BERGER MEGA POINT User manual

BERGER AG • Dept. Bohrerschleiftechnik

C.F.L. Lohnerstrasse 28E • CH-3645 Gwatt/Thun

Telefon +41 (0) 33 336 15 66 • Telefax +41 (0) 33 336 16 66

UNIVERSAL OPTICAL DRILL GRINDING MACHINE

OPERATING INSTRUCTIONS

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 I

Contents

Safety instructions

General safety instructions .............................................................................................................. 1

This is the symbol for your safety .................................................................................................... 1

Protective devices ........................................................................................................................... 1

Safety and accident prevention regulations ..................................................................................... 1

Points to remember when operating MEGA-POINT ........................................................................ 1

General information on MEGA-POINT

General information on MEGA-POINT............................................................................................. 2

Delivery, transportation and installation

Delivery ........................................................................................................................................... 3

Standard with basic machine................................................................................................. 3

Options.................................................................................................................................. 3

Checking the delivery ............................................................................................................ 3

Transportation ................................................................................................................................. 3

Installing the machine...................................................................................................................... 4

Space requirements ..............................................................................................................4

Locationrequirements...........................................................................................................4

Connection ...................................................................................................................................... 4

Electrical connection ............................................................................................................. 4

Connect flexible shaft ............................................................................................................ 5

Dust extraction ...................................................................................................................... 6

Dust collector ........................................................................................................................ 6

Preparing tools ................................................................................................................................ 6

Component discription

Componentdiscription..................................................................................................................... 7

Setup

Basic adjustment for right-hand drills............................................................................................... 8

Completing and using the setup sheet............................................................................................. 8

Contents

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 II

Operating the machine

Switching on the machine - Master switch....................................................................................... 9

Adjusting the angle ........................................................................................................................ 10

Setting the point angle A ..................................................................................................... 10

Adjusting primary cutting angle B1 ...................................................................................... 10

Adjusting secondary clearance angle B2............................................................................. 10

Install collets.................................................................................................................................. 11

Collets MP 6.5 (1.0 to 6.5 mm dia.) ..................................................................................... 11

Collets MP 20 (6.0 - 20.0 mm dia.) ...................................................................................... 11

Swivel arm MP 30 (option) and collets MP 30 (20.0 - 30.0 mm dia.).................................... 11

Chucking drills ............................................................................................................................... 12

Aligning right-hand drillsup to 20 mm dia. ......................................................................................12

Chucking and aligning right-hand drills over 20 mm dia. (MP 30) .................................................. 13

Aligning projection image............................................................................................................... 13

Switch on motor............................................................................................................................. 14

Grinding drills ................................................................................................................................ 14

Indexing cycle ............................................................................................................................... 15

Feed .............................................................................................................................................. 15

Checking ....................................................................................................................................... 15

Shielding from bright outside light.................................................................................................. 16

Point splitting ................................................................................................................................. 17

Procedure ........................................................................................................................... 17

Changing over for special drills

Changing over from right-hand to left-hand drills ........................................................................... 18

Changing over machine ...................................................................................................... 18

Changing over point splitting device .................................................................................... 18

Grinding left-hand drills.................................................................................................................. 19

Aligning the cutting edge for left-hand drills ......................................................................... 19

Point splitting on left-hand drills ........................................................................................... 19

Changing over from left-hand to right-hand drills ........................................................................... 20

Changing over machine ...................................................................................................... 20

Changing over point splitting device .................................................................................... 20

Changing over for 3-lip drills .......................................................................................................... 21

Changing over for flat-bottom drills ................................................................................................ 22

Handling grinding wheels

Mounting Diamond and CBN grinding wheels ............................................................................... 23

Contents

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 III

Cleaning & Maintenance

Cleaning & Maintenance................................................................................................................ 24

Maintenance

Changing the 10x lens................................................................................................................... 25

Focusing the 10x lens ................................................................................................................... 25

Mounting and focusing Zoom Lens................................................................................................ 26

Replacing projection lamp ............................................................................................................. 27

Changing the sapphire lens ........................................................................................................... 27

Changing viewing screen .............................................................................................................. 27

Replacing the fuses....................................................................................................................... 28

Replacing the main fuse ...................................................................................................... 28

Replacing fuse for projection lamp ...................................................................................... 28

Adjusting cutting edge geometry ................................................................................................... 29

Reproducing the factory adjustment ..............................................................................................30

Troubleshooting

General faults ................................................................................................................................ 31

Technical datas

Technical datas ............................................................................................................................. 32

Setup values for different drills

Setup values for different drills ...................................................................................................... 33

Wiring diagram

Wiring diagram .............................................................................................................................. 34

Contents

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 1

Safety instructions

Safety instructions

General safety instructions

General conditions for use of MEGA-POINT:

- MEGA-POINT is only intended for grinding

twist drills, 3-lip drills, carbide drills and flat-

bottom drills.

