings again and the “M”

shall dissapear.

Catch depth memory can be permanently disabled by setting Cooperation mode [E651 PPP] to

"Out". To do this, the Communication mode[E651] first has to be activated, ”Master” or “Slave”.

When change is done, turn off network connection by setting Communication mode[E651] to

“Out”.

Catch depth memory in network.

When Ex is connected into a network, the machine's Catch depth memory can be shared

(depends on Cooperation mode [E651 PPP]) with other machines within the same Group [E651

PP]. In the same way as the Catch detecting machine, the other machines' Depth and Jig length

will be replaced during the Cooperation time by adopting the settings from the last machine in the

Group that detects catch. Machines that helps another machine shows that machines address,

instead of the "M". In the example above, machine number 5 has detected catch. When the

Cooperation time expires, all machines return to their original settings.

More about network.

•Only one Catch depth memory is used in each Group. However, up to 6 groups can be used,

all with their own Catch depth memory.

•Machine detecting the catch last, decides where machines in the Group will fish. When a

machine detects a catch, the machine's settings will apply to all machines in the group. It then

writes over previous Catch depth memory and Cooperation time.

Machine - 5

Symbol for Catch memory

This machine now helps machine no 5.

Symbol for Catch memory

This machine has detected catch.

Machine no 5. Machine 1,2,3,4 or 6.

COMMUNICATION

Communication - 1

Main screen

From the main screen, hold [Z]ero button for about 1 second.

GROUP screen first shown at the start is the one in which the

machine is a member. Press [P]rog button for the next group.

After the last group screen, the first appears again. . NOTE.

Shown only if communication is enabled.

GROUP screens

GROUP SET Screens.

Individual activation / Deactivation for

each address. NOTE This screen is only

available in master machine.

From the main screen, hold the button until it sounds

(approximately 2 seconds). The GROUP screen will

be passed and now shows GROUP SET screen.

NOTE This is only available in master machine

With communication between machines, the following can be done ...

•Monitor all (36) machines Line out, motor, wheel, and fish status from any machine in groups of 6

machines per display image.

•Send pushbutton to all machines (36pcs) in a group of 6pcs from any machine. Applies to the [Z]ero,

[A]uto, [S]top and [U]p.

•Co-operation between the machines at the time of registration in the group. If multiple groups are

used, machines within the groups can collaborate, but not between them. All machines can also be

individually configured to help other machines and if they want help, or work individually, see

Cooperation mode [E651 PPP].

To get started easily.

1. To avoid avoid Complications , start with two machines only.

2. Connect the electrical cables for the communication, see Chapter Installation.

3. Set Communication Mode [E651] to “Master” on machine 1. (this machine is from now on called

master machine).

4. Set Address [E651 P] to “1” and Group [E651 PP] to “A” (Default).

5. Set Communication Mode [E651] on machine 2 to “Slave”.

6. Set Address [E651 P] to “2” and Group [E651 PP] to “A” (Default).

7. When more machines are attached to the newtwork repeate from step 5, but change Address. The

combination of Address and Group, like “1A” and “1B” must never be the same in the network. “1A”

and “1B” have the same address “1”, but in two different Groups which is okay.

See other machines in the network.

Probably the communication between the machines has already started. To see if a machine is in contact

with other machines, hold the [E]enter button while the Line Out screen appears until GROUP A

appears. Group images display information about up to 6 machines. Each machine's address correlates

with a fixed location in the display. Addresses 1, 2 and 3 are shown on the top row and 4.5 and 6 on the

bottom. When a machine is contactable on the network, the respective machine's information will be

displayed. If the communication fails with a machine or is disconnected, a line will appear (-----).

Press [E]nter again to return to Main screen.

Enable / disable network machines for optimized communication.

In order to minimize lost time in communication, deactivate not used addresses in each group in the

master machine. This makes the master just skip asking and waiting for response, and jump to next used

machine. From the Main screen hold the [E]nter button, the group image is showed but keep the [E]nter

button passed until it will sounds and shows “SET” in the upper right corner. Here machines are

individual enabled or disabled. Machines set to “ON” are enabled and deactivated “OFF”. To change,

press the respective buttons [1-6] below the display. To return to the Group screen, press [E]nter.

