Bender ISOSCAN W Series User manual

ISOSCAN® EDS440 and EDS441

Insulation fault locator to locate insulation faults

in ungrounded DC, AC and three-phase power supplies

EDS44x_D00201_10_M_XXEN/11.2023

2 EDS44x_D 2 1_1 _M_XXEN/11.2 23

ISOSCAN® EDS44 and EDS441

Table of contents

1General information...........................................................................................7

1.1 How to use the manual.................................................................................................................................7

1.2 Indication of important instructions and information.......................................................................7

1.3 Signs and symbols...........................................................................................................................................7

1.4 Service and Support....................................................................................................................................... 7

1.5 Training courses and seminars...................................................................................................................8

1.6 Delivery conditions......................................................................................................................................... 8

1.7 Inspection, transport and storage.............................................................................................................8

1.8 Warranty and liability.....................................................................................................................................8

1.9 Disposal of Bender devices..........................................................................................................................9

1.1 Safety.................................................................................................................................................................... 9

2Function.............................................................................................................10

2.1 Intended use................................................................................................................................................... 1

2.2 Features.............................................................................................................................................................1

2.2.1 Areas of application..................................................................................................................................... 1

2.2.2 Standards..........................................................................................................................................................1

2.2.3 System variants.............................................................................................................................................. 11

2.2.4 System properties......................................................................................................................................... 11

2.2.5 Compatibility...................................................................................................................................................12

2.3 Operating principle of the EDS system................................................................................................ 13

2.4 Schematic diagram of an EDS system...................................................................................................15

3Device overview............................................................................................... 16

3.1 External dimensions of EDS44… and IOM441-S............................................................................... 16

3.2 View and connections of EDS44…-L.....................................................................................................17

3.3 View and connections of EDS44…-S.....................................................................................................18

4ounting...........................................................................................................19

4.1 General information..................................................................................................................................... 19

4.2 Installation clearances................................................................................................................................. 19

4.3 Screw mounting............................................................................................................................................ 2

4.4 DIN rail mounting......................................................................................................................................... 21

4.5 Connection of the BB bus..........................................................................................................................21

4.6 Connection to the voltage supply..........................................................................................................22

4.7 Connection of the X1 interface (I1, I2, A, B, M+, ...).......................................................................... 22

EDS44x_D 2 1_1 _M_XXEN/11.2 23 3

Table of contents

4.8 Connection of the relays............................................................................................................................ 23

4.9 BS bus termination....................................................................................................................................... 23

4.1 Connection of the X2 interface (k1-12/l1-12).....................................................................................24

4.1 .1 Connection of CTAC… series measuring current transformers...................................................24

4.1 .2 Connection of measuring current transformer CTBC… to EDS441-LAB-4...............................26

4.1 .3 Connection of CTAF…SET series measuring current transformers to EDS44 -LAF-4..........27

4.11 Connection to a 3(N)AC system.............................................................................................................. 28

4.12 Connection to an AC system....................................................................................................................29

4.13 Connection to a DC system...................................................................................................................... 3

4.14 Connection example: ISOMETER® iso685-D-P, EDS44 -S, IOM441-S and EDS44 -L.............31

5Display and alarm messages...........................................................................32

5.1 Display elements EDS44…-S.................................................................................................................... 32

5.2 Operating and display elements EDS44…-L...................................................................................... 32

5.3 Standard display in operating mode.....................................................................................................33

5.3.1 Standard display EDS44…-S..................................................................................................................... 33

5.3.2 Standard display EDS44…-L..................................................................................................................... 33

5.4 Alarm messages.............................................................................................................................................34

5.4.1 Insulation fault (ALARM IΔL).......................................................................................................................34

5.4.2 Residual current exceeded (ALARM IΔn)............................................................................................... 35

5.4.3 Connection fault of the current transformers....................................................................................35

5.4.4 Device error, BB bus error..........................................................................................................................36

5.4.5 Device error, failure BS bus master........................................................................................................ 37

5.4.6 Error message................................................................................................................................................. 37

5.4.7 Acoustic alarm message.............................................................................................................................37

6Commissioning................................................................................................. 38

6.1 Requirements for reliable insulation fault location..........................................................................38

6.2 Before switching on..................................................................................................................................... 38

6.3 Switching on................................................................................................................................................... 39

6.4 Steps for commissioning ISOMETER® and EDS..................................................................................39

6.5 Periodic verification......................................................................................................................................4

7Device communication.................................................................................... 41

7.1 RS-485 interface.............................................................................................................................................41

7.2 Bender Sensor bus (BS bus)...................................................................................................................... 41

