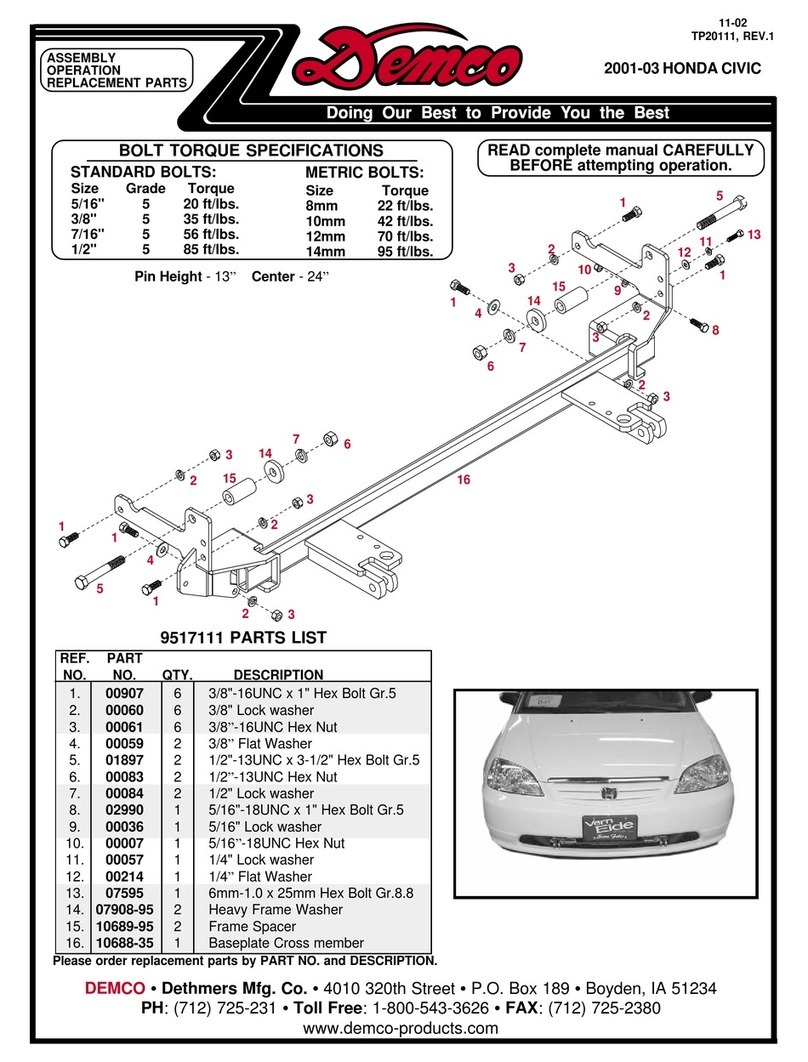

2

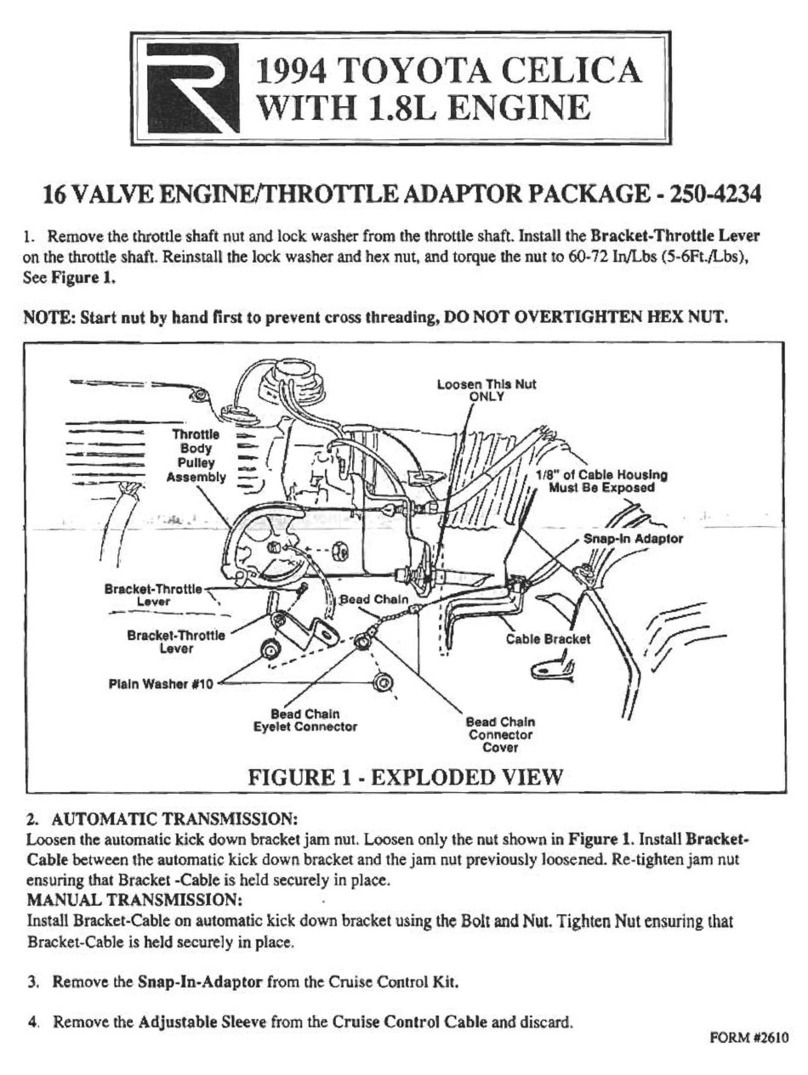

FIGURE2-PIGGYBACKSPRINGBRAKEDIAGRAM

EMERGENCY

PORT

SERVICE

PORT

MOUNTING

NUT

COTTERPIN

YOKE

LOCKNUT

SERVICE

PUSHROD

2. Checkpushrod toslackadjuster alignmentfromrelease

tofullstrokepositiontobesurethepushrodmovesout

andreturns properlywithoutbindingatthenon-pressure

plateholeorwithotherstructures.Alsochecktheangle

formedbythe slackadjusterarm and pushrod.It should

begreater than 90 degrees when thechamber is in the

releasedpositionandapproach90degreesatmaximum

readjustmentstroke.

3. Check tightness of mounting nuts. Torque on the non-

pressure plate mounting nuts should be 110 ft/lbs.

4. Check cotter pins to ensure they are in place.

5. Check all hoses and lines. They should be secure and

in good condition with sufficient length to allow for axle

movement.

Every3,600operating hours,100,000milesor one(1)year:

1. Disassemble and clean all parts. Clean all metal parts

incleaningsolvent,removingallrustandscale.Carefully

inspectallmetalparts for cracks, distortion or damage.

All diaphragm sealing surfaces should be smooth and

clean.

2. Installnewdiaphragm oranyotherparts if theyareworn

ordeteriorated. Performstepsoutlinedin"Replacingthe

Service Diaphragm". When the diaphragm, spring, or

both are replaced, they should be replaced in the

correspondingchamberonthesameaxle.

WARNING!

A piggyback spring brake chamber cannot have the

emergency diaphragm replaced. Replace the whole

piggyback spring brake chamber.

OPERATION & LEAKAGE TESTS

OPERATING TEST

1. Applybrakesand observe that the push rodsmoveout

promptlyandwithoutbinding.

2. Releasebrakesand observethatthe pushrodsreturn to

thereleasedpositionpromptlyandwithoutbinding.

3. Check push rod travel. Push rod travel should be as

shortaspossiblewithoutbrakes dragging.Adjust travel

of push rod at slack adjuster if necessary.

LEAKAGE TEST

1. Makeandhold a full brake application.

2. Usingsoapsolution,coatclampingring(s).If leakage is

detected, tighten clamping ring only enough to stop

leakage. DO NOT OVERTIGHTEN as this can distort

the sealing surface or clamping ring. Coat area around

pushrodhole(loosen boot if necessary). No leakageis

permitted. If leakage is detected, the diaphragm must

bereplaced.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURYOR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the park-

ing brakes, and always block the wheels. Always

wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When work-

ing in the engine compartment, the engine should

beshutoff and the ignition keyshould be removed.

Where circumstances require that the engine be

in operation, EXTREME CAUTION should be used

to prevent personal injury resulting from contact

with moving, rotating, leaking, heated or electri-

cally charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended proce-

dures. Use only the proper tools and observe all

precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air sys-

tems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS™

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.