Communication - 2

Line out. Note, when ”-” is showed

the font size is reduced to fit.

Excample shows machine

with address 3 i group 1.

Fishing mode

Automatic

Fishing mode.

Automatic.

Fish caught

(Flashes)

Manual mode

(Empty sign)

ARROW DOWN. Motor

stopped. BRAKE force

on wheel

ARROW UP. Motor runs.

DRAG force on wheel.

EMPTY SIGN. Motor

stopped. DRAG force on

wheel.

Motor and wheel status

Group screen

Dashes. Machine is not responding to communication. Possible reasons.

•Error in communication. Temporary stops may occur but

communication will automatically restart.

•Collision. Two or more machines have the same address setting, while

they are in the same group. Change address or move machine to

another group.

•Machine turned off.

•Machine is addressed into a group that master does not call.

•Machine is deactivated (set to OFF) in setup, in the master. See page

Communication-1 Chapter "Enable / Disable Network Machines" for

changes.

No answer

Information in GROUP screens.

Information as Line out, Fishing mode, Wheel and Motor status is shown as described below.

GROUPA

123

456

Address position in

GROUP screens

COMMUNICATION

Communication - 3

Group screen

Manage / control machines in the group.

The machines that will be controlled are selected by pressing the buttons 1-6 below the display.

Machines that are chosen get an inverted graphics. Light text on the black background, while machines

that will not be affected appear in plain text, black on light background.

GRUPPE A

1 2 3

4 5 6

Inverted text:

Light text on Black background

Normal text:

Black text on light background.

Machine Chosen to receive commandsMachine NOT chosen for receiving command

Example

Machine 1,2 and 5 chosen .

Machine 3, 4 and 6 not chosen ,

and machine 4 does not respond

OR is deactivated.

COMMUNICATION

Address position in

Group screens

The buttons that can be sent as command to other machines are as follows.

•[Z]ero. Works at any time if the machine is selected.

•[A]uto. Works at any time if the machine is selected.

•[S]Top. Works at any time if the machine is selected.

•[U]p. Works at any time except in these two cases.

•To prevent accidents while working with the fishing line. Bringing up the GROUP screen will

block the Key [U]p button command.

•Line out is above the Zeropoint. Motor does not start because it’s already up.

When GROUP screen is showed, the local machine is also controlled like all other machines. The local

4 buttons above only affects the local machine, unless it’s GROUP is shown and local machines

address is selected. This is because otherwise the local machine would react on every button pushed

that is made to all other machines.

MENYSYSTEMET [E]

The [E]nter button is used to jump in and out of the menu system, which results in functions described in

Chapter [E]. Below is an overview of the menu system.

[E]

[E]

[E4]

[E5]

[E44]

[E15]

[E6]

[E441]

[E443]

[E442]

[E444]

[E51]

[E52]

[E53]

[E41]

[E42]

[E43]

[E445]

[E13]

[E14]

[E151]

[E152]

[E153]

[E154]

Settings for Line Mess (L.MESS)

Base Torque for Motor and Wheel.

Soft stop when motor stops.

Motor speed settings at Zeropoint

Speed Brake settings

Depth Brake settings.

Air brake speed settings

Wheel settings

Settings for Line diam. and Amount.

Counter (Line out) settings.

Stop at Zeropoint settings

Stop At Sea settings

[E45]

MOTOR

PAUSE

CATCH

WHEEL

BRAKE

MORE

JIG

CATCH

HAUL..

MANU.

MORE

[E1 ]

[E11]

[E12]

[E2]

[E3]

DIM

LINE

COUNTER

STOP-P

RP

ZERO

SEA

PULLEY

SOFTS..

PAUSE

BRAKE

DEPTH

AIR

TANGLE

TORQE

STOP

MINSPEED

Motor settings during fishing (Jig)

Motor settings during Catch

Motor settings during Hauling up

Motor settings during Manual run

Pause settings

Catch settings

Stop At Pulley settings.

Soft stop at Zeropoint settings

Pause mode settings

RP settings for clutch.