7.3 Modbus RTU....................................................................................................................................................42

8Operation.......................................................................................................... 43

4 EDS44x_D 2 1_1 _M_XXEN/11.2 23

ISOSCAN® EDS44 and EDS441

8.1 Reading out and setting the BS address..............................................................................................43

8.1.1 Reading out a BS address.......................................................................................................................... 43

8.1.2 Setting a BS address.................................................................................................................................... 44

8.1.3 Extended address range (offset = 8 )...................................................................................................46

8.2 Display and change of transmission protocols..................................................................................47

8.2.1 Displaying the current transmission protocol....................................................................................47

8.2.2 Changing the transmission protocol..................................................................................................... 48

8.3 Resetting saved alarm messages (RESET button)............................................................................. 48

8.4 Deactivating the buzzer (EDS44…-L only).......................................................................................... 48

8.5 Running a test (TEST button)................................................................................................................... 48

9Settings..............................................................................................................50

9.1 EDS settings on the ISOMETER®.............................................................................................................. 5

9.1.1 Locating current injector settings...........................................................................................................5

9.1.2 Trigger function............................................................................................................................................. 51

9.1.3 Fault memory..................................................................................................................................................51

9.2 Settings of inputs and outputs of the EDS44…-L............................................................................ 51

9.2.1 Digital inputs of the EDS44…-L (I1, I2)................................................................................................. 51

9.2.2 Digital outputs of the EDS44…-L........................................................................................................... 52

9.3 Factory settings..............................................................................................................................................54

10 Alarm messages................................................................................................56

11 Diagrams........................................................................................................... 57

11.1 Response sensitivity curves.......................................................................................................................57

11.1.1 Characteristic curves EDS44 for 3AC systems..................................................................................58

11.1.2 Characteristic curves EDS44 for AC systems.................................................................................... 6

11.1.3 Characteristic curve of EDS44 for low voltages in DC, AC and 3NAC systems..................... 61

11.1.4 Characteristic curves EDS44 for DC systems.................................................................................... 62

11.1.5 Characteristic curves EDS441 for AC systems.................................................................................... 65

11.1.6 Characteristic curves EDS441 for DC systems.................................................................................... 66

11.1.7 Characteristic curves of EDS441-LAB for AC systems......................................................................68

11.1.8 Characteristic curves EDS441-LAB for DC systems........................................................................... 69

11.1.9 Response values of EDS44 -LAF for DC systems.............................................................................. 71

11.1.1 Response values of EDS44 -LAF for AC systems...............................................................................71

11.2 Fault curve EDS44 and EDS441.............................................................................................................72

12 Technical data...................................................................................................73

12.1 Technical data ISOSCAN® EDS44 and EDS441................................................................................. 73

EDS44x_D 2 1_1 _M_XXEN/11.2 23 5

Table of contents

12.2 Standards and certifications..................................................................................................................... 79

12.3 Ordering data..................................................................................................................................................8

12.3.1 Insulation fault locators.............................................................................................................................. 8

12.3.2 Accessories.......................................................................................................................................................8

12.3.3 Measuring current transformers..............................................................................................................81

12.4 Change history............................................................................................................................................... 83

6 EDS44x_D 2 1_1 _M_XXEN/11.2 23

ISOSCAN® EDS44 and EDS441

1 General information

1.1 How to use the manual

ADVICE

This manual is intended for qualified personnel working in electrical engineering and electronics!

Part of the device documentation in addition to this manual is the enclosed supplement ‘Safety

instructions for Bender products’.

ADVICE

Read the operating manual before mounting, connecting and commissioning the device. Keep the

manual within easy reach for future reference.

1.2 Indication of important instructions and information

DANGER

Indicates a high risk of danger that will result in death or serious injury if not avoided.

WARNING

Indicates a medium risk of danger that can lead to death or serious injury if not avoided.

CAUTION

Indicates a low-level risk that can result in minor or moderate injury or damage to property if not

avoided.

ADVICE

Indicates important facts that do not result in immediate injuries. They can lead to malfunctions if the

device is handled incorrectly.

Information can help to optimise the use of the product.

1.3 Signs and symbols

Disposal Protect from moisture Protect from dust

Temperature range Recycling RoHS directives

1.4 Service and Support

Information and contact details about customer service, repair service or field service for Bender devices are

available on the following website: Fast assistance | Bender GmbH & Co. KG.

EDS44x_D 2 1_1 _M_XXEN/11.2 23 7

General information

1.5 Training courses and seminars

Regular face-to-face or online seminars for customers and other interested parties:

www.bender.de > know-how > seminars.