- The manufacturer is not liable for damage or

accidents caused by improper use.

- The operating, maintenance and repair

instructions in this manual must be observed.

- The machine may only be operated, used,

maintained and repaired by specially trained

personnel.

- The manufacturer is not liable for any

modifications made to the machine by the

customer.

Safety and accident prevention

regulations

Basic regulations

- Check the operation reliability of MEGA-

POINT before every startup.

- The prevailing safety and accident prevention

regulations must be observed in addition to the

instructions contained in this manual.

- Before starting work, make sure you are

familiar with all the devices and controls on the

machine and their functions. It will be too late

during operation.

This symbol marks passages in the manual relating to

safety for man and machine.

Protective devices

All protective devices integrated in or added to the

machine are intended for your safety. They must be

kept in their original condition and must be maintained

and tested in accordance with the maintenance

instructions.

Points to remember when operating

MEGA-POINT

- Check every time before use.

- Certain jobs can only be performed when the

machine is at standstill.

- Always wear protective goggles when performing

grinding work.

- The point-splitting grinding wheel is automatically

switched on when the swivel arm is moved to the

right.

- Do not dress diamond and Borazon wheels.

- Dismounting: when the feed ring is removed, a

pretension spring inside is released.

- The projection lamp is hot.

- Never touch the glass body of a protection lamp.

- Do not smudge the inside of the sapphire lens.

- Never touch the lined side of the viewing screen.

This is the symbol for your safety

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 2

General information on MEGA-POINT

The MEGA-POINT Universal Optical Drill Grinding Machine is designed for the precision grinding of all

types of drills. The cutting edge can be precisely aligned and checked for quality after grinding using optical

aids.

The primary cutting angle, the secondary clearance angle and the point angle are freely adjustable.

In order to optimize the angles for machining different materials, the required values are listed in tables on

the last page.

In addition to grinding the cutting edge, MEGA-POINT offers a device for point-splitting facility in the same

fixture. Here, too, a wide variety of point-splitting types can be adjusted depending on the requirements.

IFANGER inside turning steels of types ABS and ECS can be perfectly reground using an add-on unit

(option).

General information on MEGA-POINT

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 3

Delivery, transportation and installation

Delivery, transportation and installation

Delivery

Check the delivery consignment using the list below (check that options are identical with the purchase

order):

Standard with basic machine

1 MEGA-POINT Universal Optical Drill Grinding Machine, comprising:

2 CBN grinding wheels (1 x Ø 125 mm; 1 x Ø 50 mm)

2 Collet chucks for drill Ø 1-6.5 mm and Ø 6-20 mm (0.040 - 0.250" and 0.250 - 0.787")

Flexible shaft

Machine lamp

Wrench set

Operator’s manual

Spare parts list

Setup templates

Options

1 Swivel arm MP 30

1 Set of collets MP 30, 5 pieces

1 Machine stand

1 Zoom lens 6 - 20 power

1 Hood

1 Additional loupe

1 Truing diamond

Checking the delivery

Check the delivery consignment on receipt of the goods. Contact the supplier immediately if materials are

found to be missing or defective.

Transportation

The machine weighs about 50 kg / 100 lbs without its stand.

Use a movable base for transportation over long distances. Two people are required to lift the machine onto

the stand or a table.

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 4

Connection

Electrical connection

Note the information on the nameplate at the machine rear.

220 V, 50 Hz or

110 V, 60 Hz

Installing the machine

In order to work optimal with MEGA-POINT, the following requirements must be met.