[E3]

[E2]

[E61]

Machine Information

Sounder settings

[E62]

[E65]

[E63]

[E64]

[E611]

[E612]

[E613]

[E614]

[E615]

Choices of Bar - Values (Line 3,4)

Showtime for Drag, Catch and Brake

Help text settings

Font size for LINE OUT

DISP

INFO

BEEP

CODE.

MORE

Theft code settings

DISP

BAR

BIG

SHOWTIME

HELP

Display settings.

[E651]

NETWORK Network settings

MENU [E654] Menu system detail settings

Ex has a total of five different motor modes with individual speed and accelerations. In essence, Jig

and Haul up modes are used when fishing, and Manual mode in manual mode and when machine is

not used. In all modes speed can be adjusted between 30-180rpm and acceleration times between 0.1-

10.0 seconds.

JIG [E11] mode. Used during automatic fishing in any of the Fish programs.

Soft start [E11] is the acceleration time from stationary to Jig speed.

Jig speed [E11 P] Normal motor speed during fishing. The power transferred to wheel is the basic

DRAG settings made by [1] and [4] from Main screen..

CATCH [E12] mode. Immediately at the time of catch registration, a temporary speed and power can

be applied for a maximum of 60 seconds to attract more fishes or safe catch. Time [E12] is the time the

temporarily speed [E12 P] Catch speed shall apply. During this time, also extra force can be applied on

wheel by [E12 PP] Drag + xxx%. When the Time [E12] runs out of time, or if it’s not used, the motor will

switch to Haul up mode. Se next page [E13]. From the factory, Catch Speed - Time [E12] is set to

zero "Out" which completely disables the function.

The transition from Jig speed to Catch speed occurs instantaneously (without a smooth transition). This

allows the Catch speed to perform behaviors for Ex like below.

Slow down and let more fish bite on:

•Set Catch Speed - Time [E12] to higher value (10 seconds or so).

• Set low Speed for Speed at – Catch [E12 P].

Secure hook penetration.

•Set short time to Catch Speed - Time [E12] (0.3-0,7 or similar)

•Set high speed to Speed for Speed at-Catch [E12 P]

•Add 10-20% to Torque at haul up - Drag + xxx% [E12 PP]. This cause a short jerk in the line at the

catch registration to snap the hook.

[E11] –[E12]

JIG [E11] - CATCH [E12]

Navigate [E]

Main screen

Screens

Min

Max Factory Step Unit Navigation Menu

MOTOR - JIG [E11]

Simple

Normal

Extended

JIG

–Soft start Out 10,0 1,0 0,1 Seconds

[E11]

-

X

X

JIG

–Speed 1 180 120 1 RPM

[E11 P]

X

X

X

MOTOR - CATCH [E12]

CATCH

–Speed time Out 60,0 Out 0,1 Seconds

[E12]

X

X

X

CATCH

–Speed 1 180 50 1 RPM

[E12 P]

X

X

X

CATCH

–Extra DRAG 0 100 0 1 Percent

[E12 PP]

-

X

X

Table shows units and value limits. See [E654] for menu detail level setting. Some screens are not visible if simple view, or normal view are Chosen .

”x” =Shows, ” – ” Hidden

Menu MOTOR [E1] reached by

pressing [E]nter button from Main

screen. From this menu all motor

settings are reached.

After Catch registration and optional Catch mode (see CATCH [12]) the motor begins with Haul up

mode. Settings found under HAUL.[E13].

Transision to Haul up –Speed [E13 P] is softly made by Soft start to - Hauling up speed [E13].

The soft transition time may also softly add force on wheel if Torque - Hauling up Drag + xxx% [E13

PP] is used. Extra force and speed is to shorten the time to haul up, and time to minimize loss of

catch.

MANU [E14]. The manual speed is the speed that applies when [U]p button is pressed. Soft Start To

Manual Speed [E14] and a Speed at manual [E14 P] decides the acceleration and speed. The force

on wheel is the basic DRAG setting. These settings are also used in Pause mode.