1.6 Delivery conditions

The conditions of sale and delivery set out by Bender GmbH & Co. KG apply. These can be obtained in printed

or electronic format.

The following applies to software products:

Die Elektroindustrie

‘Software clause in respect of the licensing of standard software as part of deliveries,

modifications and changes to general delivery conditions for products and services in the

electrical industry’

1.7 Inspection, transport and storage

Check the shipping and device packaging for transport damage and scope of delivery. In the event of

complaints, the company must be notified immediately, see ‘www.bender.de > service & support.’.

The following must be observed when storing the devices:

1.8 Warranty and liability

Warranty and liability claims for personal injury and property damage are excluded in the case of:

•Improper use of the device.

•Incorrect mounting, commissioning, operation and maintenance of the device.

•Failure to observe the instructions in this operating manual regarding transport, commissioning, operation

and maintenance of the device.

•Unauthorised changes to the device made by parties other than the manufacturer.

•Non-observance of technical data.

•Repairs carried out incorrectly.

•The use of accessories or spare parts that are not provided, approved or recommended by the

manufacturer.

•Catastrophes caused by external influences and force majeure.

•Mounting and installation with device combinations not approved or recommended by the manufacturer.

This operating manual and the enclosed safety instructions must be observed by all persons working with the

device. Furthermore, the rules and regulations that apply for accident prevention at the place of use must be

observed.

8 EDS44x_D 2 1_1 _M_XXEN/11.2 23

ISOSCAN® EDS44 and EDS441

1.9 Disposal of Bender devices

Abide by the national regulations and laws governing the disposal of this device.

For more information on the disposal of Bender devices, refer to

www.bender.de > service & support.

1.10 Safety

If the device is used outside the Federal Republic of Germany, the applicable local standards and regulations

must be complied with. In Europe, the European standard EN 5 11 applies.

DANGER Risk of fatal injury due to electric shock!

Touching live parts of the system carries the risk of:

•Risk of electrocution due to electric shock

•Damage to the electrical installation

•Destruction of the device

Before installing the device and before working on its connections, make sure that the installation

has been de-energised. The rules for working on electrical systems must be observed.

EDS44x_D 2 1_1 _M_XXEN/11.2 23 9

Function

2 Function

2.1 Intended use

The insulation fault locators ISOSCAN® EDS44 and EDS441 are used to locate insulation faults in unearthed

DC, AC and three-phase power supply systems (IT systems). Depending on the locating current injector, AC

and three-phase systems can be monitored within the range from AC 42 to 1 V; DC systems, within the

range from DC 24 to 15 V.

An AC residual current can be indicated in these ranges:

•EDS44 : 42…1 Hz, .1…2 A

•EDS441: 42…6 Hz, .1…2 A

An EDS system (insulation fault location system) consists of an EDS44x insulation fault locator and a locating

current injector. EDS44… insulation fault locators detect locating current signals generated by the locating

current injector via measuring current transformers and evaluate them accordingly.

Intended use also implies

•the observation of all information in the operating manual and

•compliance with test intervals.

In order to meet the requirements of the applicable standards, customised parameter settings must be made

on the equipment in order to adapt it to local equipment and operating conditions. Please heed the limits of

the range of application indicated in the technical data.

Do not make any unauthorised changes to the device. Only use spare parts and optional accessories sold or

recommended by the manufacturer.

The messages of the device must be perceptible even if it is installed in a control cabinet.

The devices is not designed for use in residential areas and may not provide sufficient protection for radio

reception there.

Any other use than that described in this manual is regarded as improper.

2.2 Features

2.2.1 Areas of application

•Insulation fault location in AC, 3(N)AC and DC IT systems

•Main circuits and control circuits in industrial plants and ships

•Diode-decoupled DC IT systems in power plants

•Systems for medical locations

2.2.2 Standards

The standard for unearthed power supplies (IT systems)

DIN VDE 0 00-4 0 (VDE 0 00- 4 0):20 8- 0 (IEC 60364-4-4 :2005, modified + A :20 7, modified)

requires that the first insulation fault is to be eliminated with the shortest practicable delay. EDS systems

enable fast localisation of this insulation fault.

1 EDS44x_D 2 1_1 _M_XXEN/11.2 23

ISOSCAN® EDS44 and EDS441

2.2.3 System variants

The devices ISOSCAN® EDS44 and EDS441 differ depending on their response sensitivity. EDS44 is suitable

for main circuits. EDS441 can be used in control circuits and in circuits in medical locations.

