9

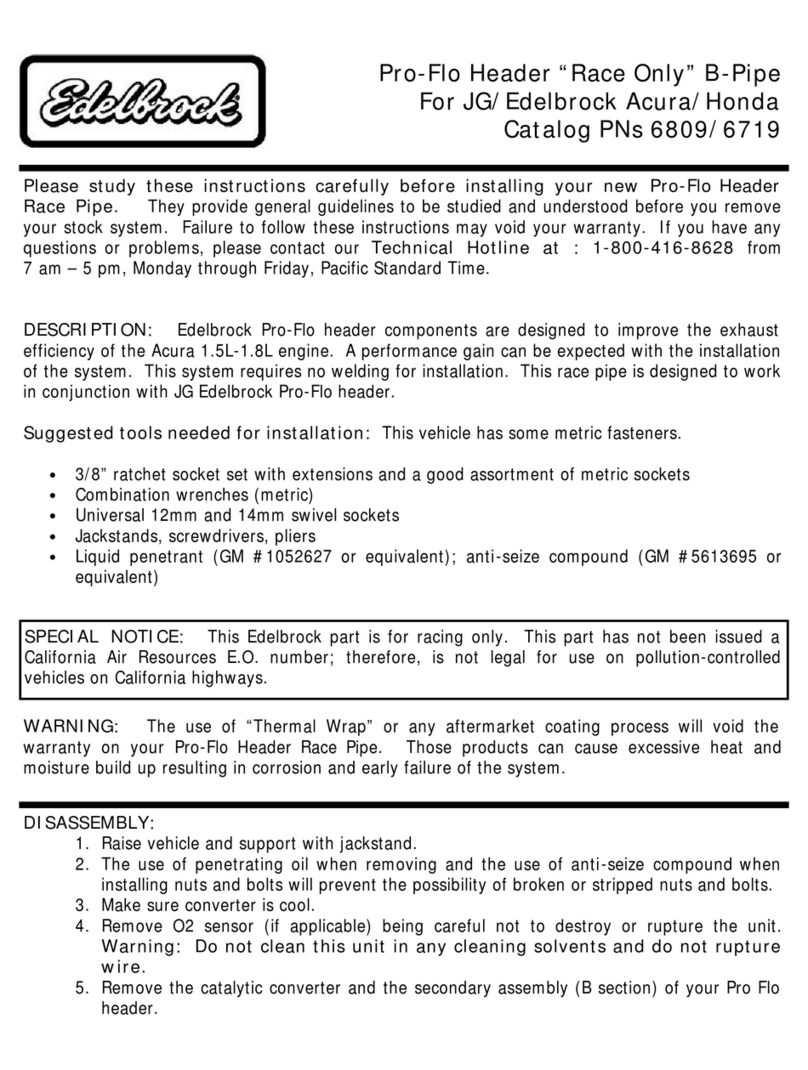

FIGURE 10 - TOOLS FOR ASSEMBLY/DISASSEMBLY

PART NUMBER 10 234 (REQUIRED)

PART NUMBER 297 7 (REQUIRED)

PART NUMBER 298077 (OPTIONAL)

PART NUMBER 10 7 2 (OPTIONAL)

SPANNER WRENCH - REQUIRED FOR REMOVAL

AND INSTALLATION OF THE VALVE NUT.

SEATING TOOL - REQUIRED TO FORM TEFLON GLIDE RINGS

AND TO INSTALL SPINDLE ASSEMBLY IN VALVE BODY.

PILOTED SCREWDRIVER - USED TO REMOVE AND

INSTALL THE PRESSURE RELIEF VALVE SEAT.

HOLDING FIXTURE - USED TO HOLD THE PISTON AND

VALVE BODY DURING ASSEMBLY AND DISASSEMBLY.

EXTERIOR BOOTS AND DUST SEALS

Inspect the inte rity of the output and input shaft boot and

dust seal. These components prevent contamination from

enterin the housin around the shaft. If deterioration is

noted, these components should be replaced. The cavities

between the boots and seals should be filled with special

hi h temperature rease.

IMPORTANT! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When workin on or around a vehicle, the followin eneral

precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the parkin

brakes, and always block the wheels.

2. Stop the en ine when workin around the vehicle.

3. If the vehicle is equipped with air brakes, make certain

to drain the air pressure from all reservoirs before

be innin ANY work on the vehicle.

4. Followin the vehicle manufacturers recommended

procedures, deactivate the electrical system in a manner

that removes all electrical power from the vehicle.

5. When workin in the en ine compartment the en ine

should be shut off. Where circumstances require that

the en ine be in operation, EXTREME CAUTION should

be used to prevent personal injury resultin from contact

with movin , rotatin , leakin , heated, or electrically

char ed components.

6. Never connect or disconnect a hose or line containin

pressure; it may whip. Never remove a component or

plu unless you are certain all system pressure has

been depleted.

7. Never exceed recommended pressures and always wear

safety lasses.

8. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thorou hly understand the recommended procedures.

Use only the proper tools and observe all precautions

pertainin to use of those tools.

9. Use only enuine Bendix replacement parts,

components, and kits. Replacement hardware, tubin ,

hose, fittin s, etc. should be of equivalent size, type,

and stren th as ori inal equipment and be desi ned

specifically for such applications and systems.

10. Components with stripped threads or dama ed parts

should be replaced rather than repaired. Repairs requirin

machinin or weldin should not be attempted unless

specifically approved and stated by the vehicle or

component manufacturer.

11. Prior to returnin the vehicle to service, make certain all

components and systems are restored to their proper

operatin condition.

REMOVING THE POWER STEERING GEAR

1. Mark or identify the inlet and return lines at the valve

body ports.

2. Drain the system followin the instructions presented

under Preventive Maintenance. Remove both inlet and

return lines.

3. Disconnect the steerin column at the input shaft

followin the vehicle manufacturers instructions.

4. Disconnect the pitman arm from the vehicles steerin

linka e usin the vehicle manfacturers instructions.

CAUTION: If it is necessary to remove the pitman arm

before the steerin ear is removed from the vehicle,

DO NOT USE HEAT OR POUND ON THE PITMAN

ARM OR OUTPUT SHAFT as dama e can result. Do

not attempt repairs to these components. They must be

replaced if dama ed. Use a lar e ear puller to remove

the pitman arm such as Snap-On puller #CG-283 or

Ford part number T64P-3590-F.