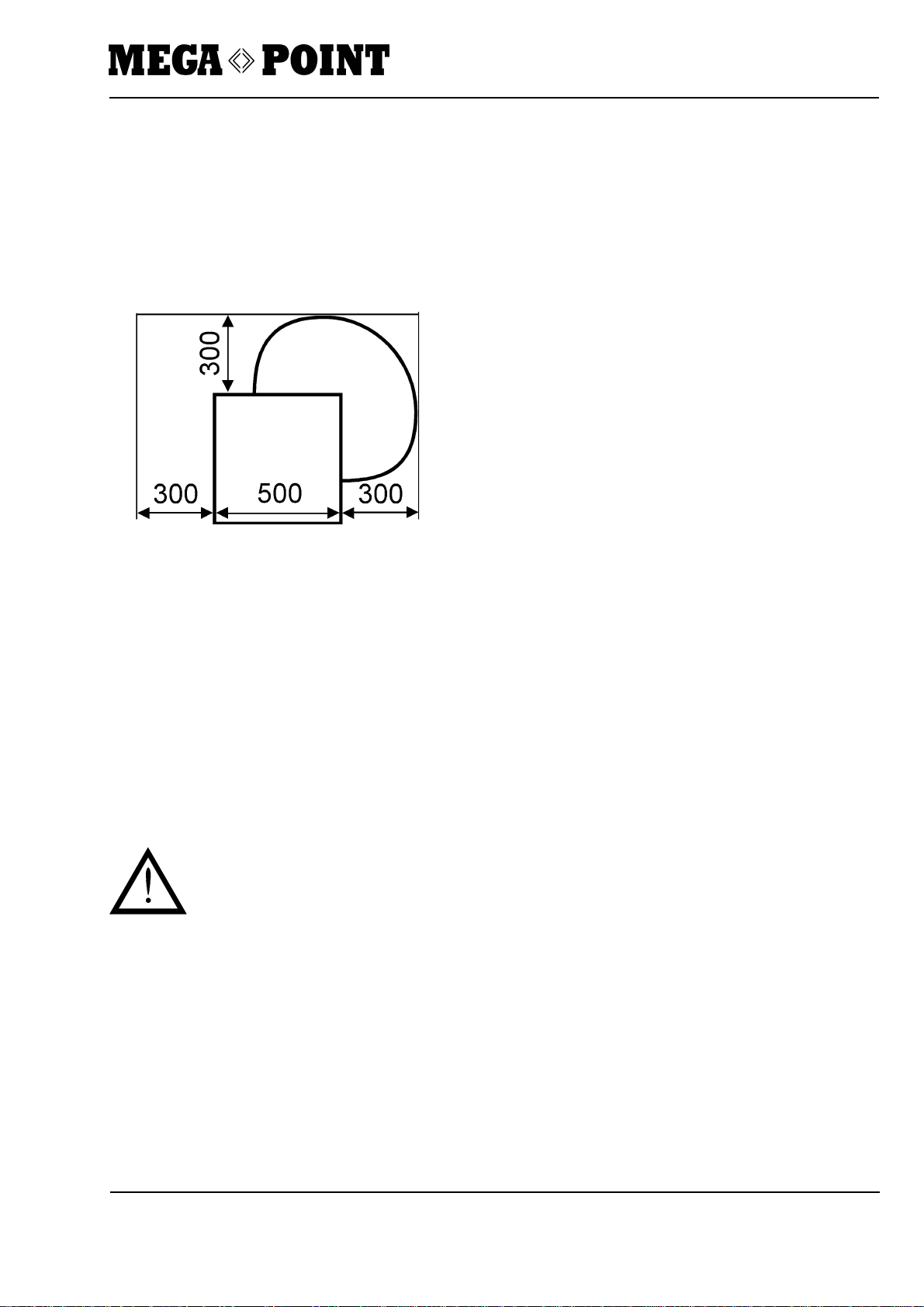

Space requirements

The minimum distances indicated in the drawing must be kept.

Location requirements

MEGA-POINT on stand (option)

The stand must be placed on a level, hard surface.

Make sure that the stand has a firm footing and does not wobble.

MEGA-POINT without stand

A steady table is sufficient as a surface. Make sure that the machine has a firm footing and does not wobble.

To ensure good ventilation of the machine, do not place it on a soft surface (foam).

Delivery, transportation and installation

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 5

Delivery, transportation and installation

Connect flexible shaft

The flexible shaft drives the point-splitting grinding

wheel.

- Connect end 1 to coupling flange on rear of

machine.