-L -S -LAB-4 -LAF-4

EDS440 Channel LED

BS bus

IΔL = 2…10 mA

Main circuits

Digital in uts and

out uts

No channel LED

BB bus

IΔL = 2…10 mA

Main circuits

No internal voltage

su ly

Channel LED

BS bus

IΔL = 10 mA 2)

Main circuits

Digital in uts and

out uts

EDS441 Channel LED

BS-Bus

IΔL = 0.2…1 mA

Control circuits

Digital in uts and

out uts

No channel LED

BB bus

IΔL = 0.2…1 mA

Control circuits

No internal voltage

su ly

Channel LED

BS-Bus

IΔL = 0.2…1 mA 1)

Control circuits

W…AB current

transformers

Digital in uts and

out uts

1) High response sensitivity with large system leakage capacitances

2) In combination with CTAF...SET series measuring current transformers

2.2.4 System properties

■Universal system design

■Modular design, therefore easily adjustable to the given circumstances

■Measuring current transformers available in various sizes and versions

■CT connection monitoring

■Twelve measuring channels for series W…, WR…, WS… measuring current transformers

■Optional extension by twelve relay channels

■Fault memory behaviour selectable

■Up to 5 EDS insulation fault locators in the system, 6 measuring channels

■Response sensitivity:

– EDS44 …: 2…1 mA

– EDS441…: .2…1 mA

■AC residual current measurement with configurable response value

■Two alarm relays with one n/o contact each

■n/o or n/c operation selectable

■External test/reset button

■Central display of faulty outgoing circuits

■Serial interface RS-485, BS bus address range 2…79

■Connection to higher-level control and visualisation systems possible.

EDS44x_D 2 1_1 _M_XXEN/11.2 23 11

Function

2.2.5 Compatibility

Legende

BS bus Full compatibility, communication via BS bus

BB bus Full compatibility, communication via BB bus

◊ Full compatibility, no communication possible

#Limited compatibility + communication via BS bus

Limited display of messages on the device.

Limited parameterisation via the device possible.

! Limited compatibility + communication via BS bus

Display of all messages on the device.

No parameter setting via the device possible.

Combination of insulation fault locators

Device EDS440-L EDS440-S EDS441-L EDS441-S EDS441-LAB EDS440-LAF

EDS440-L BS bus ◊

EDS440-S ◊ BB bus

EDS441-L BS bus ◊

EDS441-S ◊ BB bus

EDS441-LAB BS bus

EDS441-LAF BS bus

EDS460/490L BS bus ◊

EDS460/490D BS bus ◊

EDS461/491L BS bus ◊

EDS461/491D BS bus ◊

EDS150 BS bus ◊

EDS151 BS bus ◊

EDS195P ◊◊◊◊

Current transformers and measuring clamps

Device Type EDS440-L /S EDS441-L /S EDS441-LAB EDS440-LAF

W…/WR…/

WS…

Type A ◊

W/WS 8000 Type A ◊ ◊

W…AB Type AB ◊

CTAS, CTAC Type A ◊

CTAS…/01,

CTAC…/01

Type A ◊

12 EDS44x_D 2 1_1 _M_XXEN/11.2 23

ISOSCAN® EDS44 and EDS441

Device Type EDS440-L /S EDS441-L /S EDS441-LAB EDS440-LAF

CTUB10 Type B ◊

CTAF…SET Type A ◊

Other Bender devices

Device EDS440-L EDS440-S EDS441-L EDS441-S EDS441-LAB EDS440-LAF

COM460 ! ! ! !

COM465 ! ! ! !

IOM441-S !!!!!!

CP700 ! ! ! !

MK 430 # #

IRDH575 # #

iso685-…-p BS bus BS bus BS bus BS bus BS bus BS bus

isoMED4 7 ◊

PGH183 ◊ ◊

PGH185 ◊ ◊

PGH186 ◊ ◊

2.3 Operating principle of the EDS system

When an insulation monitoring device detects an insulation fault, it starts the insulation fault location.

In the event of a first insulation fault, an undefined residual current flows in IT systems, which is primarily

defined by the system leakage capacitances and the value of the insulation fault. The basic idea of insulation

fault location is therefore to generate a defined locating current IL that flows through the insulation fault. The

locating current is driven by the system voltage and can be located in the faulty outgoing circuit using the

measuring current transformer.

The locating current is generated by the locating current injector. It is limited in amplitude and time. The

amplitude depends on the size of the existing insulation fault and the system voltage. It is limited depending

on the settings.

The locating current flows from the locating current injector via the live lines to the insulation fault location

taking the shortest route. From there, it flows through the insulation fault and the earth conductor back to the

locating current injector. This locating current pulse is detected by the measuring current transformers on the

insulation fault path and signalled by the connected insulation fault locator.