To prevent line tangle the motor stops by a deceleration time for about 0,7 seconds (see MOTOR -

Softstop [E153]). During deceleration time, motor force is reduced from any extra drag (Drag + xxx%)

back to basic DRAG. Since the machine is still in Haul up mode, the motor will start and using the

higher power again if the line is pulled out. However, close to the Zeropoint the speed, acceleration

and force switch time depends on how close the Zeropoint line is. If the line stopps outside Softstop

to 0 –Automatic [E444], which is the point at which the minimum speed begins and the motor uses

Haul up mode settings. But if the line stays above this point, then the Minimum Speed

[E154] settings are used.

[E13] –[E14]

HAUL. [E13] - MANU [E14]

Screens Min Max Factory Step Unit Navigation Menu

MOTOR –HAULING [E13]

Simple

Normal

Extended

HAUL

–Hauling up speed

Out

10,0 2,0 0,1 Second

[E13]

X X

X

HAUL

–Speed a hauling 1 160 120 1 RPM

[E13 P]

- X

X

HAUL

–Extra DRAG 0 100 0 1

Percent

[E13 PP]

- X

X

MOTOR - MANUAL UP [E14]

MANU

–Soft start Out 10,0 1,0 0,1 Second

[E14]

- X

X

MANU

–Speed 1 160 120 1 RPM

[E14 P]

X X x

”x” =Shows, ” – ” Hidden

Table shows units and value limits. See [E654] for menu detail level setting. Some screens are not visible if simple view, or normal view are Chosen .

Menu MOTOR [E1] reached by

pressing [E]nter button from Main

screen. From this menu all motor

settings are reached.

Navigate [E]

Main screen

[E151]

Main screen L.MESS [E151]

Screens Min Max Factory

Step

Unit Navigation Menu

MOTOR –MORE - L.MESS [E151]

Simple

Normal

Extended

L.MESS

–Value 0 20 4 1 AMP

[E151]

-

X

X

L.MESS

–Speed Out 160 Out 1 RPM

[E151P]

-

X

X

L.MESS

–Detect time 1 50 10 0,1 Second

[E151 PP]

-

X

X

L.MESS

–Distance 0 99 5 1

M/Fm/Ft

[E151 PPP]

-

X

X

Motor current without sinker or line.

Max motor current

Suitable limit for Value for line mess

Motorcurrent (Weigh)

Normal motor current with sinker and hooks Motor current with load.

Menu MOTOR MORE [E15] reached

by pressing [E]nter button from

MOTR MENU and contains

advanced motor settings.

”x” =Shows, ” – ” Hidden

Table shows units and value limits. See [E654] for menu detail level setting. Some screens are not visible if simple view, or normal view are Chosen .

Navigate [E1]

General about motor torque. The motor in BJ5000Ex is brushless without gearbox with 50% more

strength and is faster than previous models. Instead of wiping out power in the clutch, the motor torque is

now adjusted to meet desired pulling force. Therefore when the load approaches the set pulling force

(DRAG), the motor and the wheel stops without affecting the pulling force. This minimizes power

consumption. If the catch is tougher and the traction of the motor exceeds, the motor and the wheel are

pulled backwards. The motor then acts as a generator that returns energy to the battery. Only when the

catch pulls so hard that the motor current gets bigger than Ex can handle, the clutch starts to slip.

L.MESS [E151]. Line mess mode (function for line tangle). When two machines tear lines together, one

of them will pick up both machines’ hooks and sinkers, with catch registration as result. The machine

without loads will then go unusually light upwards, and the wheel will not roll out when it’s supposed to.

Unless the line is hauled up in at the same rate as the machine detecting catch, line tangle will occur. Ex

solves this by putting less load on the machine into Catch mode. Note that abnormal low loads may also

be due to catch overcoming the weight of the sinker. To enter lighter Catch mode in this case might be a

good solution.

Speed [E151 P] is the speed used in (Line mess mode). Probably best if set to full speed. As soon as

normal load occurs, the motor returns to Haul up speed [E13 P]. In order for this to work well put Speed

[151 P] to same, or higher then all machines Haul up speed [E13 P] otherwise they will never catch up.

Value for line mess [E151]. This limit should be set to almost (a bit less) same as the motor current

(Showed as Weight) used when motor runs with Sinker and Hooks only. When motor current gets

underneath this limit during the Detect time [E151 PP] the machine gets into Line mess mode.