- Connect end 2 of flexible shaft to coupling piece of

point-splitting device.

- Relieve load on flexible shaft.

Do not connect when twisted.

- Tighten nuts.

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 6

Dust extraction

The MEGA-POINT can be connected to a central dust

extraction system.

Connection: 38 mm dia.

Dust collector

However, the machine is also prepared for connection

to a standard industrial vacuum cleaner. A vacuum

cleaner can be connected to the machine as follows:

- Connect vacuum cleaner power cord to socket at

machine rear.

- Connect cable according to electrical diagram on

page 38.

The vacuum cleaner is now connected in such a way

that it starts together with the grinding motor.

Delivery, transportation and installation

Machine lamp (optional)

- Attach the 6V/10W machine lamp, article number

976 009 (optional), to the right side of the machine

using the supplied holder.

- Insert the cable into the housing through the desig-

nated opening and seal with a gland.

- Connect cable according to electrical diagram on

page 38.

Preparing tools

Unpack and clean the supplied tools.

All tools must be dried before use. Grinding dust

sticks to wet, oily tools and can damage them.

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 7

Component discription

Component discription

The illustrations below and their legends are intended as a reference guide. In this operator’s manual, all the

components are labelled in accordance with these legends. If you have any queries, please refer to this

section.

1 Master switch

2 Motor switch

3 Connection for vacuum cleaner

4 Protective hood (hood and slide)

5 Stop

6 Trueing Diamond

7 Grinding Wheel, Motor

8 Index Pin

9 Sapphire lens

10 Swivel arm MP 20 or MP 30

11 Feed ring

12 Tension nut

13 Scale ring for point angle

14 Blocking lever for point angle

15 Vertical scale

16 Horizontal scale

17 Clamping Levers

18 Swing Arm

19 Scale ring for primary cutting angle and

secondary clearance angle

20 Stop screw and locknut for secondary

clearance angle

21 Stop screws with locknut for primary cutting angle

22 Point-splitting attachement

23 Flexible shaft

24 Viewing screen

25 Dresser lever

26 Machine lamp

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 8

Startup

Startup

When it is delivered, the machine contains several transportation adjustments. Before starting up, perform the

following basic adjustment.

Basic adjustment for right-hand

drills

Point Angle

- Loosen clamping lever 14

- Turn swivel arm 18 and adjust point angle

scale A to 118º

- Tighten clamping lever 14

Secondary Relief Angle

- Loosen locknut 20

- Slightly raise swivel arm 10

- Loosen locknut 20

- With screw 20 adjust secondary clearance angle

scale B1 to 30º

- Tighten locknut 20

Primary Relief Angle

- Loosen locknut 21

- Lift swivel arm 10

- Set primary angle scale „B“ with screw 21 to

the value of 6º

- Tighten locknut 21

Point Splitting Device

Adjust the scales for the point-splitting device as

follows:

C = 7 E = 6

D = 40 G = 5 R

Completing and using the setup sheet

In order to record the best adjustments for your applications, use one of the enclosed adjustment sheets.

Enter the adjustment values for repeated applications. This will save you a lot of work later.

The adjustment values include:

A: Point angle C, D, E, G: Angles on point-splitting device

B1: Secondary clearance angle

B2: Primary cutting angle

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 9

Operating the machine

Before using the machine, check the following

- The condition of the grinding wheel

- The condition of the point-splitting grinding wheel

- The condition of the grinding wheel cover

- The general condition of the machine

Check the following machine adjustments

- Correct grinding wheel?

- Right- or left-hand drill?

- Point-splitting device for right- or left-hand drill?

To grind carbide drills, use the same procedure as for standard drills.

However, use a diamond grinding wheel.

See section on Mounting and aligning diamond and Borazon wheels on page 25.

The work steps in this section are arranged in chronological order so that you can perform the steps in the

order described. However, if the section does not meet the requirements of your application, please skip it

and continue with the next section.

Operating the machine

Switching on the machine

Master switch

- Press master switch 1

Projection lamp comes on

The machine is now ready for you to perform adjust-

ment and grinding work.

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 10

Operating the machine

Adjusting primary cutting angle B1

- Slightly raise swivel arm

- Slacken locknut

- Adjust required angle on primary cutting angle

scale B1 as follows:

- Turn stop screw

- Tighten locknut

Adjusting the angle

In the appendix to this operator’s manual, you will find

a table containing the various angles required for

various materials.