EDS44x_D 2 1_1 _M_XXEN/11.2 23 13

Function

Locating pulse pattern

x s

y s

x s

y s

The length of the pulse and pause intervals depends on the system conditions (RF, Ce).

For further information, refer to Bender Main Catalogue, chapter “Equipment for insulation fault location” at

https://www.bender.de/en/service-support/download-area/.

Measured value depending on the system leakage capacitance

The influence of system leakage capacitances may cause false indication of the locating current.

The locating current of the locating current injector is limited. Due to this limitation, the resistance of the

insulation fault may be lower than the value signalled by the indicated locating current.

Project planning

During project planning care must be taken that there are no system parts where the locating current can

cause harmful reactions even in unfavourable cases.

Symmetrical insulation faults

Under certain conditions, symmetrical insulation faults located downstream of the measuring current

transformer are not detected. Lowfrequency residual currents (e.g. caused by converters) may prevent

insulation faults from being detected if their frequency is identical or almost identical to the test pulse

frequency of the locating current injector.

Influence by other components

Components, loads or EMC influences within an IT system may interfere with the locating of insulation

faults. Thus, reliable localisation may not be possible under all circumstances or false tripping may occur.

14 EDS44x_D 2 1_1 _M_XXEN/11.2 23

ISOSCAN® EDS44 and EDS441

2.4 Schematic diagram of an EDS system

Un

L1

L2

PE

RF

IL

IL

A1/+

A2/-

21 22 24

11 12 14

L1/+

L2 L3/- KE E

iso685

ISOMETER

®

RX2

X1

l1 l2 l3 A B

EKEL3/-L2

L1/+

EDS440

ISOSCAN

®

I

ΔL

I

Δn

13 14 23 24

l1

k1

l2

k2

l3

k3

l4

k4

l5

k5

l6

k6

l7

k7

l8

k8

l9

k9

l10

k10

l11

k11

l12

k12

X1

l1 l2 A B

A1/+ A2/-

l1 k1 l2 k2

EDS44x Insulation fault locator

iso685-D-P Insulation monitoring device with an integrated locating current injector

UnVoltage source of IT system

UsSupply voltage

W Measuring current transformers

ILLocating current

RFInsulation fault downstream of the measuring current transformer

PE Protective earth conductor or equipotential bonding conductor

BS bus BS bus for device communication

EDS44x_D 2 1_1 _M_XXEN/11.2 23 15

Device overview

3 Device overview

3.1 External dimensions of EDS44… and IO 441-S

93

71,7 48,5

62,9

66,9

45

Figure 3-1: External dimensions in mm

16 EDS44x_D 2 1_1 _M_XXEN/11.2 23

ISOSCAN® EDS44 and EDS441

3.2 View and connections of EDS44…-L

ISOSCAN®

EDS440

I

L

I

n

-1

>3sADDR.

RESET

+1

+10

TEST

CHANNELS / ADDR.

12

11109

87

345621

+10 +20 +40

Addr. Mode

n

∆

I

ALARM

L

∆

I

ALARM

SERVICE

COM/ADDR.

ON

l1 l2 l3 l4 l5 l6 l7 l8 l9 l10 l11 l12

k1 k2 k3 k4 k5 k6 k7 k8 k9 k10 k11 k12

l l

A1/+ A2/-

12 3 4 5 6 7 8 9 10 11 12

L

13 14 23 24

I1 I2 A B

M+ BA

R switch

Termination RS-485 interface

Operating and display

elements

A1/+ A2/-

Connection

supply voltage Us

X2 (k1-12 | l1-12)

Connection

current transformer

Connection 13 | 14

Alarm relay 1

Connection 23 | 24

Alarm relay 2

X1

I/O interface

X3 (rear side)

BB bus interface

EDS44x_D 2 1_1 _M_XXEN/11.2 23 17

Device overview

3.3 View and connections of EDS44…-S

ISOSCAN®

EDS440

I

L

I

n

ON

l1 l2 l3 l4 l5 l6 l7 l8 l9 l10 l11 l12

k1 k2 k3 k4 k5 k6 k7 k8 k9 k10 k11 k12

12 3 4 5 6 7 8 9 10 11 12

L

13 14 23 24

R switch

Termination RS-485 interface

X3 (rear side)

BB bus interface

X2 (k1-12 | l1-12)

Connection

current transformer

Connection 13 | 14

Alarm relay 1

Connection 23 | 24

Alarm relay 2

Power LED

18 EDS44x_D 2 1_1 _M_XXEN/11.2 23

ISOSCAN® EDS44 and EDS441

4 ounting

4.1 General information

The devices are suitable for the following installation methods:

•Distribution panels according to DIN 43871

•Quick DIN rail mounting according to IEC 6 715

•Screw mounting using M4 screws

For UL applications:

•Only use 60/75 °C copper lines.