Detect time [E151 PP]. In order not to change speed too often, giving a rough ride, the average load is

measured during this time.

Distance for line mess [E151 PPP]. When the machine works with Bottom fishing, the first meters

after the bottom detection always goes easy because the sinker is on the bottom and the line slacks.

Therefore, the L.MESS [E151] function is disabled near bottom until this distance is pulled up.

Menu [E15]

[E152] –[E153] –[E154]

TORQUE [E152] This chapter contains advanced settings for the Motor and Clutch when it comes to

DRAG, to avoid clutch slipping. The idea is that DRAG shall give a linear force on wheel from 0-30 Kg for

DRAG 0-100%. To achive this two values are needed. When adjusting the values below, first start with

the Motor –Minimum Torqe, then the Clutch - Minimum Torque. Tie the fishing line to the frame of

the machine.

CLUTCH –Minimum Clutch torque [E152]. This value should be as low as possible, but too low will

make the clutch slipp, and that is not good. Too high values will cause a lower value to DRAG and make

no change in force to the wheel.

MOTOR –Minimum Motor torque [E152 P]. This is the minimum amount of energy sent to motor. At

0% the motor does not even start. To adjust this. Set DRAG to 0 %. Set Motor –Minimum torque to

100%. Press [S]top once. Press [U]p button so motor starts. Decrease Motor –Minimum torque slowly

untill the motor gets a new sound(around 10%). Go back up to value where it sounds as when it was at

100%.

Soft stop [E153]. The motor in EX can start and stop very quickly compared to previous models. To get

a softer stop ddeceleration is made during this time. The time can be adjusted to zero if desired and

applies to driving in both automatic and manual mode.

Minimum speed near Zeropoint [E154]. Minimum speed is the speed of the motor when it arrives to

the Zeropoint and also if it continues above the stop point if stop 0 is disconnected. The speed reduction

occurs over a number of laps determined by the Soft Stop in Auto [E444] in Manual mode and Soft

Stop in Manu [E444 P] in manual mode. If the line is inside the Soft Stop in Manu [E444 P] when the

engine is started manually, then minimum speed will be disconnected.

Soft Start to Minimum Speed [E154 P] is the acceleration time applicable from standstill to minimum

speed and may be set to larger numbers, such as 5 seconds or more to minimize jerk in the line at risk of

losing catch.

Wheel laps before motor starts [E154 PP] In Haul up mode if line is pulled out from the Zeropoint

the motor starts to haul back up. This can be adjustable for better functionality when using hook winch.

TORQUE [E152] - STOP [E153] - MINSPEED [E154]

Screens

Min

Max

Factory

Step

Unit Navigation

MOTOR –MORE - TORQ [E152]

TORQ

–Minimum Clutch Torque 0 100 16 1 %

[E152]

TORQ

–Minimum Motor Torque 0 100 10 1 %

[E152 P]

MOTOR - MORE - STOP [E153]

STOP

–Motor Soft Stop 0 3,0 1,0 0,1 Second

[E153]

MOTOR –MORE - MINSPEED [E154]

MINSPEED

–Minimum speed around

Z

eropoint 50 180 50 1 Rpm

[E154]

MINSPEED

–Softstart to Minimum speed 0,1

99,9

4,0 0,1 Second

[E154 P]

MINSPEED

–Wheel laps before motor starts 0,1

33,0

1,0 0,1

Wheel laps

[E154 PP]

Menu MOTOR MORE [E15] reached

by pressing [E]nter button from

MOTR MENU and contains

advanced motor settings.

Table shows units and value limits. See [E654] for menu detail level setting. Some screens are not visible if simple view, or normal view are Chosen .

Main screen

Navigate [E1]

Menu [E15]

Table of contents

Popular Tools manuals by other brands

U-Line

U-Line H-3533 Operation instructions

Cleco

Cleco 48CAE15AL3 instruction manual

Porter-Cable

Porter-Cable 4112, 4113, 4114, 4115 instruction manual

Welch Allyn

Welch Allyn Q-Tel RMS Installation and user manual

BGS technic

BGS technic 569 quick start guide

Sioux Tools

Sioux Tools SCO7AX184 Instructions-parts list