Setting the point angle A

- Slacken clamping lever

- Turn swivel arm and adjust required value on point

angle scale A

- Tighten clamping lever

Adjusting secondary clearance angle B2

- Slightly raise swivel arm

- Slacken locknut

- Adjust required angle on secondary clearance angle

scale B2 as follows:

- Turn stop screw

- Tighten locknut

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 11

Operating the machine

Install collets

Collets MP 6.5 (1.0 to 6.5 mm dia.)

Collets MP 20 (6.0 - 20.0 mm dia.)

- Remove knurled handle 1

- Remove pressure tube 2

- Select desired collet dia.

- Insert collet 3 into holder

- Insert pressure tube 2

- Screw knurled handle 1 on

Swivel arm MP 30 (option) and

collets MP 30 (20.0 - 30.0 mm dia.)

- Use 6x lens if necessary

- See section on Changing lens on page 25/26

- Slacken screw 1

- Remove swivel arm MP 20

- Mount swivel arm MP 30

- Tighten screw 1

- Slacken tension nut 2

- Remove tension nut and pressure tube

- Select required collet dia.

- Insert collet 3

- Mount tension nut and pressure tube

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 12

Chucking drills

Chuck drills as follows:

- Insert drill in collet

- A length of about 2 times drill dia.

must project from collet

e.g. drill dia.: 5 mm

projecting length: 10 mm

- Tighten holder

Operating the machine

Aligning right-hand drills

up to 20 mm dia.

Align drills without 4-facet grind as well as possible

using the following procedure.

- Slide holder using spigot sleeve

- Lightly press drill against sapphire lens

- View cutting edge in viewing screen

If the drill is not visible or only partly visible,

proceed as described in the next section on

Aligning projection image on page 13. Then

continue as described here.

- Turn drill until cutting edge is parallel to lines on

viewing screen

- Lightly press drill against sapphire lens

- Tighten tension nut

If the cutting edge is not parallel to the viewing screen

lines after the first grind, slacken the tension nut, re-

align the drill and re-grind.

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 13

Operating the machine

Chucking and aligning right-hand

drills over 20 mm dia. (MP 30)

- Insert drill in collet 1

- Clamp drill using tension nut 2 as follows:

- no play

- do not clamp drill, allow drill to turn

- Turn drill until cutting edge is parallel to viewing

screen lines

- Lightly press drill against sapphire lens

- Turn feed ring by 1 turn anticlockwise

- Then tighten tension nut

Aligning projection image

- Slacken screws 1 and 2

- Observe cutting edge in viewing screen, and move

swivel arm until drill is in right third of viewing

screen

- Tighten screws 1 and 2

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 14

Operating the machine

Wear protective goggles

Check that grinding wheel

can turn freely

Switch on motor

Switch on grinding wheel as follows:

- Press motor switch 2

Grinding wheel starts to rotate

Grinding drills

- Grip swivel arm

- Using swivel arm, smoothly pass drill inward along

grinding wheel

- Raise swivel arm to stop

- Using swivel arm, smoothly pass drill outwards

along grinding wheel

Primary cutting angle is ground

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 15

Operating the machine

Indexing cycle

- Latch swivel arm in center position between

grinding wheel and sapphire lens

- Abut collet holder against machine

- Turn collet holder through

180° (2-lip drills)

120° (3-lip drills)

- Allow collet holder to latch

Now grind second drill cutting edge

Feed

- Latch swivel arm 1 in center position between

grinding wheel and sapphire lens

- Turn feed ring 2 as follows:

- 1 to 2 divisions clockwise

After feeding, regrind both cutting edges.

See section on Grinding drill on page 14

Checking

- Use swivel arm to move drill in front of sapphire

lens

- Check cutting edge for:

- Wear marks

- Clean cutting edge

- Index

See section on Indexing cycle above

- Check other cutting edge(s) as described above.

If the cutting edges still have defects, regrind by

feeding again until wear marks are no longer visible.

See section on Feed above

Universal Optical Drill Grinder

Operator's Manual Issue 06/01 Rev 02 16

Shielding from bright outside light

To optimize work in bright light conditions, you can

place a shield over the viewing screen cover.

Operating the machine

Table of contents