•Install in pollution degree 2 environment only.

4.2 Installation clearances

20 mm

20 mm

0 mm

0 mm

Application in rail ay vehicles / DIN EN 45545-2:2016

If the distance to adjacent components that do not meet the requirement of DIN EN 45545-2 Table 2 is

horizontally < 20 mm or vertically < 200 mm, they are to be considered as grouped. See DIN EN 45545-2

chapter 4.3 Grouping rules

EDS44x_D 2 1_1 _M_XXEN/11.2 23 19

Mounting

4.3 Screw mounting

1. Insert the mounting clips as illustrated below.

2. Drill the mounting holes for the M4 thread according to the drilling template.

3. Fix the EDS using two M4 screws.

M4

36 (1.42)

107

(4.22)

100

(3.94)

2 EDS44x_D 2 1_1 _M_XXEN/11.2 23

This manual suits for next models

37

Table of contents

Other Bender Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

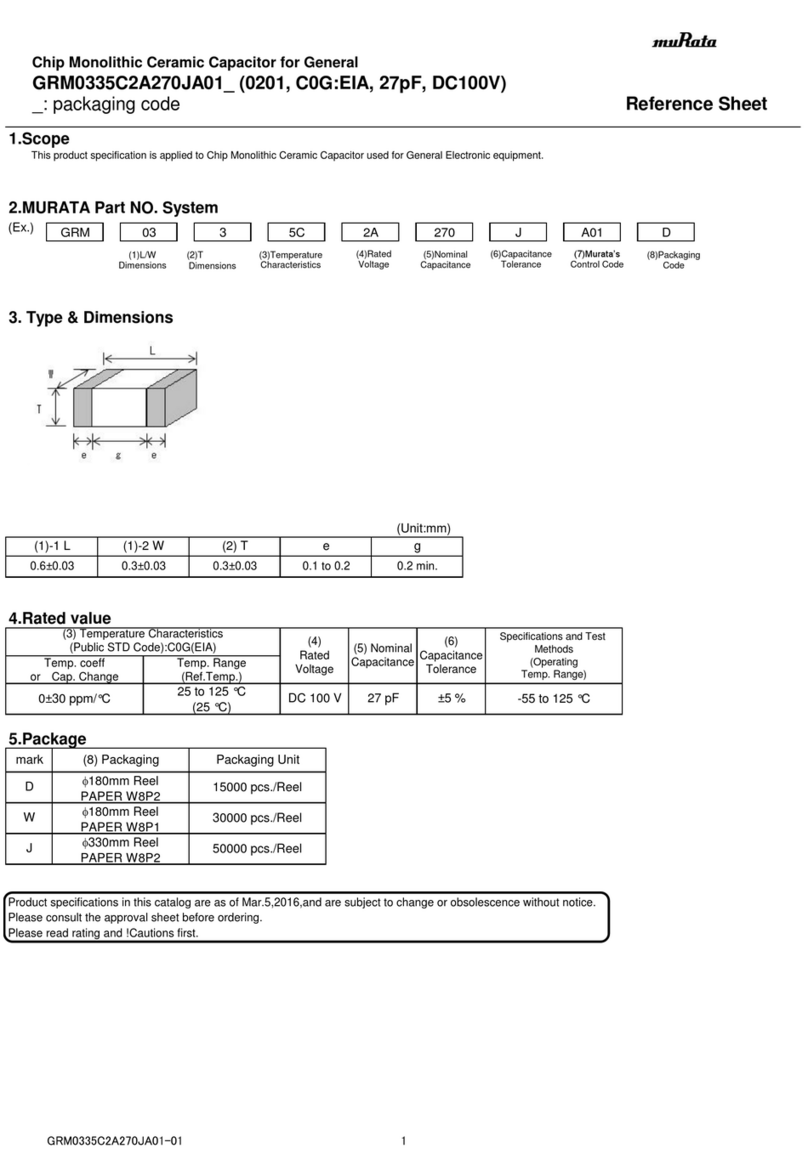

Murata

Murata GRM0335C2A270JA01 Series Reference sheet

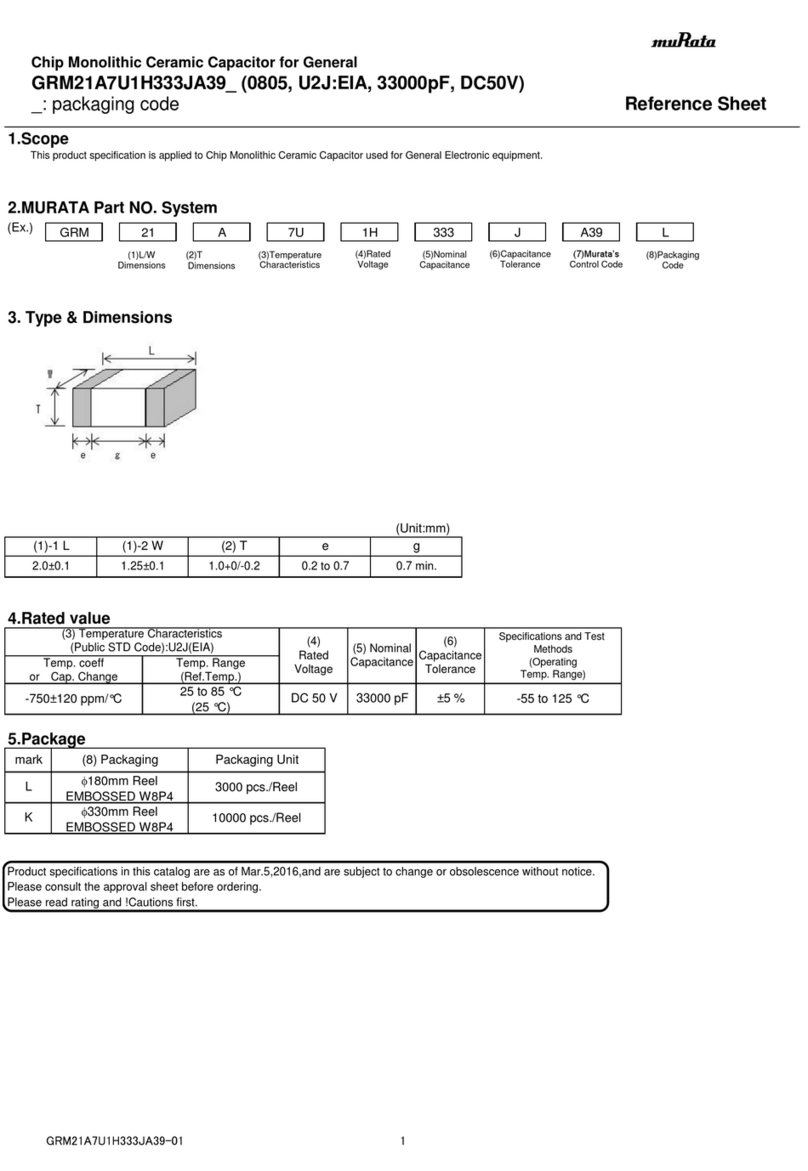

Murata

Murata GRM21A7U1H333JA39 Series Reference sheet

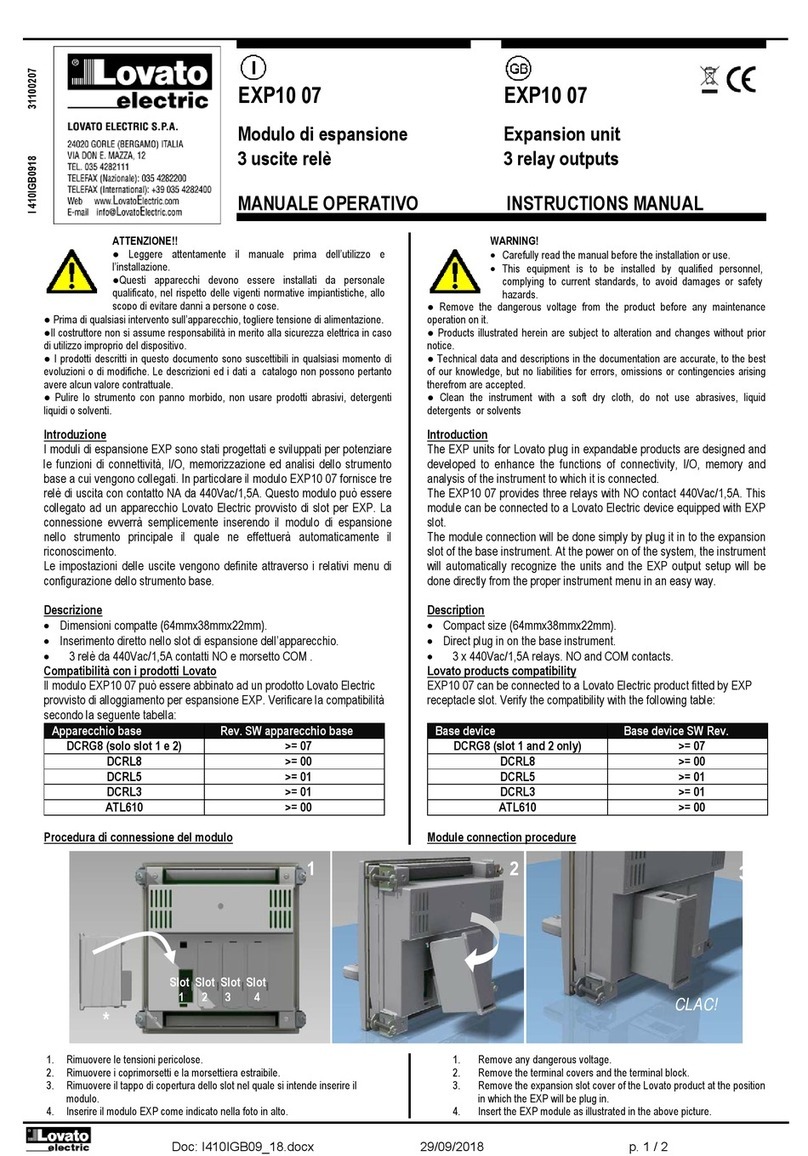

LOVATO ELECTRIC

LOVATO ELECTRIC EXP10 07 instruction manual

IFM Electronic

IFM Electronic Efector250 E3D304 installation instructions

Command access

Command access VLP-UL-M-KIT installation instructions

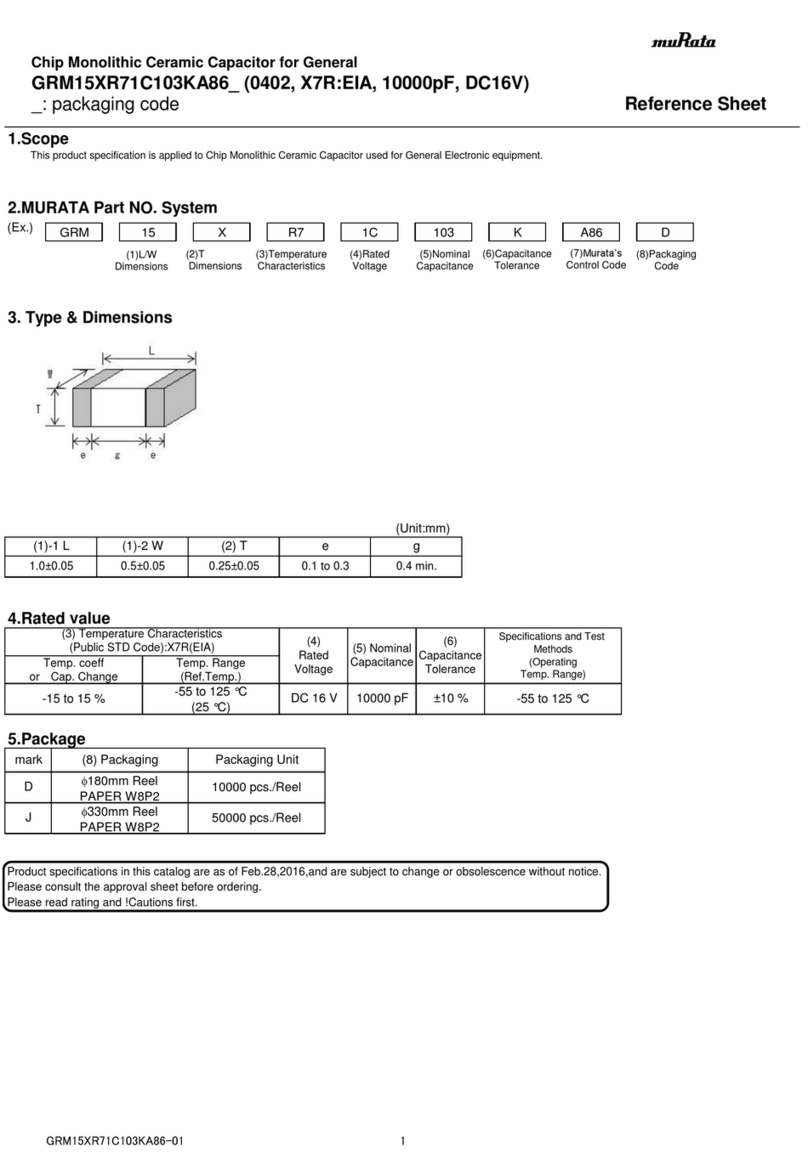

Murata

Murata GRM15XR71C103KA86 Series Reference sheet